Technical Contents

Engineering Guide: Plastic Injection Mold Agent

Engineering Insight: Precision in Plastic Injection Mold Manufacturing

In plastic injection molding, the mold is not merely a tool—it is the foundational determinant of part quality, production efficiency, and total cost of ownership. Sub-micron deviations in mold geometry directly propagate into finished components, causing flash, warpage, sink marks, or assembly failures. For high-volume automotive, medical, or aerospace applications, where tolerances often fall below ±0.025mm, mold precision transcends technical specification; it becomes a non-negotiable pillar of operational success. At Wuxi Lead Precision Machinery, we engineer molds where thermal stability, material integrity, and geometric accuracy converge to eliminate costly trial-and-error cycles.

The consequences of inadequate mold precision extend beyond defective parts. Poorly machined cavities or cores accelerate wear, disrupt cooling uniformity, and force production slowdowns to compensate for dimensional drift. This erodes throughput and inflates per-part costs—particularly devastating in industries where seconds per cycle dictate competitiveness. Our approach begins with finite element analysis (FEA) to predict thermal deformation under 10,000+ ton clamping forces, followed by strategic material selection (e.g., H13 tool steel with vacuum-hardened microstructures) and 5-axis CNC machining calibrated to ISO 2768-f7 standards. Every electrode, insert, and ejector pin undergoes interferometric verification, ensuring alignment within 0.002mm across multi-cavity layouts.

This rigor stems from validating processes under extreme demands. We engineered molds for Olympic-grade sporting equipment requiring zero-defect surface finishes at 120 cycles/hour and produced military-certified housings where salt-spray resistance and dimensional stability were tested under -55°C to 150°C thermal cycling. Such projects demand more than technical capability—they require a philosophy where tolerances are treated as promises.

Below are critical precision parameters where Wuxi Lead exceeds industry baselines:

| Parameter | Industry Standard | Wuxi Lead Capability | Impact on Production |

|---|---|---|---|

| Cavity Flatness | ≤ 0.010 mm | ≤ 0.002 mm | Eliminates flash, ensures seal integrity |

| Core Parallelism | ≤ 0.015 mm | ≤ 0.003 mm | Prevents part sticking, reduces ejection force |

| Cooling Channel Position | ±0.05 mm | ±0.01 mm | Optimizes cycle time, minimizes warpage |

| Surface Roughness (Cavity) | Ra 0.4 µm | Ra 0.05 µm | Achieves Class A finishes without polishing |

| Thermal Deformation | ≤ 0.030 mm | ≤ 0.008 mm | Maintains tolerances through 500k+ cycles |

Precision molds are capital investments that pay dividends in yield rates, tool life, and brand reputation. Wuxi Lead’s integration of aerospace-grade metrology (Zeiss CONTURA CMMs), in-process thermal monitoring, and military-proven validation protocols ensures your mold performs identically on day one and day 50,000. When tolerances define market leadership—as they do in medical implants or electric vehicle components—partner with an engineer who treats precision as non-negotiable. Contact us to transform your injection molding challenges into competitive advantages.

Precision Specs & Tolerances

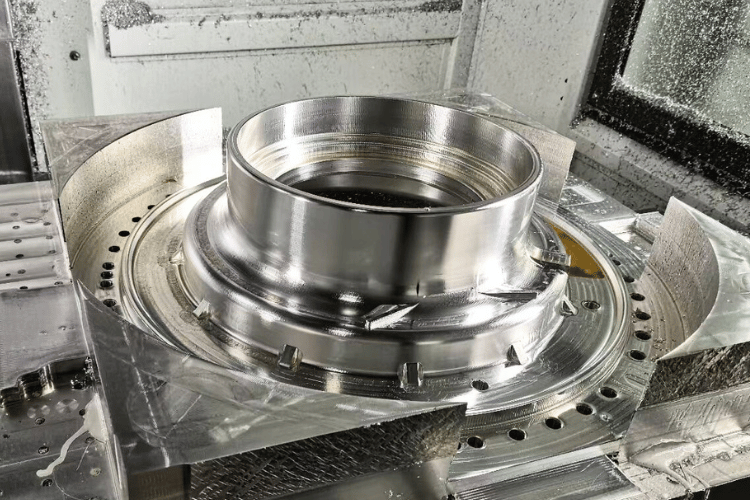

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the stringent demands of high-performance industries such as automotive, medical, and industrial automation. At the core of our precision manufacturing process is our 5-axis CNC machining technology, which enables complex geometries, tight tolerances, and superior surface finishes on a wide range of metal substrates. Our 5-axis systems provide simultaneous multi-directional cutting, allowing for intricate mold features and undercuts that are unachievable with conventional 3-axis platforms. This level of precision ensures optimal mold performance, extended tool life, and consistent part replication for plastic injection molding applications.

Our machining centers operate with high-speed spindles, real-time tool monitoring, and automated tool changers to maintain efficiency without compromising accuracy. Materials such as P20, 718H, S136, NAK80, and hardened steels are routinely processed with optimized cutting strategies tailored to each alloy’s characteristics. This ensures dimensional stability and minimizes residual stress in the final mold structure. In addition to steel and aluminum, we support specialized alloys including titanium and copper-based materials for high-thermal-conductivity mold inserts.

Quality assurance is integral to our manufacturing workflow. Every component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing micron-level verification of critical dimensions, form, and positional tolerances. Our CMM routines are fully programmed and repeatable, supporting First Article Inspection (FAI) reports and Production Part Approval Process (PPAP) documentation as required. In addition to CMM, we employ optical comparators, surface roughness testers, and hardness measurement systems to validate material and finish specifications.

The following table outlines the standard precision tolerances we consistently achieve across our 5-axis CNC and inspection platforms:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Circular Runout | 0.01 mm | 0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm (polished) |

| Angular Tolerance | ±0.05° | ±0.02° |

| Hole Diameter (drilled/reamed) | ±0.01 mm | ±0.005 mm |

All manufacturing and inspection data are documented and traceable, aligning with ISO 9001 standards. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to ensure mold designs are optimized for precision, durability, and cycle efficiency. With integrated 5-axis CNC machining and rigorous CMM-based quality control, Wuxi Lead Precision Machinery ensures every custom metal component meets the highest standards for use in plastic injection mold systems.

Material & Finish Options

Material Selection for Injection Mold Construction

Selecting optimal materials for plastic injection molds demands rigorous material science understanding, not merely cost considerations. At Wuxi Lead Precision Machinery, we prioritize longevity, thermal management, and dimensional stability to ensure your production achieves maximum ROI. Common confusion arises between mold construction materials and mold release agents; this guide addresses the former—the metals forming the mold cavity and core.

Aluminum 7075-T6 excels in rapid prototyping and low-volume production due to its exceptional machinability and thermal conductivity. However, its lower hardness (150 HB) limits use to under 10,000 cycles for abrasive resins. Steel variants dominate medium-to-high volume applications. P20 pre-hardened steel (28–32 HRC) offers balanced toughness and polishability for 50,000–100,000 cycles. For demanding thermoplastics like glass-filled nylon, H13 tool steel (48–52 HRC) provides superior wear resistance and thermal fatigue strength, sustaining 500,000+ cycles. Titanium’s extreme strength-to-weight ratio is theoretically appealing but rarely practical for molds due to exorbitant costs, welding complexities, and marginal thermal benefits over specialty steels.

Surface finishes further define performance. Anodizing—specifically Type II (sulfuric acid) or Type III (hardcoat)—enhances aluminum molds by creating a corrosion-resistant, non-stick oxide layer. Critical parameters include:

| Material | Anodizing Type | Thickness Range (μm) | Hardness (HV) | Primary Application Benefit |

|---|---|---|---|---|

| Aluminum | Type II | 5–15 | 200–300 | Basic corrosion resistance, ease of release |

| Aluminum | Type III | 15–25 | 300–600 | High abrasion resistance, extended tool life |

| Steel | Not applicable | N/A | N/A | Requires alternative coatings (e.g., PVD) |

Critical note: Anodizing is exclusively viable for aluminum molds. Steel requires nitriding, chrome plating, or PVD coatings for comparable wear protection. Anodized layers add negligible dimensional change (<0.005mm per side) but significantly reduce resin adhesion—critical for complex geometries or sticky polymers like PVC. Always specify anodizing after final CNC machining and polishing to maintain tolerances.

Material choice must align with resin abrasiveness, part complexity, and annual production volume. A medical device manufacturer running 200,000 cycles/year of PEEK resin requires H13 steel with nitriding, not aluminum. Conversely, a consumer electronics firm prototyping polycarbonate housings gains speed and cost efficiency with anodized 7075-T6. Wuxi Lead’s engineering team conducts resin-mold interaction analysis to eliminate guesswork, ensuring your material selection prevents premature wear, sink marks, or ejection failures. Consult our technical specialists to match your application’s thermal, mechanical, and economic requirements with precision-engineered solutions.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the foundation of every successful plastic injection mold begins with meticulous design engineering. Our team of senior mold designers utilizes advanced CAD/CAM software—such as UG (NX), SolidWorks, and AutoCAD—to develop fully optimized mold structures tailored to the client’s exact specifications. Every design is subjected to rigorous internal review, focusing on part geometry, material flow, cooling efficiency, and ejection mechanisms. We conduct comprehensive mold flow analysis using Moldflow to simulate filling, packing, cooling, and warpage behavior, ensuring optimal performance before any metal is cut. This proactive approach eliminates potential defects at the conceptual stage, reducing rework and accelerating time-to-market.

Prototyping: Validating Performance with Zero Tolerance for Error

Following design approval, we transition into the prototyping phase—a critical checkpoint in our zero-defect manufacturing philosophy. Using high-precision CNC machining centers, wire EDM, and high-speed milling, we fabricate prototype molds from pre-hardened or hardened tool steels, depending on application requirements. These molds undergo strict dimensional verification via CMM (Coordinate Measuring Machine) and 3D scanning to ensure tolerances are held within ±0.002 mm. The prototype parts are then injection molded using production-intent parameters on our in-house 50–1,300-ton machines. Each sample is evaluated for dimensional accuracy, surface finish, gate quality, and structural integrity. Any deviations trigger immediate design or process adjustments, ensuring the final mold will perform flawlessly in mass production.

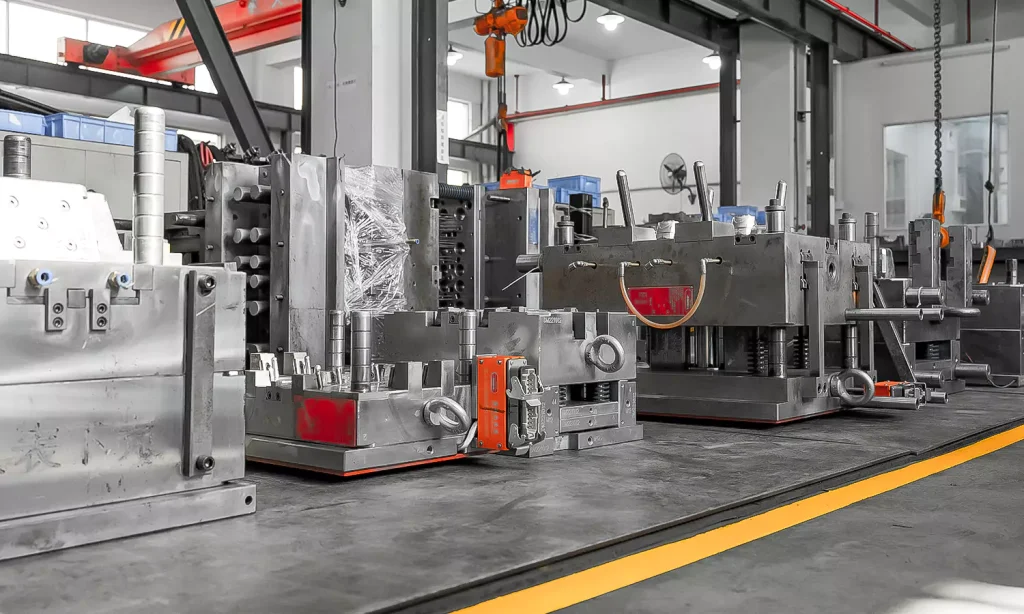

Mass Production: Consistency, Control, and Continuous Monitoring

Once the prototype is validated and approved, we scale to full-scale production with an unwavering commitment to zero defects. Our automated production lines integrate robotic part removal, real-time process monitoring, and in-mold sensors to track pressure, temperature, and cycle time. Each mold is maintained under a preventive maintenance schedule, and production batches are subject to statistical process control (SPC) to detect trends before deviations occur. All finished parts undergo 100% visual inspection and random sampling per AQL 1.0 standards. Traceability is ensured through serialized lot tracking, from raw material certification to final packaging.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (mirror to textured) |

| Mold Material Options | P20, 718H, S136, H13, 420 Stainless, Aluminum |

| Mold Life | 500,000+ cycles (hardened steel) |

| Machine Tonnage Range | 50–1,300 tons |

| Lead Time (Prototype) | 2–4 weeks (based on complexity) |

| Quality Standards | ISO 9001:2015, IATF 16949, PPAP Level 3 |

At Wuxi Lead Precision Machinery, our integrated process—from precision design to defect-free mass production—ensures every plastic injection mold meets the highest global standards for performance, durability, and consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Mold Performance

In the high-stakes realm of plastic injection molding, mold failure is not an option. Substandard tooling erodes profitability through downtime, scrap rates, and compromised part integrity. Wuxi Lead Precision Machinery delivers the engineering rigor and manufacturing excellence mold agents require to eliminate these risks. For over 15 years, we have engineered custom metal solutions for Tier-1 automotive, medical, and consumer electronics suppliers where tolerances below ±0.002mm are non-negotiable. Our ISO 9001 and AS9100-certified facility integrates advanced CNC milling, grinding, and EDM processes under one roof, ensuring seamless execution from CAD file to production-ready mold base, cavity, or core. We understand that your reputation hinges on mold longevity and repeatability—our commitment is to become your silent partner in reliability.

Precision begins with capability. Our dedicated mold manufacturing division operates cutting-edge machinery calibrated for the most demanding specifications. The table below outlines core competencies directly impacting mold performance and lifecycle:

| Capability | Specification | Impact on Mold Performance |

|---|---|---|

| Machining Tolerance | ±0.001 mm (sub-micron) | Eliminates flash, ensures perfect shutoff |

| Surface Finish | Ra 0.05 µm (mirror grade) | Reduces ejection force, extends polish life |

| Material Mastery | P20, H13, S136, 420SS, Beryllium Copper | Optimized thermal conductivity & wear resistance |

| Lead Time (Complex Mold Base) | 18-25 days from approved drawing | Accelerates time-to-market for clients |

| Quality Verification | 100% CMM inspection + GD&T reporting | Guarantees dimensional integrity pre-shipment |

Unlike commodity manufacturers, we engage as an engineering extension of your team. Our process starts with a technical consultation to dissect your mold’s functional requirements—not just the drawing. Will thermal management dictate beryllium copper inserts? Does high-cavity count demand hardened steel with specialized coatings? We proactively identify failure points before metal is cut, leveraging simulation data to recommend geometries that maximize cooling efficiency and minimize stress concentrations. This consultative approach reduces revision cycles by up to 40% and extends mold life by 25% or more in high-volume production.

Your clients demand flawless parts at scale. They will not tolerate sink marks from uneven cooling or dimensional drift after 50,000 cycles. Partnering with Lead Precision means embedding manufacturing intelligence into every mold component we produce. We do not sell parts—we deliver risk mitigation through precision.

Initiate your precision partnership today. Email [email protected] with your next mold project specifications. Our engineering team will respond within 4 business hours with a detailed capability assessment and timeline. For urgent requirements, reference “MOLD URGENT” in your subject line. Trust the partner where 98.7% of molds achieve first-article approval without rework—because in injection molding, excellence is measured in microns, not margins.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.