Technical Contents

Engineering Guide: Metal Cnc Service

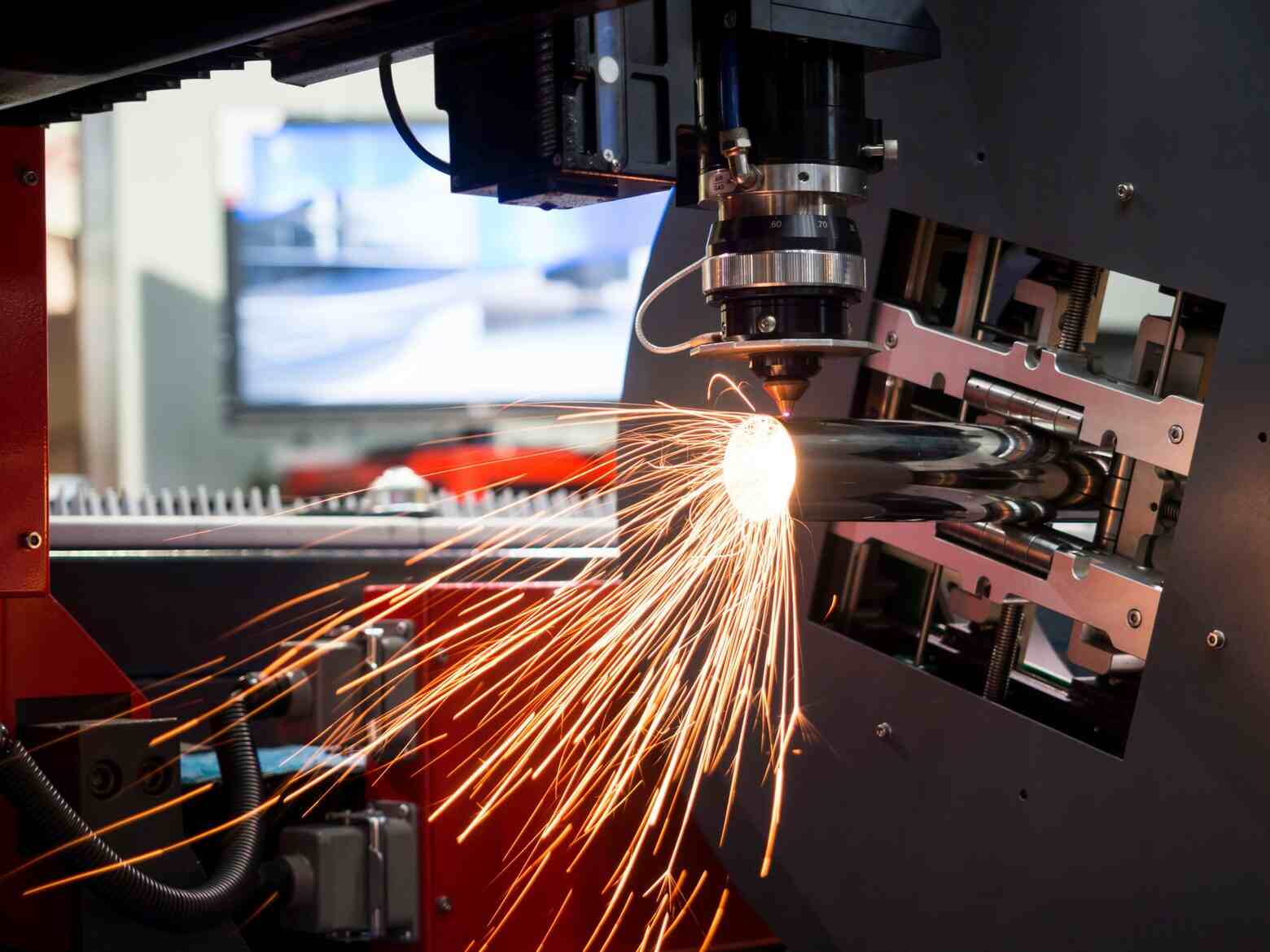

Engineering Insight: The Critical Role of Precision in Metal CNC Services

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, functionality, and innovation are built. In high-stakes industries such as aerospace, defense, medical technology, and high-performance automation, even micron-level deviations can lead to catastrophic system failures or costly rework. At Wuxi Lead Precision Machinery, we understand that precision in metal CNC services transcends technical capability; it embodies engineering discipline, process control, and unwavering commitment to quality.

Precision machining involves the removal of material from metal stock using computer-controlled tools to achieve exact geometries, tight tolerances, and superior surface finishes. The ability to consistently produce parts within ±0.005 mm tolerance is not accidental—it results from advanced 3-, 4-, and 5-axis CNC systems, rigorous calibration protocols, and a deeply ingrained culture of continuous improvement. At Lead Precision, our engineering team leverages over 15 years of experience in high-accuracy manufacturing to deliver components that meet the most stringent international standards.

Our proven track record includes mission-critical projects for Olympic-standard sporting equipment and certified military-grade components. These applications demand not only dimensional accuracy but also material integrity, repeatability, and full traceability. For instance, components used in precision timing systems for Olympic events require thermal stability and near-zero tolerance variation under dynamic conditions. Similarly, military applications often involve complex geometries in hardened alloys, where failure is not an option. Our success in these domains underscores our technical mastery and our ability to meet extreme performance requirements.

Beyond equipment and software, true precision is achieved through an integrated approach—material selection, toolpath optimization, in-process inspection, and post-machining validation using coordinate measuring machines (CMM) and optical profilometers. Every stage of production is monitored and documented, ensuring full compliance with ISO 9001 and other relevant quality management systems.

The following table outlines key capabilities of our metal CNC service platform:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 600 mm |

| Typical Surface Finish | Ra 0.8 μm (polished to Ra 0.2 μm) |

| Standard Tolerances | ±0.005 mm (tight tolerances to ±0.001 mm achievable) |

| Materials Processed | Aluminum alloys, stainless steel, titanium, Inconel, brass, tool steels |

| Quality Certification | ISO 9001:2015, Full First Article Inspection (FAI) reporting |

At Wuxi Lead Precision Machinery, precision is not just a specification—it is our standard of excellence. By combining cutting-edge technology with deep engineering insight, we enable global partners to achieve breakthrough performance in their most demanding applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers advanced metal CNC services engineered to meet the stringent requirements of aerospace, medical, energy, and high-tech industrial sectors. Our core strength lies in integrating cutting-edge multi-axis machining with rigorous, traceable quality control, ensuring components perform reliably in the most critical applications. Central to our process is a modern fleet of 5-axis CNC machining centers, featuring simultaneous 5-axis interpolation capabilities. This technology enables the precise fabrication of complex geometries—such as organic contours, deep cavities, and intricate undercuts—in a single setup. The elimination of multiple fixturing stages significantly reduces cumulative error potential, enhances positional accuracy between features, and accelerates lead times while maintaining exceptional surface integrity across diverse materials including titanium grade 5, Inconel 718, aluminum 7075-T6, and hardened tool steels.

Achieving micron-level precision demands more than advanced machinery; it requires an uncompromising quality assurance framework. Every critical dimension and geometric feature undergoes verification using state-of-the-art Coordinate Measuring Machines (CMMs). Our CMM inspection protocols, compliant with ISO 10360 standards, provide full first-article inspection reports (FAIR) and comprehensive dimensional validation against ASME Y14.5 GD&T specifications. This metrology backbone ensures absolute traceability from raw material to finished component, providing clients with documented confidence in part conformance. Our quality management system is ISO 9001:2015 certified, with processes rigorously designed to prevent defects rather than merely detect them.

The achievable precision across our production spectrum is defined by material properties, part geometry, and feature complexity. The following table outlines our standard tolerance capabilities under controlled production conditions:

| Material Category | Standard Dimensional Tolerance | Geometric Tolerance (GD&T) | Typical Surface Finish (Ra) |

|---|---|---|---|

| Aluminum Alloys | ±0.010 mm | ±0.015 mm | 0.8 – 1.6 µm |

| Stainless Steels | ±0.008 mm | ±0.012 mm | 0.4 – 0.8 µm |

| Titanium Alloys | ±0.008 mm | ±0.012 mm | 0.4 – 1.6 µm |

| High-Temperature Alloys | ±0.010 mm | ±0.015 mm | 0.8 – 3.2 µm |

| Engineering Plastics | ±0.025 mm | ±0.050 mm | 1.6 – 6.3 µm |

These specifications represent our standard production capability; tighter tolerances down to ±0.002 mm are achievable for critical features through optimized process planning and dedicated metrology. Our engineering team collaborates closely with clients during the Design for Manufacturability (DFM) phase to identify opportunities for enhancing precision, reducing cost, and ensuring robust manufacturability. By combining 5-axis flexibility, in-house CMM validation, and deep process expertise, Wuxi Lead transforms complex engineering concepts into precision metal components that consistently exceed operational expectations. This integrated capability forms the foundation of our commitment to delivering zero-defect manufacturing outcomes.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC services tailored to industrial and engineering demands. Our expertise spans a range of high-performance materials, including aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific operational environments.

Aluminum is widely favored in aerospace, automotive, and electronics applications due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. The 6061 and 7075 alloys are particularly common, with 6061 offering good weldability and machinability, while 7075 delivers higher strength for structural components under stress. Aluminum’s lightweight nature reduces inertia in moving parts and lowers transportation costs in end-use applications.

Steel, particularly in its stainless (304, 316) and alloy (4140, 4340) forms, provides superior strength, wear resistance, and thermal stability. Stainless steels are ideal for medical devices, food processing, and marine environments due to their outstanding corrosion resistance and cleanability. Alloy steels are often selected for high-stress mechanical systems such as gears, shafts, and tooling, where toughness and fatigue resistance are paramount.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments such as aerospace, defense, and biomedical implants. It offers an exceptional strength-to-density ratio, performs reliably at elevated temperatures, and resists corrosion in saline and acidic conditions. While more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s long-term performance justifies its use in mission-critical applications.

Surface finishing further enhances material performance. Anodizing is a widely used electrochemical process for aluminum, creating a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) anodizing is standard for industrial parts, while Type III (hardcoat anodizing) provides increased thickness and wear resistance for high-abrasion environments. Proper masking and post-treatment sealing ensure dimensional accuracy and long-term integrity.

Below is a comparative overview of key material properties relevant to CNC machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Key Applications |

|---|---|---|---|---|

| Aluminum | 180–570 | 2.7 | 6061, 7075 | Aerospace, Electronics, Automotive |

| Stainless Steel | 505–965 | 7.9 | 304, 316 | Medical, Food Processing, Marine |

| Alloy Steel | 655–1200 | 7.85 | 4140, 4340 | Industrial Machinery, Tooling |

| Titanium | 900–1170 | 4.5 | Ti-6Al-4V (Grade 5) | Aerospace, Defense, Biomedical |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish based on functional requirements, environmental exposure, and production volume. Our CNC machining capabilities ensure tight tolerances and repeatability, regardless of material complexity.

Manufacturing Process & QC

Precision Metal CNC Service: The Zero Defect Production Process

At Wuxi Lead Precision Machinery, our metal CNC service delivers uncompromising quality through a rigorously controlled production sequence. We integrate engineering excellence with systematic process validation from initial concept to final shipment, ensuring every component meets exacting specifications and achieves true zero defects. This disciplined approach is fundamental to serving demanding industries like aerospace, medical device manufacturing, and advanced automation where failure is not an option.

The process begins with collaborative design refinement. Our engineering team conducts in-depth Design for Manufacturability (DFM) analysis, identifying potential production challenges early. We utilize advanced CAD/CAM simulation software to validate toolpaths, prevent collisions, and optimize machining strategies virtually. This phase ensures the design is not only functional but inherently manufacturable to micron-level tolerances, eliminating costly iterations later. Material selection is critically assessed against application requirements for strength, thermal stability, and corrosion resistance.

Prototyping is a non-negotiable validation step, not merely a sample run. We produce initial units using the exact production-grade CNC equipment, tooling, and materials intended for full-scale manufacturing. Each prototype undergoes comprehensive metrology: CMM inspection, surface roughness testing, and critical feature verification against the original CAD model. Dimensional reports and material certifications are provided. This stage confirms process capability, validates the DFM outcomes, and secures formal client sign-off before committing to mass production, mitigating risk significantly.

Mass production executes under our Zero Defect Management System. Every CNC machine operates with real-time process monitoring; tool wear is tracked via sensor data and automated offset adjustments. Statistical Process Control (SPC) charts monitor critical dimensions on a per-batch basis, triggering immediate corrective action if trends approach tolerance limits. In-process inspections occur at defined stages, not just at the end. Final inspection is exhaustive, exceeding standard AQL levels, with 100% critical feature verification for high-risk components. Full material traceability and documented inspection records accompany every shipment. Our AS9100 and ISO 13485 certified quality management system underpins every action, ensuring consistent output meeting the strictest global standards.

Critical process parameters are maintained within tightly controlled ranges throughout production. The table below outlines key capabilities ensuring defect prevention:

| Parameter | Capability Range | Control Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.005 mm | Real-time SPC, CMM validation |

| Surface Roughness (Ra) | 0.4 µm to 3.2 µm | Profilometer checks, process audit |

| Materials | Aluminum, Stainless Steel, Titanium, Inconel, Brass | Certified material certs, PMI testing |

| Critical Feature Inspection | 100% verification | Automated optical, CMM, manual gauging |

| Process Monitoring | Continuous | Machine sensors, operator logs, SPC |

This integrated Design-Prototyping-Mass Production workflow, governed by relentless process discipline and advanced metrology, is how Wuxi Lead achieves demonstrable zero defects. We transform complex metal part requirements into flawless, reliable components, providing our global clients with absolute manufacturing confidence and reducing their total cost of quality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

When your manufacturing demands require precision, reliability, and technical mastery, partnering with Wuxi Lead Precision Machinery is the strategic advantage you need. As a leading provider of high-end metal CNC services in China, we specialize in delivering complex, high-tolerance components for industries where performance is non-negotiable. From aerospace and medical devices to automotive and industrial automation, our CNC machining solutions are engineered to exceed expectations.

At Lead Precision, we understand that your success depends on more than just parts—it depends on precision engineering, on-time delivery, and a partner who anticipates your challenges. Our facility in Wuxi is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, supported by state-of-the-art metrology and quality assurance systems. Every component we produce is subject to rigorous inspection protocols, ensuring dimensional accuracy down to ±0.002 mm. With full in-house capabilities including CNC turning, milling, grinding, and secondary operations, we streamline your supply chain and reduce lead times without compromising quality.

Our engineering team works closely with clients from concept through production, offering Design for Manufacturability (DFM) analysis, rapid prototyping, and scalable production runs. Whether you require a single prototype or high-volume manufacturing, we adapt to your timeline and specifications with unmatched responsiveness. Materials we routinely machine include aluminum alloys, stainless steel, titanium, brass, and high-performance engineering plastics, all sourced to meet international standards.

We are committed to transparency, traceability, and continuous improvement. Our ISO 9001:2015 certification reflects our adherence to global quality benchmarks, while our digital project management system ensures real-time visibility into every order. When you partner with us, you gain more than a supplier—you gain a precision engineering ally invested in your product’s success.

Below are key technical capabilities that define our metal CNC service:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning; multi-axis Swiss machining |

| Tolerance | ±0.002 mm (standard), tighter upon request |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, Copper, Inconel, PEEK |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), custom setups available |

| Surface Finish | As-machined, anodizing, powder coating, passivation, polishing (Ra 0.4 μm standard) |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP, CMM reporting |

| Lead Time | Prototypes: 5–7 days; Production: 10–20 days (varies by complexity) |

Your next breakthrough component starts with the right manufacturing partner. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual tour of our facility. Let Wuxi Lead Precision Machinery bring your precision designs to life—on time, to spec, and with engineering integrity.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.