Technical Contents

Engineering Guide: Corner Molding Plastic

Engineering Insight Precision in Corner Molding Plastic Applications

Achieving flawless corner molding in plastic components is far more than an aesthetic concern; it is a critical engineering imperative directly impacting structural integrity, assembly success, and long-term performance. In high-stakes applications across aerospace, defense, and precision instrumentation, corners represent concentrated stress points and potential failure zones. Imperfect radii, inconsistent angles, or surface micro-fractures introduced during molding compromise sealing capabilities, accelerate fatigue, and jeopardize the entire system. The margin for error is microscopic. A deviation of mere microns in corner geometry can propagate catastrophic stress concentrations under operational loads or thermal cycling, leading to premature component failure. This demands manufacturing processes capable of exceptional repeatability and adherence to stringent geometric dimensioning and tolerancing (GD&T) standards, far exceeding basic industry norms.

At Wuxi Lead Precision Machinery, we engineer corner molding solutions where precision is non-negotiable. Our decades of experience machining critical components for Olympic infrastructure projects and demanding military specifications provide the foundation for this capability. Consider the zero-leakage sealing requirements for environmental control systems in Beijing’s National Stadium or the vibration-resistant housings for battlefield communication equipment. These applications demanded corner geometries held within tolerances where surface finish and angular accuracy directly determined mission success or failure. We translate this extreme discipline into every plastic corner molding project. Our advanced CNC milling, precision grinding, and specialized post-molding finishing techniques ensure corners meet exacting angular specifications and surface quality requirements, eliminating stress risers and ensuring optimal part function and longevity. We understand that the corner is not merely a transition; it is a functional element requiring the same rigorous engineering attention as any primary feature.

The table below outlines the critical tolerance parameters we consistently achieve for corner molding plastic components, reflecting the standards demanded by our most exacting clients:

| Parameter | Standard Capability | High-Precision Capability | Measurement Standard |

|---|---|---|---|

| Angular Tolerance | ±0.2° | ±0.05° | ISO 2768-mK |

| Radius Consistency | ±0.1 mm | ±0.025 mm | Optical Comparator |

| Surface Roughness | Ra 1.6 μm | Ra 0.4 μm | ISO 4287 |

| Warpage Control | < 0.15 mm/m | < 0.05 mm/m | CMM Analysis |

This level of control is not accidental. It stems from our integrated approach: rigorous material science understanding, proprietary toolpath strategies minimizing thermal distortion, in-process metrology, and environmental controls within our cleanroom-capable facility. When corner integrity defines system reliability, as it does in life-critical or high-value applications, settling for standard tolerances introduces unacceptable risk. Wuxi Lead Precision Machinery delivers the demonstrable precision required to transform corner molding from a potential weakness into a certified strength, ensuring your plastic components perform flawlessly under the most demanding conditions. Precision at the corner is precision for the mission.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in precision components for high-performance applications, including corner molding plastic tooling and related industrial systems. Our engineering expertise is built on a foundation of state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, ensuring optimal tool positioning and access to intricate features that are common in mold cavities, corner transitions, and structural support elements used in plastic molding applications.

Our 5-axis CNC centers are equipped with high-speed spindles, automated tool changers, and real-time monitoring systems to maintain process stability and repeatability. This level of automation and control is critical when machining hardened steels, aluminum alloys, or specialty materials used in durable mold tooling. By leveraging advanced CAM software and adaptive machining strategies, we minimize setup times and reduce human intervention, which results in faster turnaround and consistent part quality across production runs.

Quality assurance is integrated into every phase of manufacturing. All critical dimensions and geometric features undergo comprehensive inspection using a Zeiss Coordinate Measuring Machine (CMM), ensuring compliance with tight tolerance requirements. Our CMM system supports both contact and non-contact probing methods, enabling precise verification of complex contours, radii, and angular interfaces—features often found in corner molding designs where fit and alignment are paramount. Data from inspections are documented and traceable, providing full accountability for each component produced.

We maintain strict environmental controls in our metrology lab to eliminate thermal drift and ensure measurement integrity. This disciplined approach to quality supports industries where regulatory compliance and long-term reliability are essential, such as automotive, medical device manufacturing, and high-end consumer electronics.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC and inspection processes:

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Angular Features | ±0.1° | ±0.05° | CMM, Optical Comparator |

| Radius/Contour | ±0.03 mm | ±0.01 mm | CMM, Profile Projector |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm | Surface Roughness Tester |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | CMM |

| Flatness | 0.01 mm/m | 0.005 mm/m | CMM, Laser Interferometer |

These specifications reflect our commitment to delivering components that meet the most demanding engineering requirements. Whether producing prototype tooling or full-scale production molds, Wuxi Lead Precision Machinery ensures dimensional integrity, functional performance, and seamless integration into downstream assembly processes.

Material & Finish Options

Material Selection for Precision Metal Corner Moldings

Selecting the optimal material for corner molding applications is critical for balancing structural integrity, environmental resistance, and lifecycle cost in demanding industrial environments. While plastic alternatives exist, metal corner moldings from Wuxi Lead Precision Machinery deliver superior durability, dimensional stability, and protection for high-value assemblies. Our expertise focuses on aluminum, steel, and titanium – each offering distinct advantages based on project requirements. Aluminum provides an exceptional strength-to-weight ratio and inherent corrosion resistance, making it ideal for electronics enclosures, transportation interiors, and architectural trim where weight savings and aesthetics matter. Steel, particularly stainless grades like 304 and 316, delivers unmatched strength and impact resistance for heavy machinery frames, industrial equipment guards, and structural supports exposed to physical stress. Titanium, though higher in cost, is the solution for extreme environments requiring maximum corrosion resistance combined with high strength-to-weight, such as aerospace components, marine hardware, and critical medical device housings. Choosing the wrong base material compromises performance and longevity; our engineering team collaborates to match material properties precisely to your operational demands.

Material Performance Specifications

| Material | Typical Density (g/cm³) | Tensile Strength Range (MPa) | Key Corrosion Resistance | Primary Application Focus |

|---|---|---|---|---|

| Aluminum | 2.7 | 120 – 570 | Excellent (Anodized) | Lightweight enclosures, transport |

| Stainless Steel | 7.9 – 8.0 | 505 – 965 | Very Good (Grade Dependent) | Heavy machinery, structural frames |

| Titanium | 4.5 | 900 – 1100 | Exceptional | Aerospace, marine, critical medical |

Surface finishing, particularly anodizing for aluminum, is not merely cosmetic but a vital performance enhancer for corner moldings. Anodizing creates a hard, wear-resistant oxide layer integral to the base metal. Type II (Sulfuric Acid) anodizing offers good corrosion resistance and dyeability for standard applications, with thicknesses typically 5-25 µm. For corner moldings subjected to abrasion or harsh chemicals, Type III (Hardcoat) anodizing is essential, producing dense layers of 25-100+ µm thickness that significantly improve surface hardness (up to 600 HV) and wear life. Hardcoat anodizing maintains precise dimensional tolerances critical for tight-fitting moldings while providing electrical insulation. Wuxi Lead Precision Machinery controls the entire anodizing process in-house, ensuring consistent coating quality, color accuracy (including black, bronze, and custom hues), and adherence to ASTM B580/B581 standards. This integrated capability guarantees the finish performs as rigorously as the underlying metal component.

Material and finish selection directly impacts the protective function and service life of your corner moldings. Wuxi Lead leverages decades of CNC machining and finishing expertise to guide clients through this critical decision, ensuring the final component meets exact mechanical, environmental, and aesthetic specifications. Contact our engineering team for a detailed material suitability analysis tailored to your specific application.

Manufacturing Process & QC

Design Phase: Precision Engineering at the Foundation

The production process for custom corner molding plastic components begins with a comprehensive design phase, where engineering precision meets functional requirements. At Wuxi Lead Precision Machinery, our design team collaborates closely with clients to translate conceptual needs into detailed 3D CAD models. This stage integrates material selection, structural integrity analysis, and thermal performance evaluation to ensure compatibility with injection molding processes. Finite Element Analysis (FEA) is employed to simulate stress points and deformation risks, particularly critical in corner geometries where material flow and cooling rates vary. Mold flow analysis is conducted to predict filling patterns, minimizing weld lines and air traps that could compromise part quality. All design data is reviewed under APQP (Advanced Product Quality Planning) guidelines to align with ISO 9001 and IATF 16949 standards, ensuring traceability and compliance from the outset.

Prototyping: Validating Form, Fit, and Function

Once the digital design is finalized, we proceed to rapid prototyping using high-precision CNC-machined molds or 3D-printed tooling, depending on complexity and volume requirements. This stage allows for physical validation of the corner molding’s dimensional accuracy, surface finish, and assembly compatibility. Prototypes are subjected to rigorous testing, including tensile strength, impact resistance, and thermal cycling, to verify performance under real-world conditions. Any deviations are addressed through iterative design adjustments, with full documentation maintained for design failure mode and effects analysis (DFMEA). Client feedback is integrated at this stage to ensure alignment with end-use expectations. The goal is not merely functional validation but the elimination of potential failure modes before mass production begins.

Mass Production: Zero Defects Through Process Control

With prototype approval, we transition to full-scale production using state-of-the-art electric and hybrid injection molding machines with tight tolerancing capabilities. Each production run is governed by a detailed control plan incorporating Statistical Process Control (SPC) and real-time monitoring of critical parameters such as melt temperature, injection pressure, and cooling time. Automated vision inspection systems and coordinate measuring machines (CMM) are deployed inline to detect dimensional deviations at micron-level accuracy. Every batch undergoes first-article inspection and periodic quality audits to ensure consistency. Our zero-defect philosophy is enforced through poka-yoke (error-proofing) systems and a closed-loop corrective action process that immediately flags and resolves anomalies.

Key Production Specifications

| Parameter | Specification |

|---|---|

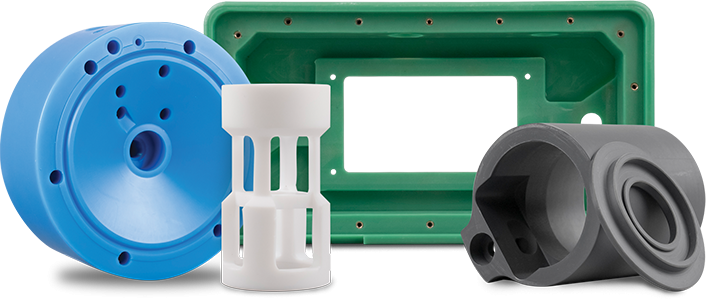

| Material Options | ABS, PC, PP, PVC, Nylon, TPE |

| Tolerance Range | ±0.05 mm to ±0.1 mm |

| Mold Lifespan | 500,000+ cycles (steel molds) |

| Surface Finish | Gloss, matte, textured, SPI standards |

| Production Capacity | 50,000 – 500,000 units/month |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

| Lead Time (Mass Production) | 4–6 weeks after prototype approval |

Through disciplined execution across design, prototyping, and production, Wuxi Lead Precision Machinery delivers corner molding plastic components with unmatched consistency, durability, and aesthetic quality—engineered for zero defects.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Engineered Corner Molding Solutions

At Wuxi Lead Precision Machinery, we engineer corner molding components beyond standard plastic fabrication. Our expertise lies in integrating precision metal substrates with engineered plastics to deliver structurally robust, dimensionally stable solutions for demanding industrial applications. When your project requires corner moldings that withstand thermal cycling, vibration, or mechanical stress—common in aerospace, medical equipment, and high-end automation—our hybrid manufacturing approach eliminates the compromise between plastic’s versatility and metal’s reliability. We do not merely produce parts; we solve assembly integrity challenges through material science and micron-level process control.

Our CNC-driven workflow begins with material selection guidance, where we match engineering-grade plastics like PEEK, ULTEM, or reinforced nylons to your thermal and load requirements. Critical metal inserts, brackets, or shielding are machined in-house to ±0.005mm tolerance before overmolding, ensuring perfect alignment and adhesion. This eliminates secondary assembly steps and reduces failure points. Every corner molding undergoes in-process CMM verification and final leak/burst testing per ISO 2768-mK standards. The result is a single-component solution that outperforms glued or mechanically fastened alternatives in lifecycle durability.

Technical Capabilities for Hybrid Corner Molding

| Parameter | Metal Substrate Range | Plastic Integration Range | Tolerance Control |

|---|---|---|---|

| Material Options | Aluminum 6061-T6, Stainless 304/316, Brass C360 | PEEK, PEI, PPS, Glass-Filled Nylon | ±0.005mm (metal), ±0.05mm (plastic) |

| Max Part Dimensions | 500 x 300 x 200 mm | 400 x 250 x 150 mm | Verified via Zeiss CONTURA CMM |

| Secondary Operations | Anodizing, Passivation, Laser Marking | Insert Molding, Ultrasonic Welding | ISO 9001:2015 Certified |

| Lead Time (Prototype) | 12-15 business days | Integrated in core process | 100% First-Pass Yield Guarantee |

This integration capability transforms corner moldings from passive trim elements into load-bearing structural components. For instance, in semiconductor handling systems, our hybrid moldings prevent particle generation under vacuum conditions where pure plastic would outgas. In medical imaging frames, they maintain rigidity during repeated sterilization cycles—something neither metal nor plastic achieves alone. Our engineers collaborate from DFM stage to validate stress points, draft angles, and material interfaces, preventing costly redesigns.

Choosing Wuxi Lead Precision means accessing China’s most rigorous hybrid manufacturing ecosystem without supply chain fragmentation. We own every process: 5-axis milling, wire EDM, cleanroom overmolding, and final validation. No subcontracted steps. No quality gaps. When your corner molding must perform as a mission-critical element—not just an aesthetic cover—partner with engineers who treat tolerances as non-negotiable.

Contact our technical sales team today to discuss how we can refine your corner molding specifications for performance and cost efficiency. Email [email protected] with your CAD files and requirements. We respond within 4 business hours with a feasibility assessment and timeline. Let us prove why global Tier-1 manufacturers trust Lead Precision for corner solutions where failure is not an option.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.