Technical Contents

Engineering Guide: Complex Parts For The Chemical Industry

Engineering Insight: Complex Parts for the Chemical Industry

In the chemical processing industry, operational environments are among the most demanding in industrial manufacturing. High pressures, extreme temperatures, and exposure to corrosive substances require components that not only meet exacting dimensional tolerances but also maintain structural integrity over prolonged service cycles. Precision in manufacturing is not merely a performance differentiator—it is a fundamental requirement for safety, compliance, and long-term reliability. At Wuxi Lead Precision Machinery, we understand that even a micron-level deviation in a reactor vessel flange, valve housing, or heat exchanger component can lead to catastrophic failure, unplanned downtime, or environmental hazards.

Our approach to producing complex metal parts for the chemical sector begins with material selection and extends through every phase of machining, inspection, and finishing. We specialize in high-performance alloys such as Hastelloy, Inconel, titanium, and duplex stainless steels—materials chosen for their resistance to chemical degradation but notoriously difficult to machine with consistency. Achieving tight tolerances in these materials demands not only advanced CNC equipment but also deep engineering expertise and process control. Our facility utilizes 5-axis milling, turning centers with live tooling, and high-pressure coolant systems to maintain precision while managing thermal deformation and tool wear.

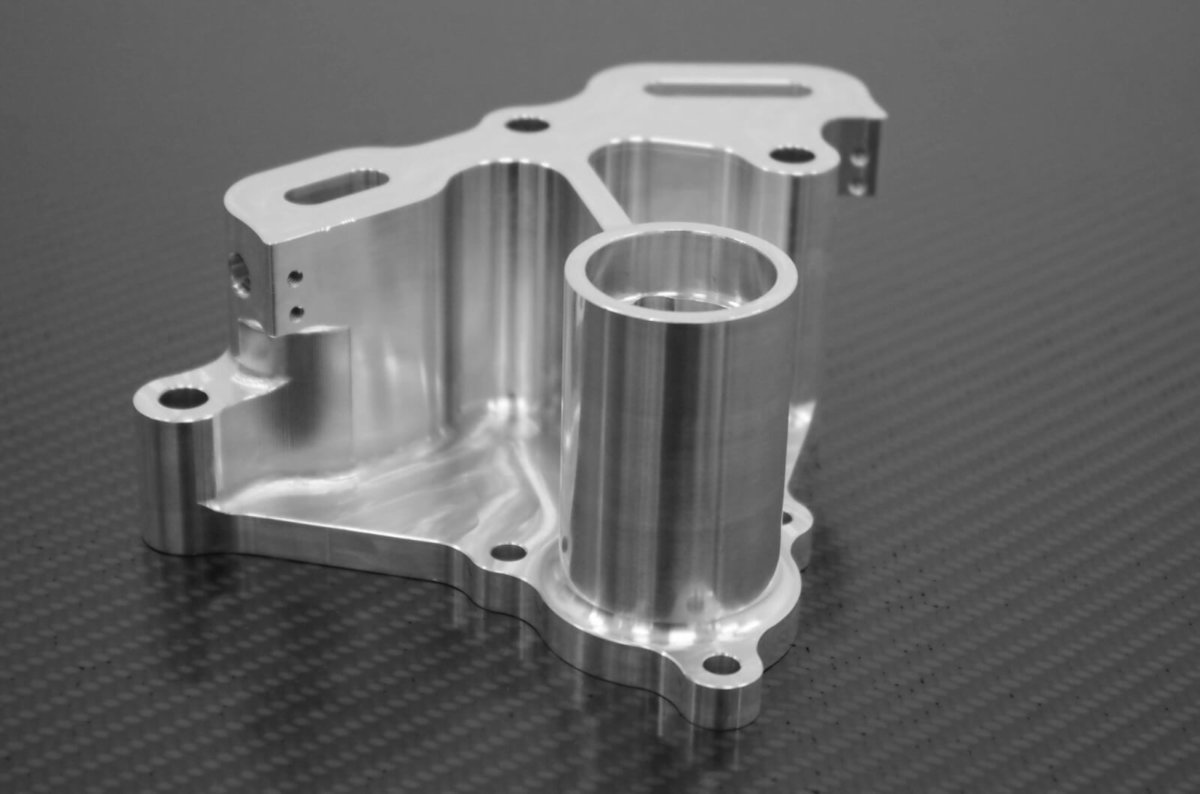

The complexity of chemical industry components often involves intricate internal geometries, thin-walled sections, and multi-port configurations that challenge conventional machining methods. At Lead Precision, we leverage 3D simulation and in-process probing to validate toolpaths and ensure dimensional accuracy in real time. Each component undergoes full CMM inspection and non-destructive testing when required, with full traceability from raw material to final shipment.

Our experience extends beyond commercial chemical plants. Having delivered mission-critical components for Olympic infrastructure projects and military-grade systems, we apply the same rigor—zero-defect standards, full documentation, and adherence to ASME, ISO, and NACE requirements—to every order, regardless of scale. This heritage of high-stakes manufacturing informs our culture of precision and accountability, ensuring that every part we produce meets the uncompromising demands of chemical processing environments.

The following table outlines typical specifications we achieve for complex chemical industry components:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.01 mm | ±0.005 mm |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm |

| Maximum Part Weight | 2,500 kg | 1,200 kg |

| Materials | Stainless Steel, Hastelloy, Inconel, Titanium, Duplex/Super Duplex | On request, including clad and bi-metallic structures |

| Certifications | ISO 9001, ASME BPVC Section VIII, NACE MR0175 | Full material traceability (MTR), PMI, NDT reports |

At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we engineer reliability into every component, ensuring performance under the most aggressive chemical conditions.

Precision Specs & Tolerances

Technical Capabilities for Chemical Industry Complex Parts

Wuxi Lead Precision Machinery delivers uncompromising precision for the most demanding complex metal components within the chemical processing sector. Our technical foundation is built upon advanced manufacturing systems and rigorous quality protocols specifically engineered to address the unique challenges of corrosive environments, high-pressure containment, and stringent regulatory compliance. Success in this critical industry demands absolute dimensional integrity and material performance; we provide the capabilities to ensure it.

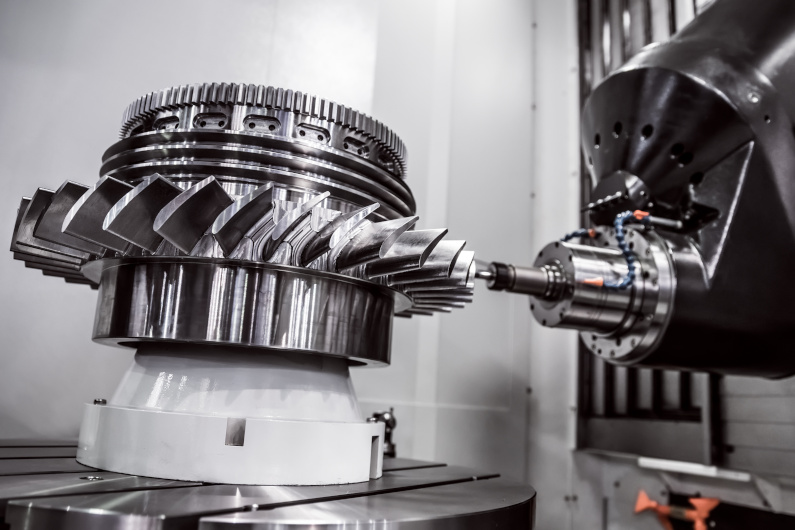

Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers, including models from DMG MORI and Hermle. These systems enable the complete, single-setup fabrication of intricate geometries common in chemical industry components such as reactor internals, specialized valves, pump housings, and custom flanges. Simultaneous 5-axis movement eliminates secondary operations, minimizing cumulative error and ensuring superior feature-to-feature relationships essential for leak-tight assemblies and precise flow dynamics. We routinely machine challenging corrosion-resistant alloys including Hastelloy, Inconel, titanium, and duplex stainless steels, maintaining tight control over thermal management and tooling strategies to prevent material distortion and ensure surface integrity.

Quality verification is integral to every stage of production, not merely a final checkpoint. Our dedicated metrology laboratory is anchored by multiple high-accuracy Coordinate Measuring Machines (CMMs), including a global leader Zeiss CONTURA system capable of measuring to 0.0001 inches (2.5 microns) accuracy. Comprehensive inspection plans are developed per ASME Y14.5 and client-specific requirements, covering all critical dimensions, geometric tolerances (GD&T), and surface finishes. Beyond CMM, we employ optical comparators, surface roughness testers, and laser scanning for complex contour validation, ensuring full dimensional conformance and providing complete traceability through documented inspection reports. Process validation and Statistical Process Control (SPC) methodologies are applied to critical features, guaranteeing consistent output batch after batch.

The following table details our standard achievable tolerance capabilities for complex chemical industry components, reflecting our commitment to exceeding typical industry benchmarks like ISO 2768-mK. Actual tolerances achieved are always part of the collaborative engineering review process, optimized for specific part geometry, material, and functional requirements.

| Feature Type | Standard Tolerance (Metric) | Standard Tolerance (Imperial) | Wuxi Lead Capability (Typical) |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.002 in | ±0.01 mm / ±0.0004 in |

| Bore Diameters | H7 (+0.018 / 0) | H7 (+0.0007 / 0) | H6 (+0.009 / 0) |

| Shaft Diameters | h6 (-0.009 / 0) | h6 (-0.00035 / 0) | h5 (-0.004 / 0) |

| Positional Tolerance | ±0.05 mm | ±0.002 in | ±0.01 mm / ±0.0004 in |

| Flatness | 0.05 mm | 0.002 in | 0.005 mm / 0.0002 in |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 63 µin | 0.4 µm (16 µin) or better |

This level of precision manufacturing, combined with our deep understanding of chemical process demands, ensures components that perform reliably under extreme conditions, minimizing downtime and supporting the safety and efficiency of your critical operations. We partner with clients from initial design for manufacturability through final inspection to deliver parts that meet the exacting standards of the chemical industry.

Material & Finish Options

Material selection is a critical decision in the production of complex metal components for the chemical industry, where performance under corrosive environments, elevated temperatures, and high mechanical loads is non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom manufacturing solutions that align material properties with operational demands. Among the most widely used metals in this sector are aluminum, stainless steel, and titanium—each offering distinct advantages depending on the application.

Aluminum is prized for its lightweight nature and excellent thermal and electrical conductivity. While pure aluminum is susceptible to corrosion, alloys such as 6061 and 7075 offer improved strength and resistance to chemical exposure, especially when paired with protective finishes like anodizing. Anodizing creates a durable oxide layer that enhances surface hardness, wear resistance, and dielectric properties, making it ideal for components exposed to mild to moderate chemical environments. However, aluminum’s limitations in high-temperature and highly acidic or alkaline conditions require careful evaluation before deployment.

Stainless steel, particularly grades 316 and 316L, remains a cornerstone in chemical processing equipment due to its robust corrosion resistance, high tensile strength, and thermal stability. The presence of molybdenum in 316-grade steel significantly improves resistance to chlorides and organic acids, making it suitable for reactors, valves, and piping systems. Unlike aluminum, stainless steel does not typically require anodizing; instead, surface passivation or electropolishing is used to remove free iron and enhance the natural chromium oxide layer, ensuring long-term integrity in aggressive media.

Titanium stands at the pinnacle of corrosion resistance among common engineering metals. Its performance in oxidizing environments—such as those involving nitric acid, chlorine, or seawater—is unmatched. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are frequently specified for critical components in chemical plants due to their excellent strength-to-density ratio and resistance to pitting and stress corrosion cracking. While titanium is more expensive and challenging to machine, its longevity and reliability in extreme conditions justify the investment for mission-critical applications.

The following table summarizes key mechanical and chemical properties of these materials:

| Material | Typical Grade | Tensile Strength (MPa) | Corrosion Resistance | Common Finishes | Max Service Temp (°C) |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | Moderate (enhanced with anodizing) | Anodizing, Passivation | 150 |

| Stainless Steel | 316/316L | 570–620 | High (especially to chlorides) | Passivation, Electropolishing | 870 |

| Titanium | Grade 2 / Grade 5 | 345 / 880 | Exceptional (oxidizing environments) | Passivation, Bead Blasting | 600 |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on chemical exposure, mechanical requirements, and lifecycle costs. Our precision CNC machining capabilities ensure that even the most complex geometries are produced to exacting standards, with full traceability and quality assurance.

Manufacturing Process & QC

Precision Manufacturing Process for Chemical Industry Components

At Wuxi Lead Precision Machinery, we engineer complex metal components for the chemical industry where failure is not an option. Our integrated process—Design, Prototyping, Mass Production—ensures zero defects through rigorous validation and control, meeting the sector’s extreme demands for corrosion resistance, pressure integrity, and traceability.

Design Phase: Engineering for Extreme Environments

We begin with collaborative design engineering, focusing on material compatibility and operational stressors. Chemical applications require alloys like Hastelloy C-276, Inconel 625, or ASTM A182 F51 duplex stainless steel, selected via NACE MR0175 compliance checks. Finite Element Analysis (FEA) simulates thermal cycling, acidic exposure, and high-pressure scenarios to optimize geometry and eliminate stress concentrations. Design for Manufacturability (DFM) reviews ensure features like tight-tolerance bores (±0.005 mm) and critical sealing surfaces are achievable without secondary operations, reducing risk points before metal cutting begins.

Prototyping: Validation Under Real-World Conditions

Prototypes undergo accelerated life testing in simulated chemical environments—exposure to 98% sulfuric acid at 120°C or 30% NaOH at 80°C—to validate material performance and dimensional stability. We deploy coordinate measuring machines (CMM) with 0.0005 mm accuracy and optical comparators to verify all critical features against ASME Y14.5 GD&T standards. Any deviation triggers immediate design iteration. This phase confirms not only form/function but also manufacturability at scale, with full material test reports (MTRs) and PMI (Positive Material Identification) documentation.

Mass Production: Zero-Defect Execution

Full-scale production leverages automated CNC machining centers with in-process probing and real-time SPC (Statistical Process Control). Each component is tracked via laser-etched serial numbers, linking to digital quality records including raw material certs, machine parameters, and inspection data. Critical dimensions are monitored at 100% frequency using automated vision systems, while surface roughness (Ra ≤ 0.4 μm for sealing faces) is verified per ISO 1302. Our closed-loop system halts production if trends approach tolerance limits, ensuring zero non-conformances reach clients. Final inspection includes helium leak testing for pressure boundaries and full traceability to ASTM/ASME standards.

Critical Process Parameters for Chemical Industry Components

| Parameter | Specification | Standard |

|---|---|---|

| Material Grades | Hastelloy C-276, Inconel 625, F51 Duplex | ASTM B575, B446, A182 |

| Dimensional Tolerance | ±0.005 mm (critical features) | ASME Y14.5 GD&T |

| Surface Roughness (Ra) | ≤ 0.4 μm (sealing surfaces) | ISO 1302 |

| Pressure Testing | 1.5x design pressure with helium leak | ASME B16.34 |

| Traceability | Full lot-to-part digital records | ISO 9001:2015 |

This disciplined workflow—grounded in chemical engineering expertise and precision manufacturing—delivers components that withstand aggressive media, thermal shocks, and cyclic fatigue. Wuxi Lead’s zero-defect commitment is not a target but a baseline, ensuring your systems operate safely, continuously, and compliantly in the world’s most demanding chemical processes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Components in the Chemical Industry

In the chemical processing sector, equipment failure is not an option. Every component in a reactor system, piping network, or containment vessel must withstand extreme temperatures, corrosive media, and high pressures—day after day. At Wuxi Lead Precision Machinery, we specialize in the production of complex, custom metal parts engineered to perform reliably in the most demanding chemical environments. When you partner with us, you gain more than a supplier—you gain a precision engineering ally committed to your operational integrity and long-term success.

Our advanced CNC machining capabilities, combined with rigorous material traceability and quality assurance protocols, ensure that every part we produce meets exacting international standards. From Hastelloy reactor flanges to Inconel valve bodies and titanium heat exchanger tubesheets, we work with high-performance alloys that resist corrosion, maintain structural stability, and extend service life. Our engineering team collaborates closely with clients during the design phase to optimize manufacturability, reduce lead times, and eliminate costly iterations.

We understand that the chemical industry demands not only precision but also compliance. Our facility operates under ISO 9001:2015 certification, with full documentation for material certifications (MTRs), dimensional inspection reports, and non-destructive testing (NDT) as required. Whether you need a single prototype or a full production run, our scalable manufacturing model supports low to medium volumes with consistent repeatability and zero compromise on quality.

Our clients rely on us because we deliver more than machined metal—we deliver confidence. With in-house 5-axis milling, turning, grinding, and precision boring, we handle geometries that challenge conventional shops. Tight tolerances, intricate internal features, and strict surface finish requirements are part of our daily work. We also offer value-added services such as passivation, polishing, and assembly to reduce your supply chain complexity.

Below are key specifications that define our manufacturing capabilities:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 2,200 mm × 1,200 mm × 1,000 mm |

| Tolerance Capability | ±0.005 mm |

| Surface Finish | As fine as Ra 0.4 μm |

| Materials Processed | Stainless Steel (316L, 904L), Duplex/Super Duplex, Hastelloy (C-276, B2), Inconel (625, 718), Titanium (Gr 2, Gr 5), Monel, Zirconium |

| Machining Centers | 5-Axis CNC, Multi-Tasking Lathes, High-Speed Milling |

| Quality Standards | ISO 9001:2015, ASME, NACE MR0175, NDT (PT, UT, RT), PMI Testing |

When performance, safety, and compliance are non-negotiable, trust your critical components to a manufacturer that understands the stakes. Contact us today at [email protected] to discuss your next project with our engineering team. Let Wuxi Lead Precision Machinery be the precision behind your process.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.