Technical Contents

Engineering Guide: Best Metal 3D Printing Service

Engineering Insight: The Critical Role of Precision in Metal 3D Printing Services

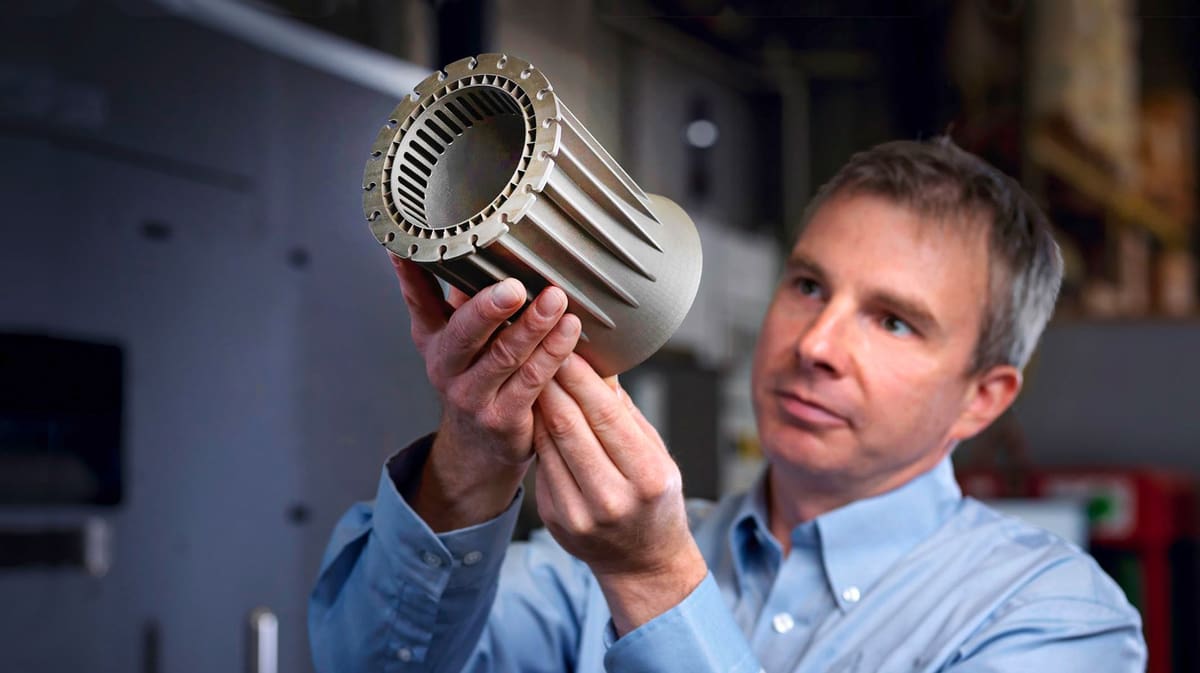

In the realm of advanced manufacturing, metal 3D printing has emerged as a transformative force, enabling the production of complex, high-performance components across aerospace, defense, medical, and high-end industrial sectors. However, the true value of a metal additive manufacturing service lies not merely in its ability to produce intricate geometries, but in its capacity to deliver uncompromising precision, repeatability, and material integrity. At Wuxi Lead Precision Machinery, we recognize that precision is not an optional attribute—it is the foundation upon which mission-critical applications are built.

Precision in metal 3D printing encompasses dimensional accuracy, surface finish control, microstructural consistency, and geometric fidelity. Even sub-millimeter deviations can lead to part failure in high-stress environments, particularly in applications such as turbine blades, structural aerospace components, or load-bearing medical implants. Achieving such precision demands more than state-of-the-art equipment; it requires deep metallurgical knowledge, rigorous process validation, and a culture of engineering excellence.

Wuxi Lead Precision Machinery has cultivated this expertise through years of serving some of the most demanding industries in the world. Our involvement in projects supporting Olympic-level sports technology and military-grade defense systems underscores our commitment to precision under extreme performance requirements. These applications demand not only adherence to tight tolerances but also full traceability, material certification, and post-processing optimization—areas where our engineering team excels.

Our metal 3D printing services leverage selective laser melting (SLM) and electron beam melting (EBM) technologies, integrated within a closed-loop quality control framework. Each build undergoes in-situ monitoring, pre- and post-build metrology, and non-destructive testing to ensure compliance with international standards such as ISO 13485 and AS9100. Material options are carefully vetted for performance, including titanium alloys, Inconel, stainless steels, and aluminum alloys, all processed in controlled, contamination-free environments.

The following table outlines key technical specifications that define our precision metal 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Layer Thickness | 20–60 μm |

| Build Volume (Max) | 250 × 250 × 325 mm |

| Dimensional Accuracy | ±0.05 mm (typical), ±0.1 mm (max) |

| Surface Roughness (as-built) | Ra 8–12 μm; down to Ra 1–2 μm with finishing |

| Minimum Feature Size | 0.3 mm (walls), 0.5 mm (pins) |

| Supported Materials | Ti6Al4V, Inconel 718, 316L, AlSi10Mg, CoCr, Tool Steel |

| Post-Processing Capabilities | HIP, stress-relief annealing, CNC finishing, polishing, coating |

Precision is not achieved by chance. It is engineered—through experience, validated processes, and a relentless focus on performance. At Wuxi Lead Precision Machinery, we bring proven expertise from Olympic and military-grade projects to every custom metal 3D printing assignment, ensuring that each component meets the highest standards of quality and reliability.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Additive Manufacturing & Finishing

Wuxi Lead Precision Machinery delivers advanced metal additive manufacturing services integrated with high-precision subtractive capabilities to meet the most demanding aerospace, medical, and industrial requirements. Our core strength lies in producing complex, high-integrity metal components directly from digital models using state-of-the-art laser powder bed fusion (LPBF) systems. We specialize in processing critical engineering alloys including Titanium Ti6Al4V, Inconel 718, Stainless Steel 316L, and Aluminum AlSi10Mg, ensuring material properties meet stringent ASTM and AMS standards. Each build undergoes rigorous in-process monitoring for melt pool stability and layer consistency, guaranteeing part density exceeding 99.95% and eliminating internal defects critical for safety-critical applications.

The true differentiator in our service is the seamless integration of 5-axis CNC machining capabilities within the same facility. Complex as-printed components often require critical feature accuracy, fine surface finishes, or precise datum establishment unattainable solely through additive processes. Our HAAS and DMG MORI 5-axis machining centers perform essential post-processing operations including precision milling, turning, drilling, and thread forming. This integrated workflow eliminates external handling risks, ensures perfect datum continuity between additive and subtractive stages, and achieves geometric tolerances impossible with standalone AM. It enables the production of fully functional assemblies with tight interface fits and critical sealing surfaces directly from the build plate.

Quality assurance is non-negotiable. Every component undergoes comprehensive metrology validation using Zeiss CONTURA and GLOBAL 3-axis Coordinate Measuring Machines (CMM). Our certified inspectors perform full first-article inspections (FAI) per AS9102 standards and batch-level verification, generating detailed inspection reports with GD&T analysis traceable to national standards. This systematic approach, combining advanced additive manufacturing, precision 5-axis CNC finishing, and rigorous CMM-based inspection, ensures dimensional conformity, functional reliability, and complete process traceability for your most challenging projects.

The following table details achievable tolerance ranges for critical features, reflecting the combined capability of our additive process and precision CNC finishing:

| Feature Type | Standard Capability (mm) | Precision Capability (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.100 | ±0.025 | Dependent on part size and orientation |

| Hole Diameter | ±0.075 | ±0.015 | Post-drilled/milled features only |

| Positional Tolerance | ±0.050 | ±0.010 | Relative to primary datums |

| Flatness | 0.100 | 0.025 | Over 100mm surface area |

| Surface Roughness (Ra) | 6.3 μm (as-printed) | 0.8 μm | CNC finished surfaces only |

These specifications represent typical achievable results under controlled production conditions for geometries amenable to our processes. Final tolerances are always determined during engineering review based on specific part geometry, material, and functional requirements. Our engineering team collaborates closely with clients during Design for Additive Manufacturing (DfAM) to optimize geometry for both printability and post-processing, ensuring the final component meets all functional and regulatory demands.

Material & Finish Options

Material Selection for High-Precision Metal 3D Printing

Selecting the appropriate material is critical when leveraging metal 3D printing for custom manufacturing applications. At Wuxi Lead Precision Machinery, we specialize in delivering high-end metal additive solutions tailored to aerospace, medical, and industrial sectors. Our expertise ensures optimal performance through precise material and finish selection.

Aluminum alloys are ideal for lightweight, high-strength applications where thermal conductivity and corrosion resistance are essential. Our primary aluminum offering, AlSi10Mg, is processed via selective laser melting (SLM) to deliver excellent mechanical properties and fine surface detail. This alloy is commonly used in heat exchangers, automotive components, and drone structures due to its favorable strength-to-density ratio and good fatigue resistance.

For applications demanding superior strength, durability, and wear resistance, steel-based materials are preferred. We offer 316L stainless steel and 15-5PH precipitation-hardening stainless steel. 316L provides exceptional corrosion resistance, making it suitable for marine and medical environments. 15-5PH, after heat treatment, achieves high tensile strength and is widely adopted in aerospace and tooling applications. Both steels are fully dense post-processing and exhibit excellent dimensional stability.

Titanium, particularly Grade 5 (Ti6Al4V), is the material of choice for high-performance environments requiring exceptional strength-to-weight ratios and biocompatibility. This alloy is extensively used in aerospace structural components, medical implants, and high-end motorsports. Its inherent resistance to oxidation and excellent performance at elevated temperatures make it a premium option in demanding operational conditions.

Post-processing surface finishes further enhance performance and aesthetics. Anodizing is a key finishing technique, especially for aluminum components. While traditional anodizing is applied to wrought aluminum, post-build machining followed by anodizing can be performed on 3D printed AlSi10Mg parts to improve surface hardness, wear resistance, and corrosion protection. Type II (standard) and Type III (hard coat) anodizing are available, with the latter providing thicker, more durable oxide layers for industrial use.

Below is a comparative summary of key materials offered at Wuxi Lead Precision Machinery:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Key Applications | Common Finishes |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 250–300 | 2.67 | Automotive, Drones, Heat Exchangers | Anodizing, Polishing |

| 316L Stainless Steel | 550–650 | 400–500 | 8.00 | Medical, Marine, Chemical Processing | Passivation, Electropolishing |

| 15-5PH Stainless Steel | 1000–1200 | 850–1000 | 7.80 | Aerospace, Tooling, Defense | H900 Heat Treatment, Coating |

| Ti6Al4V (Grade 5) | 900–1000 | 800–880 | 4.43 | Implants, Jet Engines, Motorsports | Anodizing (Medical Grade), Shot Peening |

Material and finish selection must align with functional requirements, environmental exposure, and lifecycle demands. At Wuxi Lead Precision Machinery, we support clients through every phase—from design consultation to final certification—ensuring optimal performance and compliance with international standards.

Manufacturing Process & QC

Integrated Metal Additive Manufacturing Process: Design to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, our metal additive manufacturing process is engineered for uncompromising quality and seamless scalability, transforming complex designs into flawless end-use components. We implement a rigorously controlled workflow spanning Design Optimization, Prototyping Validation, and Mass Production, all governed by our Zero Defects mandate. This integrated approach ensures every part meets the most stringent aerospace, medical, and industrial specifications before it reaches your assembly line.

The foundation is our collaborative Design for Additive Manufacturing (DfAM) phase. Our engineering team works directly with your CAD data, analyzing geometry for printability, structural integrity, and thermal management. We identify potential stress concentrations, overhangs requiring support, and opportunities for topology optimization to reduce weight without sacrificing strength. Critical to Zero Defects, we simulate the build process using advanced thermal and stress modeling software, predicting and mitigating distortion or porosity risks before the laser engages. Material selection is validated against your application’s mechanical, thermal, and regulatory requirements, ensuring compatibility from the outset.

Prototyping is not merely a model check; it is a critical validation step for the entire production system. We produce functional prototypes using the exact material, machine parameters, and post-processing sequence planned for final production. Each prototype undergoes comprehensive metrology, including CT scanning for internal integrity and full mechanical testing per ASTM/ISO standards. Any deviation triggers immediate root cause analysis and process refinement. This iterative loop ensures the digital design, machine settings, and post-processing are perfectly synchronized, eliminating surprises during volume production. Only when prototypes consistently achieve all dimensional and performance criteria do we approve the process for scale-up.

Mass production leverages the validated parameters within our controlled factory environment. Our industrial-grade metal AM systems operate under strict environmental monitoring and calibration protocols. Real-time melt pool monitoring and layer-wise imaging provide in-situ quality feedback, automatically flagging anomalies for immediate intervention. Every build is supported by full statistical process control (SPC), tracking critical parameters like oxygen levels, laser power stability, and powder characteristics. Post-processing, including precision heat treatment, HIP (Hot Isostatic Pressing) where specified, and CNC finishing, adheres to documented procedures with traceable documentation. Final inspection employs CMM, optical scanning, and destructive testing per agreed AQL levels, guaranteeing every shipped component meets the Zero Defects standard. This closed-loop system minimizes scrap, ensures batch-to-batch consistency, and delivers parts ready for mission-critical integration.

Wuxi Lead Precision Metal AM Capabilities

| Parameter | Specification Range | Key Materials Supported | Quality Standard |

|---|---|---|---|

| Build Volume | Up to 500 x 500 x 500 mm | Titanium (Ti6Al4V), Inconel 718/625 | ISO 9001, ISO 13485 |

| Layer Thickness | 20 – 60 µm | Stainless Steel (17-4PH, 316L) | ASTM F3301, F3055 |

| Typical Tolerance | ±0.05 mm to ±0.1 mm (post-machining) | Aluminum (AlSi10Mg), Cobalt Chrome | PPAP Level 3 Available |

| Surface Roughness | As-built: Ra 10-25 µm; Machined: Ra <1.6 µm | Tool Steel (Maraging M300) | 100% Dimensional Report |

| Max Build Height | 500 mm | Custom Alloys (upon qualification) | Full Material Traceability |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Metal 3D Printing Excellence

At Wuxi Lead Precision Machinery, we don’t just provide metal 3D printing services—we deliver precision-engineered manufacturing solutions tailored to the exact demands of high-performance industries. As a trusted leader in custom metal manufacturing, we invite forward-thinking companies to partner with us for projects that require uncompromising quality, technical expertise, and on-time delivery. Whether you’re developing aerospace components, medical devices, or complex industrial parts, our advanced additive manufacturing capabilities ensure your designs transition seamlessly from concept to certified production.

Our state-of-the-art metal 3D printing systems are built to handle the most demanding applications. We specialize in laser powder bed fusion (LPBF) and direct energy deposition (DED) technologies, enabling us to produce parts with intricate geometries, internal channels, and lightweight lattice structures that traditional machining cannot achieve. Every component is manufactured under strict quality control protocols, including in-process monitoring, post-build heat treatment, and full metrology validation using coordinate measuring machines (CMM) and CT scanning. With full ISO 9001 certification and NDT-compliant processes, we ensure every part meets or exceeds international standards.

What sets us apart is our engineering-first approach. Our team of CNC and additive manufacturing specialists collaborates directly with your design and R&D teams to optimize part geometry, select the ideal material, and refine support structures—all aimed at reducing weight, minimizing post-processing, and improving functional performance. From prototyping to full-scale production, we offer scalable solutions that maintain consistency across batches, ensuring your supply chain remains agile and reliable.

We work with a wide range of high-performance alloys, including titanium (Ti6Al4V), Inconel 718 and 625, stainless steels (316L, 17-4 PH), aluminum (AlSi10Mg), and tool steels (Maraging Steel MS1). Our facility supports secondary operations such as CNC machining, heat treatment, surface finishing, and non-destructive testing, providing a complete turnkey service under one roof.

Below is an overview of our core metal 3D printing capabilities:

| Specification | Detail |

|---|---|

| Build Envelope (Max) | 500 x 500 x 500 mm |

| Layer Thickness | 20 – 60 µm |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8–12 µm (can be polished to Ra <1 µm) |

| Supported Materials | Ti6Al4V, Inconel 718/625, 316L, 17-4 PH, AlSi10Mg, Maraging Steel MS1 |

| Post-Processing | Stress relief, HIP, CNC machining, polishing, anodizing, passivation |

| Quality Standards | ISO 9001, Full inspection reports, First Article Inspection (FAI) available |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to innovation, precision, and long-term collaboration. We understand the challenges of high-stakes industrial production—and we’re equipped to solve them.

Contact us today at [email protected] to discuss your next project. Let’s build the future of manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.