Technical Contents

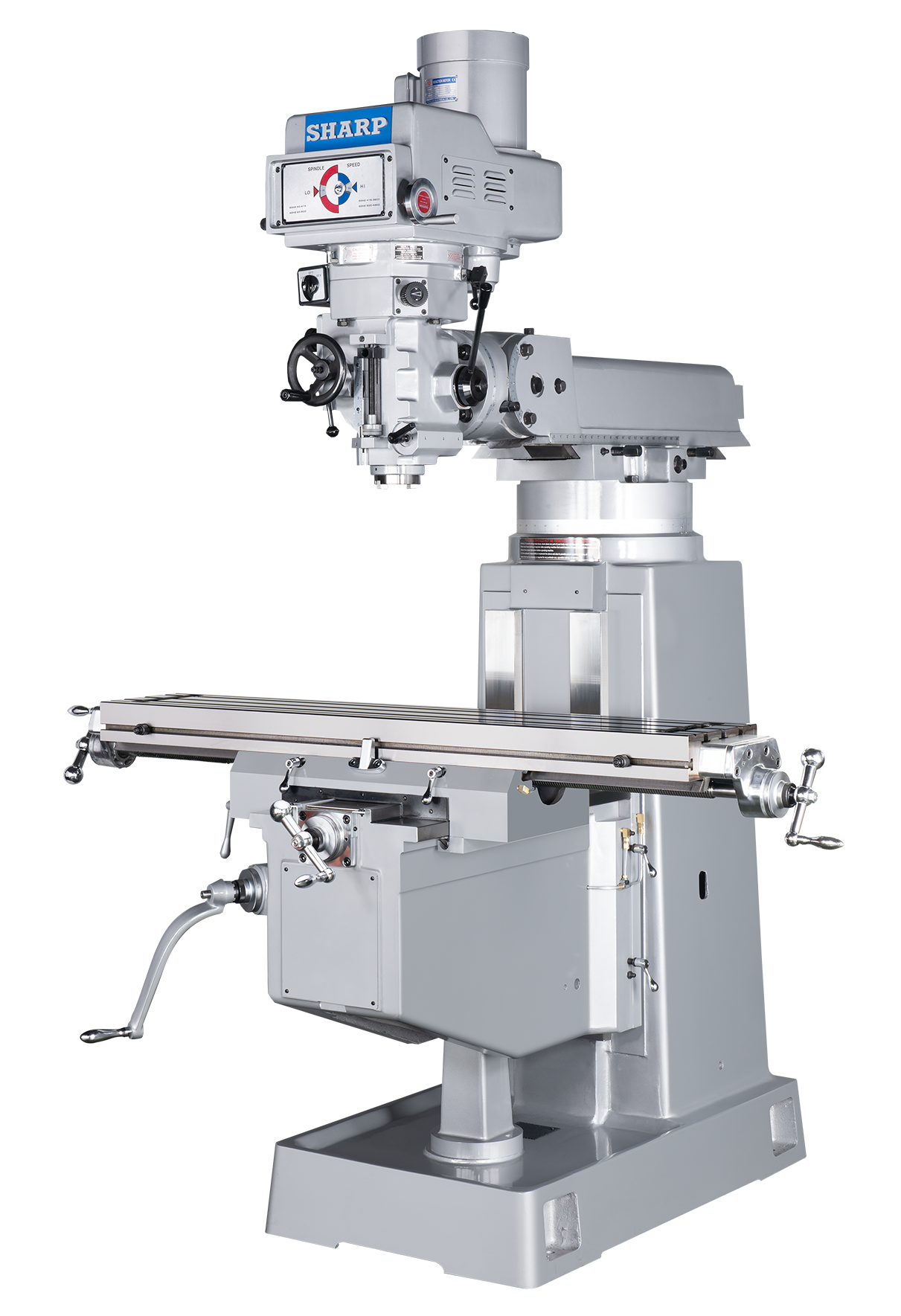

Engineering Guide: Sharp Mill Parts

Engineering Insight: The Critical Role of Precision in Sharp Mill Parts

In high-performance manufacturing, the term “sharp mill parts” refers to components produced through precision milling operations that demand exacting tolerances, superior surface finishes, and consistent repeatability. These parts are often mission-critical, serving in aerospace, defense, medical, and advanced industrial systems where failure is not an option. At Wuxi Lead Precision Machinery, we understand that the difference between functional reliability and system failure often lies in microns. Our engineering philosophy centers on achieving and sustaining precision at every stage of production, from material selection to final inspection.

Precision in sharp mill parts is not merely a quality metric—it is a foundational requirement. As machining processes push the limits of speed, feed rate, and tool engagement, maintaining dimensional accuracy becomes exponentially more challenging. Thermal expansion, tool wear, and material inconsistencies can all introduce deviations that compromise part performance. At Lead Precision, we counter these variables with advanced CNC milling centers equipped with real-time monitoring, temperature compensation, and closed-loop feedback systems. Our facility utilizes 5-axis simultaneous milling, high-speed spindles, and in-process probing to ensure that each component meets or exceeds design specifications.

Our expertise is not theoretical. Over the past decade, Wuxi Lead has delivered precision-milled components for projects demanding the highest levels of reliability, including support systems for Olympic-grade timing equipment and subsystems used in military-grade communication devices. These applications require not only compliance with international standards such as ISO 2768 and AS9100 but also rigorous traceability, material certification, and first-article inspection reports. Our quality management system is built to meet these demands, with full CMM inspection, 3D scanning, and metallurgical analysis capabilities in-house.

Material selection further underscores the importance of precision. Whether working with aerospace-grade aluminum alloys, titanium, stainless steel, or exotic superalloys, our engineering team evaluates thermal stability, machinability, and end-use environmental conditions to ensure optimal performance. Even minor deviations in grain structure or residual stress can lead to part distortion under load—something we proactively mitigate through controlled stress-relief cycles and adaptive machining strategies.

The table below outlines typical specifications achievable for sharp mill parts at Wuxi Lead Precision Machinery:

| Specification | Capability |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.012 mm |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm |

| Maximum Part Size | 1200 mm × 800 mm × 600 mm |

| Minimum Feature Size | 0.3 mm radius / 0.5 mm slot |

| Materials | Aluminum 7075-T6, Titanium Grade 5, Stainless Steel 316L, Inconel 718, Brass C3604 |

| Machining Axes | 3-axis, 4-axis, 5-axis simultaneous |

| Quality Standards | ISO 9001, ISO 13485, AS9100D, RoHS compliant |

At Wuxi Lead Precision Machinery, precision is not just a capability—it is our commitment. When industries that demand perfection choose their manufacturing partner, they choose experience, technology, and unwavering attention to detail. We continue to set the benchmark in sharp mill parts manufacturing, delivering components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

At Wuxi Lead Precision Machinery, our technical foundation is engineered to transform complex “sharp mill parts” concepts into reality with uncompromising accuracy. We specialize in high-mix, low-volume custom metal manufacturing where geometric intricacy, material diversity, and micron-level tolerances are non-negotiable. Our integrated facility leverages advanced 5-axis CNC machining centers as the cornerstone of production, enabling single-setup machining of prismatic, organic, and deeply contoured components. This eliminates cumulative error from multiple fixtures, ensuring critical feature relationships—such as intersecting radii, compound angles, and thin-walled geometries—are held to specification without manual intervention. We routinely process aerospace-grade titanium, medical stainless steels, high-temp alloys, and engineered composites on our Haas UMC-750 and DMG MORI CTX beta 1250 platforms, equipped with high-resolution probing systems for in-process verification and adaptive material removal strategies.

Quality control is not a final checkpoint but a continuous thread woven into every manufacturing phase. Our dedicated metrology lab houses Zeiss CONTURA G2 and Hexagon GLOBAL S 1210 CMMs, calibrated to ISO 17025 standards. Each component undergoes full-feature inspection against CAD models, with real-time SPC data analysis tracking dimensional stability across batches. This proactive approach identifies process drift before non-conformities occur, guaranteeing that surface finishes down to Ra 0.4 µm and critical positional tolerances are consistently achieved. Comprehensive inspection reports—including 3D deviation maps and GD&T analysis—are provided with every shipment, offering full traceability for regulated industries.

The table below details our standard capability envelope for machined features. These tolerances represent achievable targets under controlled thermal conditions (20°C ±0.5°C) using optimized toolpaths and in-process gauging; tighter specifications are attainable for mission-critical applications through specialized process validation.

| Feature Type | Standard Tolerance | Critical Feature Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.02 mm | ±0.005 mm | CMM / Air Gaging |

| Geometric Position | ±0.03 mm | ±0.01 mm | CMM (GD&T Analysis) |

| Surface Profile | ±0.05 mm | ±0.02 mm | CMM / Optical Comparator |

| Hole Concentricity | 0.03 mm | 0.01 mm | CMM / Precision Mandrel |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Profilometer |

This capability suite directly addresses the root challenges in high-end mill part production: eliminating assembly scrap due to mismatched interfaces, ensuring fluid dynamics in turbine components, and meeting biocompatibility requirements for implantable devices. By combining 5-axis agility with closed-loop quality assurance, Wuxi Lead delivers parts that perform exactly as engineered—reducing client validation cycles and accelerating time-to-market. Our commitment extends beyond machining; we collaborate during DFM reviews to optimize manufacturability without sacrificing design intent, ensuring your “sharp mill parts” achieve peak functional performance in the most demanding operational environments.

Material & Finish Options

Material selection is a critical step in the design and production of high-performance sharp mill parts, directly influencing durability, precision, and operational efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for demanding industrial applications, where the right combination of base material and surface treatment ensures optimal performance under stress, heat, and corrosion. The three most widely used materials for precision-machined components—aluminum, steel, and titanium—each offer distinct mechanical and chemical properties tailored to specific functional requirements.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. It is particularly suitable for aerospace, automotive, and electronics applications where weight reduction is essential without sacrificing structural integrity. The most common grades used in milling operations are 6061 and 7075, with the latter offering higher tensile strength for more demanding environments. However, aluminum’s lower hardness compared to steel makes it more susceptible to wear, necessitating protective finishes such as anodizing.

Steel, particularly alloy and stainless variants, delivers superior strength, hardness, and wear resistance. Materials like 4140 alloy steel and 304/316 stainless steel are routinely selected for tooling, machinery components, and high-load applications. Stainless steel further provides excellent corrosion resistance, making it ideal for medical, food processing, and marine environments. While steel is more challenging to machine than aluminum due to higher tool wear and cutting forces, our advanced CNC systems ensure tight tolerances and smooth surface finishes.

Titanium stands at the premium end of material performance, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion and high temperatures. Grade 5 (Ti-6Al-4V) is the most commonly machined titanium alloy, widely used in aerospace, defense, and medical implant manufacturing. Despite its high cost and difficult machinability—requiring specialized tooling and slower feed rates—titanium’s performance in extreme conditions justifies its use in mission-critical components.

Surface finishing, particularly anodizing, plays a vital role in enhancing the functional lifespan of aluminum mill parts. Anodizing creates a durable, corrosion-resistant oxide layer that can also be dyed for identification or aesthetic purposes. Type II (sulfuric acid) anodizing is standard for general protection, while Type III (hardcoat anodizing) provides increased thickness and wear resistance for industrial use. It is important to note that anodizing is not applicable to steel or titanium in the same manner, though these materials may receive alternative treatments such as passivation or nitriding.

The following table summarizes key mechanical and finishing properties of the primary materials used in sharp mill part production.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Suitable Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310 (7075) | 2.8 | 6061, 7075 | Anodizing (Type II/III) | Aerospace, Electronics, Automotive |

| Steel | 655 (4140) | 7.85 | 4140, 304, 316 | Passivation, Plating | Tooling, Industrial Machinery |

| Titanium | 900 (Ti-6Al-4V) | 4.43 | Gr2, Gr5 (Ti-6Al-4V) | Passivation, Coating | Aerospace, Medical, Defense |

Selecting the appropriate material and finish requires a thorough understanding of the operating environment, load conditions, and lifecycle expectations. At Wuxi Lead Precision Machinery, we work closely with engineering teams to ensure every sharp mill part meets both design intent and real-world performance demands.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for sharp mill parts integrates engineering rigor with advanced CNC capabilities to eliminate defects before they occur. We treat every project as a closed-loop system where design validation, prototyping fidelity, and production control converge to guarantee perfection. This methodology ensures your critical components meet aerospace, medical, and semiconductor tolerances without compromise.

The journey begins with collaborative design engineering. Our team conducts in-depth Design for Manufacturability (DFM) analysis on your CAD models, identifying potential stress points, tool access limitations, and material behavior under high-speed milling. We simulate chip evacuation, thermal deformation, and toolpath dynamics using Siemens NX CAM software to preempt micro-vibrations that cause edge chipping. Only after mutual sign-off on the optimized digital twin do we proceed—ensuring the physical part will mirror the virtual intent.

Prototyping is not a separate phase but a stress test of the production system. We machine prototypes on the same DMG MORI and Makino 5-axis platforms designated for your final run, using identical tooling, coolant parameters, and workholding. Each prototype undergoes full CMM inspection against your GD&T callouts, with surface roughness verified via profilometry. If Ra 0.4μm is specified, we measure it—not estimate it. This step validates that the process—not just the part—is capable. Revisions focus on refining machine programs and fixturing, never on compromising tolerances.

Mass production operates under our Zero Defects Framework. Every batch runs with real-time SPC monitoring: laser micrometers track critical diameters, acoustic emission sensors detect tool wear at 0.0005mm degradation, and in-process probes verify feature alignment after each operation. We implement First Article Inspection (FAI) per AS9102 standards and maintain full material traceability from raw bar stock to finished part. Crucially, our operators are trained to halt production at the first statistical anomaly—not after 100 flawed pieces.

This relentless focus yields measurable outcomes. Below are the performance specifications we consistently achieve for sharp mill parts:

| Specification | Capability | Verification Method |

|---|---|---|

| Positional Tolerance | ±0.001mm | Zeiss CONTURA CMM |

| Surface Roughness | Ra 0.2μm – 0.8μm | Mitutoyo SJ-410 Profilometer |

| Edge Integrity | Burr-free (ISO 13715) | Optical Comparator 200x |

| Process Capability | Cpk ≥ 1.67 | SPC Control Charts |

| Material Traceability | Full lot-to-part record | ERP Digital Log |

Zero defects is non-negotiable because your application likely powers life-critical systems. We engineer out failure points at the design stage, prove process stability through production-intent prototyping, and enforce discipline via statistical control. When your sharp mill part leaves Wuxi Lead, it carries not just a certificate of conformance—but the certainty of engineered perfection.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Sharp Mill Parts Manufacturing

When precision, reliability, and performance define your product requirements, partnering with Wuxi Lead Precision Machinery ensures your sharp mill parts are manufactured to the highest global standards. As a leading custom metal manufacturing provider based in Wuxi, China, we specialize in delivering complex, high-tolerance components for industries where failure is not an option—ranging from aerospace and medical devices to semiconductor equipment and advanced automation.

Our engineering team combines decades of CNC machining experience with state-of-the-art 5-axis milling, turning, and grinding technologies to produce sharp mill parts with exceptional edge definition, surface finish, and dimensional accuracy. Whether you require single prototypes or high-volume production runs, our flexible manufacturing systems adapt to your project’s scale and timeline without compromising quality.

At Lead Precision, we understand that sharp mill parts are not just components—they are critical elements in your final assembly. That’s why every part we produce undergoes rigorous in-process inspections and final quality verification using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Our ISO 9001:2015 certification reflects our commitment to consistent, auditable quality across every production phase.

We work with a broad range of materials, including hardened steels, stainless alloys, titanium, aluminum, and engineered composites, ensuring your parts meet both mechanical and environmental demands. Our design-for-manufacturability (DFM) review process helps optimize your components for performance, cost-efficiency, and faster lead times—giving you a competitive edge in your market.

Below are key technical capabilities that define our sharp mill parts production:

| Specification | Capability |

|---|---|

| Tolerance | ±0.001 mm (±0.00004 in) |

| Surface Finish | As fine as Ra 0.2 µm (8 µin) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Materials | Steel, Stainless Steel, Aluminum, Titanium, Brass, PEEK, Delrin |

| Machining Processes | 5-Axis Milling, CNC Turning, Micro-Machining, Surface & ID Grinding |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), PPAP Level 3 Available |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Your success is our priority. From initial design consultation to final delivery, we provide full transparency, responsive communication, and on-time performance. Our global logistics network ensures seamless delivery to North America, Europe, and Asia with customs documentation handled efficiently.

Don’t settle for compromises in precision or service. Contact us today at [email protected] to discuss your sharp mill parts requirements. Let Wuxi Lead Precision Machinery be your trusted manufacturing partner—where engineering excellence meets industrial reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.