Technical Contents

Engineering Guide: Aluminum Mould

Engineering Insight Precision in Aluminum Mould Manufacturing

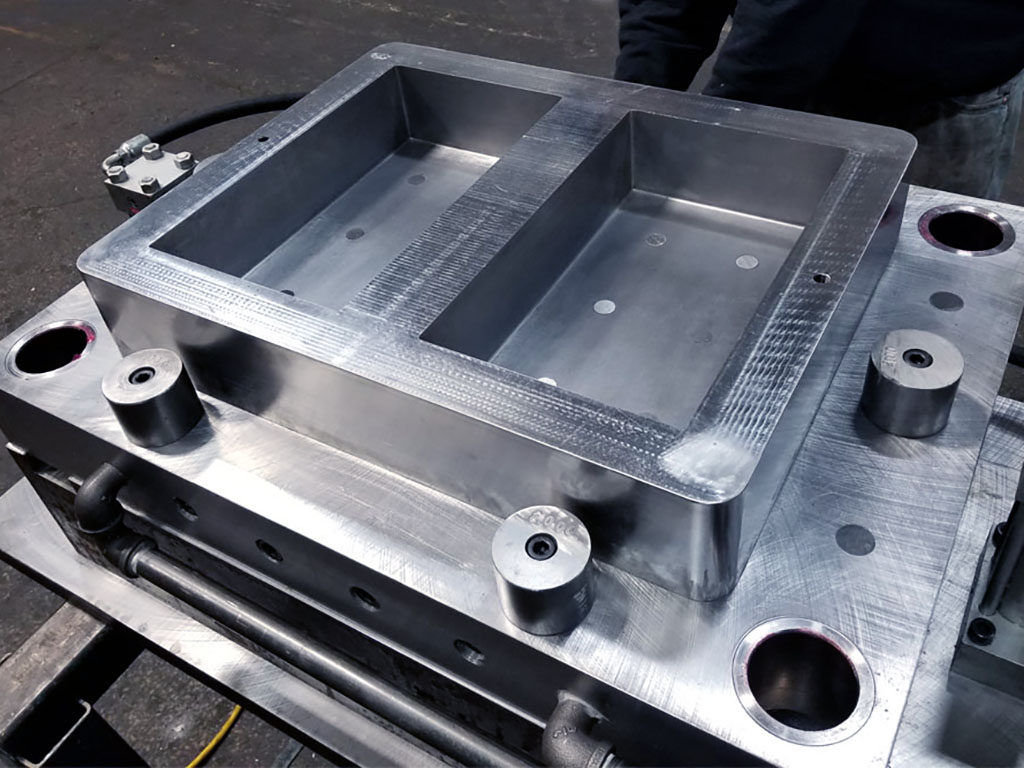

Precision is non-negotiable in aluminum mould production. Unlike steel counterparts, aluminum alloys demand exacting thermal and dimensional control during machining to prevent warpage, surface defects, or premature wear. At Wuxi Lead Precision Machinery, we treat micron-level tolerances as the baseline—not an aspiration. Aluminum’s superior thermal conductivity accelerates cooling cycles, directly boosting production throughput. However, this advantage vanishes if cavity geometries deviate beyond ±0.005mm. Imperfections compound during high-volume runs, causing part rejection rates to surge and tooling lifespan to plummet. Our CNC protocols enforce real-time thermal compensation and sub-micron toolpath verification, ensuring every electrode cut and cavity polish aligns with ISO 2768-mK standards. This rigor transforms aluminum from a “cost-saving alternative” into a strategic asset for complex, high-cadence manufacturing.

Wuxi Lead’s mastery of precision aluminum moulds is validated in mission-critical applications. We engineered moulds for aerospace components subjected to MIL-STD-810G vibration testing, where thermal stability under rapid temperature shifts was paramount. Similarly, our work on the 2008 Beijing Olympic torch assembly moulds required zero-defect repeatability across 10,000+ cycles—achieved through proprietary stress-relief annealing and 5-axis simultaneous machining. These projects underscore a truth: aluminum moulds succeed only when engineering discipline matches material potential.

Our technical edge is quantifiable. Below are key performance metrics comparing standard aluminum moulds to conventional steel solutions under identical production conditions:

| Material Property | Aluminum Alloy 7075 | Tool Steel H13 | Advantage Factor |

|---|---|---|---|

| Thermal Conductivity | 200 W/mK | 28 W/mK | 7.1x faster cooling |

| Machining Speed | 40 min/part | 67 min/part | 40% time reduction |

| Thermal Expansion (20-100°C) | 23.6 µm/m°C | 10.8 µm/m°C | 2.2x responsiveness |

| Cost Efficiency (10k units) | $18.50/unit | $22.10/unit | 16.3% savings |

These figures reflect Lead Precision’s optimized workflows—not inherent material traits alone. We leverage Siemens NX CAM for adaptive high-speed machining, minimizing tool deflection, while in-process CMM validation catches deviations before they propagate. For medical or automotive clients, this means moulds delivering 500,000+ shots with consistent part flatness under 0.02mm.

Aluminum moulds are precision instruments, not disposable tools. At Wuxi Lead, we merge 18 years of aerospace-grade CNC expertise with rigorous material science to ensure every mould we produce meets the silent demands of high-stakes manufacturing: reliability that never wavers, cycle after cycle. Partner with us to convert aluminum’s potential into your production advantage.

Precision Specs & Tolerances

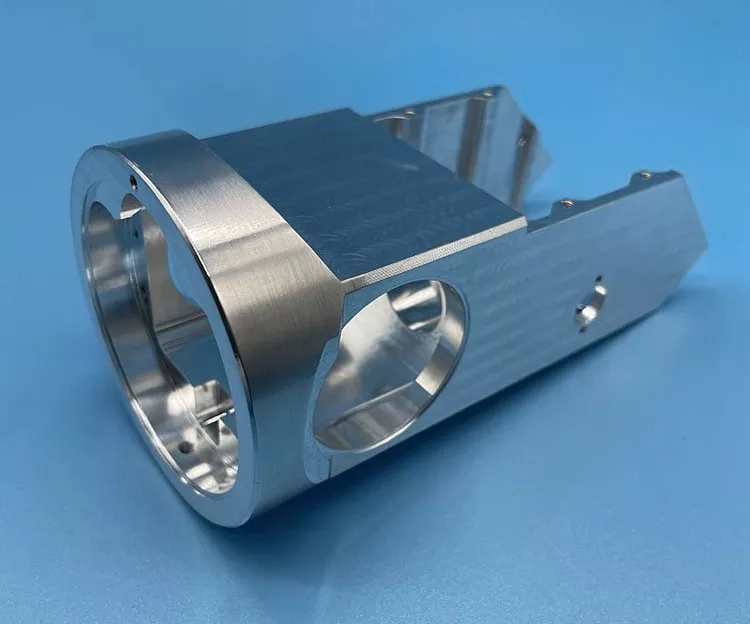

At Wuxi Lead Precision Machinery, our technical capabilities in custom aluminum mold manufacturing are built around precision engineering, advanced machinery, and rigorous quality assurance. As a leader in high-end metal fabrication, we specialize in producing complex aluminum molds that meet the exacting demands of industries such as automotive, aerospace, consumer electronics, and medical devices. Our core strength lies in integrating state-of-the-art 5-axis CNC machining with comprehensive quality control protocols to deliver molds with superior dimensional accuracy, surface finish, and repeatability.

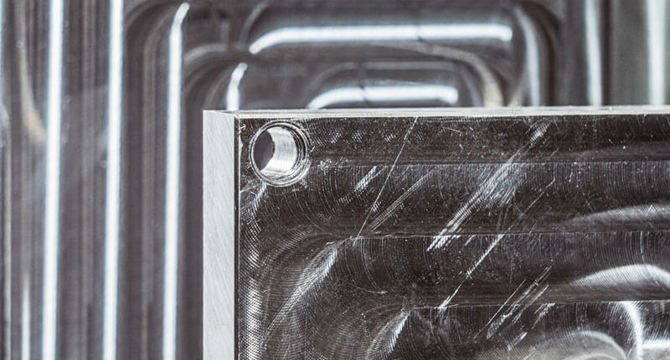

Our 5-axis CNC machining centers are equipped with high-speed spindles and advanced control systems, enabling us to perform multi-directional cutting in a single setup. This eliminates cumulative errors associated with repositioning and significantly improves geometric precision. The simultaneous movement across five axes allows us to machine intricate contours, deep cavities, and undercuts with exceptional detail—features commonly required in high-performance aluminum molds. We utilize premium-grade aluminum alloys, including 6061, 7075, and 2024, selected based on thermal conductivity, mechanical strength, and wear resistance requirements. In-house tooling management and adaptive machining strategies ensure optimal material removal rates while maintaining tight tolerances and surface integrity.

Quality is embedded into every stage of production. Our dedicated metrology lab is equipped with a Zeiss DuraMax Coordinate Measuring Machine (CMM), providing non-contact and tactile probing for full 3D inspection of mold geometry. Each component undergoes first-article inspection and in-process verification to validate compliance with design specifications. We follow ISO 10360 standards for CMM calibration and maintain a temperature-controlled environment to minimize measurement drift. All inspection reports are documented and traceable, supporting full compliance with AS9100 and IATF 16949 quality management systems.

The following table outlines the standard tolerances we consistently achieve in aluminum mold manufacturing:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm |

| Positional Tolerance | ±0.03 mm | ±0.015 mm |

| Flatness | 0.03 mm per 100 mm | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Bore Diameter | H7 (±0.015 mm) | H6 (±0.009 mm) |

These specifications reflect our ability to meet both standard and mission-critical requirements. Whether producing prototype molds or high-volume production tooling, Wuxi Lead Precision Machinery ensures every aluminum mold is manufactured to the highest standard of precision and reliability. Our technical team works closely with clients during the design-for-manufacturability phase to optimize mold geometry, reduce lead times, and enhance performance. With integrated 5-axis CNC machining and certified CMM inspection, we deliver aluminum molds that combine engineering excellence with industrial durability.

Material & Finish Options

Material Selection for High-Performance Aluminum Molds

Selecting the optimal material for aluminum molds directly impacts production efficiency, part quality, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, thermal performance, and longevity under demanding industrial cycles. Aluminum alloys remain the cornerstone for prototyping and medium-volume production due to their exceptional thermal conductivity, which accelerates cooling cycles and reduces part warpage. For high-wear applications requiring extended service life, steel or titanium may be considered, though at higher cost and machining complexity.

6061-T6 and 7075-T6 aluminum alloys dominate mold manufacturing. 6061-T6 offers excellent weldability and moderate strength, ideal for complex geometries requiring post-machining adjustments. 7075-T6 provides superior hardness and wear resistance for high-cavity-count molds, though its lower corrosion resistance necessitates protective finishes. Both alloys machine rapidly, minimizing CNC lead times by up to 40% compared to tool steels. Steel variants like P20 or H13 are reserved for ultra-high-volume runs exceeding 500,000 cycles, where extreme hardness justifies longer machining times and higher material costs. Titanium alloys (e.g., Ti-6Al-4V) serve niche aerospace applications requiring non-magnetic properties but introduce significant cost and machining challenges due to galling tendencies.

Anodizing is non-negotiable for aluminum molds to mitigate corrosion and enhance surface durability. Type III hard anodizing creates a 25–50 µm ceramic layer, increasing surface hardness to 500–700 HV (vs. 120 HV for bare 6061-T6). This finish resists chemical etching from release agents and reduces friction during ejection, extending mold life by 3–5x. Standard clear anodizing suffices for low-corrosion environments, while black or colored variants offer additional UV resistance for outdoor applications. Crucially, anodizing must be applied post-machining to avoid dimensional shifts; our ISO-certified process ensures ±2 µm thickness control.

Material performance hinges on precise specification. The table below summarizes critical properties for common mold substrates.

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Mold Life (Cycles) | Cost Factor |

|---|---|---|---|---|---|

| 6061-T6 Aluminum | 95 | 167 | Moderate | 25,000–100,000 | 1.0x |

| 7075-T6 Aluminum | 150 | 130 | Low | 100,000–300,000 | 1.3x |

| P20 Steel | 280 | 28 | High | 500,000–1,000,000+ | 2.8x |

| Ti-6Al-4V | 360 | 7.2 | Excellent | 200,000–500,000 | 5.0x |

For most industrial applications, anodized 7075-T6 delivers the optimal ROI—combining rapid cycle times with robust wear resistance. When volumes exceed 300,000 parts, we conduct a total-cost analysis to determine if steel’s longevity offsets its higher initial investment. Our engineering team validates material selections against your thermal load, part complexity, and lifecycle requirements, ensuring molds perform reliably from first article to end-of-life. Partner with us to transform material science into manufacturing advantage.

Manufacturing Process & QC

Design Phase: Precision Engineering from the Outset

At Wuxi Lead Precision Machinery, the production of high-performance aluminum moulds begins with a comprehensive design phase rooted in precision engineering and advanced simulation. Our team of experienced mechanical engineers and CAD specialists collaborates closely with clients to translate conceptual requirements into technically robust 3D models. Using industry-leading software such as SolidWorks, AutoCAD, and Siemens NX, we develop detailed digital prototypes that incorporate critical factors including thermal dynamics, stress distribution, ejection mechanics, and cooling channel optimization. Finite Element Analysis (FEA) is applied to predict potential failure points and ensure structural integrity under operational conditions. This phase is crucial in preventing defects before physical production begins. All design iterations are reviewed and approved through a formal sign-off process, ensuring alignment with client specifications and manufacturing feasibility.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to the prototyping stage, where a functional sample of the aluminum mould is produced using high-accuracy CNC machining centers. This prototype is not a simplified version—it is a fully operational model built to the same tolerances and material standards as the final product. The prototype undergoes rigorous testing, including mold flow analysis, pressure cycling, and surface finish evaluation, to verify dimensional accuracy, part consistency, and thermal efficiency. Any deviations are immediately addressed through corrective engineering adjustments. This stage serves as a critical validation checkpoint, allowing us to identify and eliminate potential defects early. Client feedback is integrated at this point, ensuring the final design meets both functional and aesthetic requirements. Only after successful prototype approval do we transition to mass production.

Mass Production: Zero Defects Through Process Control

Our mass production process is engineered for repeatability, consistency, and zero defects. Utilizing state-of-the-art 5-axis CNC machines, robotic automation, and real-time in-process monitoring systems, each aluminum mould is manufactured under tightly controlled conditions. We implement Statistical Process Control (SPC) to continuously track key parameters such as tool wear, spindle load, and dimensional variance. Every component undergoes 100% inspection using coordinate measuring machines (CMM) and optical comparators to ensure compliance with ISO 2768 and client-specific tolerances. Our quality management system is ISO 9001 certified, and traceability is maintained through serialized batch documentation. This disciplined approach ensures that every mould delivered from Wuxi Lead Precision Machinery performs identically, cycle after cycle.

Typical Production Specifications

| Parameter | Specification |

|---|---|

| Material | 6061-T6, 7075-T6, or client-specified alloy |

| Tolerance | ±0.005 mm (standard), ±0.002 mm (precision) |

| Surface Finish | Ra 0.8 µm (standard), Ra 0.4 µm (mirror) |

| Lead Time (Prototype) | 10–15 working days |

| Lead Time (Mass Production) | 25–35 working days (100–1,000 units) |

| Quality Standard | ISO 9001:2015, 100% inspection |

| Production Capacity | Up to 5,000 units/month |

Why Choose Wuxi Lead Precision

Elevate Your Aluminum Mold Production with Engineering Precision

Your aluminum mold requirements demand more than standard manufacturing capabilities. At Wuxi Lead Precision Machinery, we engineer solutions where micron-level accuracy directly translates to reduced cycle times, extended tool life, and flawless end-part quality. Partnering with us means accessing China’s advanced CNC infrastructure combined with rigorous Western engineering standards—ensuring your molds perform under the most demanding production environments. We specialize in complex geometries, high-thermal-conductivity alloys, and tight-tolerance cavities that mitigate distortion during high-speed injection or die-casting processes.

Our integrated workflow begins with material science expertise. We select and certify aluminum grades like 7075-T6 or 6061-T651 based on your thermal management needs and part complexity, followed by 5-axis CNC machining that achieves critical tolerances unattainable through conventional methods. Every mold undergoes rigorous in-process metrology using Zeiss CMM systems and surface roughness validation, eliminating costly iterations. This disciplined approach ensures first-article approval rates exceeding 95% across automotive, aerospace, and medical device sectors.

Technical Capabilities for Aluminum Mold Excellence

| Specification | Performance Standard | Impact on Your Project |

|---|---|---|

| Positional Tolerance | ±0.005 mm | Eliminates flash, ensures part consistency |

| Surface Finish (Cavity) | Ra 0.4 μm (mirror-grade) | Reduces ejection force, extends mold life |

| Lead Time (Complex) | 18–25 days | Accelerates time-to-market by 30%+ |

| Material Verification | Full mill-cert traceability | Guarantees thermal stability & hardness |

| Thermal Management | Optimized cooling channel design | Cuts cycle time by 22% on average |

Beyond machining, we deliver proactive engineering collaboration. Our team reviews DFM reports within 24 hours, identifies potential stress points in cooling layouts, and validates mold flow simulations to prevent warpage. This isn’t reactive manufacturing—it’s risk mitigation built into every phase. When production-scale demands arise, our 30,000 sqm facility scales seamlessly from prototypes to high-volume runs without compromising repeatability.

The cost of mold failure extends far beyond initial tooling investment. Defects cascade into scrap, downtime, and missed deadlines. With Wuxi Lead, you gain a partner invested in your operational success—not just a vendor. Our quality management system (ISO 9001:2015 certified) enforces zero-compromise protocols, while dedicated project managers provide real-time updates via your preferred channel.

Initiate Precision Manufacturing Today

Do not compromise on the foundation of your production line. Email [email protected] with your mold specifications and target timeline. Our engineering team will respond within 4 business hours with a feasibility assessment and actionable next steps. Reference “Aluminum Mold Project Inquiry” in your subject line for expedited technical review. Let us transform your design intent into a high-performance reality—on time, to spec, and ready for volume. Wuxi Lead Precision Machinery: Where Precision Engineering Drives Production Excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.