Technical Contents

Engineering Guide: Threaded Inserts For Plastic Molding

Engineering Insight: Threaded Inserts for Plastic Molding

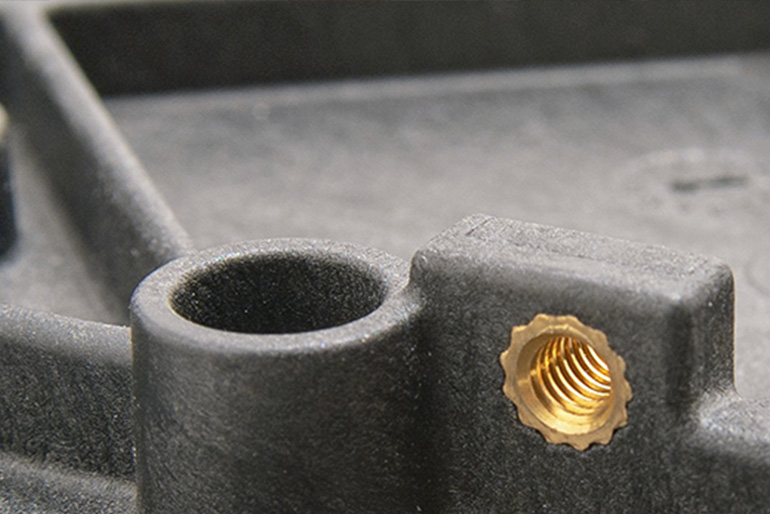

In high-performance manufacturing, the integration of threaded inserts into plastic molding processes represents a critical junction between polymer engineering and precision metal fabrication. These inserts serve as reinforced threaded interfaces within plastic components, enabling reliable mechanical fastening in applications where durability, load-bearing capacity, and long-term stability are non-negotiable. The success of this integration hinges on one foundational element: precision.

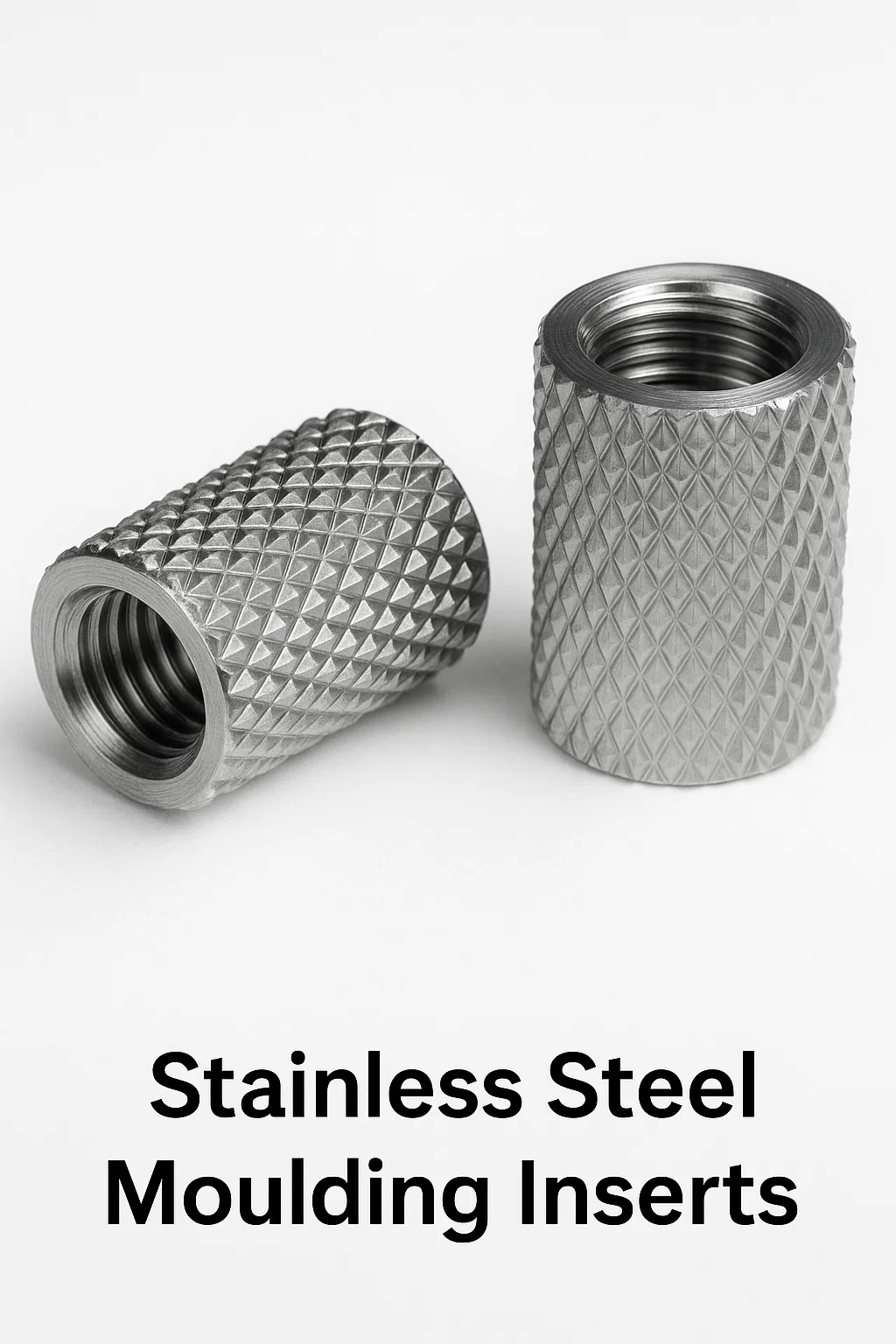

Threaded inserts must be manufactured to exacting tolerances to ensure seamless embedding during the injection molding process. Even minor deviations in outer diameter, thread pitch, or knurling profile can lead to insert misalignment, resin leakage, or compromised pull-out strength. At Wuxi Lead Precision Machinery, we recognize that precision is not a target—it is a standard. Our threaded inserts are engineered with micron-level accuracy, ensuring consistent performance across millions of molding cycles.

The challenges intensify in mission-critical applications. In aerospace, defense, and high-end industrial systems, failure is not an option. Components must withstand extreme thermal cycling, mechanical stress, and corrosive environments. Our experience supplying precision metal components for Olympic-grade equipment and military-grade systems has reinforced our understanding of these demands. These projects required not only flawless dimensional accuracy but also rigorous material traceability, batch consistency, and compliance with international quality standards—benchmarks we apply to every threaded insert we produce.

Material selection plays a pivotal role in performance. Stainless steel, brass, and specialized alloys are commonly used, each offering distinct advantages in strength, corrosion resistance, and thermal stability. Our engineering team collaborates closely with clients to match insert material and geometry to the specific resin type, molding parameters, and end-use conditions. This holistic approach ensures optimal adhesion between the insert and the surrounding polymer matrix, minimizing the risk of creep, cracking, or thread stripping.

Insert design must also account for thermal expansion differentials between metal and plastic. Precision in thread form, undercut features, and knurling patterns enhances mechanical anchoring, preventing rotation or ejection under load. Our in-house tooling and automated inspection systems allow us to maintain tight control over every production variable, from blanking to threading to final deburring.

Below are typical specifications for our custom threaded inserts, tailored to client requirements:

| Parameter | Standard Range | Tolerance | Material Options |

|---|---|---|---|

| Insert Diameter | M2 to M12 | ±0.02 mm | 303/304/316 Stainless Steel, Brass, Custom Alloys |

| Thread Pitch | Coarse and Fine (metric & UNC) | ±0.01 mm/revolution | — |

| Length | 3 mm to 25 mm | ±0.05 mm | — |

| Knurling Type | Straight, Diagonal, or Custom | Controlled depth | — |

| Plating/Coating | — | Optional: Ni, Zn, PTFE | — |

| Application Environment | High-temp, high-vibration, corrosive | Designed for stability | — |

At Wuxi Lead Precision Machinery, we combine decades of metallurgical expertise with advanced CNC manufacturing to deliver threaded inserts that perform under the most demanding conditions. Precision isn’t just part of our process—it’s the foundation of our reputation.

Precision Specs & Tolerances

Technical Capabilities: Precision Threaded Inserts for Plastic Molding

Wuxi Lead Precision Machinery delivers mission-critical threaded inserts engineered specifically for high-performance plastic injection molding applications. Our core competency lies in transforming complex metal insert designs into flawless production realities, ensuring seamless integration into demanding polymer assemblies across aerospace, medical, and automotive sectors. We address the fundamental challenge of insert failure—caused by dimensional inaccuracies, thread weakness, or poor material compatibility—through an integrated manufacturing and quality ecosystem centered on advanced CNC technology and rigorous metrology.

Our precision machining foundation is built upon state-of-the-art 5-axis CNC milling and turning centers. This capability is essential for producing inserts with intricate geometries, undercuts, and non-standard thread forms that 3-axis machines cannot achieve in a single setup. Eliminating secondary operations significantly reduces cumulative error, ensures superior concentricity between critical features like the outer diameter and thread axis, and guarantees consistent thread profile integrity vital for load distribution within the plastic matrix. We expertly machine a wide range of materials including stainless steels (303, 304, 316), brass, aluminum alloys, and specialty materials like titanium 6Al-4V for medical implants, adhering strictly to material certifications and traceability requirements.

Quality assurance is not a final checkpoint but an embedded process throughout production. Every batch undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMMs). These systems perform full geometric dimensioning and tolerancing (GD&T) verification, measuring critical features such as thread pitch diameter, major/minor diameters, positional tolerances of locating features, and surface finishes to micron-level accuracy. This data-driven approach provides objective evidence of conformance and enables immediate process correction, ensuring every insert meets the stringent demands of high-cycle molding and long-term part reliability.

The following table details our standard and achievable tolerance capabilities for critical insert features, reflecting our commitment to precision:

| Feature | Standard Tolerance | Tight Tolerance Capability | Typical Application Context |

|---|---|---|---|

| Outer Diameter (OD) | ±0.025 mm | ±0.005 mm | Precision press-fit into mold cavities |

| Inner Diameter (ID) | ±0.025 mm | ±0.005 mm | Thread root diameter control |

| Thread Pitch Diameter | ±0.025 mm | ±0.005 mm | Critical for thread strength & engagement |

| Thread Major Diameter | ±0.025 mm | ±0.010 mm | External thread fit specification |

| Positional Tolerance | ±0.050 mm | ±0.010 mm | Alignment of locating features |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Optimizing plastic adhesion |

This level of dimensional control directly translates to reduced molding defects, enhanced pull-out strength, and extended mold life. Partner with Wuxi Lead Precision Machinery for threaded inserts where absolute precision, material integrity, and unwavering consistency are non-negotiable requirements for your plastic component’s success. Our engineering team collaborates closely with clients from design validation through production to optimize insert performance within your specific molding process.

Material & Finish Options

Material Selection for Threaded Inserts in Plastic Molding

Selecting the appropriate material for threaded inserts used in plastic molding is critical to ensuring long-term performance, durability, and compatibility with both the molding process and the end-use environment. The most commonly used materials—aluminum, steel, and titanium—each offer distinct mechanical, thermal, and chemical properties that influence their suitability across various applications. Understanding these differences enables manufacturers to optimize insert performance while minimizing failure risks such as galling, corrosion, or thread stripping.

Aluminum is frequently chosen for its lightweight nature and excellent thermal conductivity. These characteristics make it ideal for applications where weight reduction is a priority, such as in automotive or aerospace components. However, pure aluminum lacks the tensile strength required for high-stress threaded applications. Therefore, aluminum alloys such as 6061-T6 or 7075-T6 are typically used to enhance mechanical performance. While aluminum offers good machinability and cost-efficiency, it is inherently softer than steel or titanium, making it more prone to wear under repeated assembly cycles. To mitigate this, surface treatments such as anodizing are strongly recommended.

Steel remains the most widely used material for threaded inserts due to its high strength, wear resistance, and affordability. Alloy steels and stainless steels (particularly grades 303, 304, and 17-4 PH) provide excellent balance between machinability and corrosion resistance. Carbon steel inserts are often employed in high-load applications but require protective coatings to prevent oxidation. Stainless steel variants are preferred in environments exposed to moisture or chemicals, offering inherent corrosion resistance without additional plating in many cases.

Titanium, while significantly more expensive, delivers an exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in marine or chemically aggressive environments. Grade 5 titanium (Ti-6Al-4V) is commonly used for high-performance applications in aerospace and medical devices. Its biocompatibility and non-magnetic properties further expand its utility in specialized fields. However, titanium’s low thermal conductivity and high reactivity during machining require precise process control, increasing production complexity.

Surface finishing plays a pivotal role in enhancing insert performance. Anodizing, particularly hard anodizing, is a widely adopted finish for aluminum inserts. This electrochemical process creates a thick, wear-resistant oxide layer that improves surface hardness and corrosion resistance. The anodized layer can also be sealed to further enhance durability in humid or corrosive environments. While anodizing is specific to aluminum, steel and titanium inserts benefit from alternative treatments such as passivation, electropolishing, or PVD coatings depending on application demands.

The following table summarizes key material properties and compatibility with anodizing:

| Material | Tensile Strength (MPa) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | Moderate | 167 | Yes | Automotive, consumer electronics |

| Stainless Steel 304 | 505–700 | High | 16.2 | No | Medical, food processing, marine |

| Carbon Steel | 400–550 | Low (requires coating) | 50.2 | No | Industrial equipment, machinery |

| Titanium Ti-6Al-4V | 900–1,000 | Very High | 6.7 | No | Aerospace, defense, medical implants |

Material and finish selection must be aligned with the operational environment, load requirements, and lifecycle expectations of the final product. At Wuxi Lead Precision Machinery, we support clients in evaluating these factors to deliver custom threaded inserts that ensure reliability and precision in every molding application.

Manufacturing Process & QC

Threaded Insert Production Process: Engineering Zero Defects from Concept to Volume

At Wuxi Lead Precision Machinery, threaded insert production for plastic molding demands unwavering precision across every phase. Our integrated process transforms client specifications into flawless components through rigorous engineering controls, ensuring seamless integration into high-cycle injection molds and eliminating field failures. Zero defects is not a target; it is the non-negotiable standard governing Design, Prototyping, and Mass Production.

The Design phase begins with deep material science analysis. Engineers evaluate the plastic substrate’s thermal expansion, flow characteristics, and mechanical stress points alongside the insert’s functional load requirements. Using advanced GD&T principles and mold-flow simulation data, we define critical geometries including thread pitch engagement depth, knurling patterns for retention, and undercuts for anti-rotation. Material selection—typically brass C36000, stainless steel 303/316, or specialized alloys—is validated against chemical resistance and temperature stability needs. This stage outputs fully dimensioned 3D models with tolerance stacks rigorously verified for manufacturability and assembly integrity before any metal is cut.

Prototyping transitions design into physical validation under real-world conditions. We produce functional samples via precision CNC Swiss turning or multi-axis milling, replicating final production methods. Each prototype undergoes dimensional certification using calibrated CMMs against the approved model, with critical features like thread major/minor diameters and positional tolerances measured to micron-level accuracy. Concurrently, we conduct press-fit retention tests in representative plastic coupons and torque-out validation to confirm thread strength. Client feedback on fitment within their mold cavities or assembly jigs is incorporated iteratively. Only inserts passing all functional and metrology checkpoints advance, ensuring the design is perfected before tooling commitment.

Mass Production leverages statistical process control and closed-loop automation to sustain zero defects at volume. Dedicated CNC cells with in-process gauging monitor key dimensions continuously, automatically adjusting for tool wear. Every batch undergoes 100% visual inspection for surface defects and automated thread gaging. Critical lots receive full CMM validation against the prototype baseline. Real-time SPC data tracks Cp/Cpk values for features like outer diameter concentricity and thread pitch diameter, triggering immediate process correction if trends approach tolerance limits. Final packaging includes traceable documentation—material certs, inspection reports, and process capability data—guaranteeing inserts meet the exacting demands of automotive, medical, and aerospace molding applications.

The following table summarizes critical production specifications maintained throughout this process:

| Feature | Standard Tolerance | Precision Option | Measurement Method |

|---|---|---|---|

| Outer Diameter | ±0.02 mm | ±0.005 mm | Laser Micrometer / CMM |

| Thread Pitch Diameter | 6H | 4H | Thread Plug Gauge / CMM |

| Knurling Depth | ±0.03 mm | ±0.01 mm | Optical Comparator |

| Surface Roughness | Ra 1.6 μm | Ra 0.8 μm | Profilometer |

| Concentricity | Ø 0.05 mm | Ø 0.01 mm | CMM / Dial Indicator |

This disciplined progression from validated design through failure-proofed prototyping to statistically controlled mass production ensures Wuxi Lead inserts deliver consistent performance, protecting your molding investment and end-product reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision-Engineered Threaded Inserts for Plastic Molding

When it comes to high-performance threaded inserts for plastic molding, precision, durability, and material integrity are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that meet the rigorous demands of advanced injection molding applications. Our threaded inserts are engineered to deliver superior thread strength, thermal stability, and long-term reliability in plastic components across aerospace, automotive, medical, and consumer electronics industries.

We understand that every molding application presents unique challenges—whether it’s maintaining dimensional accuracy during high-volume production, ensuring compatibility with engineering-grade resins, or integrating inserts into complex mold designs. That’s why we don’t offer off-the-shelf solutions. Instead, we collaborate closely with design engineers and manufacturing teams to develop fully customized threaded inserts tailored to your exact specifications.

Our manufacturing process combines cold forming, precision threading, and optional surface treatments to produce inserts with exceptional mechanical properties. Utilizing high-grade materials such as stainless steel, brass, and low-carbon steel, we ensure compatibility with both thermoplastics and thermosets. Whether your project requires heat-staked, ultrasonically inserted, or molded-in-place solutions, our inserts are designed for seamless integration and maximum holding strength.

What sets Wuxi Lead apart is our end-to-end engineering support. From initial concept and 3D modeling to prototyping and full-scale production, we maintain tight tolerances—down to ±0.01 mm—and adhere to international quality standards, including ISO 9001. Our in-house tooling and CNC machining capabilities allow rapid iteration and fast time-to-market, critical for OEMs operating under tight development cycles.

We also recognize that performance data is essential for validation. Below are the standard technical specifications for our most commonly requested threaded inserts. All parameters can be modified based on customer requirements, including thread type, length, outer diameter, underhead geometry, and plating.

| Specification | Standard Option | Customizable Range |

|---|---|---|

| Material | Stainless Steel 304/316, Brass, C1018 | Any machinable metal alloy |

| Thread Type | M2 to M12, UNC, UNF, Metric | Custom threads, left-hand options |

| Outer Diameter | 3.0 mm – 15.0 mm | 2.0 mm – 20.0 mm |

| Insert Length | 4.0 mm – 25.0 mm | 3.0 mm – 30.0 mm |

| Tolerance | ±0.01 mm | Up to ±0.005 mm (precision grade) |

| Surface Treatment | Plain, Zinc Plated, Ni-Plated | PTFE coating, Passivation |

| Installation Method | Heat Staking, Ultrasonic, Mold-in | Design-specific configurations |

| Minimum Order Quantity | 1,000 pcs | Prototype to mass production |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to innovation, quality, and responsive service. We don’t just supply components—we deliver engineered solutions that enhance the performance and reliability of your plastic assemblies.

For technical consultation or to request a quote, contact us today at [email protected]. Let our team help you integrate high-performance threaded inserts into your next generation of molded products.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.