Technical Contents

Engineering Guide: Custom Machining Services Inc

Engineering Insight Precision as the Non-Negotiable Foundation

In high-stakes custom metal manufacturing, precision transcends mere specification adherence; it defines product integrity, operational safety, and lifecycle reliability. For industries like aerospace, defense, and medical technology, a tolerance deviation of even 5 microns can cascade into catastrophic system failure or regulatory rejection. Precision engineering ensures components perform predictably under extreme stress, thermal cycling, or corrosive environments—where theoretical designs meet unforgiving physical reality. At Wuxi Lead Precision Machinery, we treat precision as a systemic discipline, integrating metrology-grade equipment, thermal-stable manufacturing cells, and closed-loop process control to eliminate variability. Our commitment isn’t theoretical: we engineered titanium structural components for the Beijing Winter Olympics’ bobsled track guidance systems, where sub-10µm tolerances ensured athlete safety at 150 km/h. Similarly, our ISO 13485-certified production of fire-control system housings for military clients demanded zero-defect repeatability under MIL-STD-810G vibration protocols. These projects underscore a critical truth—precision is the cost of entry for mission-critical applications, not a value-add.

Wuxi Lead’s 18-year legacy in ultra-precision machining stems from obsessive process rigor. We deploy Zeiss CONTURA CMMs with 1.9+L/300 µm accuracy for in-process verification and utilize Siemens-controlled 5-axis DMG MORI machines with <1µm linear positioning repeatability. This infrastructure enables consistent delivery of geometries where angular tolerances hold ±2 arc-seconds and surface finishes reach Ra 0.1 µm. Crucially, our AS9100D and NADCAP-accredited quality management system mandates full material traceability and first-article inspection per PPAP Level 3—ensuring every component aligns with the client’s engineering intent, not just nominal drawings.

The table below summarizes our core precision capabilities for demanding custom machining projects:

| Parameter | Capability Range | Verification Standard |

|---|---|---|

| Linear Tolerance | ±0.00004″ (1µm) to ±0.0005″ (12µm) | ISO 2768-mK / ASME Y14.5 |

| Geometric Tolerance | ±0.00008″ (2µm) flatness/circularity | GD&T per drawing |

| Surface Finish (Ra) | 0.1 µm to 1.6 µm | ISO 1302 |

| Material Range | Titanium Gr5, Inconel 718, 17-4PH SS, Aluminum 7075 | AMS, ASTM, EN standards |

| Max Work Envelope | 1200 x 800 x 600 mm | 5-axis simultaneous milling |

For partners like custom machining services inc seeking to elevate their supply chain, precision engineering mitigates total cost of ownership. Reduced scrap rates, elimination of field failures, and accelerated time-to-market stem directly from manufacturing processes that treat tolerances as inviolable. At Wuxi Lead, we don’t just meet specifications—we engineer confidence into every micron. When your application demands zero margin for error, our Olympic-proven methodology ensures dimensional stability where it matters most.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom machining services with a focus on precision, repeatability, and technical excellence for global industrial clients. Our facility in Wuxi, China, is equipped with state-of-the-art 5-axis CNC machining centers, enabling the production of highly complex geometries with superior surface finishes and tight tolerances. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and accuracy for intricate components used in aerospace, medical, automation, and high-performance industrial applications.

Our 5-axis CNC platforms are integrated with high-precision spindles and automated tool changers, ensuring minimal setup times and consistent part quality across both prototyping and high-volume production runs. This capability eliminates the need for multiple fixtures and secondary operations, reducing cumulative error and lead time while improving geometric accuracy. Materials commonly machined include aluminum alloys, stainless steels, titanium, brass, and engineering plastics such as PEEK and Delrin, all processed under stringent environmental controls.

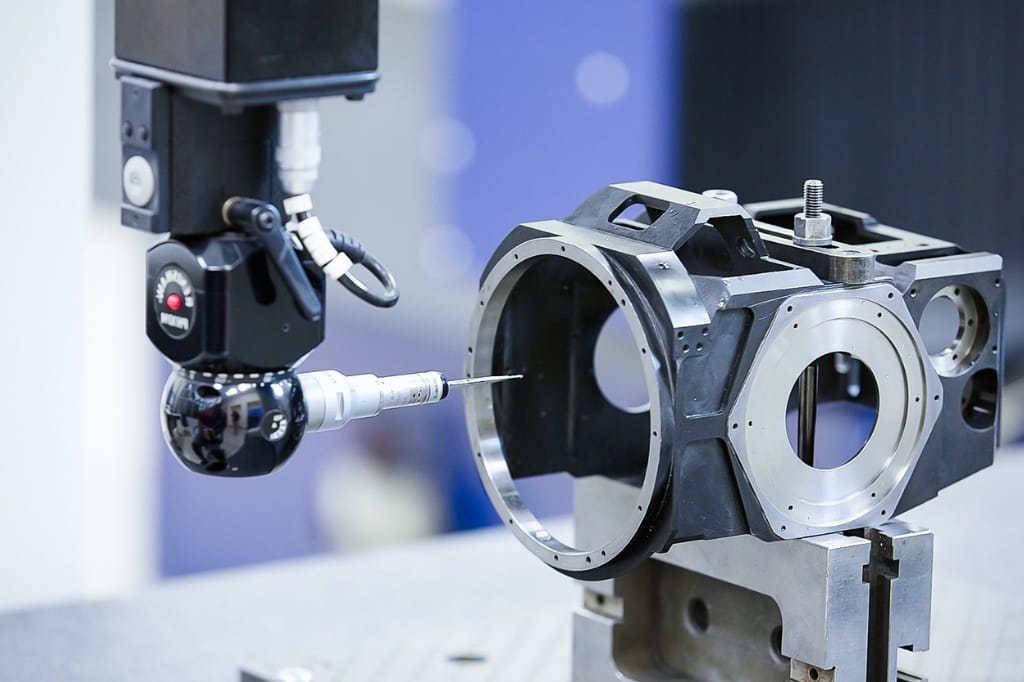

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes comprehensive inspection using a Zeiss DuraMax Coordinate Measuring Machine (CMM), providing full 3D metrology validation. The CMM system ensures compliance with GD&T (Geometric Dimensioning and Tolerancing) standards and supports first-article inspection reports (FAIR), production part approval protocols (PPAP), and full traceability documentation. Our quality management system is ISO 9001:2015 certified, reflecting our commitment to continuous improvement and process reliability.

We maintain tight control over dimensional accuracy, with standard and precision tolerance ranges achievable depending on part geometry, material, and functional requirements. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part designs for performance, cost-efficiency, and producibility.

The following table outlines our standard and precision machining tolerances:

| Feature | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm |

| Hole Diameter | ±0.05 mm | ±0.0125 mm |

| Positional Tolerance | ±0.05 mm | ±0.025 mm |

| Flatness | 0.05 mm | 0.01 mm |

| Perpendicularity | 0.05 mm | 0.02 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

| Thread Tolerance (metric) | 6H / 6g | 4H / 4g |

| Angular Dimensions | ±0.2° | ±0.1° |

All tolerances are validated in our on-site metrology lab, ensuring full compliance with customer specifications and industry standards. Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous quality control to deliver custom metal components that meet the most demanding technical requirements.

Material & Finish Options

Material Selection for Precision Engineered Components

Selecting optimal materials is fundamental to achieving performance, durability, and cost-efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we guide clients through data-driven decisions for aluminum, steel, and titanium based on application demands, environmental exposure, and functional requirements. Each material offers distinct advantages in strength-to-weight ratio, corrosion resistance, and machinability, directly impacting CNC fabrication complexity and final part integrity.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio and thermal conductivity. These grades machine efficiently at high speeds, minimizing tool wear while maintaining tight tolerances. Aluminum’s natural corrosion resistance is significantly enhanced through anodizing, making it ideal for exposed components. Steel variants like 4140 and 304 stainless provide superior hardness and wear resistance for structural or high-stress applications such as tooling and hydraulic systems. While requiring slower machining parameters and robust tooling, steel delivers unmatched durability in demanding mechanical environments. Titanium Grade 5 (Ti-6Al-4V) excels in extreme conditions—medical implants, marine, and aerospace—where weight savings and immunity to saltwater or chemical corrosion are non-negotiable. Its high strength and biocompatibility come with challenging machinability, necessitating specialized CNC strategies to manage heat generation and work hardening.

Surface finishing, particularly anodizing, is critical for aluminum components. Type II (sulfuric acid) anodizing offers economical corrosion and wear resistance with dyeing capability for identification. For mission-critical parts, Type III (hardcoat) anodizing delivers superior abrasion resistance and electrical insulation at thicknesses up to 125µm, essential in military or aerospace applications. Our in-house finishing ensures precise coating uniformity and adherence to ASTM B580/B579 standards.

The following table summarizes key properties to inform your selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Primary Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Excellent (9/10) | Enclosures, brackets, heat sinks |

| Steel 4140 | 7.85 | 655 | Moderate (5/10) | Shafts, gears, tooling |

| Stainless 304 | 8.0 | 515 | Fair (4/10) | Valves, fasteners, food processing |

| Titanium Ti-6Al-4V | 4.43 | 900 | Poor (2/10) | Aircraft fittings, medical implants |

Material choice directly influences CNC programming, toolpath optimization, and production economics. Wuxi Lead leverages 15+ years of metallurgical expertise to balance performance targets with manufacturability—avoiding over-engineering while ensuring reliability. For instance, substituting aluminum for steel in non-load-bearing assemblies reduces weight and machining costs without compromising function. Conversely, titanium’s premium cost is justified only where its unique properties are indispensable.

Partner with our engineering team early in your design phase. We provide material certification, DFMA analysis, and finishing validation to eliminate prototyping delays. Contact Wuxi Lead Precision Machinery to align your material specifications with precision manufacturing realities.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of every successful custom machining project begins with meticulous design engineering. Our team collaborates directly with clients to translate conceptual ideas into actionable, manufacturable designs. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we ensure every dimension, tolerance, and geometric feature aligns with functional requirements and industry standards. Design for Manufacturability (DFM) analysis is conducted early in the process to identify potential production challenges, optimize material usage, and reduce lead times. This proactive approach ensures that designs are not only precise but also cost-effective and scalable for future production. All design data is securely stored and version-controlled, enabling full traceability throughout the project lifecycle.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to the prototyping phase—a critical step in verifying form, fit, and function. Using high-precision CNC machining, 3D printing, and sheet metal fabrication techniques, we produce functional prototypes that mirror the final product in both material and performance. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and mechanical property validation. Clients receive detailed inspection reports and sample units for field evaluation. Feedback is incorporated swiftly, and iterative revisions are executed with minimal delay. This phase serves as a risk mitigation strategy, ensuring that design integrity is maintained before committing to large-scale manufacturing.

Mass Production: Scalable Excellence with Zero Defects

With prototype approval, Wuxi Lead transitions seamlessly into mass production. Our 15,000-square-meter facility in Wuxi, China, is equipped with over 80 CNC machining centers, automated assembly lines, and real-time monitoring systems. Every production run follows standardized work instructions and is governed by a comprehensive Quality Management System compliant with ISO 9001:2015. Statistical Process Control (SPC) and First Article Inspection (FAI) protocols are enforced to maintain consistency. Our zero-defect philosophy is supported by inline inspection stations, automated defect detection, and 100% critical dimension checks. Production data is logged and analyzed daily to identify trends and prevent non-conformances before they occur.

Key Production Specifications

| Parameter | Capability |

|---|---|

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Tolerances | Up to ±0.005 mm |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (custom finishes available) |

| Max Part Size | 1200 x 800 x 600 mm |

| Production Capacity | 50,000+ units/month |

| Lead Time (Mass Production) | 15–25 days after prototype approval |

| Quality Standards | ISO 9001:2015, PPAP, FAI, SPC, CMM Reports |

Through integrated design validation, precision prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers custom metal components with uncompromising quality—ensuring reliability, repeatability, and zero defects for global manufacturing partners.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

In the high-stakes arena of custom metal manufacturing, selecting a partner transcends transactional procurement. It demands a strategic alliance grounded in engineering rigor, unwavering quality, and responsive collaboration. Wuxi Lead Precision Machinery operates at this intersection, delivering mission-critical components where failure is not an option. Our ISO 9001:2015-certified facility in Wuxi, China, serves global aerospace, medical, and energy leaders by transforming complex designs into precision realities—on time, to spec, and with full supply chain transparency. We understand that your reputation hinges on the integrity of every part we produce.

Our competitive edge lies in marrying advanced CNC capabilities with proactive engineering partnership. From initial design for manufacturability (DFM) analysis to final inspection, our team engages as an extension of your engineering department. We eliminate guesswork through real-time process validation and material traceability, ensuring compliance with AS9100, ISO 13485, and NADCAP standards. Below outlines our core technical capacity for demanding custom projects:

| Capability | Specification Detail |

|---|---|

| Materials Expertise | Aluminum 7075-T6, Titanium Grade 5, Inconel 718, Stainless 17-4PH, Tool Steels |

| Dimensional Tolerance | ±0.0002″ (5µm) for critical features |

| Surface Finish | Ra 0.4µm to 3.2µm (as required) |

| Equipment Portfolio | 5-Axis DMG MORI, Makino, Haas; Swiss Lathes; CMM up to 1000mm |

| Max Work Envelope | 1200 x 800 x 600 mm (5-Axis) |

| Lead Time (Prototype) | 10-15 business days (complex geometries) |

This technical foundation enables us to solve challenges others decline—micro-bore drilling in hardened tool steel, thin-wall aerospace brackets under 0.5mm thickness, or biocompatible medical implants requiring zero-defect validation. We invest in continuous process refinement, not just machinery, ensuring your project benefits from statistical process control (SPC) and first-article inspection (FAI) protocols that prevent costly rework.

Your next project demands more than a vendor; it requires a precision engineering partner committed to your success. Initiate a technical dialogue today by contacting our engineering team directly at Contact [email protected]. Include your CAD files, material specifications, and target volumes for a confidential capability assessment within 24 business hours. We will provide a detailed DFM report, timeline, and actionable cost analysis—no generic quotes. For urgent RFQs, reference project code LEAD-CTA-2024 to expedite review. Trust Wuxi Lead Precision Machinery to deliver the uncompromising quality your application demands, backed by 15 years of complex metal fabrication excellence. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.