Technical Contents

Engineering Guide: T Plastic Molding

Engineering Insight: The Critical Role of Precision in t Plastic Molding

In the realm of high-performance manufacturing, t plastic molding represents a specialized process where thermal stability, structural integrity, and dimensional accuracy converge to define product success. While often associated with advanced polymer applications, the tooling and supporting components used in t plastic molding are predominantly manufactured from precision-machined metals—particularly hardened steels, aluminum alloys, and specialty stainless grades. At Wuxi Lead Precision Machinery, we recognize that the reliability of the molding process is directly tied to the precision of the metal components that form its backbone.

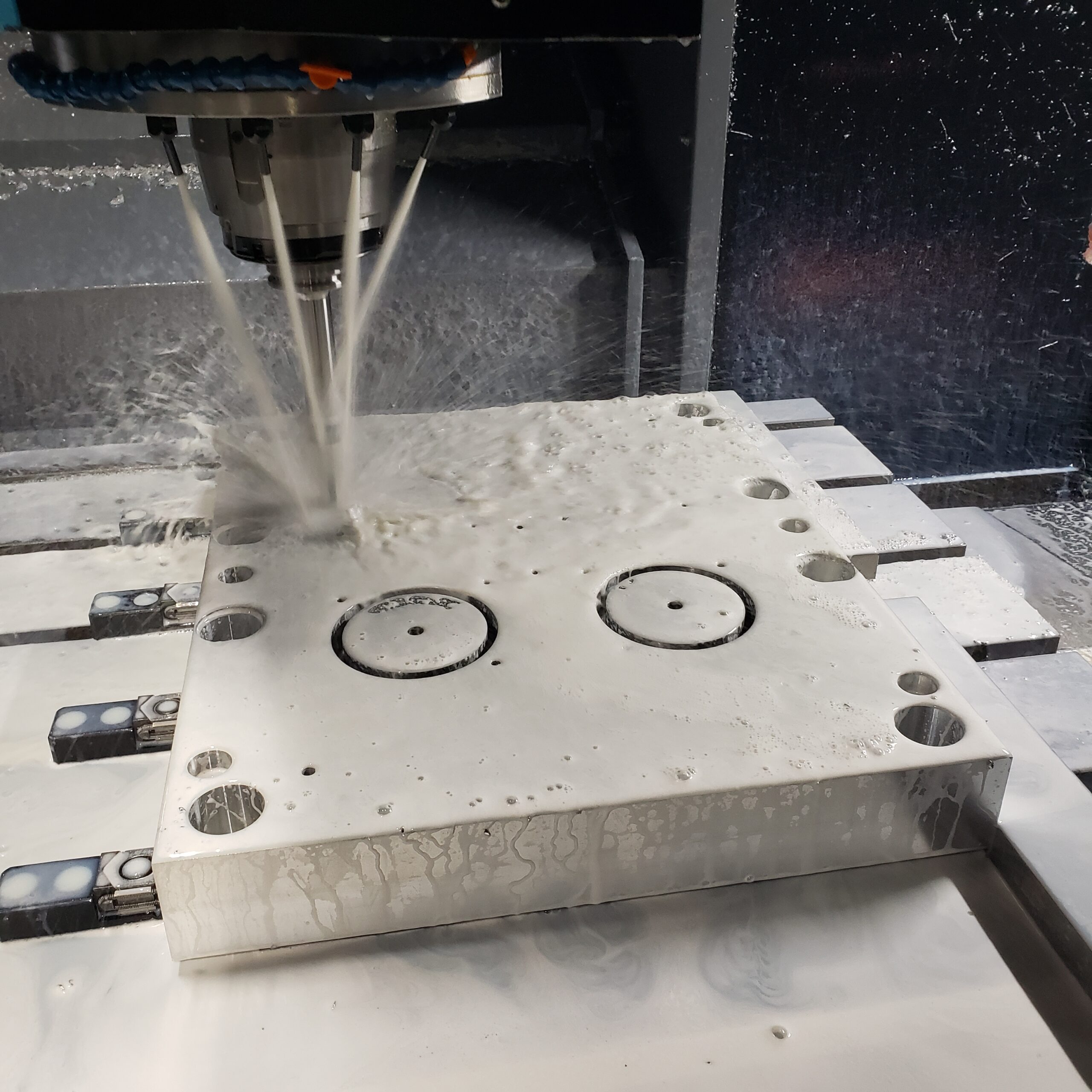

t Plastic molding environments are inherently demanding, subjecting tooling to extreme thermal cycling, mechanical stress, and chemical exposure. Even micron-level deviations in mold cavity geometry or support structure alignment can result in part warpage, flash, or premature tool failure. This is where our engineering philosophy centers on micron-level tolerances, advanced metrology, and material science integration. Our CNC machining centers, operating under strict ISO 9001 and IATF 16949 standards, ensure that every component meets exacting specifications—before it ever reaches the molding floor.

With over 15 years of experience in custom metal manufacturing for high-criticality sectors, Wuxi Lead Precision Machinery has delivered mission-critical components for applications in Olympic-standard sports equipment and defense-grade systems. These projects demanded not only flawless repeatability but also full traceability of materials, processes, and inspection data. The same rigor is applied to every t plastic molding project we support. Whether producing mold inserts, ejector systems, or cooling channel manifolds, our team leverages 5-axis milling, wire EDM, and surface grinding technologies to achieve tolerances down to ±0.002 mm.

Our collaboration with global partners in automotive, aerospace, and medical device manufacturing has reinforced a fundamental truth: precision in metal components directly translates to efficiency, yield, and longevity in t plastic molding operations. By minimizing thermal distortion and mechanical play, our components reduce downtime and maintenance cycles, ultimately lowering total cost of ownership.

Below are key specifications that define our t plastic molding support components:

| Specification | Detail |

|---|---|

| Material Options | P20, H13, S136, 718H Steel, Aluminum 7075, Stainless 316L |

| Tolerance Range | ±0.002 mm to ±0.01 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.8 µm (polished & textured options) |

| Machining Capabilities | 5-axis CNC milling, Wire EDM, CNC turning, Surface grinding |

| Quality Standards | ISO 9001, IATF 16949, Full CMM inspection reporting |

| Lead Time | 15–30 days (based on complexity and batch size) |

At Wuxi Lead Precision Machinery, we do not merely supply parts—we engineer solutions that uphold the integrity of advanced manufacturing processes. In t plastic molding, where performance margins are razor-thin, precision is not optional. It is the foundation.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Plastic Molding Applications

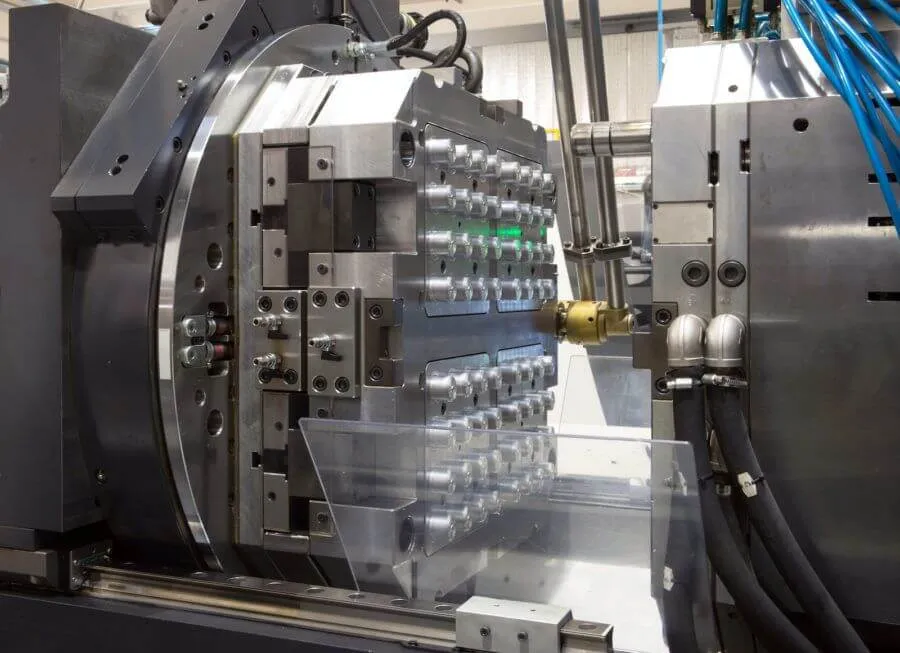

Wuxi Lead Precision Machinery delivers mission-critical metal components engineered specifically for high-performance plastic injection molding systems. While our core expertise lies in custom metal manufacturing—not plastic processing—we specialize in producing the hardened steel and aluminum tooling, inserts, cores, and precision-engineered mold bases that define molding success. Our capabilities directly address the thermal stability, wear resistance, and micron-level accuracy demands inherent in advanced plastic molding operations, ensuring consistent part quality and extended tool life.

Central to our service is a modern fleet of 5-axis CNC machining centers, including DMG MORI and MAZAK platforms. These systems enable complex geometry fabrication in a single setup, eliminating cumulative errors from multiple fixtures. We routinely machine intricate cooling channels, venting systems, and conformal surfaces within mold plates up to 1,200 x 800 x 600 mm, using materials such as H13, S136, 2738HH, and beryllium-copper alloys. Integrated high-speed spindles (up to 24,000 RPM) and rigid tapping ensure superior surface integrity on critical sealing surfaces and cavity finishes, directly impacting plastic flow dynamics and part ejection reliability.

Every component undergoes rigorous quality control aligned with ISO 9001 and IATF 16949 standards. Our Zeiss CONTURA CMMs perform full 3D geometric inspections against CAD models, verifying critical dimensions, flatness, and positional tolerances. Statistical process control (SPC) data is provided with each shipment, documenting capability indices (Cp/Cpk) for high-risk features. This closed-loop inspection methodology prevents non-conformances from reaching the molding press, reducing client scrap rates and downtime.

The table below summarizes our standard machining and inspection tolerances for mold-critical features:

| Feature | Capability | Standard Applied | Typical Application |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ISO 2768-mK | Core pin diameters, ejector holes |

| Geometric Tolerances | ±0.003 mm (GD&T) | ASME Y14.5-2018 | Cavity alignment, parting lines |

| Surface Roughness | Ra 0.2 µm | ISO 1302 | Optical lens cavities, seal zones |

| Flatness | 0.002 mm/m | ISO 1101 | Mold base mounting surfaces |

| Hole Position | ±0.002 mm | ISO 2768-fH | Leader pin bushings, cooling lines |

Our engineering team collaborates early in the mold design phase to optimize manufacturability, suggesting modifications that enhance thermal management or simplify maintenance without compromising plastic part specifications. By controlling the entire metal fabrication workflow—from material certification to final CMM validation—we guarantee that every component meets the exacting demands of high-cavitation, multi-shot, or micro-molding applications. This precision foundation translates directly to your production floor: reduced cycle times, elimination of flash, and extended mold service life. Partner with Wuxi Lead to convert challenging plastic molding requirements into reliable, high-yield metal tooling solutions.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, especially when producing high-precision components for industries such as aerospace, medical devices, and advanced automation. At Wuxi Lead Precision Machinery, we specialize in CNC machining of aluminum, steel, and titanium—each offering unique mechanical properties and performance characteristics. The optimal material choice depends on application requirements including strength, weight, corrosion resistance, thermal stability, and cost efficiency.

Aluminum is widely favored for its excellent strength-to-weight ratio and machinability. It is particularly suitable for applications where weight reduction is essential without sacrificing structural integrity. Grade 6061-T6 is commonly used for prototyping and production parts due to its good weldability and moderate strength. For more demanding environments, 7075-T6 offers superior strength, making it ideal for aerospace components.

Steel remains the go-to material for high-strength, wear-resistant applications. Among the various grades, 4140 and 1045 are frequently selected for their toughness and response to heat treatment. Stainless steel grades such as 304 and 316 provide excellent corrosion resistance, making them suitable for medical and food-processing equipment. Steel’s durability and dimensional stability under load make it a preferred choice for tooling, fixtures, and structural components.

Titanium, particularly Grade 5 (Ti-6Al-4V), is used in extreme environments where high strength, low density, and exceptional corrosion resistance are required. Its biocompatibility makes it ideal for surgical implants, while its performance at elevated temperatures benefits aerospace and defense applications. Although more challenging to machine than aluminum or steel, titanium’s long-term reliability justifies its use in mission-critical systems.

Surface finishing plays a vital role in enhancing both functionality and aesthetics. Anodizing is a widely used electrochemical process, primarily applied to aluminum. It increases surface hardness, improves wear resistance, and provides excellent adhesion for paint and primers. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) delivers thicker, more durable layers suitable for industrial applications. Anodized surfaces can also be dyed in various colors for identification or branding purposes.

Below is a comparative overview of key material properties and anodizing specifications.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications |

|---|---|---|---|---|

| Aluminum | 310–570 | 2.7 | 6061-T6, 7075-T6 | Aerospace, automotive, enclosures |

| Steel | 500–900 | 7.8 | 1045, 4140, 304 | Tooling, machinery, medical |

| Titanium | 900–1100 | 4.5 | Ti-6Al-4V (Grade 5) | Aerospace, implants, marine |

| Finish Type | Material Compatibility | Thickness Range (µm) | Key Benefits |

|---|---|---|---|

| Type II Anodizing | Aluminum | 5–25 | Corrosion resistance, dye capability |

| Type III Anodizing | Aluminum | 25–100 | Extreme wear resistance, durability |

Selecting the right material and finish ensures optimal performance, longevity, and cost-effectiveness. Wuxi Lead Precision Machinery provides expert consultation to guide your material decisions based on functional requirements and production goals.

Manufacturing Process & QC

Precision Metal Molding: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our metal molding process transcends standard manufacturing through rigorous engineering discipline. We specialize in high-integrity metal components for aerospace, medical, and industrial automation sectors where failure is non-negotiable. Our integrated workflow—Design, Prototyping, Mass Production—ensures absolute compliance with ISO 13485 and AS9100 standards, eliminating defects before they reach your assembly line.

Design: Engineering Flaw Prevention at the Source

Our engineers collaborate with clients during the conceptual phase to optimize part geometry for manufacturability. Using Siemens NX and Moldflow simulation, we analyze stress points, material flow, and thermal dynamics specific to aluminum, stainless steel, and titanium alloys. Critical factors like draft angles, wall thickness transitions, and gate placement are validated digitally to prevent warpage, sink marks, or voids. This phase includes Design for Six Sigma (DFSS) reviews, ensuring tolerances align with your functional requirements while minimizing post-molding machining.

Prototyping: Validating Reality Against Simulation

Rapid prototyping occurs within our climate-controlled metrology lab using hardened H13 steel molds. Each prototype undergoes full-spectrum inspection:

CMM verification against 3D CAD models (±0.005mm accuracy)

Material composition certification via OES spectroscopy

In-process pressure and temperature mapping during molding cycles

We deliver functional prototypes within 15 days, complete with First Article Inspection (FAI) reports. Only when dimensional stability, surface finish, and mechanical properties meet your zero-defect threshold do we proceed to mass production.

Mass Production: Closed-Loop Precision at Scale

Our automated production cells integrate real-time SPC (Statistical Process Control) monitoring. Every molding cycle is tracked via IoT sensors measuring clamp force, injection speed, and cooling rates. Deviations beyond ±0.5% trigger immediate machine lockout. Components undergo 100% automated vision inspection for surface defects, followed by batch sampling for destructive testing (tensile strength, hardness). This closed-loop system—coupled with our traceability database logging every material lot and machine parameter—ensures batch-to-batch consistency.

Process Specifications for Critical Applications

| Parameter | Capability Range | Industry Standard | Wuxi Lead Precision Standard |

|---|---|---|---|

| Tolerance | ±0.05mm | ±0.1mm | ±0.005mm |

| Material Options | Aluminum 6061, 7075 | Basic alloys | Ti-6Al-4V, Inconel 718 |

| Max Part Weight | 5kg | 2kg | 15kg |

| Production Volume | 1,000–100,000 units | 5,000+ | 100–500,000+ units |

| Defect Rate (PPM) | 1,000 PPM | 500 PPM | < 10 PPM |

Wuxi Lead’s process guarantees defect elimination through physics-based design validation, empirical prototyping, and machine-intelligence-driven production. We deliver not just parts, but documented reliability—ensuring your end product performs flawlessly in mission-critical environments. Partner with us to transform precision requirements into certified manufacturing outcomes.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

When precision, reliability, and performance define your product requirements, partnering with a trusted leader in custom metal manufacturing becomes a strategic imperative. At Wuxi Lead Precision Machinery, we specialize in delivering high-end solutions tailored to the rigorous demands of advanced plastic molding applications. Our engineering expertise, advanced CNC capabilities, and unwavering commitment to quality make us the preferred partner for global manufacturers seeking durable, high-tolerance components.

Our facility in Wuxi, China, is equipped with state-of-the-art multi-axis CNC machining centers, automated inspection systems, and material testing laboratories. We serve industries where failure is not an option—medical device manufacturing, automotive injection molding, aerospace tooling, and high-speed packaging systems. Each component we produce is engineered to withstand extreme pressures, maintain dimensional stability, and ensure long-term operational integrity in plastic molding environments.

From mold bases and cavity inserts to ejector systems and precision guide pins, our custom metal components are manufactured to exacting specifications. We work with high-grade tool steels, pre-hardened alloys, stainless materials, and specialty composites, ensuring optimal performance under thermal cycling and abrasive molding conditions. Our in-house heat treatment and surface finishing processes further enhance wear resistance and part longevity.

What sets Wuxi Lead Precision Machinery apart is our engineering-first approach. We collaborate closely with design teams to optimize manufacturability, reduce lead times, and improve mold service life. Our technical team provides full DFM (Design for Manufacturability) analysis, 3D modeling support, and prototyping services to de-risk production and accelerate time-to-market.

We understand that in plastic molding, even micron-level deviations can result in costly downtime or part defects. That’s why every component undergoes rigorous quality control using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Our ISO 9001-certified processes guarantee consistency across batches, whether you require a single prototype or high-volume production runs.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Materials Processed | P20, H13, S136, 420SS, 17-4PH, Aluminum 7075, and custom alloys |

| Surface Finish | As low as Ra 0.05 µm (polished), Ra 0.8 µm (machined) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI) reports |

| Lead Time (Typical) | 15–25 days for complex mold components, depending on volume |

Partnering with Wuxi Lead Precision Machinery means gaining a true engineering ally—one that combines precision manufacturing with responsive service and technical depth. We are committed to supporting your success through innovation, transparency, and consistent delivery.

For expert support on your next custom metal manufacturing project, contact us today at [email protected]. Let us help you achieve superior performance in every mold.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.