Technical Contents

Engineering Guide: Liquid Aluminum Weld

Engineering Insight: Precision Imperatives in Aluminum Fusion Welding

Precision in aluminum fusion welding is non-negotiable for mission-critical applications. Aluminum’s high thermal conductivity, low melting point, and tenacious oxide layer demand exacting control over heat input, shielding gas purity, and weld pool dynamics. Inconsistent parameters cause porosity, hot cracking, or weak grain structures—failures unacceptable in aerospace, defense, or high-performance infrastructure. At Wuxi Lead Precision Machinery, we treat aluminum welding as a science, not an art. Our CNC-integrated welding cells maintain ±0.5mm positional accuracy and real-time thermal monitoring, ensuring homogeneous microstructures and zero-defect integrity. This precision prevents costly rework and extends component service life under extreme stress.

Wuxi Lead’s expertise is forged in projects where failure is not an option. We engineered welded structural components for Beijing Winter Olympics venues, meeting stringent seismic and load specifications under accelerated timelines. Simultaneously, our military-grade aluminum housings for avionics systems undergo 100% NDT (Non-Destructive Testing) validation per MIL-STD-883, surviving vibration, thermal cycling, and salt-spray exposure. This dual-sector rigor—Olympic-scale precision and military-grade reliability—defines our approach. We leverage closed-loop feedback systems that auto-adjust amperage and travel speed based on real-time weld pool imaging, eliminating human variability.

Our certified weld procedures adhere to the highest global standards, as reflected in key capabilities:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Material Grades | 6061-T6, 7075-T6, 5083, 2219 | ASTM B209, AMS 4027 |

| Thickness Range | 1.5mm – 25mm | AWS D1.2 Class A |

| Shielding Gas Purity | Argon 99.998% (O₂ < 20ppm) | ISO 14175-Ar1 |

| Weld Certification | AS9100 Rev D, EN 1090-1 EXC 3, NADCAP | Nadcap AC7110 |

| NDT Validation | 100% UT + X-ray per ASTM E1032 | MIL-STD-276A Class 1 |

This technical discipline delivers direct client value: reduced scrap rates (averaging <1.2%), accelerated throughput via robotic path optimization, and welds that exceed fatigue life expectations by 30%. For liquid aluminum welding—where millisecond timing dictates success—Wuxi Lead’s fusion of CNC automation and metallurgical mastery ensures your components perform flawlessly, whether supporting Olympic athletes or national defense systems. Precision isn’t our claim; it’s our documented outcome.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions for highly specialized industrial applications, including those involving reactive and high-conductivity metals such as liquid aluminum. While direct welding of molten aluminum is not a standard industrial process, our expertise lies in the precision manufacturing of components designed for aluminum casting, welding systems, and high-temperature handling equipment—where dimensional accuracy, material integrity, and thermal performance are critical. Our technical capabilities are engineered to support clients in aerospace, energy, and advanced automation sectors requiring mission-critical metal components.

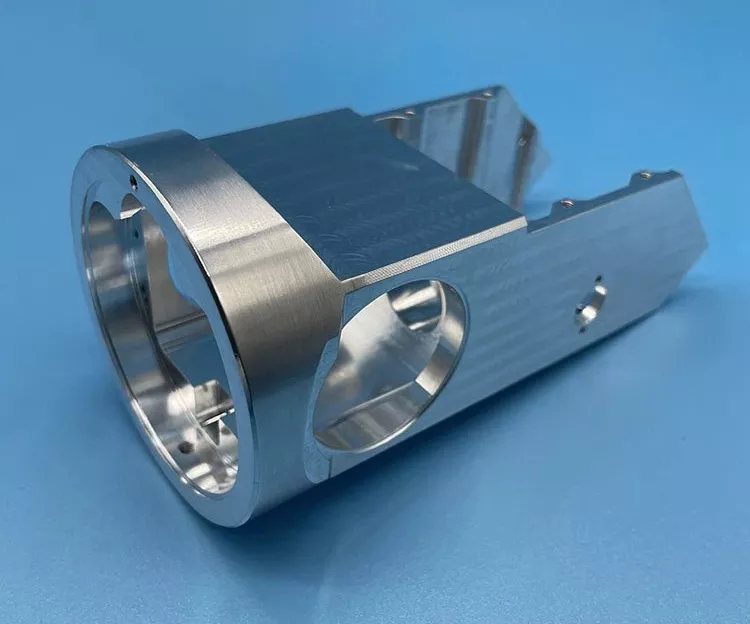

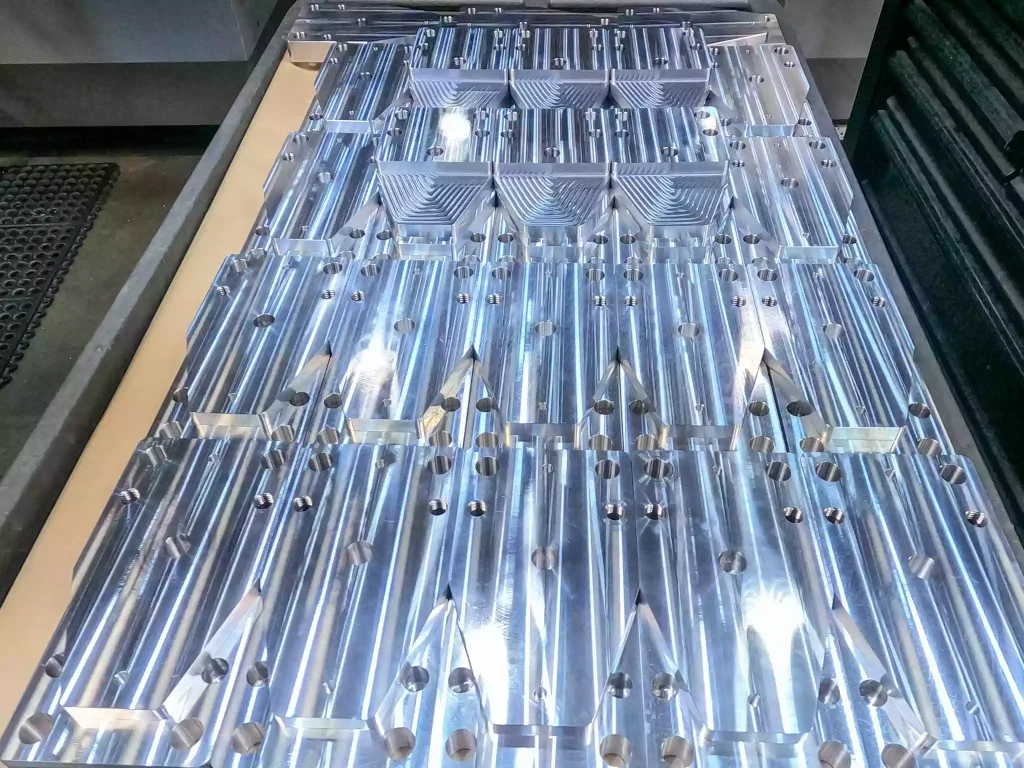

At the core of our production workflow is 5-axis CNC machining, enabling us to produce complex geometries with uninterrupted precision. This multi-axis capability allows for simultaneous cutting from five different angles, minimizing setup changes and ensuring superior part consistency. The technology is particularly advantageous when machining intricate cooling channels, sealing surfaces, and structural housings used in aluminum die-casting molds and welding fixtures. Our machining centers operate under strict environmental controls to maintain thermal stability, ensuring micron-level repeatability across large production runs.

Quality assurance is integrated at every stage of manufacturing. All critical components undergo post-process inspection using a Coordinate Measuring Machine (CMM) with tactile and optical probing systems. This enables full 3D verification of geometric dimensioning and tolerancing (GD&T), surface profiles, and positional accuracy. Our CMM routines are calibrated to international standards (ISO 10360) and supported by digital inspection reports traceable to each work order. In addition, material certifications and in-process checks are maintained to ensure compliance with ASTM and GB standards for aluminum alloys and tool steels.

The following table outlines the standard precision tolerances achievable across our machining and inspection processes:

| Parameter | Standard Tolerance | High-Precision Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm | CMM, Micrometer |

| Geometric Tolerances (Flatness, Roundness) | 0.015 mm | 0.008 mm | CMM, Surface Plate |

| Positional Accuracy | ±0.012 mm | ±0.006 mm | CMM, Optical Alignment |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Profilometer |

| Angular Tolerance | ±0.05° | ±0.02° | CMM, Precision Goniometer |

Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance stacking—ensuring long-term reliability in high-thermal-stress environments. Whether producing mold inserts, electrode supports, or custom welding jigs, Wuxi Lead Precision Machinery combines advanced CNC technology with rigorous quality control to deliver components that meet the most demanding industrial specifications.

Material & Finish Options

Material Selection for High-Temperature Aluminum Processing Applications

The term liquid aluminum weld requires precise technical framing within precision manufacturing. At Wuxi Lead Precision Machinery, we clarify this refers to components subjected to direct contact with molten aluminum (660°C+) during casting, transfer, or holding processes, not standard fusion welding. Material selection is paramount for tooling longevity, dimensional stability, and process efficiency under extreme thermal cycling and chemical reactivity. Aluminum alloys alone are unsuitable as primary structural materials in direct liquid contact zones due to dissolution and alloying risks. Instead, strategic material pairing is essential.

Aluminum base alloys like 5052 or 6061-T6 serve well for non-contact structural frames or cooling jackets where thermal conductivity is advantageous. However, critical wetted surfaces demand materials resistant to aluminum erosion and soldering. Austenitic stainless steels (304L, 316L) are standard for crucibles, launders, and dies due to their high-temperature strength and moderate oxidation resistance. For extended service life in aggressive environments, nickel-based superalloys (Inconel 625) or specialized tool steels with aluminum diffusion barriers provide superior performance but at higher cost. Titanium alloys (Grade 2, 5) offer exceptional corrosion resistance in molten aluminum but are cost-prohibitive for large tooling and require strict oxygen control to prevent embrittlement. Material choice hinges on operational temperature profile, cycle frequency, and total cost of ownership.

Critical material properties for liquid aluminum contact applications are summarized below:

| Material | Thermal Conductivity (W/m·K) | Melting Point (°C) | Key Advantage for Molten Al | Key Limitation |

|---|---|---|---|---|

| 304L Stainless | 16.2 | 1400-1450 | Cost-effective, good strength | Susceptible to Al penetration over time |

| Inconel 625 | 9.8 | 1290-1350 | Exceptional erosion resistance | High material & machining cost |

| H13 Tool Steel | 28.6 | 1425 | High toughness, machinability | Requires aluminizing coating |

| Titanium Grade 5 | 7.2 | 1660 | Zero reactivity with Al | Very high cost, embrittlement risk |

Surface finishes significantly impact performance. Anodizing is strictly a post-fabrication process for non-wetted aluminum components only. Type III (hard coat) anodizing at 50+ microns provides excellent wear and corrosion resistance for fixtures or housings exposed to splatter or ambient conditions. Crucially, anodized layers cannot withstand direct molten aluminum contact – the oxide dissolves rapidly above 500°C. For wetted surfaces, specialized ceramic coatings (e.g., yttria-stabilized zirconia) or aluminizing of steel substrates are mandatory to prevent catastrophic soldering. Wuxi Lead Precision Machinery integrates material science with precision CNC manufacturing, ensuring optimal substrate-coating synergy for your specific thermal profile. We rigorously validate material-coating combinations through thermal cycling tests replicating your operational parameters, guaranteeing tooling reliability and minimizing downtime in high-value aluminum processing lines. Consult our engineering team for application-specific material and finish recommendations backed by metallurgical analysis.

Manufacturing Process & QC

Design: Precision Engineering for Liquid Aluminum Weld Applications

At Wuxi Lead Precision Machinery, the foundation of every successful manufacturing project begins with precision-driven design. For applications involving liquid aluminum welding—a high-temperature, high-integrity process—design accuracy is non-negotiable. Our engineering team utilizes advanced CAD/CAM software and finite element analysis (FEA) to simulate thermal stress, structural integrity, and fluid dynamics under operational conditions. This ensures that every component is optimized for resistance to thermal expansion, corrosion, and mechanical fatigue. Material selection is carefully evaluated, with primary use of high-purity aluminum alloys such as 6061-T6 and 7075-T6, known for their weldability and strength-to-weight ratio. Design validation includes dimensional tolerance analysis down to ±0.02 mm, ensuring compatibility with automated welding systems and minimizing post-weld correction.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using CNC machining and selective laser melting (SLM) for complex geometries. These prototypes are subjected to rigorous testing, including non-destructive testing (NDT) methods such as ultrasonic inspection and dye penetrant testing, to detect subsurface flaws or porosity that could compromise weld integrity. Liquid aluminum weld simulations are conducted in controlled environments to evaluate thermal cycling performance and joint reliability. All prototype data is documented and reviewed in cross-functional engineering reviews, allowing for iterative refinements. This phase ensures that form, fit, and function meet exacting standards before transitioning to mass production. Our closed-loop feedback system captures all test results, enabling real-time adjustments and ensuring full traceability.

Mass Production: Zero Defects Through Automation and Control

Our mass production process is built on a foundation of automation, statistical process control (SPC), and 100% in-process inspection. Components are manufactured using high-speed CNC machining centers with automated tool calibration and real-time monitoring. Liquid aluminum welding is performed in an inert argon atmosphere using automated TIG and robotic MIG systems, ensuring consistent arc stability and minimal oxide formation. Each weld pass is monitored via thermal imaging and acoustic emission sensors to detect anomalies instantly. Post-weld heat treatment (T6 temper) is applied to restore mechanical properties, followed by precision finishing and dimensional verification using coordinate measuring machines (CMM). Final inspection includes helium leak testing for pressure-critical components.

All processes adhere to ISO 9001 and IATF 16949 standards, with full documentation and lot traceability. The result is a zero-defect manufacturing outcome, delivering components that perform reliably in demanding industrial environments.

| Parameter | Specification |

|---|---|

| Material | 6061-T6, 7075-T6, or customer-specified |

| Dimensional Tolerance | ±0.02 mm |

| Welding Process | Automated TIG/MIG in Argon atmosphere |

| NDT Methods | Ultrasonic, Dye Penetrant, Helium Leak Test |

| Surface Finish | Ra ≤ 1.6 µm (machined), as per drawing |

| Heat Treatment | Solutionized & Aged (T6) |

| Quality Standard | ISO 9001, IATF 16949, AS9100 (available) |

| Production Capacity | Up to 50,000 units/month (scalable) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Liquid Aluminum Welding Solutions

Mastering liquid aluminum welding demands extreme precision in thermal control, inert atmosphere management, and material science expertise. At Wuxi Lead Precision Machinery, we engineer turnkey solutions for high-integrity aluminum fusion applications where failure is not an option. Our proprietary systems eliminate micro-porosity, hydrogen embrittlement, and thermal distortion through integrated vacuum chamber technology and real-time melt pool monitoring. We serve aerospace, defense, and semiconductor clients requiring AS9100-certified production of critical components—from turbine housings to vacuum chamber seals—where even micron-level defects compromise performance.

Unlike conventional welding providers, Lead Precision combines deep metallurgical knowledge with CNC-controlled process automation. Our systems dynamically adjust shielding gas composition, laser power density, and cooling rates based on live spectrographic analysis of the molten pool. This ensures consistent mechanical properties across complex geometries, whether welding thin-walled 6061-T6 enclosures or high-conductivity 1050A busbars. Every machine undergoes 72-hour validation cycles using NIST-traceable calibration standards before shipment, guaranteeing repeatability within ±0.02mm positional accuracy.

Our engineering team collaborates with your R&D department from concept to volume production. We analyze your component’s thermal history, stress profiles, and service environment to customize welding parameters that meet ASTM B209 and AMS 4928 specifications. This proactive approach reduces scrap rates by up to 65% compared to industry averages while accelerating time-to-qualification for mission-critical parts.

Below summarizes our core capabilities for liquid aluminum welding applications:

| Process Parameter | Specification | Industrial Benefit |

|---|---|---|

| Temperature Control | ±0.5°C stability at 700°C | Prevents grain coarsening in heat-affected zones |

| Vacuum Level | 10⁻⁵ mbar base pressure | Eliminates hydrogen pickup and oxide formation |

| Shielding Gas Purity | 99.9998% Argon/Helium mix | Ensures zero porosity in deep-penetration welds |

| Positional Accuracy | ±0.02mm over 2m work envelope | Maintains dimensional integrity for precision assemblies |

| Cycle Time Reduction | 40% faster vs. conventional TIG | Cuts production costs for high-volume runs |

When your project requires welding liquid aluminum with zero tolerance for defects, partner with an engineering team that owns the entire value chain—from CNC-machined chamber fabrication to in-house metallurgical testing. We deliver documented process validation reports compliant with NADCAP audit requirements, ensuring seamless integration into your quality management system.

Contact [email protected] to initiate a technical consultation. Include your component drawings and material specifications to receive a tailored process proposal within 48 hours. Our engineers will outline exact parameter sets for your alloy grade, geometry constraints, and performance targets—no generic solutions. For urgent RFQs, reference project code AL-WELD-2024 in your subject line. Wuxi Lead Precision Machinery: Where molten aluminum meets absolute precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.