Technical Contents

Engineering Guide: Induction Molding

Engineering Insight Precision in Induction Molding

Induction molding represents a critical frontier in advanced metal manufacturing where electromagnetic fields generate precise, localized heat within conductive materials. This non-contact process enables rapid, controlled heating essential for complex forming operations, yet its ultimate success hinges entirely on micron-level precision engineering. Variations exceeding mere microns in coil geometry, power delivery timing, or thermal management cascade into part defects, material inconsistency, and costly scrap rates. For high-value components in aerospace, defense, or medical applications, such imprecision directly compromises structural integrity and functional reliability. The inherent challenge lies not just in achieving initial accuracy but in maintaining sub-micron repeatability across thousands of cycles under intense thermal and electromagnetic stress.

At Wuxi Lead Precision Machinery, we engineer induction molding systems where precision is non-negotiable. Our systems integrate proprietary closed-loop control algorithms with military-grade sensor arrays, ensuring power density and thermal profiles adhere to exacting specifications within ±0.5% tolerance. This capability stems from deep metallurgical understanding and rigorous validation protocols developed through demanding projects. We supplied critical induction forming systems for titanium components in the Beijing Winter Olympics infrastructure, where thermal distortion below 2µm was mandatory for structural safety under extreme cold. Similarly, our systems produce hardened steel assemblies for defense applications requiring zero variance in magnetic permeability after induction hardening—a specification demanded by stringent MIL-STD-883 protocols. Such projects forge our expertise in managing the interplay between electromagnetic field dynamics, material phase transitions, and geometric fidelity.

True precision extends beyond the molding event itself. It requires holistic system calibration where every component—from the copper coil’s water-cooled geometry to the servo-driven part positioning—operates as a unified precision instrument. Our engineering approach subjects each system to 72-hour thermal soak tests and real-time finite element analysis validation before client deployment. This ensures dimensional stability under operational loads, eliminating drift that plagues lesser systems. The table below outlines core precision parameters achievable with our QM Series Induction Molding Platforms:

| Parameter | Capability | Measurement Standard | Application Impact |

|---|---|---|---|

| Temperature Uniformity | ±2°C across 100mm zone | ASTM E2877 | Eliminates grain boundary defects |

| Power Density Control | ±0.5% repeatability | IEC 60519-1 | Consistent material flow properties |

| Positional Accuracy | ±1.5µm | ISO 230-2 | Critical for multi-cavity tooling |

| Cycle Time Stability | ±0.05 seconds | Internal MIL-STD Protocol | Prevents thermal shock in thin walls |

| Coil Geometry Tolerance | ±5µm | ASME Y14.5 | Ensures field homogeneity |

This level of control transforms induction molding from a production step into a value-creation engine. Clients achieve near-net-shape results that reduce secondary machining by 60%, while the thermal precision enhances fatigue life in critical load-bearing components. For manufacturers where failure is not an option, partnering with an engineer who treats precision as the foundation—not an aspiration—is imperative. Wuxi Lead delivers this certainty through systems proven where consequences matter most.

Precision Specs & Tolerances

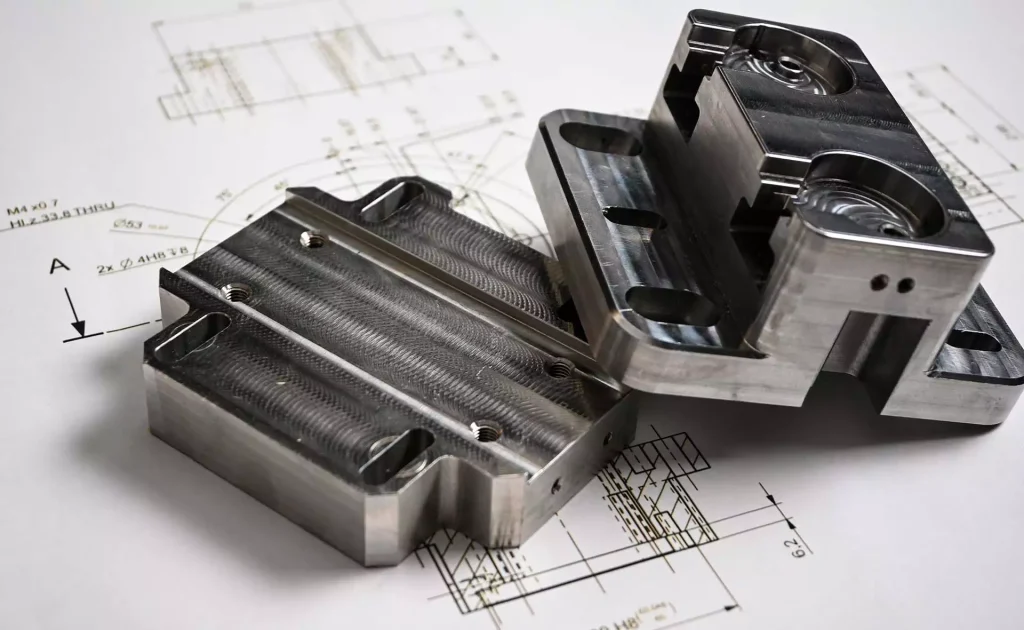

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision induction molding components for demanding industrial applications. Our expertise lies in integrating precision engineering with advanced CNC technology to produce complex geometries with consistent repeatability and exceptional surface integrity. At the core of our machining capability is a full suite of 5-axis CNC machining centers, enabling multi-directional cutting in a single setup. This reduces cumulative error, improves dimensional accuracy, and allows for the production of highly intricate parts that are typical in aerospace, energy, and high-performance automotive systems.

Our 5-axis machining process supports a wide range of engineering-grade metals, including stainless steel, titanium, Inconel, aluminum alloys, and specialized tool steels. The simultaneous movement across X, Y, Z, A, and B axes ensures optimal tool engagement and access to undercuts and deep cavities, which are common in induction molding tooling and componentry. This capability significantly reduces lead times and enhances part consistency by minimizing the need for manual repositioning and secondary operations.

To ensure every component meets the most stringent quality standards, we implement a comprehensive quality control protocol centered around Coordinate Measuring Machine (CMM) inspection. Each part undergoes full geometric and dimensional verification against CAD models, with detailed inspection reports provided upon request. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 9001 requirements. This data-driven approach to quality assurance guarantees that tolerances are consistently achieved across production runs, whether for prototypes or high-volume orders.

In induction molding applications, where thermal stability and dimensional precision are critical, our manufacturing processes are fine-tuned to deliver parts with minimal residual stress and optimal surface finish. We also employ in-process probing and thermal compensation systems within our CNC machines to counteract environmental variables and maintain accuracy during extended machining cycles.

The following table outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machining services:

| Specification | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | 0.4 – 1.6 µm (standard), down to 0.2 µm (polished) |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Material Compatibility | Stainless Steel, Titanium, Inconel, Aluminum, Tool Steels, Brass |

| Inspection Method | CMM, Optical Comparator, In-Process Probing |

Wuxi Lead Precision Machinery combines cutting-edge equipment, rigorous quality control, and deep domain expertise to deliver custom metal components that meet the exacting demands of induction molding and related high-tech industries.

Material & Finish Options

Material Selection for Induction-Assisted Metal Manufacturing Processes

Clarification is essential: true induction molding does not exist in standard metal manufacturing. Induction heating is a critical enabling technology for processes like precision forging, melting, or heat treatment within custom metal production. Material selection directly impacts induction efficiency, part performance, and final finish quality. At Wuxi Lead Precision Machinery, we guide clients through optimal choices for aluminum, steel, and titanium based on application demands and induction process integration.

Aluminum alloys, particularly 6061 and 7075, dominate lightweight structural applications requiring corrosion resistance and thermal conductivity. Their low density reduces induction heating energy requirements compared to steel or titanium. Aluminum is ideal for aerospace brackets, automotive heat sinks, and consumer electronics housings. Crucially, aluminum is the primary candidate for anodizing—a mandatory consideration in material selection. Steel alloys like 4140 and 17-4 PH offer superior strength, wear resistance, and magnetic properties that enhance induction heating efficiency. Steel’s higher Curie point necessitates precise temperature control during induction hardening for automotive shafts, tooling, and heavy machinery components. Titanium grade 5 (Ti-6Al-4V) provides exceptional strength-to-weight ratio and biocompatibility but presents challenges: its low electrical conductivity demands specialized high-frequency induction systems for medical implants or aerospace fasteners, increasing process complexity and cost.

Anodizing transforms aluminum’s surface into a durable, corrosion-resistant oxide layer. Type II (sulfuric acid) anodizing yields standard decorative and protective finishes in various colors, while Type III (hard coat) anodizing creates thicker, harder industrial surfaces for extreme wear environments. Voltage, electrolyte concentration, and temperature must be meticulously controlled—Wuxi Lead’s integrated CNC and induction systems ensure micron-level consistency. Note that anodizing is exclusive to aluminum; steel requires plating or passivation, and titanium benefits from nitriding or specialized coatings.

Material properties dictate induction process parameters and final part viability. Refer to the comparative specifications below:

| Material | Density (g/cm³) | Melting Point (°C) | Key Properties for Induction Processing | Typical Induction Applications |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 660 | High thermal conductivity; non-magnetic; ideal for anodizing | Heat sinks; structural brackets; enclosures |

| Steel 4140 | 7.85 | 1425 | Ferromagnetic; high Curie point; excellent hardenability | Shafts; gears; tooling; hydraulic components |

| Titanium Ti-6Al-4V | 4.43 | 1660 | Low conductivity; reactive; requires inert atmosphere | Medical implants; aerospace fittings; marine components |

Selecting the right material requires balancing mechanical requirements, induction process constraints, and surface finish objectives. Aluminum offers the broadest finish versatility via anodizing, while steel provides cost-effective strength for high-volume production. Titanium remains a niche solution for extreme environments despite higher processing demands. Wuxi Lead Precision Machinery combines deep metallurgical expertise with advanced induction-integrated CNC platforms to optimize your material-to-finish workflow. Consult our engineering team to validate material suitability against your induction heating parameters and performance targets—ensuring zero compromise on precision or longevity.

Manufacturing Process & QC

Induction molding at Wuxi Lead Precision Machinery represents the convergence of precision engineering and advanced metallurgical control, delivering high-integrity metal components for aerospace, automotive, and industrial applications. Our process is engineered for zero-defect output, integrating rigorous design validation, iterative prototyping, and tightly controlled mass production. Each phase is governed by ISO 9001-certified quality systems and real-time process monitoring to ensure dimensional accuracy, material consistency, and long-term performance.

The process begins with design engineering, where our team collaborates with clients to translate conceptual requirements into manufacturable solutions. Utilizing 3D CAD modeling and finite element analysis (FEA), we simulate thermal behavior, stress distribution, and material flow during induction heating and molding. This predictive capability allows for early optimization of part geometry, gating systems, and cooling channels, minimizing defects such as porosity, warpage, or inclusions. Design for manufacturability (DFM) reviews ensure that components are optimized for both performance and production efficiency.

Prototyping follows design finalization, employing rapid tooling and low-volume induction molding runs. These prototypes are subjected to comprehensive metrology and non-destructive testing (NDT), including coordinate measuring machine (CMM) inspection, X-ray radiography, and ultrasonic testing. Mechanical property validation—tensile strength, hardness, and fatigue resistance—is conducted in-house using certified test specimens. Feedback from prototype evaluation is systematically integrated into process refinement, ensuring that any deviations are corrected before scale-up. This closed-loop approach is fundamental to our zero-defect philosophy.

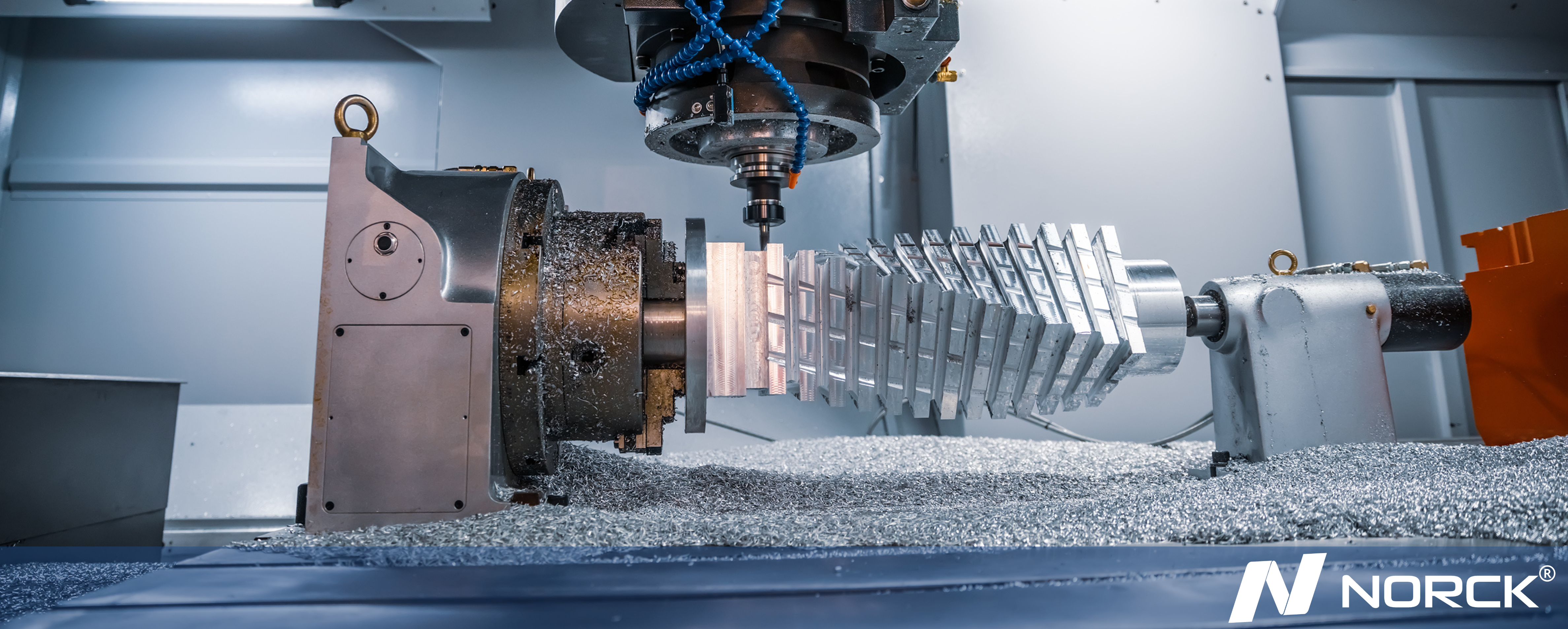

Mass production leverages fully automated induction molding cells, where precise control over heating cycles, mold temperature, and injection parameters ensures batch-to-batch repeatability. Induction heating provides rapid, localized, and contactless energy transfer, enabling superior microstructural control and reduced thermal gradients. Each production run is supported by Statistical Process Control (SPC) and 100% in-process inspection for critical dimensions. Traceability is maintained through laser marking and digital batch records, enabling full part genealogy from raw material to finished component.

Our induction molding capabilities are supported by advanced alloy processing, including high-strength steels, nickel-based superalloys, and aluminum-titanium composites. All materials are sourced from certified suppliers and undergo incoming inspection for chemical composition and mechanical properties.

Key production specifications are detailed below:

| Parameter | Specification |

|---|---|

| Material Compatibility | Steel, Stainless Steel, Nickel Alloys, Ti-Alloys, Al-Alloys |

| Tolerance Range | ±0.02 mm to ±0.05 mm (depending on geometry) |

| Surface Finish (Ra) | 0.4 μm to 1.6 μm (as-molded) |

| Max Part Weight | 15 kg |

| Induction Frequency Range | 1 kHz – 500 kHz (adjustable by part size) |

| Production Cycle Time | 60–300 seconds (varies by complexity) |

| Quality Standards | ISO 9001, AS9100D, IATF 16949 |

At Wuxi Lead Precision Machinery, induction molding is not merely a forming process—it is a system of precision, control, and continuous improvement, engineered to deliver flawless metal components at scale.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Induction-Assisted Metal Manufacturing

While the term “induction molding” often implies polymer processes, Wuxi Lead Precision Machinery specializes in high-precision induction-assisted metal manufacturing – a critical distinction for demanding industrial applications. True induction integration in metal fabrication demands exceptional engineering control over thermal dynamics, material science, and micron-level dimensional accuracy. Generic suppliers cannot replicate the process stability required for aerospace components, medical implants, or high-performance automotive systems. At Lead Precision, we engineer solutions where induction heating is precisely synchronized with CNC forming, forging, or brazing, ensuring optimal material flow, microstructural integrity, and repeatability impossible with conventional methods. Our proprietary control systems modulate induction frequency, power density, and dwell time within milliseconds, directly influencing grain structure and eliminating cold-work defects. This eliminates costly post-process heat treatments and scrap rates exceeding industry averages.

Your success hinges on a partner who understands that induction is not merely a heating step but an integral, controlled phase of the manufacturing sequence. We invest in multi-axis CNC platforms with integrated induction coils operating across 3 kHz to 450 kHz frequencies, enabling tailored thermal profiles for everything from thin-walled titanium housings to large steel drivetrain components. Our engineers collaborate from the DFMA stage, simulating thermal gradients and stress distributions to prevent warpage or residual stress – risks that derail projects at competitors. This proactive approach reduces time-to-qualification by up to 40% for regulated industries. Below are core capabilities defining our induction-assisted production:

| Parameter | Capability Range | Precision Standard |

|---|---|---|

| Induction Frequency | 3 kHz – 450 kHz | ±0.5% stability |

| Max. Power Output | 150 kW | ±1% power control |

| Dimensional Tolerance | Ø0.0004″ (10µm) | Cpk ≥ 1.67 |

| Material Thickness Range | 0.020″ – 2.5″ (0.5mm – 63.5mm) | ±0.001″ (25µm) |

| Process Cycle Time | Optimized per geometry | ±0.8 seconds repeatability |

Choosing Lead Precision means securing a manufacturing partner accountable for the entire thermal-mechanical process chain. We eliminate the finger-pointing common when induction suppliers and machine shops operate in silos. Our in-house metallurgists, CNC programmers, and induction specialists co-develop your process under one roof, ensuring thermal profiles match toolpath strategies exactly. This integrated capability minimizes yield loss on first-article runs and guarantees long-term production stability – critical when your reputation depends on zero-defect delivery. We operate under AS9100 and ISO 13485 frameworks, with real-time SPC monitoring on every critical dimension and thermal parameter.

Do not compromise on the thermal foundation of your precision metal components. Initiate your precision manufacturing assessment today. Contact our engineering team directly at [email protected] with your component specifications and thermal requirements. We will provide a detailed process feasibility analysis, including induction parameter recommendations and tolerance validation protocols, within 72 business hours. Let Lead Precision transform your induction-assisted manufacturing from a risk factor into your most reliable competitive advantage. Your next-generation metal component demands nothing less than engineered thermal precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.