Technical Contents

Engineering Guide: A 1 Sheet Metal

Engineering Insight: The Critical Imperative of Grade 1 Precision in Sheet Metal Fabrication

In high-performance sheet metal fabrication, precision transcends mere specification; it is the fundamental determinant of structural integrity, assembly success, and long-term operational reliability. Standard tolerances often prove inadequate for advanced applications where component interaction, thermal cycling, or dynamic loads demand absolute dimensional fidelity. Grade 1 precision represents the pinnacle of manufacturability – the tightest achievable tolerances within standard industrial practice, essential for mission-critical assemblies where even minute deviations trigger catastrophic cascade failures. The cost of non-conformance here extends far beyond scrap; it manifests as field failures, safety hazards, and reputational damage irreparable in demanding sectors like aerospace, defense, and advanced medical instrumentation. Achieving true Grade 1 consistency requires more than capable machinery; it demands a holistic engineering ecosystem encompassing material science understanding, thermal compensation protocols, in-process metrology, and an ingrained culture of zero-defect manufacturing. This level of control prevents tolerance stack-up during assembly, ensures perfect mating of complex sub-assemblies, and guarantees the dimensional stability required for components operating under extreme stress or precision alignment.

Wuxi Lead Precision Machinery operates at this exacting Grade 1 threshold as standard practice. Our engineering foundation is forged in projects where precision is non-negotiable. We engineered and delivered critical structural and enclosure components for the Beijing 2022 Winter Olympics infrastructure, where environmental exposure and public safety mandated flawless dimensional accuracy under severe climatic conditions. Similarly, our certified production lines consistently meet the stringent geometric and material certification requirements for sensitive military communication and sensor housings, where electromagnetic interference shielding and environmental sealing depend entirely on micron-level consistency in bends, cut edges, and hole patterns. This experience is not peripheral; it defines our core manufacturing philosophy and process control rigor.

The tangible output of this commitment is reflected in our adherence to the most demanding dimensional standards. Below outlines the typical Grade 1 precision capabilities consistently achieved across our facility for critical sheet metal features:

| Feature | Grade 1 Tolerance | Critical Application Impact |

|---|---|---|

| Linear Dimensions (L ≤ 30mm) | ±0.05 mm | Precision mating surfaces, optical alignment |

| Hole Position (L ≤ 100mm) | ±0.10 mm | Bolt circle accuracy, multi-part assembly fit |

| Bend Angle (90°) | ±0.25° | Structural rigidity, sealing surface conformity |

| Flatness (per 100mm) | 0.05 mm | Critical mounting interfaces, vibration control |

This precision is not accidental. It is systematically engineered through our integrated approach: certified laser cutting with dynamic focus control, CNC press brakes featuring real-time angle feedback and thermal compensation, dedicated CMM verification at defined process gates, and material handling protocols preventing stress-induced distortion. We understand that Grade 1 fabrication is an end-to-end discipline, from raw material certification through final inspection. For your most challenging sheet metal applications – whether supporting next-generation technology infrastructure or national defense systems – Wuxi Lead Precision Machinery delivers the uncompromising dimensional accuracy that forms the bedrock of performance and trust. Partner with us to transform precision from a requirement into your competitive advantage.

Precision Specs & Tolerances

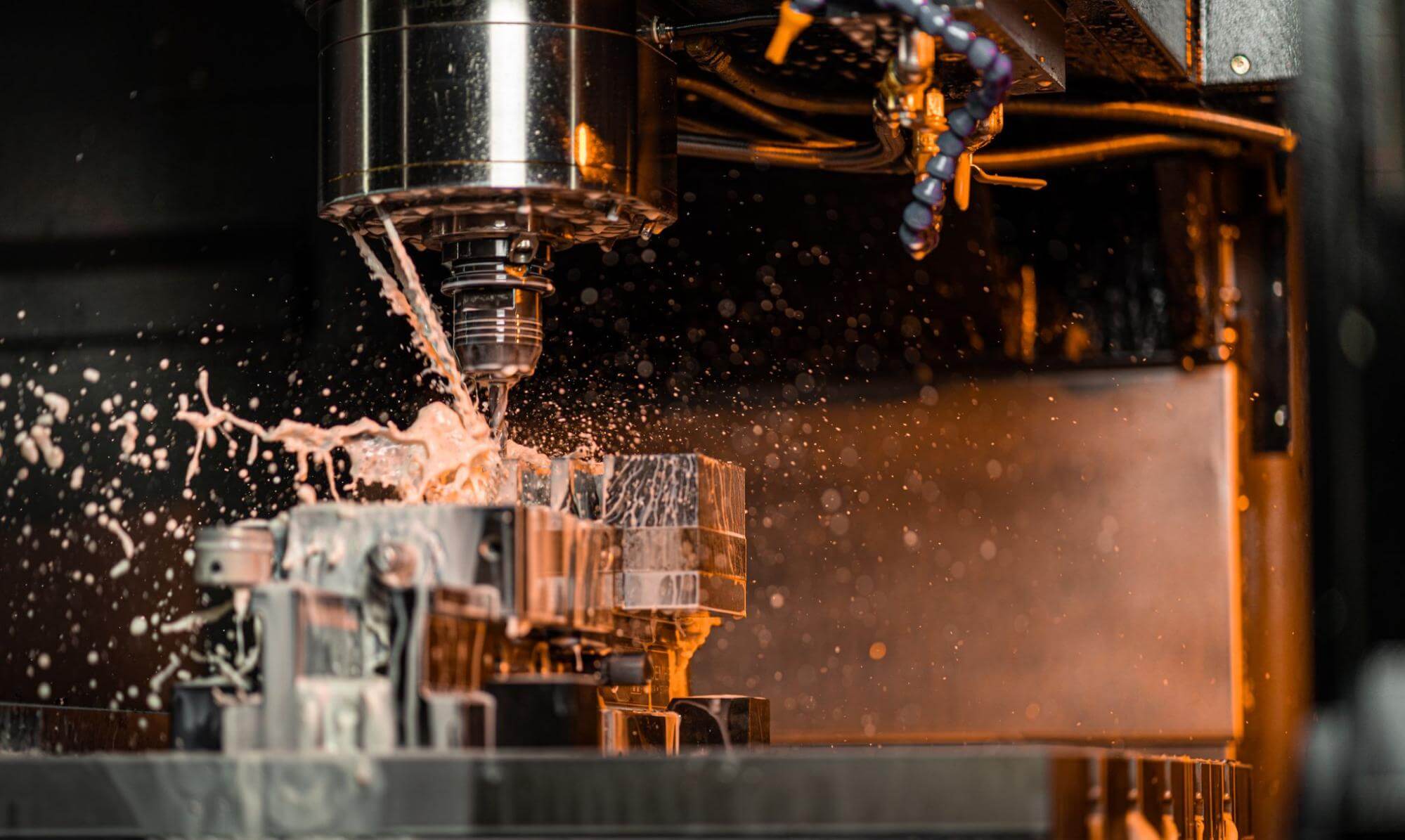

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance in high-demand industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, which enable complex geometry processing with exceptional accuracy and efficiency. These multi-axis platforms allow for simultaneous tool movement across five planes, minimizing setup changes and ensuring seamless integration of intricate features directly into sheet metal components. This level of machining flexibility supports the production of highly sophisticated parts used in aerospace, medical devices, automation, and high-end industrial equipment.

Our 5-axis CNC technology is complemented by a comprehensive digital workflow that includes CAD/CAM integration, real-time toolpath simulation, and adaptive machining strategies. This ensures optimal material utilization, reduced cycle times, and consistent dimensional integrity across both prototype and high-volume production runs. We process a wide range of sheet metals, including stainless steel, aluminum alloys, carbon steel, and specialty materials, with thicknesses ranging from 0.5 mm to 12 mm, depending on part geometry and design requirements.

Quality assurance is embedded throughout our manufacturing process. Every critical component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), providing micron-level verification of geometric dimensions and tolerances. Our CMM system operates under temperature-controlled conditions and is calibrated to international standards, ensuring measurement repeatability and full traceability. This metrology capability supports GD&T (Geometric Dimensioning and Tolerancing) validation, first-article inspection reports (FAIR), and production batch certification, meeting the compliance demands of ISO 9001 and customer-specific quality protocols.

The following table outlines our standard achievable tolerances for sheet metal fabrication processes:

| Feature | Process | Typical Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | 5-Axis CNC Machining | ±0.025 mm | For features within 300 mm |

| Hole Diameter | CNC Drilling/Tapping | +0.03 / 0 mm | Reamed holes to ±0.01 mm |

| Positional Accuracy | Multi-Axis Machining | ±0.03 mm | Relative to datum |

| Angular Features | 5-Axis Milling | ±0.1° | Complex bevels and contours |

| Surface Flatness | Machined Panels | 0.05 mm per 100 mm | Verified via CMM |

| Sheet Thickness | Laser Cutting Prep | ±0.1 mm | For formed components |

| Formed Bends | Precision Brake Press | ±0.2° | With CNC backgauging |

All fabrication workflows are supported by in-house engineering review, allowing for Design for Manufacturability (DFM) feedback prior to production. This proactive approach reduces lead times, enhances yield, and ensures that final components meet both functional and aesthetic specifications. At Wuxi Lead Precision Machinery, we combine cutting-edge equipment with disciplined quality control to deliver sheet metal solutions that meet the highest standards of precision engineering.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your functional requirements, environmental exposure, and lifecycle demands. Below, we detail key considerations for aluminum, steel, and titanium, alongside anodizing finishes for enhanced surface integrity.

Aluminum

Aluminum alloys like 6061-T6 dominate aerospace, electronics, and transportation for their exceptional strength-to-weight ratio and inherent corrosion resistance. Its malleability allows complex forming on our CNC bending centers, while low density reduces component weight without sacrificing structural integrity. Aluminum excels in thermal and electrical conductivity applications but requires protective finishes like anodizing for abrasive environments.

Steel

Carbon steel (e.g., A36) offers high tensile strength and affordability for structural frames and heavy machinery. For corrosive settings, stainless steel grades 304 and 316 provide superior resistance via chromium content. 304 balances weldability and corrosion protection for general use, while 316’s molybdenum addition resists pitting in marine or chemical exposure. Note that stainless steel’s work-hardening tendency demands precise tooling parameters during laser cutting or bending to avoid edge cracking.

Titanium

Titanium Grade 2 and 5 (Ti-6Al-4V) deliver unparalleled strength-to-weight ratios and extreme corrosion resistance, ideal for medical implants, aerospace, and chemical processing. Its biocompatibility and non-magnetic properties are unmatched. However, titanium’s high reactivity during machining necessitates specialized tooling and slower feed rates—a capability our CNC centers excel in, mitigating galling and heat buildup. Expect premium pricing but exceptional longevity in harsh conditions.

Anodizing Finishes

Anodizing electrochemically enhances aluminum’s surface durability and aesthetics. Type II (sulfuric acid) anodizing provides decorative color options (black, blue, red) and moderate wear resistance for enclosures or consumer products. For industrial applications demanding abrasion resistance—such as hydraulic manifolds or military hardware—Type III (hard coat) anodizing delivers a 50–75 µm thick ceramic layer with Rockwell hardness up to 60 HRC. Both processes improve adhesion for paints or adhesives while maintaining precise dimensional tolerances critical to your assembly.

Material Property Comparison

| Material | Key Grades | Yield Strength (MPa) | Density (g/cm³) |

|---|---|---|---|

| Aluminum | 6061-T6 | 276 | 2.7 |

| Stainless Steel | 304 / 316 | 215 / 205 | 8.0 |

| Titanium | Gr 2 / Gr 5 | 345 / 880 | 4.5 |

Material choice directly impacts manufacturability, cost, and end-product reliability. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to guide your selection, ensuring seamless integration with our laser cutting, CNC bending, and finishing capabilities. Partner with us to transform material potential into precision-engineered reality.

Manufacturing Process & QC

Sheet Metal Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for precision, repeatability, and zero defects. We integrate advanced technology with rigorous quality control to deliver high-end components for aerospace, medical, and industrial automation sectors. Our end-to-end workflow ensures seamless transition from concept to mass production, maintaining tolerance integrity and material performance throughout.

The process begins with collaborative design engineering. Our team works directly with client CAD models, performing detailed design for manufacturability (DFM) analysis. We evaluate material selection, bend allowances, weld accessibility, and geometric complexity to optimize for both performance and production efficiency. Using Siemens NX and SolidWorks, we simulate forming stresses and thermal distortion, ensuring the design is robust before any metal is cut.

Prototyping follows DFM validation, employing our fiber laser cutting systems with ±0.1 mm positional accuracy and CNC press brakes with automatic angle feedback. Each prototype is fully documented, with first-article inspection reports (FAIR) and coordinate measuring machine (CMM) validation. This stage is critical for identifying potential flaws and confirming fit, function, and assembly compatibility. Clients receive detailed feedback loops, enabling rapid iteration without delaying the production timeline.

Once approved, we transition to high-volume manufacturing on automated production lines. Our laser cutting center features 6 kW fiber lasers capable of processing steel up to 25 mm and aluminum up to 30 mm. Turrets and robotic bending cells ensure consistent forming, while automated welding stations with real-time seam tracking maintain weld integrity. Throughout mass production, statistical process control (SPC) monitors key dimensions, and in-line optical inspection systems detect surface defects or dimensional drift before components proceed to finishing.

Zero defects are achieved through embedded quality gates at every stage. Each batch undergoes material traceability checks, hardness testing, and coating thickness verification. Final assemblies are subjected to functional testing where applicable, ensuring full compliance with ISO 9001 and client-specific standards.

Our production specifications reflect our commitment to precision and consistency.

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm (steel), up to 30 mm (Al) |

| Laser Cutting Accuracy | ±0.1 mm |

| CNC Bending Tolerance | ±0.2°, ±0.1 mm linear |

| Welding Processes | MIG, TIG, Spot, Robotic Pulsed Arc |

| Surface Roughness (Ra) | ≤1.6 µm (machined), ≤3.2 µm (formed) |

| Coating Options | Powder coating, anodizing, zinc plating |

| Quality Standards | ISO 9001, ISO 13485 (medical), AS9100 (aero) |

From design validation to final shipment, Wuxi Lead ensures every component meets the highest standards of precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Excellence

In high-stakes industrial manufacturing, the margin for error in sheet metal components is nonexistent. Complex geometries, stringent tolerances, and rigorous material specifications define your projects. Wuxi Lead Precision Machinery operates at the intersection of advanced engineering and flawless execution, transforming your most demanding sheet metal designs into reality. We do not merely fabricate parts; we engineer solutions that ensure your assemblies integrate seamlessly, perform reliably, and exceed industry benchmarks. Our ISO 9001-certified facility in Wuxi, China, leverages German-engineered machinery and a team of veteran CNC specialists to deliver precision where it matters most—on your production line and in your final product.

Our technical capabilities are built for mission-critical applications across aerospace, medical device, and industrial automation sectors. The table below details our core sheet metal fabrication specifications, reflecting our commitment to micron-level accuracy and repeatability:

| Capability | Specification | Application Impact |

|---|---|---|

| Laser Cutting | 0.5–25mm Thickness; ±0.05mm Tolerance | Clean edges, minimal burr, complex contours |

| CNC Punching | 0.8–6.0mm Thickness; ±0.03mm Positional Accuracy | High-speed prototyping, intricate perforations |

| Precision Bending | 0.5–12mm Thickness; ±0.1° Angular Tolerance | Consistent flange alignment, zero springback |

| Welding & Assembly | TIG/MIG; Sub-0.1mm Weld Seam Control | Hermetic seals, structural integrity |

| Finishing | Anodizing, Powder Coating, Passivation | Corrosion resistance, regulatory compliance |

Partnering with Lead Precision means eliminating the supply chain risks inherent in offshore manufacturing. We integrate directly with your engineering workflows through secure CAD/CAM data exchange, providing real-time DFM feedback to optimize manufacturability before cutting begins. Our dedicated project managers—each with 15+ years in precision metalwork—oversee every phase, from material sourcing (verified to ASTM/EN standards) to in-process CMM inspections. This proactive collaboration reduces scrap rates by up to 30% and accelerates time-to-market without compromising quality. When your design requires tolerances tighter than 0.05mm or materials like Inconel 718 and titanium Grade 5, our engineers develop custom tooling and process protocols to meet your exact requirements.

The cost of precision is not measured in initial quotes but in the lifetime reliability of your product. Lead Precision delivers documented process validation, full material traceability, and on-time delivery rates exceeding 98.7%—metrics that protect your brand reputation and reduce total cost of ownership. We understand that your success hinges on partners who anticipate challenges, not just react to them.

Initiate your precision workflow today. Email [email protected] with your technical requirements packet, including 3D models, material specifications, and volume needs. Our engineering team will respond within 4 business hours with a detailed capability assessment and actionable timeline. For urgent RFQs, reference “URGENT-ENGINEERING” in the subject line to expedite review. Let us prove why global leaders trust Lead Precision to turn sheet metal constraints into competitive advantages. Your next breakthrough component begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.