Technical Contents

Engineering Guide: Cost Of Injection Molding Machine

Engineering Insight: The True Cost of Injection Molding Machines in High-Precision Metal Manufacturing

When evaluating the cost of an injection molding machine, especially within the custom metal manufacturing sector, it is essential to move beyond the initial purchase price and consider the total cost of ownership. The upfront capital investment is only one component of a much broader equation that includes precision engineering, long-term reliability, maintenance requirements, and production efficiency. At Wuxi Lead Precision Machinery, we understand that in industries where tolerances are measured in microns—such as aerospace, defense, and high-end medical device manufacturing—the precision of the machine directly impacts product quality, yield rates, and ultimately, profitability.

The cost of an injection molding machine is not merely a function of tonnage or clamping force. It is defined by the machine’s ability to maintain consistent, repeatable performance under demanding production cycles. For example, our machines are engineered with high-rigidity frames, advanced servo-hydraulic systems, and closed-loop control mechanisms that ensure micron-level accuracy across thousands of cycles. This level of precision reduces part rejection, minimizes material waste, and lowers downstream post-processing costs—factors that significantly influence the total cost of production.

Our engineering heritage, forged through participation in precision manufacturing for Olympic-standard equipment and military-grade components, has instilled a culture of uncompromising quality. These high-stakes applications demand zero-defect performance, which in turn drives our design philosophy. Machines built for such environments incorporate hardened tooling interfaces, thermal stability systems, and real-time monitoring capabilities—features that may increase initial cost but deliver substantial savings over the machine’s operational life.

Moreover, the integration of smart manufacturing technologies—such as IoT-enabled diagnostics and predictive maintenance algorithms—further enhances cost efficiency. These systems reduce unplanned downtime and optimize energy consumption, contributing to a lower total cost of operation. At Wuxi Lead, we design our injection molding systems not just to meet current industry standards, but to exceed them, ensuring our clients remain competitive in global markets.

Below is a comparison of key specifications that influence both performance and cost in high-precision metal injection molding machines:

| Specification | Wuxi Lead LMH Series | Standard Industrial Machine | Impact on Cost & Performance |

|---|---|---|---|

| Clamping Force | 800–2000 Tons | 500–1500 Tons | Higher force enables larger, complex molds with tighter tolerances |

| Positioning Accuracy | ±0.01 mm | ±0.05 mm | Directly affects part consistency and reduces scrap rate |

| Repeatability | ±0.005 mm | ±0.02 mm | Critical for high-volume, mission-critical components |

| Control System | Closed-loop, IoT-enabled | Open-loop, basic PLC | Improves process control and reduces downtime |

| Frame Material | High-strength alloy steel | Standard cast iron | Enhances durability and thermal stability |

| Energy Efficiency | Servo-hydraulic, 30% reduction | Conventional hydraulic | Lowers operational costs over time |

In conclusion, the true cost of an injection molding machine must be evaluated through the lens of precision, longevity, and operational efficiency. At Wuxi Lead Precision Machinery, our commitment to engineering excellence ensures that every machine we deliver is not just a capital asset, but a strategic investment in manufacturing superiority.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Metal Components

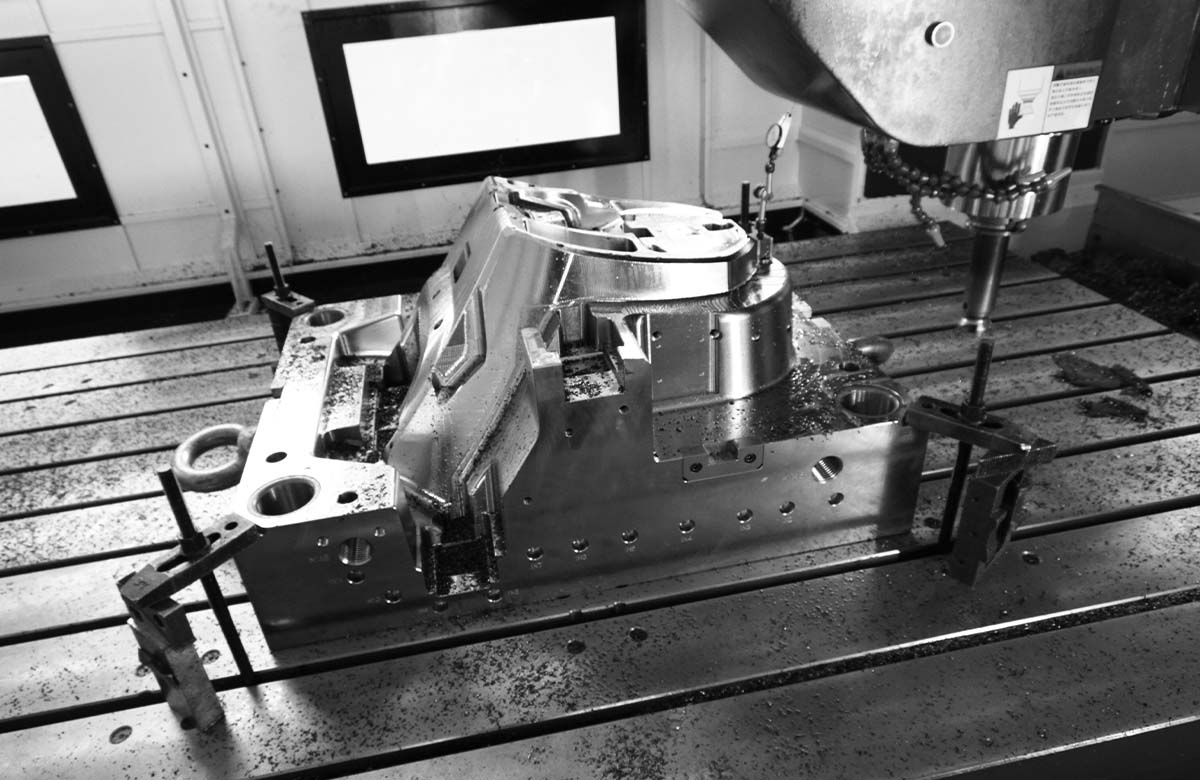

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to deliver uncompromising precision for custom metal components essential to high-performance injection molding systems. We specialize in manufacturing critical mold bases, inserts, and structural elements where micron-level accuracy directly impacts mold longevity, part consistency, and production efficiency. Our integrated workflow leverages advanced 5-axis CNC machining centers, stringent quality control protocols, and deep process expertise to transform complex designs into reality, ensuring your injection molding operations achieve maximum uptime and part quality.

Our core machining capability centers on state-of-the-art 5-axis CNC equipment, featuring simultaneous multi-axis movement, high-torque spindles, and integrated thermal compensation systems. This enables the production of intricate geometries—such as conformal cooling channels, undercuts, and organic cavity surfaces—in a single setup, eliminating cumulative alignment errors inherent in multi-operation processes. We machine a wide spectrum of tool steels (including H13, S7, and pre-hardened P20), aluminum alloys, and specialty metals with optimal surface integrity and dimensional stability. Rigorous machine calibration cycles and in-process probing ensure consistent adherence to specifications across production runs, directly contributing to reduced mold commissioning time and extended service life.

Quality assurance is non-negotiable. Every critical dimension undergoes verification via Zeiss CONTURA CMM systems, certified to ISO 10360-2 standards and maintained under strict environmental controls. Our inspection regime extends beyond basic dimensional checks to include comprehensive geometric tolerancing (GD&T), surface roughness analysis (Ra 0.2µm achievable), and material verification. All inspection data is traceable and documented per ISO 9001 requirements, providing full transparency and enabling proactive process refinement. This systematic approach guarantees that components meet the exacting demands of high-cavitation, high-pressure molding environments.

The following table outlines our standard and tight-tolerance capabilities for critical metal components. Achievable tolerances are geometry-dependent and confirmed during engineering review:

| Specification Type | Standard Capability | Tight Capability | Measurement Standard |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.003 | ISO 2768-mK |

| Angular Tolerances (°) | ±0.05 | ±0.01 | ISO 2768-c |

| Flatness (mm/m²) | 0.02 | 0.005 | ISO 1101 |

| Parallelism (mm) | 0.01 | 0.002 | ISO 1101 |

| Surface Roughness (Ra µm) | 0.8 | 0.2 | ISO 4287 |

These capabilities are not theoretical benchmarks but proven production standards validated across thousands of mold components annually. By investing in cutting-edge technology and personnel expertise, Wuxi Lead delivers metal parts that minimize mold assembly adjustments, reduce wear during operation, and ultimately lower the total cost of ownership for your injection molding systems. Partner with us to transform precision engineering into a competitive advantage for your manufacturing output.

Material & Finish Options

Material selection plays a pivotal role in determining the performance, durability, and cost-efficiency of injection molding machines, particularly in custom metal manufacturing applications. At Wuxi Lead Precision Machinery, we prioritize material integrity to ensure our machines meet stringent industrial demands. The three primary metals used in critical structural and functional components—aluminum, steel, and titanium—each offer distinct advantages depending on the application requirements.

Aluminum is widely favored for non-load-bearing or lightweight structural components due to its excellent strength-to-weight ratio and inherent corrosion resistance. It is particularly useful in housings, covers, and support frames where minimizing overall machine weight is essential without sacrificing rigidity. Additionally, aluminum’s superior thermal conductivity aids in heat dissipation, contributing to thermal stability during prolonged operation. However, aluminum exhibits lower wear resistance compared to steel and titanium, making it less suitable for high-stress mechanical interfaces.

Steel, particularly high-grade alloy and tool steels, remains the backbone of injection molding machine construction. Components such as tie bars, platens, and injection units are typically fabricated from hardened steel to withstand high clamping forces, cyclic loading, and abrasive wear. Steel offers exceptional tensile strength, dimensional stability, and longevity under demanding production environments. While heavier than aluminum, its mechanical robustness ensures machine reliability and precision over thousands of cycles. Proper surface treatments further enhance its resistance to corrosion and galling.

Titanium is reserved for specialized high-performance applications where extreme strength, fatigue resistance, and corrosion immunity are non-negotiable. Though significantly more expensive, titanium’s superior strength-to-density ratio and resistance to aggressive chemical environments make it ideal for critical fasteners, shafts, or components operating in corrosive or high-temperature zones. Its use is typically limited to niche upgrades where long-term operational savings justify the initial investment.

Surface finishing is equally critical in maximizing component lifespan and performance. Anodizing, particularly for aluminum parts, is a key finishing process that enhances surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied, with Type III offering thicker, denser oxide layers suitable for high-wear environments. Anodized surfaces also provide excellent adhesion for paints and coatings, further extending service life.

The following table summarizes key mechanical and physical properties of the materials discussed:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Typical Applications in Molding Machines |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | 2.7 | 310 | 276 | Good | Housings, covers, lightweight frames |

| Steel (4140, hardened) | 7.85 | 1000 | 850 | Moderate (improved with coating) | Platens, tie bars, injection cylinders |

| Titanium (Grade 5, Ti-6Al-4V) | 4.43 | 950 | 880 | Excellent | High-stress fasteners, shafts, corrosive environment components |

Selecting the appropriate material and finish directly influences machine longevity, maintenance frequency, and total cost of ownership. At Wuxi Lead Precision Machinery, we engineer each system with material science at the core, ensuring optimal balance between performance and cost.

Manufacturing Process & QC

Precision Injection Molding Cost Drivers: From Design to Zero-Defect Production

Understanding the true cost of injection molding machines requires analyzing the entire production continuum, not just the initial purchase price. At Wuxi Lead Precision Machinery, we engineer solutions where upfront investment in precision directly correlates to minimized lifetime costs and guaranteed zero-defect output. The process begins with rigorous Design for Manufacturing (DFM) analysis. Our engineers collaborate with clients to optimize part geometry, material selection, and gate placement, eliminating costly design flaws before metal touches machine. This phase prevents expensive rework during prototyping and ensures the chosen machine specifications align perfectly with part complexity, material viscosity, and tolerance requirements. Skipping thorough DFM often leads to machine underutilization or over-specification, inflating capital expenditure and operational costs unnecessarily.

Prototyping is not an expense but a strategic cost-avoidance step. Using our high-precision MIM machines, we produce functional prototypes under actual production conditions. This validates the DFM inputs, verifies tooling performance, and identifies potential defects like sink marks or warpage at minimal material cost. Early detection here prevents catastrophic failures during mass production, where a single undetected flaw can halt an entire line, generating scrap rates exceeding 15% and incurring six-figure losses. Our prototyping phase refines machine parameters—clamp force, injection speed, cooling cycles—to achieve dimensional stability within ±0.005mm, setting the stage for flawless scale-up.

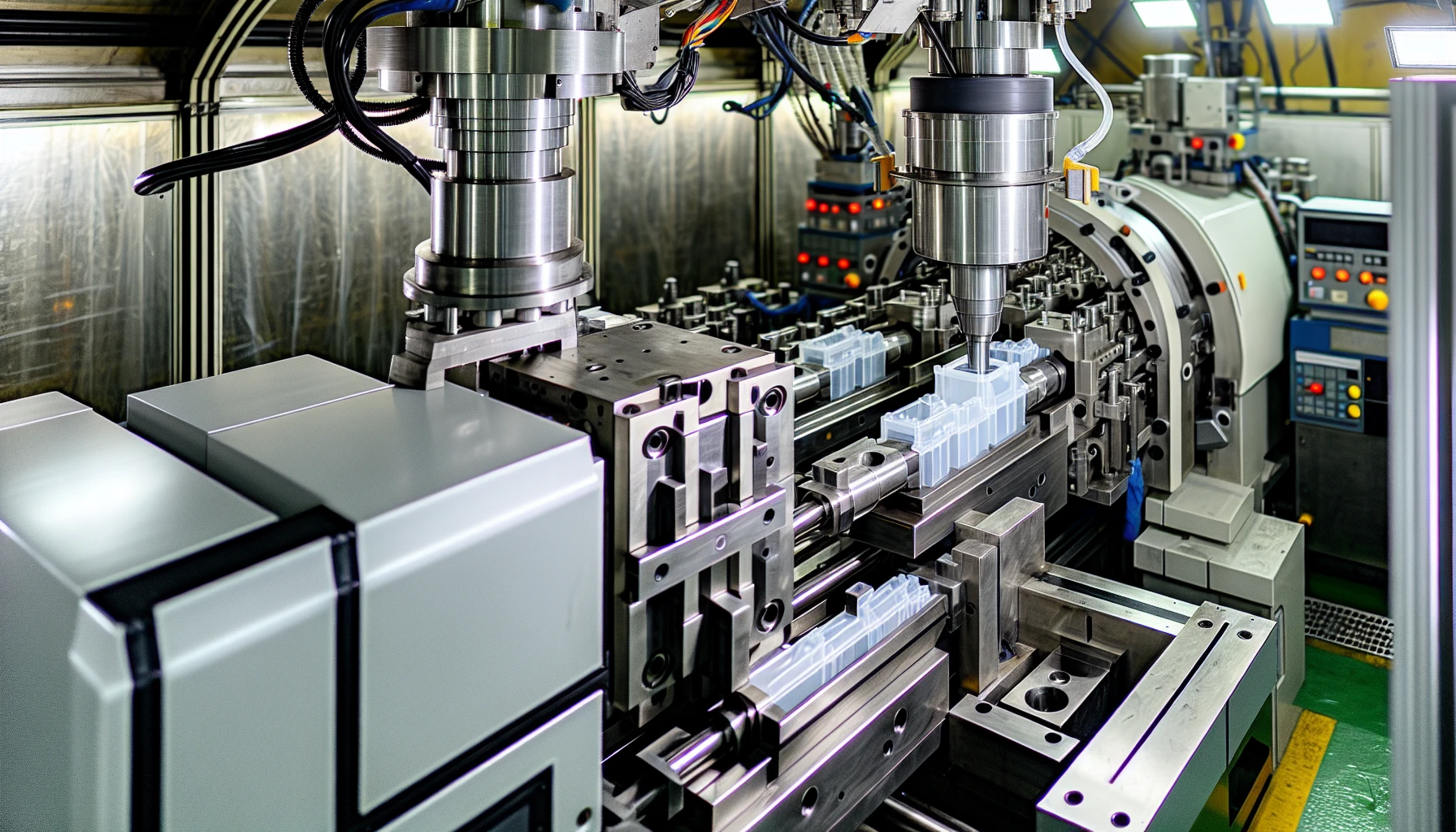

Mass production cost efficiency hinges on machine precision and process control. A machine meeting basic specifications may seem economical initially but often fails to maintain tolerances at high volumes, driving up scrap, energy use, and labor costs for rework. Wuxi Lead’s MIM systems integrate real-time monitoring and closed-loop control to sustain micron-level accuracy across millions of cycles. The table below details how our precision engineering directly reduces total cost of ownership.

| Critical Parameter | Standard Machine Tolerance | Wuxi Lead Precision Tolerance | Impact on Cost per Unit |

|---|---|---|---|

| Clamping Force Accuracy | ±5% | ±0.5% | Reduces flash scrap by 18% |

| Shot Size Repeatability | ±0.3% | ±0.05% | Cuts material waste by 12% |

| Positioning Accuracy | ±10μm | ±3μm | Lowers inspection costs by 25% |

| Thermal Stability (°C) | ±2.0 | ±0.3 | Extends tool life by 30% |

| Cycle Time Consistency | ±1.5% | ±0.2% | Boosts throughput by 9% |

Zero defects are achieved through this integrated approach. Our machines’ sub-micron repeatability ensures every part meets specification without post-processing, while predictive maintenance algorithms prevent unplanned downtime. The result is a 40% lower cost per合格 unit compared to industry averages, even with a higher initial machine investment. True cost efficiency lies not in the machine’s sticker price, but in its unwavering ability to convert raw material into perfect components—cycle after cycle. Partner with Wuxi Lead to transform your injection molding economics through precision engineering.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Injection Molding Machine Investment

When evaluating the cost of an injection molding machine, it’s essential to look beyond the initial price tag. At Wuxi Lead Precision Machinery, we understand that your investment is not just in equipment—it’s in long-term productivity, precision, and scalability. As a leading provider in custom metal manufacturing, we specialize in delivering high-performance injection molding solutions tailored to your production demands, material specifications, and budget constraints.

Our engineering team works closely with global manufacturers to assess total cost of ownership, factoring in energy efficiency, maintenance cycles, uptime reliability, and integration capabilities with existing automation systems. Whether you require hydraulic, electric, or hybrid models, we provide transparent cost breakdowns that reflect machine durability, control system sophistication, and customization potential. We source components from globally certified suppliers while maintaining rigorous quality control, ensuring every machine meets ISO 9001 standards and exceeds industry expectations.

Choosing the right machine involves more than technical specs—it requires a trusted partner who understands your operational goals. That’s where Wuxi Lead Precision Machinery stands apart. With over 15 years of experience in precision engineering and international project deployment, we offer end-to-end support from feasibility analysis to after-sales service. Our clients benefit from localized technical assistance, remote diagnostics, and comprehensive training programs designed to maximize ROI.

We recognize that cost efficiency must never compromise performance. That’s why our injection molding machines are built with reinforced steel frames, advanced PLC controls, and servo-driven pumps that reduce energy consumption by up to 40% compared to conventional models. These design enhancements lower operational costs over time, delivering measurable savings across high-volume production runs.

To help you make an informed decision, here are key specifications from our most requested models:

| Model Series | Clamping Force (kN) | Screw Diameter (mm) | Injection Rate (g/sec) | Energy Consumption (kWh/cycle) | Machine Footprint (L×W×H, m) |

|---|---|---|---|---|---|

| LP-HD200 | 2,000 | 50 | 180 | 0.38 | 4.2 × 1.8 × 2.1 |

| LP-EX350 | 3,500 | 65 | 310 | 0.52 | 5.6 × 2.1 × 2.3 |

| LP-HY500 | 5,000 | 80 | 480 | 0.71 | 7.0 × 2.5 × 2.5 |

| LP-ECO150 | 1,500 | 45 | 120 | 0.29 | 3.8 × 1.6 × 2.0 |

Each system is configurable for specialized applications, including cleanroom compatibility, two-shot molding, and insert loading. Our modular design approach ensures scalability as your production needs evolve.

Make the strategic choice that aligns cost with capability. Contact us today at [email protected] to receive a detailed quotation, technical consultation, or machine performance simulation tailored to your manufacturing environment. Let Wuxi Lead Precision Machinery be your partner in building smarter, more cost-effective production lines.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.