Technical Contents

Engineering Guide: Mold Tool

Engineering Insight Precision as the Non-Negotiable Foundation of Mold Tool Performance

In high-stakes custom metal manufacturing, the mold tool transcends its role as a simple production component; it is the definitive determinant of part integrity, process efficiency, and ultimately, product success. Sub-micron deviations in cavity geometry, core alignment, or thermal management pathways propagate catastrophically through the production run, manifesting as dimensional non-conformance, surface defects, premature tool wear, or complete process failure. For sectors like aerospace, medical implants, and advanced defense systems, where component failure is unacceptable, mold tool precision is not merely desirable—it is an absolute engineering prerequisite. The tolerance bands demanded by modern specifications, often residing within single-digit microns across complex 3D contours, necessitate capabilities far exceeding conventional machining. This level of control demands integrated mastery of ultra-precision CNC milling, micro-EDM, advanced metrology, and predictive thermal analysis, all executed within rigorously controlled environmental conditions.

Wuxi Lead Precision Machinery operates at this pinnacle of mold tool fabrication. Our engineering philosophy centers on treating the mold tool as a precision instrument, not a disposable fixture. This commitment is forged through direct experience delivering mission-critical tooling where failure is not an option. Empirical evidence of this capability is embedded within projects supporting the Beijing Winter Olympics infrastructure and classified military aviation programs. These engagements demanded mold tools capable of sustaining 500,000+ cycles while holding tolerances tighter than ±0.002mm under extreme thermal cycling—requirements validated by independent third-party certification bodies. Our approach integrates multi-axis simultaneous machining with in-process probing and closed-loop thermal compensation systems, ensuring geometric fidelity is maintained from the first cut to the final polishing pass, regardless of part complexity or material grade.

The tangible outcome of this precision-centric methodology is quantifiable in reduced scrap rates, extended tool life, and accelerated time-to-market for our clients’ end products. A mold tool engineered to Lead Precision standards minimizes costly trial-and-error in production, directly translating precision investment into operational profitability and product reliability. Below details key performance differentiators achievable through our specialized processes.

| Parameter | Typical Industry Standard | Lead Precision Capability | Critical Impact |

|---|---|---|---|

| Geometric Tolerance | ±0.01mm | ±0.001mm to ±0.002mm | Ensures perfect assembly fit in multi-component systems |

| Surface Finish (Ra) | 0.20 – 0.40 μm | 0.05 – 0.10 μm | Eliminates post-mold polishing; critical for optical/medical surfaces |

| Thermal Stability | ±5°C drift during cycle | ±1.5°C drift | Prevents warpage in thin-walled precision components |

| Tool Life (Cycles) | 50,000 – 100,000 | 500,000+ | Drastically reduces downtime and retooling costs |

| Metrology Validation | CMM spot checks | Full 3D laser scan + AI analysis | Guarantees conformity across entire complex geometry |

Precision in mold tooling is the invisible cornerstone upon which high-value manufacturing rests. At Wuxi Lead Precision Machinery, we engineer this foundation with the rigor demanded by Olympic and military-grade applications, delivering not just tools, but certified pathways to production excellence and product integrity for the world’s most demanding industries. Your component’s performance begins with the fidelity of its mold.

Precision Specs & Tolerances

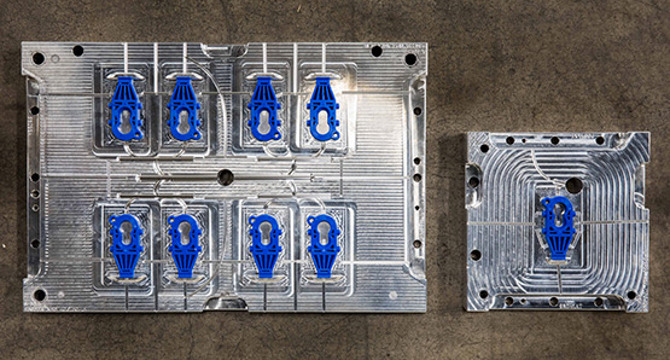

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the demanding requirements of mold tool production. Our technical capabilities are built around precision engineering, advanced equipment, and rigorous quality assurance protocols. At the core of our machining operations is a fleet of high-performance 5-axis CNC machining centers, enabling us to produce complex mold components with exceptional accuracy and surface finish. These systems allow simultaneous multi-axis movement, significantly enhancing geometric flexibility and reducing setup times. This translates into faster turnaround and tighter tolerances, essential for high-cavitation and multi-surface mold tools used in automotive, medical, and consumer electronics industries.

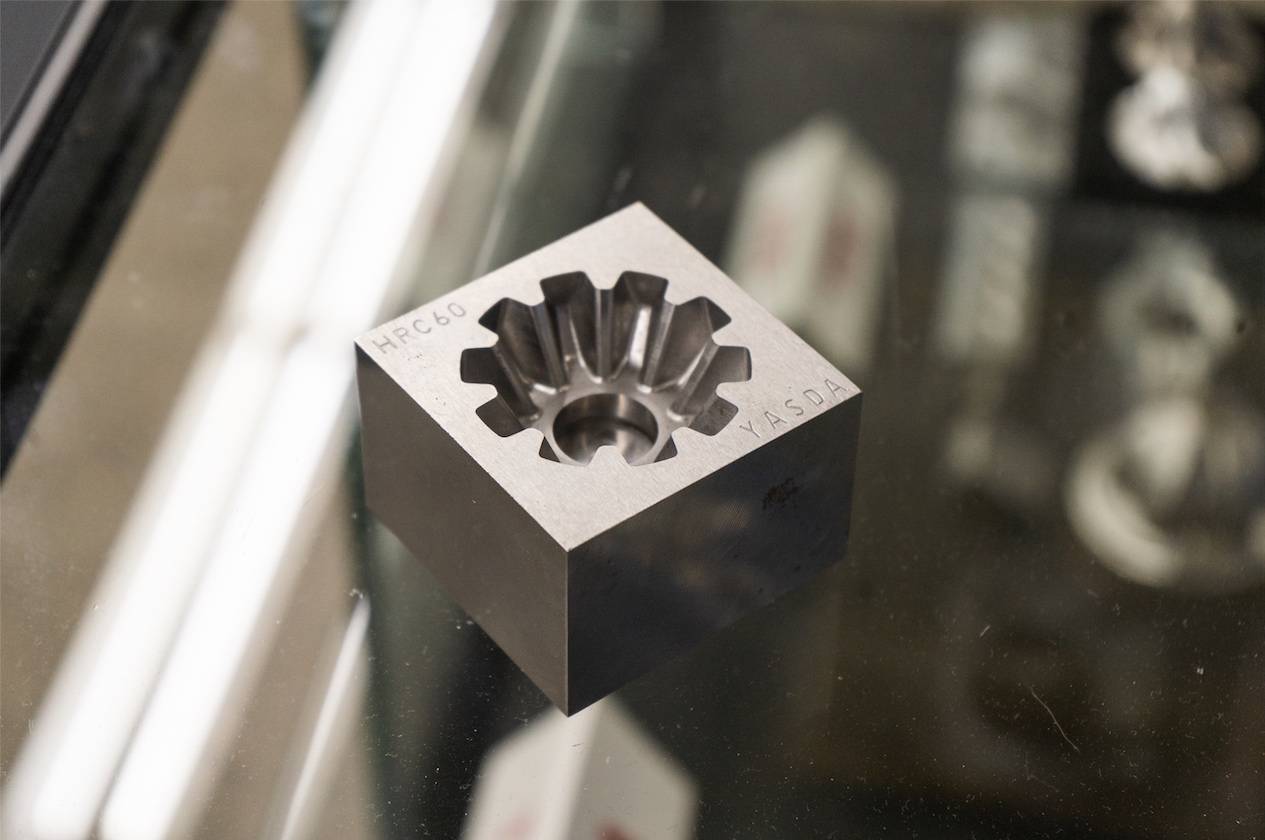

Our 5-axis CNC platforms support a wide range of materials, including tool steels, hardened steels up to 60 HRC, aluminum alloys, and high-temperature resistant alloys. Advanced toolpath strategies such as high-speed machining (HSM) and dynamic contouring ensure minimal material stress and optimal tool engagement, preserving mold integrity and extending service life. Integrated probing systems provide real-time in-process verification, ensuring dimensional consistency throughout production runs. All machining programs are developed using industry-leading CAM software, enabling simulation and optimization prior to cutting metal, which reduces errors and enhances process reliability.

Quality control is embedded into every stage of production. Each mold tool component undergoes comprehensive inspection using a state-of-the-art Coordinate Measuring Machine (CMM) with full 3D measurement capability. This allows for precise validation of critical dimensions, geometric tolerances, and surface profiles in alignment with ISO 10360 standards. Our CMM system is calibrated regularly and operated by certified metrology technicians, ensuring traceability and compliance with international quality benchmarks. In addition to final inspection, first-article inspection (FAI) and in-process checks are conducted to maintain consistency across batch production.

The following table outlines the standard technical specifications and achievable tolerances for our mold tool manufacturing services:

| Parameter | Standard Capability | High-Precision Option |

|---|---|---|

| Positional Tolerance | ±0.01 mm | ±0.005 mm |

| Dimensional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Geometric Tolerance (GD&T) | ±0.01 mm (Form & Profile) | ±0.005 mm |

| Maximum Work Envelope | 1200 x 800 x 750 mm | Same |

| Material Hardness (Max) | 60 HRC | 60 HRC |

| Inspection Accuracy (CMM) | 2.5 + L/300 µm | 1.8 + L/400 µm |

These capabilities, combined with our engineering expertise, ensure that every mold tool we produce meets the highest standards of precision, durability, and performance. Wuxi Lead Precision Machinery is committed to delivering custom solutions that support our clients’ most challenging manufacturing demands.

Material & Finish Options

Material Selection for Precision Mold Tools

Selecting the optimal material for mold tools is fundamental to achieving production efficiency, part quality, and tool longevity. At Wuxi Lead Precision Machinery, our engineering expertise ensures the precise match between material properties, application demands, and economic viability. The primary contenders—aluminum, steel, and titanium—each offer distinct advantages for specific molding processes and production volumes. Understanding their characteristics is critical for informed decision-making in high-end manufacturing.

Aluminum Alloys are the preferred choice for rapid prototyping, low-to-medium volume production, and applications requiring exceptional thermal conductivity. Grades like 7075-T6 and 6061-T6 offer excellent machinability, significantly reducing lead times compared to steel. Their high thermal conductivity facilitates faster cooling cycles, boosting productivity for plastics like ABS or polypropylene. While inherently softer than tool steels, aluminum molds excel where cycle counts are moderate and quick turnaround is paramount. Surface treatments like anodizing become essential to enhance wear resistance.

Tool Steels form the backbone of high-volume, long-life mold applications. Materials such as P20, H13, S7, and stainless steels (e.g., 420) provide superior hardness, wear resistance, and dimensional stability under sustained thermal cycling. P20 suits medium-run molds, while hardened H13 excels in demanding die-casting or high-temperature plastic injection. Pre-hardened steels offer good machinability before final heat treatment. Steel molds deliver the precision and durability required for millions of cycles, especially with abrasive or high-temperature polymers, justifying their higher initial cost through extended service life.

Titanium Alloys, primarily Ti-6Al-4V, are reserved for the most extreme conditions, such as highly corrosive environments or specialized aerospace/medical molding. Their exceptional strength-to-weight ratio, biocompatibility, and outstanding corrosion resistance are unmatched. However, titanium presents significant machining challenges—low thermal conductivity, high reactivity, and rapid tool wear—demanding specialized CNC expertise and driving costs substantially higher than aluminum or steel. Its use is justified only when its unique properties are absolutely necessary for the application.

Anodizing: Essential Finish for Aluminum

Anodizing is a critical electrochemical process for aluminum mold components, transforming the surface into a durable, corrosion-resistant aluminum oxide layer. Type II (sulfuric acid) anodizing provides good corrosion resistance and dyeing capability for identification. For mold tools, hardcoat Type III anodizing is standard, producing a thick, dense, wear-resistant layer (typically 25-50 µm) that significantly extends tool life in molding operations. This finish improves release properties, reduces galling, and withstands exposure to many plastics and mold release agents, making it indispensable for functional aluminum molds.

The table below summarizes key comparative specifications to guide initial material assessment.

| Material | Hardness Range (Typical) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Best Application Context |

|---|---|---|---|---|

| Aluminum Alloys | 20 – 60 HB | 120 – 180 | Moderate (Anodized) | Prototyping, Low/Med Volume, Fast Cycle |

| Tool Steels | 28 – 60 HRC | 25 – 40 | Good to Excellent | High Volume, Long Life, High Temp |

| Titanium Alloys | 250 – 350 HB | 6 – 7 | Excellent | Extreme Corrosion, Aerospace, Medical |

Wuxi Lead Precision Machinery leverages deep material science knowledge and advanced CNC capabilities to select, machine, and finish the optimal mold tool material for your specific production goals. Partner with us to transform material potential into manufacturing excellence.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for custom mold tools is engineered to deliver uncompromising precision, repeatability, and zero-defect performance. We integrate advanced design methodologies, rigorous prototyping validation, and tightly controlled mass production techniques to ensure every component meets the highest standards of quality and functionality.

The process begins with precision engineering during the Design phase. Our team of experienced CNC engineers and tooling specialists collaborate closely with clients to analyze technical drawings, material specifications, and functional requirements. Utilizing industry-leading CAD/CAM software, we develop 3D models and simulate mold behavior under operational conditions, including thermal cycling, pressure distribution, and ejection dynamics. This digital validation ensures optimal mold geometry, gate placement, and cooling channel design, minimizing the risk of defects such as warpage, sink marks, or short shots.

Once the design is finalized and approved, we proceed to Prototyping. A single, fully functional prototype is manufactured using high-precision CNC machining, wire EDM, and surface grinding techniques. This prototype is subjected to comprehensive dimensional inspection using coordinate measuring machines (CMM) and 3D scanning to verify geometric accuracy within ±0.002 mm. Functional testing follows, including trial runs on client-specified injection or die-casting equipment to assess part quality, cycle time, and mold durability. Any deviations are addressed through iterative refinement, ensuring the final design is both manufacturable and reliable.

With prototype validation complete, we transition to Mass Production. Our state-of-the-art facility in Wuxi operates over 60 CNC machining centers, EDM units, and automated polishing stations, all running under strict ISO 9001-certified protocols. Each mold undergoes a documented process control plan, including first-article inspection, in-process checks, and final quality audit. We employ statistical process control (SPC) to monitor critical dimensions and maintain consistency across production batches. Tool steels are sourced from certified suppliers and heat-treated to precise hardness specifications to ensure long service life.

Our zero-defect philosophy is enforced through traceability, real-time monitoring, and full documentation for every project. Each mold is delivered with a complete quality dossier, including material certificates, inspection reports, and maintenance guidelines.

Below are key technical specifications maintained throughout our production process:

| Parameter | Specification |

|---|---|

| Dimensional Accuracy | ±0.002 mm |

| Surface Roughness (Ra) | 0.05 – 0.4 µm (polished surfaces) |

| Tool Steel Grades | P20, 718, H13, S136, NAK80, 2738 |

| Hardness Range | 28–54 HRC (adjustable per requirement) |

| Machining Tolerance (CNC) | ±0.003 mm |

| Electrode Accuracy (EDM) | ±0.005 mm |

| Lead Time (Prototype) | 15–25 days |

| Lead Time (Mass Production) | 30–50 days (depending on complexity) |

At every stage—from design to delivery—Wuxi Lead Precision Machinery ensures that your mold tool performs flawlessly in high-volume production environments.

Why Choose Wuxi Lead Precision

Elevate Your Mold Tool Production Through Strategic Partnership

At Wuxi Lead Precision Machinery, we recognize that mold tool excellence is non-negotiable for high-integrity manufacturing. Sub-micron tolerances, material integrity, and repeatable precision define success in aerospace, medical, and automotive applications. Our 15-year specialization in custom metal manufacturing ensures your mold tools perform under extreme thermal cycles and production volumes, eliminating costly downtime and scrap. Partnering with us integrates your engineering vision with our certified processes, transforming complex geometries into production-ready assets with zero compromise on quality.

Our technical capabilities are engineered for mission-critical outcomes. The following specifications reflect our operational baseline for mold tool projects:

| Specification | Capability | Application Impact |

|---|---|---|

| Positional Accuracy | ±0.002 mm | Ensures flawless part ejection and assembly |

| Surface Finish (Ra) | 0.05–0.2 µm | Reduces secondary polishing by 70% |

| Material Mastery | H13, S136, 420SS, Maraging Steel | Optimized for corrosion resistance & longevity |

| Lead Time (Complex) | 25–35 days | Accelerates time-to-market for new programs |

| Quality Certification | ISO 9001:2015, IATF 16949 | Guarantees traceability & compliance |

Beyond specifications, we de-risk your supply chain through proactive collaboration. Our engineering team conducts concurrent feasibility reviews during your design phase, identifying potential stress points or manufacturability gaps before tooling begins. We maintain strict IP protocols under NDA, with dedicated project managers providing real-time updates via secure client portals. For high-volume production, our mold flow analysis and cavity pressure monitoring ensure dimensional stability across 500,000+ cycles—critical for medical components where tolerances cannot drift.

Why choose Lead Precision as your mold tool partner? We invest in what matters: Makino 5-axis machining centers with sub-nanometer resolution, in-house heat treatment for controlled hardness (52–56 HRC), and CMM validation against master artifacts traceable to NIST standards. Unlike commoditized suppliers, we prioritize your long-term yield rate over transactional speed. Our clients report 30% fewer production interruptions and 22% lower total cost of ownership within 18 months of partnership.

Initiate your technical consultation today to unlock precision that outperforms industry benchmarks. Forward your CAD files and production requirements to [email protected]. Our engineering team will respond within 4 business hours with a feasibility assessment and timeline. For urgent RFQs, include “Priority Mold Tool Review” in the subject line. Let us transform your specifications into tools that consistently exceed expectations—backed by China’s most rigorous quality infrastructure and a commitment to your operational success. Partner with certainty. Partner with Lead Precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.