Technical Contents

Engineering Guide: Prototype Molding

Engineering Insight: The Non-Negotiable Role of Precision in Prototype Molding

Prototype molding is far more than a preliminary manufacturing step; it is the critical validation phase where theoretical design confronts physical reality. In high-stakes custom metal manufacturing for aerospace, defense, medical, and advanced industrial applications, the precision achieved during prototyping directly dictates the viability, safety, and performance of the final production component. Tolerances measured in microns are not merely specifications – they are fundamental requirements for functional integrity, assembly compatibility, and regulatory compliance. A prototype failing to meet exacting dimensional and material property standards risks cascading failures: costly design reiterations, delayed time-to-market, compromised product performance, or, in extreme cases, catastrophic field failure. The cost of imprecision at this stage exponentially multiplies downstream.

Wuxi Lead Precision Machinery operates at this demanding intersection of engineering theory and physical execution. Our extensive experience fabricating mission-critical components for Olympic venue structural systems and military-grade aerospace subsystems underscores our unwavering commitment to micron-level accuracy. These projects demanded not only adherence to stringent international standards like ISO 13485 and AS9100 but also the ability to consistently reproduce complex geometries under intense scrutiny. The lessons learned validating prototypes for applications where failure is not an option are embedded in our core processes. We understand that a prototype mold must faithfully replicate the intended production environment, capturing thermal dynamics, material flow characteristics, and stress points with absolute fidelity. This requires sophisticated simulation integrated with empirical testing, not just on the mold itself, but on the resulting prototype parts under simulated operational loads.

Our technical capability for precision prototype molding is grounded in advanced infrastructure and rigorous process control. The table below outlines key specifications achievable within our facility:

| Capability Category | Specification Range | Key Technology/Process |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.025 mm (standard) | Multi-axis CNC Machining (5-axis) |

| Surface Finish (Ra) | 0.2 µm to 1.6 µm | Precision Grinding & Polishing |

| Material Compatibility | Titanium Alloys, Inconel, Tool Steels, Aluminum Alloys, Specialty Brass | Controlled Atmosphere Furnaces, Advanced Metrology |

| Prototype Lead Time | 10-25 working days (complex geometries) | Integrated CAD/CAM, Rapid Tooling |

| Quality Validation | CMM, Optical Comparators, Metallurgical Analysis | ISO 17025 Accredited Lab |

Achieving this level of precision requires moving beyond standard machining practices. It necessitates a holistic approach where material science, thermal management, real-time process monitoring, and iterative metrology are seamlessly integrated. At Wuxi Lead, every prototype mold undergoes iterative validation cycles against the original CAD model and functional requirements. We employ in-process gauging and post-mold analysis to identify and correct microscopic deviations before they propagate. This disciplined methodology, forged through demanding projects where precision is synonymous with reliability, ensures that the prototype you receive is not just a physical model, but a true predictor of production success. It transforms risk into confidence, accelerating your path from concept to certified production.

Precision Specs & Tolerances

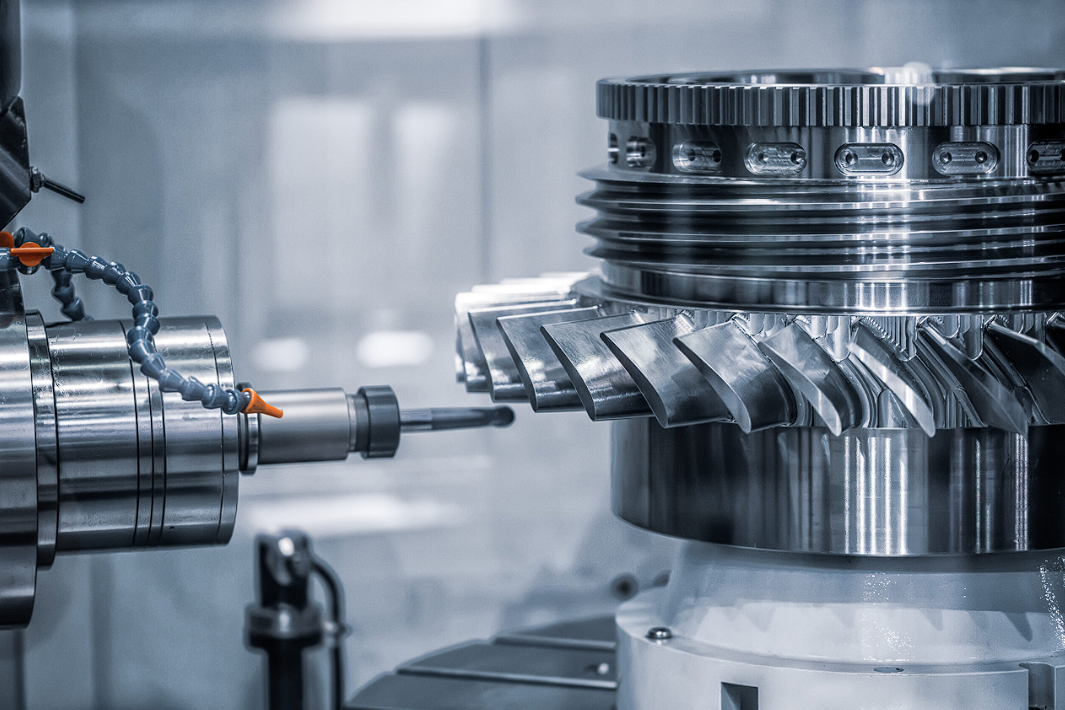

Wuxi Lead Precision Machinery delivers advanced prototype molding solutions tailored for high-precision industries including aerospace, medical devices, automotive engineering, and industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining platforms, enabling the production of complex geometries with exceptional accuracy and surface integrity. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and part handling while maintaining tight tolerances across intricate features. This level of machining flexibility is essential for prototype molding applications where design validation, fit, and function must be precisely replicated before full-scale production.

All prototype molding operations are supported by an integrated quality assurance framework centered on CMM (Coordinate Measuring Machine) inspection. Every component undergoes rigorous dimensional verification using Zeiss and Hexagon CMM systems, ensuring compliance with ISO 10360 standards. Our inspection protocols cover geometric dimensioning and tolerancing (GD&T), surface finish analysis, and first-article inspection reporting (FAIR), providing clients with full traceability and data-backed validation of each prototype. This commitment to metrology ensures that every mold, cavity, or core produced meets the exacting requirements of functional testing and downstream manufacturing scalability.

Our facility specializes in custom metal manufacturing using a broad range of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steels (303, 304, 316), tool steels, titanium, and brass. Each prototype mold is machined from solid billet to eliminate weld lines and ensure structural consistency, critical for pressure and thermal cycling during molding trials. In addition to machining, we offer surface treatments such as hard anodizing, passivation, and precision polishing to enhance wear resistance and release performance.

The following table outlines our standard machining tolerances for prototype molding components:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Measured via CMM; dependent on geometry |

| Hole Diameter | +0.008 / -0.000 mm | +0.005 / -0.000 mm | Reamed or precision bored |

| Positional Tolerance | ±0.010 mm | ±0.005 mm | Per GD&T, relative to datum |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | Verified on granite surface plate |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Achieved via fine finishing passes |

| Angular Features | ±0.05° | ±0.02° | 5-axis simultaneous interpolation |

These specifications reflect our ability to meet demanding engineering requirements typical of high-performance prototype molding applications. By combining 5-axis CNC technology with certified inspection processes, Wuxi Lead Precision Machinery ensures that every prototype not only meets design intent but also serves as a reliable benchmark for production tooling development. Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce cycle risk, and accelerate time-to-market.

Material & Finish Options

Material Selection for Precision Prototype Molding

Selecting the optimal material during the prototyping phase is critical for validating design functionality, performance, and manufacturability before full-scale production. At Wuxi Lead Precision Machinery, we leverage our advanced CNC capabilities to machine complex prototypes from high-performance metals, ensuring your design intent is accurately realized. The choice between Aluminum, Steel, and Titanium hinges on specific application requirements including strength-to-weight ratio, environmental exposure, thermal properties, and budget constraints. Understanding these core material characteristics prevents costly redesigns and accelerates time-to-market.

Aluminum alloys, particularly 6061-T6, offer an exceptional balance of lightweight properties, good machinability, and inherent corrosion resistance. This makes them ideal for prototypes requiring structural integrity without excessive weight, such as aerospace components, consumer electronics housings, or automotive brackets. While not as strong as steel or titanium, aluminum’s ease of machining allows for rapid iteration and complex geometries during the prototyping stage. Steel, specifically grades like 4140 or 17-4 PH, delivers superior strength, hardness, and wear resistance. It is the preferred choice for prototypes subjected to high mechanical loads, impact, or demanding wear environments, such as hydraulic fittings, tooling fixtures, or heavy machinery parts. Steel prototypes accurately simulate the durability of production parts but require more robust machining strategies due to higher hardness.

Titanium 6Al-4V stands apart for applications demanding the ultimate strength-to-weight ratio combined with outstanding corrosion resistance, particularly in harsh chemical or marine environments. Its biocompatibility also makes it essential for medical device prototyping. However, titanium’s low thermal conductivity and high chemical reactivity present significant machining challenges, including tool wear and potential for work hardening. Wuxi Lead’s specialized CNC processes and tooling expertise are essential to overcome these hurdles and produce dimensionally precise titanium prototypes that faithfully represent final part behavior.

Surface finish selection, particularly anodizing for aluminum, directly impacts prototype performance and testing validity. Type II (Sulfuric Acid) Anodizing provides moderate corrosion and wear resistance with excellent dyeing capability for visual identification. Type III (Hardcoat) Anodizing delivers a much thicker, harder, and more wear-resistant surface, crucial for prototypes undergoing functional testing under abrasive conditions. Anodizing thickness must be carefully considered as it adds dimensionally to the part; our engineering team integrates this factor into the initial CAD model to ensure final dimensions meet specifications after finishing.

The following table summarizes key properties for common prototyping materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Corrosion Resistance | Typical Prototype Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (A) | Good | Aerospace brackets, enclosures, heat sinks |

| Steel 4140 | 7.85 | 655 | Fair (C) | Moderate (Requires finish) | Hydraulic components, shafts, tooling |

| Titanium 6Al-4V | 4.43 | 900 | Poor (D) | Excellent | Medical implants, marine hardware, high-performance aerospace |

Wuxi Lead Precision Machinery provides comprehensive material consultation and precision machining for all critical prototyping phases. Our expertise ensures the selected material and finish accurately reflect the intended production environment, mitigating risk and providing reliable data for your next development stage. Contact our engineering team to optimize your prototype material strategy.

Manufacturing Process & QC

From Concept to Consistency: The Prototype Molding Production Process at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components through an integrated prototype molding process that ensures zero defects from design inception to full-scale production. Our methodology is engineered for reliability, repeatability, and dimensional accuracy, serving industries where performance under extreme conditions is non-negotiable.

The journey begins with Design Engineering, where our team collaborates closely with clients to transform conceptual CAD models into manufacturable designs. Utilizing advanced simulation software, we perform mold flow analysis, structural stress testing, and thermal behavior modeling to identify potential weaknesses before any metal is cut. This virtual validation phase reduces downstream risks and accelerates time-to-market.

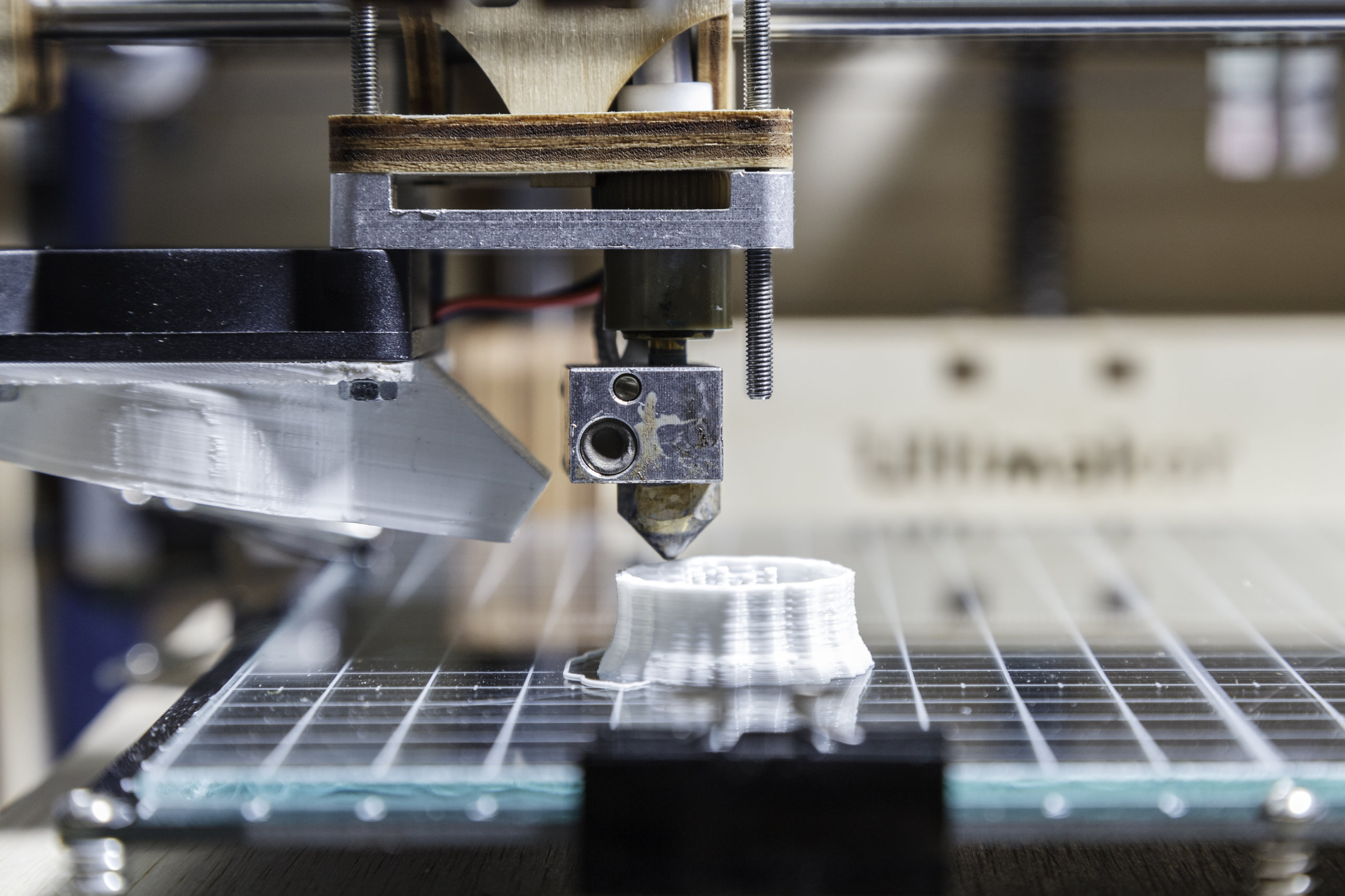

Next is the Prototyping Phase, a critical step in verifying both form and function. Using CNC machining, precision stamping, or additive manufacturing as appropriate, we produce functional prototypes in the actual target material—such as stainless steel, aluminum alloys, or titanium. These prototypes undergo rigorous testing for fit, durability, and performance under real-world conditions. Feedback from this stage is systematically incorporated into final design adjustments, ensuring that every geometric tolerance and surface finish meets exact specifications.

Only after prototype approval do we transition to Mass Production, where our automated molding lines—equipped with in-process monitoring and real-time SPC (Statistical Process Control)—deliver consistent part quality at scale. Each production run is supported by a comprehensive First Article Inspection Report (FAIR), and every component is traceable through our digital quality management system. Our zero-defect philosophy is enforced through multi-stage quality checkpoints, including 100% visual inspection via machine vision systems and random CMM (Coordinate Measuring Machine) sampling.

Our production process is certified under ISO 9001:2015 and adheres to IATF 16949 standards for automotive-grade quality. From low-volume pilot runs to high-volume manufacturing, we maintain strict control over material sourcing, tooling wear, and environmental variables to eliminate variability.

The following table outlines key capabilities across our prototype molding workflow:

| Parameter | Specification |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum Alloys, Titanium, Brass, Tool Steels |

| Tolerance Range | ±0.005 mm to ±0.025 mm (depending on part geometry and size) |

| Surface Finish | Ra 0.2 µm to Ra 3.2 µm (custom finishes available) |

| Prototype Lead Time | 7–15 days (including design review and sample delivery) |

| Production Cycle Time | As low as 30 seconds per part (automated stamping/molding lines) |

| Quality Assurance Tools | CMM, Optical Measuring Systems, Hardness Testers, X-ray Inspection (for internal defects) |

| Production Capacity | Up to 1 million parts per month (scalable based on client demand) |

At Wuxi Lead Precision Machinery, prototype molding is not a preliminary step—it is the foundation of flawless mass production. By integrating precision engineering, iterative validation, and industrial automation, we ensure that every component we manufacture meets the highest standards of quality, consistency, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Prototype Molding Excellence

In high-stakes industries like aerospace, medical device development, and advanced robotics, the prototype molding phase is not merely a step—it is the critical validation of your entire design philosophy. Substandard prototyping introduces unacceptable risk: delayed time-to-market, costly redesigns, and compromised functional integrity. At Wuxi Lead Precision Machinery, we engineer prototype molding solutions where precision is non-negotiable and material performance is guaranteed. Our integrated approach merges decades of Chinese manufacturing expertise with German-engineered CNC infrastructure, delivering metal prototypes that mirror final production quality down to the micron. This eliminates the traditional prototyping gap, ensuring your design transitions seamlessly from concept to certified component.

Our facility operates under ISO 9001:2015 and AS9100D standards, with in-house capabilities spanning multi-axis milling, Swiss turning, and 5-axis wire EDM. Every prototype undergoes metrology-grade validation using Zeiss CMM systems, guaranteeing dimensional stability before it reaches your engineering team. We specialize in challenging materials including Inconel 718, titanium Grade 5, beryllium-copper alloys, and maraging steel—processing them with sub-5μm tolerances that meet FAA and FDA pre-certification requirements. This technical rigor transforms prototyping from a bottleneck into your strategic advantage, accelerating validation cycles by up to 40% versus conventional suppliers.

The following specifications demonstrate our commitment to engineering-grade prototyping:

| Capability | Specification | Impact for Your Project |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Eliminates fit/interference issues in assemblies |

| Surface Finish | Ra 0.2 μm (8 μin) achievable | Validates sealing surfaces & fatigue life |

| Material Range | Titanium, Inconel, Tool Steels, Exotic Alloys | Tests real-world performance under stress |

| Lead Time | 7–12 days for complex geometries | Cuts development cycles without compromising quality |

| Metrology Validation | Full CMM report + GD&T analysis | Provides auditable data for regulatory submissions |

Choosing Lead Precision means partnering with engineers who speak your technical language and prioritize your project’s success over transactional volume. Our APQP-driven workflow includes Design for Manufacturability (DFM) reviews at the quoting stage, identifying potential failures before metal is cut. We implement zero-defect protocols with real-time SPC monitoring—ensuring every prototype reflects the exact mechanical properties and geometric intent of your CAD model. This level of control is why global Tier-1 aerospace suppliers and MedTech innovators trust us for mission-critical prototyping.

Do not compromise your innovation on suppliers lacking true engineering depth. Initiate your precision prototype project with a team that delivers certified accuracy, material integrity, and actionable data—not just a physical part. Contact our engineering team directly at [email protected] to submit your CAD files and receive a DFM analysis within 24 hours. Let us demonstrate how Lead Precision becomes your force multiplier in de-risking product development. Your breakthrough design deserves nothing less than manufacturing perfection from the very first prototype.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.