Technical Contents

Engineering Guide: Mga Parts For Sale

Engineering Insight: The Critical Role of Precision in MGA Parts for Sale

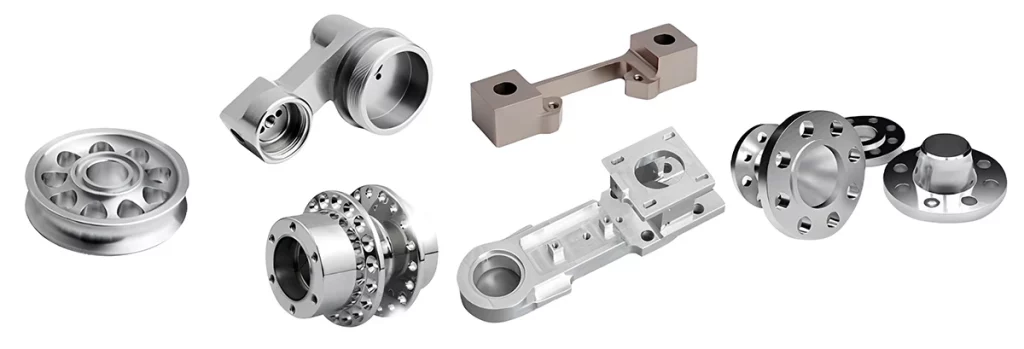

In the realm of custom metal manufacturing, MGA parts for sale are more than components—they are engineered solutions designed to meet exacting performance standards. MGA, or Machined, Ground, and Assembled parts, represent a tier of precision that transcends conventional machining. These parts undergo a sequence of tightly controlled processes: precision CNC machining to achieve initial geometry, surface and cylindrical grinding for micron-level dimensional accuracy, and final assembly with calibrated fitment. The result is a component capable of operating reliably under high stress, thermal variation, and dynamic loads—common in aerospace, defense, and high-performance industrial systems.

At Wuxi Lead Precision Machinery, we understand that precision is not an outcome but a discipline. With over 15 years of specialization in high-tolerance manufacturing, our facility has delivered MGA components for mission-critical applications, including systems used in Olympic-grade timing equipment and military-grade actuation modules. These projects demanded tolerances within ±0.001 mm and surface finishes below Ra 0.4 µm—benchmarks that reflect our commitment to engineering excellence.

The importance of precision in MGA parts cannot be overstated. Even minor deviations in dimensional accuracy or surface integrity can lead to premature wear, misalignment, or catastrophic failure in high-cycle environments. For instance, in servo-driven motion systems, a ground shaft with inconsistent roundness can introduce vibration, reducing system lifespan and accuracy. Similarly, in hydraulic manifolds, improperly machined sealing surfaces compromise pressure integrity, leading to leaks and performance degradation.

Our approach integrates advanced metrology with process control. Every MGA component passes through a multi-stage inspection protocol using coordinate measuring machines (CMM), roundness testers, and surface profilometers. We maintain ISO 9001 and IATF 16949 certifications, ensuring that our processes align with global quality standards. Additionally, our engineers collaborate directly with clients during the design-for-manufacturability (DFM) phase, optimizing geometries for both performance and producibility.

Material selection further defines the performance envelope of MGA parts. We routinely work with hardened steels (e.g., 17-4 PH, 440C), titanium alloys, and high-strength aluminum grades, each processed with tailored heat treatment and grinding strategies to preserve material integrity while achieving target tolerances.

The following table outlines typical specifications achievable for MGA components at Wuxi Lead Precision Machinery:

| Specification | Typical Range | High-Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.001 mm |

| Surface Finish (Ra) | 0.8 µm | < 0.4 µm |

| Roundness | 2 µm | 0.5 µm |

| Flatness | 3 µm | 1 µm |

| Material Hardness Range | Up to HRC 60 | Machining post-heat treatment |

| Maximum Part Weight | 150 kg | Custom fixturing available |

Precision in MGA parts is not a luxury—it is a necessity for systems where failure is not an option. At Wuxi Lead Precision Machinery, our experience in delivering components for elite engineering applications underscores our capability to meet and exceed the most demanding requirements. When sourcing MGA parts for sale, buyers must prioritize not only cost but proven technical mastery, process rigor, and a track record in high-stakes industries.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy for mission-critical MGA (Machined Geometrical Assembly) components through integrated advanced manufacturing and metrology systems. Our core strength lies in mastering complex geometries inherent in aerospace, medical, and energy sector components where conventional machining fails. Central to this capability is our fleet of 22 state-of-the-art 5-axis CNC machining centers, including DMG MORI CTX beta 1250 and MAZAK INTEGREX i-200S models. These systems enable simultaneous multi-surface machining with a single setup, eliminating cumulative error from repositioning and achieving intricate contours, deep cavities, and undercuts impossible with 3-axis technology. Material versatility spans aerospace-grade titanium alloys (Ti-6Al-4V), high-strength stainless steels (17-4PH, 316L), aluminum alloys (7075-T6), and exotic superalloys (Inconel 718), processed with optimized parameters for thermal stability and surface integrity.

Rigorous quality control is non-negotiable. Every critical feature undergoes 100% verification using calibrated Zeiss CONTURA and Hexagon GLOBAL S-Class Coordinate Measuring Machines (CMMs). Our AS9100D-certified inspection protocol includes first-article inspection (FAI) per AS9102 standards, in-process checks at defined milestones, and full final inspection with comprehensive GD&T validation. Advanced metrology software (PC-DMIS) generates detailed reports with traceable NIST-certified measurements, ensuring full dimensional compliance and process capability (Cp/Cpk ≥ 1.67). Statistical process control (SPC) data is actively monitored to preempt deviations, guaranteeing batch consistency and reducing scrap rates below 0.25%.

Our commitment to micron-level precision is quantified in the achievable tolerances below, validated across production runs and material types. These specifications reflect our standard production capability; tighter tolerances are attainable with specialized processes upon engineering review.

| Material Category | Dimension Range | Standard Tolerance (ISO 2768-mK) | Tight Tolerance Capability |

|---|---|---|---|

| Aluminum Alloys | ≤ 500 mm | ±0.05 mm | ±0.005 mm |

| Stainless Steel | ≤ 600 mm | ±0.08 mm | ±0.010 mm |

| Titanium Alloys | ≤ 400 mm | ±0.06 mm | ±0.008 mm |

| Exotic Superalloys | ≤ 300 mm | ±0.10 mm | ±0.012 mm |

This technical foundation translates directly into client value: reduced assembly time through perfect part fit, elimination of secondary operations, and certified reliability in extreme operational environments. We partner with engineering teams from DFM analysis through serial production, ensuring your MGA components meet not just specifications, but the functional demands of the most challenging applications. Wuxi Lead’s precision is engineered into every spindle rotation and verified by every probe touch—delivering confidence where failure is not an option.

Material & Finish Options

Material Selection for High-Performance MGA Components

Selecting the appropriate material is critical in custom metal manufacturing, particularly for mission-critical MGA (Mechanical, Guidance, and Actuation) components used in aerospace, automation, and precision instrumentation. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity parts from aluminum, steel, and titanium—each offering distinct mechanical, thermal, and environmental performance characteristics. Understanding these differences ensures optimal component longevity, reliability, and cost-efficiency.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications requiring lightweight structures without sacrificing rigidity, such as drone frames, optical mounts, and robotic arms. The most commonly used grades are 6061-T6 and 7075-T6, with the latter offering higher tensile strength suitable for demanding environments. Aluminum’s natural oxide layer provides baseline protection, but when enhanced with anodizing, it achieves superior surface hardness and wear resistance.

Steel, particularly alloy and stainless variants like 4140, 17-4PH, and 304/316, delivers exceptional strength, durability, and thermal stability. These properties make steel the preferred choice for high-load bearing components, actuator housings, and structural supports exposed to extreme mechanical stress. While heavier than aluminum, steel’s fatigue resistance and dimensional stability under load are unmatched. Passivation and electroplating are common finishing options, though we also offer precision polishing and black oxide treatments based on application requirements.

Titanium, specifically Grade 5 (Ti-6Al-4V), combines the best attributes of both materials—high strength, low density, and outstanding corrosion resistance—even in extreme temperatures and corrosive environments. It is the material of choice for aerospace actuators, medical robotics, and deep-sea instrumentation. Though more challenging to machine due to its low thermal conductivity and tendency to gall, our advanced CNC processes ensure tight tolerances and excellent surface integrity.

Anodizing is a key surface treatment for aluminum components, enhancing durability and performance. The electrochemical process thickens the natural oxide layer, improving wear resistance and enabling color coding for part identification. Type II (sulfuric acid) anodizing is standard for general-purpose applications, while Type III (hardcoat anodizing) delivers a thicker, harder surface for industrial and aerospace use.

Below is a comparative overview of key material properties for typical MGA applications.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Good | Anodizing, Passivation | Lightweight frames, brackets, enclosures |

| Aluminum 7075-T6 | 570 | 2.8 | Moderate | Hardcoat Anodizing | High-stress aerospace components |

| Steel 4140 | 950 | 7.85 | Fair (with coating) | Electroplating, Black Oxide | Shafts, gears, high-load structures |

| Stainless 17-4PH | 1000 | 7.75 | Excellent | Passivation, Polishing | Precision actuators, valves |

| Titanium Ti-6Al-4V | 900 | 4.43 | Exceptional | As-machined, Passivation | Aerospace, medical, marine systems |

Material and finish selection must align with functional demands, environmental exposure, and lifecycle requirements. Our engineering team at Wuxi Lead Precision Machinery supports clients in making informed decisions, ensuring every MGA component meets the highest standards of performance and reliability.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process for custom MGA (Metal Gear Assembly) components is engineered for uncompromising quality and repeatability. We adhere to a rigorous three-phase methodology—Design, Prototyping, Mass Production—integrated with Zero Defects protocols at every stage. This ensures your final parts meet exacting aerospace, medical, or industrial specifications without costly rework or field failures.

The Design phase begins with deep collaboration. Our engineering team conducts thorough Design for Manufacturability (DFM) reviews, analyzing CAD models for optimal material utilization, toolpath efficiency, and geometric feasibility. We leverage advanced simulation software to predict thermal deformation, stress points, and vibration effects during machining. Critical material properties—such as 17-4 PH stainless steel hardness or Inconel 718 thermal conductivity—are validated against your performance requirements. This phase includes metallurgical analysis and tolerance stack-up studies to preempt potential deviations, ensuring the design is inherently manufacturable to micron-level accuracy before metal is cut.

Prototyping transforms validated designs into physical reality under controlled conditions. Using dedicated CNC Swiss-type lathes and 5-axis milling centers, we produce initial units with the same fixtures, tooling, and inspection protocols as full production. Each prototype undergoes comprehensive First Article Inspection (FAI) per AS9102 standards. Dimensional verification uses Zeiss coordinate measuring machines (CMM), while surface integrity is assessed via profilometry and optical comparators. Material certifications and non-destructive testing (NDT) like fluorescent penetrant inspection are standard. Client feedback on prototypes triggers immediate process refinement, eliminating ambiguities before scaling.

Mass Production activates only after prototype sign-off, deploying Statistical Process Control (SPC) as the cornerstone of Zero Defects execution. Every machine cell runs with real-time in-process gauging, monitoring critical dimensions after each operation. Automated tool wear compensation and closed-loop feedback systems maintain tolerances within ±0.002 mm. Our production floor implements poka-yoke (error-proofing) fixtures and 100% automated vision inspection for geometric features. Final parts undergo batch-level material traceability checks and full-spectrum dimensional validation. Continuous monitoring of process capability indices (Cp/Cpk > 1.67) guarantees sustained conformance, with corrective actions triggered at the first statistical anomaly—never after defective parts are produced.

Typical Achievable Specifications for MGA Components

| Parameter | Capability Range | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm to ±0.01 mm | CMM, Vision Systems, Air Gaging |

| Surface Roughness (Ra) | 0.2 µm to 1.6 µm | Profilometry, Optical Comparison |

| Geometric Tolerancing | GD&T per ISO 1101 | CMM, Functional Gauges |

| Material Compliance | Full Mill Certs + PMI | Spectrometry, Hardness Testing |

| Batch Traceability | 100% Part Serialization | ERP-Integrated Lot Tracking |

This integrated approach—where design foresight, prototype validation, and statistically controlled mass production converge—ensures Wuxi Lead delivers MGA parts that perform flawlessly in mission-critical applications. We engineer out defects at the source, providing not just components, but guaranteed operational reliability.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Quality in Custom MGA Parts Manufacturing

When your operations demand precision-engineered MGA (Machined, Ground, and Assembled) components, settling for average is not an option. At Wuxi Lead Precision Machinery, we specialize in high-end custom metal manufacturing tailored to the exacting standards of global industries including aerospace, medical devices, automation, and advanced industrial equipment. Our integrated production capabilities, strict quality control, and engineering-first approach ensure every MGA part we deliver exceeds performance expectations.

Our manufacturing ecosystem combines state-of-the-art CNC machining centers, high-precision surface and cylindrical grinding systems, and automated assembly cells. This integration allows us to manage the entire production workflow in-house—from raw material sourcing to final inspection and packaging. By maintaining full control over each process stage, we guarantee consistency, reduce lead times, and eliminate supply chain vulnerabilities.

What sets us apart is our commitment to technical collaboration. We don’t just manufacture parts—we partner with engineers and procurement teams to optimize designs for manufacturability, durability, and cost-efficiency. Whether you require low-volume prototyping or high-volume serial production, our team provides DFM analysis, material selection guidance, and tolerance validation to ensure your components perform flawlessly in real-world applications.

All components are produced under ISO 9001:2015 certified processes, with full traceability and comprehensive inspection reports available upon request. Our quality assurance protocols include CMM measurement, surface roughness testing, and geometric tolerance verification to meet international standards such as AS9100, ISO 13485, and DIN EN ISO 2768.

To support global clients, we offer flexible production scheduling, just-in-time delivery options, and multilingual engineering support. Our logistics network ensures reliable shipment to North America, Europe, and Asia with customs documentation handled seamlessly.

Below are key technical capabilities that define our MGA manufacturing excellence

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.1 µm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Materials Processed | Stainless Steel, Aluminum Alloys, Titanium, Tool Steels, Brass, Plastics (PEEK, PTFE) |

| Secondary Processes | Heat Treatment, Passivation, Anodizing, Plating, Laser Marking |

| Quality Standards | ISO 9001:2015, ISO 13485, AS9100, RoHS Compliant |

| Lead Times | Prototype: 7–14 days; Production: 15–25 days (varies by volume) |

Your next-generation product deserves a manufacturing partner with precision, experience, and integrity. We invite you to contact us today at [email protected] to discuss your MGA parts requirements. Our engineering team is ready to provide technical consultation, NDA-protected design review, and a competitive quotation within 24 hours. Let Wuxi Lead Precision Machinery become your trusted extension in precision manufacturing—where quality is not promised, it is proven.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.