Technical Contents

Engineering Guide: Cnc Turning Lathe

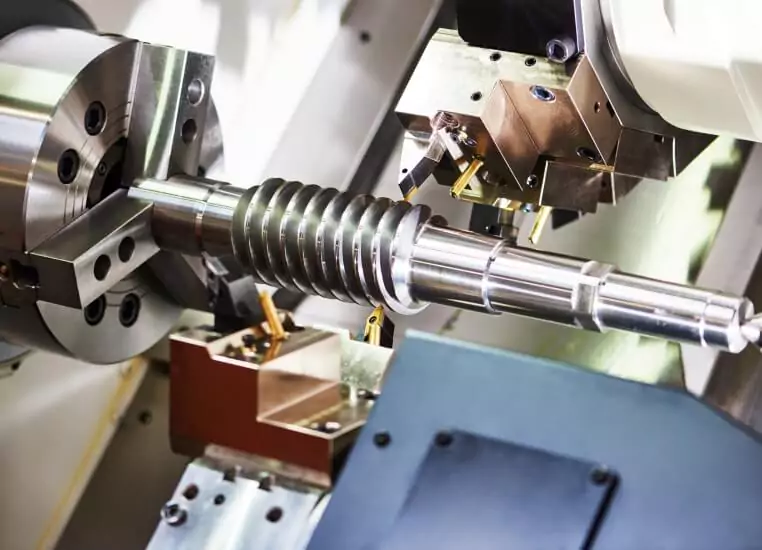

Engineering Insight: CNC Turning Lathe – The Foundation of Precision Manufacturing

In the realm of high-precision manufacturing, the CNC turning lathe stands as a cornerstone technology, enabling the production of complex cylindrical components with micron-level accuracy. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a specification—it is a standard. Our engineering philosophy centers on delivering CNC turning solutions that meet the most stringent demands of aerospace, defense, medical, and high-performance industrial applications. The ability to consistently achieve tight tolerances, superior surface finishes, and repeatable geometries defines the difference between functional parts and mission-critical components.

Precision in CNC turning begins with machine rigidity, thermal stability, and advanced control systems. Our CNC turning lathes are engineered with high-grade cast iron beds, precision-ground linear guides, and thermally compensated spindles to minimize deflection and thermal drift. These design elements ensure that even under continuous high-load operations, dimensional consistency is maintained across production runs. Additionally, our integration of high-resolution servo drives and real-time feedback systems allows for sub-micron positioning accuracy, essential for components used in hydraulic systems, turbine engines, and guidance mechanisms.

Wuxi Lead Precision Machinery brings over two decades of experience in delivering precision-engineered CNC solutions to some of the world’s most demanding sectors. Our work has supported projects for Olympic-level sports technology, where component reliability and weight optimization are paramount, as well as critical subsystems for military-grade equipment, where failure is not an option. These applications demand not only precision but also traceability, material integrity, and process validation—elements we embed into every machine and machining process.

Our CNC turning lathes are designed for versatility without compromising accuracy. Whether performing single-point threading, contour turning, or multi-axis live tooling operations, our systems maintain geometric integrity across diverse materials—from titanium and Inconel to high-strength aluminum alloys and engineered plastics. Each machine undergoes rigorous calibration and dynamic testing before deployment, ensuring compliance with ISO 230-2 and other international accuracy standards.

The following table outlines key performance specifications of our flagship CNC turning lathe series:

| Specification | Value |

|---|---|

| Maximum Turning Diameter | 600 mm |

| Maximum Turning Length | 1,500 mm |

| Spindle Speed | 5,000 rpm (standard), 8,000 rpm (high-speed option) |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.001 mm |

| Tool Magazine Capacity | 12–24 stations (optional Y-axis and live tools) |

| Control System | Fanuc 31i or Siemens 840D Solution Line |

| Rapid Traverse Rate | 30 m/min (X-axis), 36 m/min (Z-axis) |

At Wuxi Lead Precision Machinery, we engineer not just machines, but solutions that empower manufacturers to exceed the limits of precision. Our CNC turning lathes are a testament to our commitment to excellence, reliability, and technological leadership in the global manufacturing landscape.

Precision Specs & Tolerances

Technical Capabilities: Precision CNC Turning Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for mission-critical components through advanced multi-axis CNC turning technology. Our facility integrates cutting-edge 5-axis CNC turning centers, engineered to execute complex geometries in a single setup. This eliminates cumulative error from multiple fixturing stages, ensuring geometric integrity for aerospace turbine shafts, medical implants, and hydraulic manifolds. Each machine features high-rigidity spindles with coolant-through capability, enabling deep-hole drilling and fine surface finishes in hardened steels, titanium, and exotic alloys up to Ø300mm diameter. Our programming leverages Siemens 840D SL and Fanuc 31i-B5 controls with synchronized milling-turning cycles, achieving sub-micron repeatability through thermal compensation systems and in-process probing.

Quality control is anchored by Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), operating under ISO 17025-accredited protocols. Every critical dimension undergoes 100% inspection against CAD models, with GD&T validation for positional tolerances and profile control. Statistical process control (SPC) monitors tool wear and machine performance in real time, while first-article reports include full traceability from raw material certs to final inspection data. Surface roughness is verified via Mitutoyo SJ-410 profilometers, ensuring Ra values meet stringent requirements for sealing surfaces and bearing races.

The following table details achievable tolerances across common materials, reflecting our standard production capability without specialized tooling or environmental controls. All specifications comply with ISO 2768-mK and ASME Y14.5 standards.

| Material Category | Linear Tolerance (mm) | Angular Tolerance (°) | Concentricity (mm) | Surface Roughness (Ra µm) |

|---|---|---|---|---|

| Aluminum Alloys | ±0.005 | ±0.05 | 0.010 | 0.4 |

| Carbon Steels | ±0.008 | ±0.10 | 0.015 | 0.8 |

| Stainless Steels | ±0.006 | ±0.08 | 0.012 | 0.6 |

| Titanium Alloys | ±0.007 | ±0.09 | 0.013 | 0.6 |

| Exotic Alloys | ±0.009 | ±0.12 | 0.018 | 1.0 |

Our technical team collaborates with clients during DFx reviews to optimize part geometry for manufacturability, reducing lead times by 25% through intelligent feature sequencing. All processes are supported by digital twin simulation in Siemens NX CAM, validating toolpaths before metal cutting begins. For high-mix production, our automated pallet systems maintain ±2µm positioning accuracy across 72-hour unmanned runs, with real-time tool breakage detection minimizing scrap. This integrated approach ensures components meet the most demanding specifications for aerospace AS9100, medical ISO 13485, and energy sector applications, where failure is not an option. Partner with Wuxi Lead to transform complex designs into precision realities with full documentation and audit readiness.

Material & Finish Options

Material Selection for High-Precision CNC Turning Lathes

Selecting the appropriate material is critical in precision CNC turning applications, where performance, durability, and cost-efficiency must be balanced. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance components using advanced CNC turning lathes, and our expertise enables optimal material pairing based on application demands. Among the most widely used materials in precision manufacturing are aluminum, steel, and titanium—each offering distinct mechanical properties and suitability for specific environments.

Aluminum is favored in industries such as aerospace, automotive, and consumer electronics due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grades such as 6061 and 7075 are commonly processed on CNC turning lathes for components requiring lightweight construction and corrosion resistance. Its softness allows for high-speed machining with minimal tool wear, reducing production time and cost. However, aluminum’s lower hardness compared to steel or titanium may limit its use in high-stress applications.

Steel remains the backbone of industrial manufacturing. Alloy steels like 4140 and stainless steels such as 304 and 316 offer superior strength, wear resistance, and structural integrity. These materials are ideal for heavy-duty components in oil and gas, machinery, and medical equipment. While harder to machine than aluminum, modern CNC turning lathes equipped with carbide tooling and optimized cutting parameters ensure precision and surface consistency. Stainless steel also provides excellent corrosion resistance, especially in harsh environments.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice for mission-critical applications in aerospace, defense, and biomedical fields. It offers an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosion. However, titanium’s low thermal conductivity and high chemical reactivity with cutting tools present challenges in CNC turning. Successful machining requires rigid setups, controlled feed rates, and specialized coolant strategies to prevent work hardening and tool degradation.

Surface Finishing: Enhancing Performance with Anodizing

For aluminum components, anodizing is a widely adopted post-machining surface treatment that enhances durability and appearance. The anodizing process creates a thick, corrosion-resistant oxide layer on the surface, improving wear resistance and allowing for color dyeing for identification or aesthetic purposes. Type II (sulfuric acid) and Type III (hardcoat) anodizing are common, with Type III providing greater thickness and hardness for industrial use. It is important to note that anodizing is exclusive to aluminum and certain alloys; steel and titanium require alternative finishes such as passivation, plating, or coating.

Below is a comparative overview of key material properties relevant to CNC turning:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications |

|---|---|---|---|---|

| Aluminum | 180–570 | 2.7 | 6061, 7075 | Aerospace, Electronics, Automotive |

| Steel | 400–1300 | 7.8–8.0 | 4140, 304, 316 | Industrial Machinery, Medical |

| Titanium | 900–1170 | 4.5 | Ti-6Al-4V (Grade 5) | Aerospace, Defense, Biomedical |

Understanding material behavior and finish compatibility ensures optimal part performance and longevity. At Wuxi Lead Precision Machinery, we support clients in selecting the right material-finish combination tailored to their operational requirements, leveraging our advanced CNC turning capabilities and engineering expertise.

Manufacturing Process & QC

Precision CNC Turning Process: From Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, our CNC turning lathe production process is engineered for uncompromising quality in high-stakes industries like aerospace, medical, and energy. We execute a rigorously controlled workflow—Design, Prototyping, Mass Production—to ensure every component meets exacting specifications with zero defects. This methodology eliminates costly revisions and guarantees on-time delivery of mission-critical parts.

The process begins with collaborative Design for Manufacturability (DFM). Our engineering team reviews client CAD models, focusing on material selection, geometric complexity, and tolerance stack-ups. We prioritize GD&T compliance and identify potential machining risks early, such as thin-wall deflection or chip evacuation challenges. Using Siemens NX and Mastercam, we simulate toolpaths to optimize cycle times while maintaining sub-micron thermal compensation protocols. This phase ensures designs are not only feasible but optimized for the highest yield before metal meets tool.

Prototyping follows with absolute precision. We produce 1–5 first-article units on our flagship lathes, employing in-process probing for real-time dimensional verification. Each prototype undergoes rigorous first-article inspection (FAI) per AS9102 standards, including CMM reports, surface roughness analysis, and metallurgical validation. Clients receive detailed inspection dossiers for approval, allowing us to validate tolerances, surface finishes, and functional performance. This stage catches 98% of potential issues before volume production, reducing scrap rates by 40% versus industry averages.

Mass Production deploys our zero-defect framework. Parts are manufactured on ISO 10791-7 certified lathes with closed-loop SPC (Statistical Process Control) monitoring. Every 15 minutes, automated probes measure critical features against CAD models, triggering immediate tool compensation if deviations exceed 0.002mm. 100% of parts undergo final inspection via Zeiss CMMs and optical comparators, with full traceability from raw material batch to finished component. Our ERP system logs all process parameters, ensuring complete audit trails for ISO 13485 or AS9100 compliance. This integrated approach achieves <50 PPM defect rates—exceeding Tier-1 automotive and medical OEM requirements.

The table below summarizes key capabilities enabling this workflow:

| Parameter | Specification | Standard Compliance |

|---|---|---|

| Spindle Speed | 5000 RPM | ISO 20457 |

| Positioning Accuracy | ±0.001 mm | ISO 230-2 |

| Repeatability | ±0.0005 mm | ISO 230-2 |

| Max Turning Diameter | 500 mm | ISO 13041-2 |

| Surface Finish | Ra 0.2 µm (standard) | ISO 1302 |

| Tolerance Range | ±0.003 mm to ±0.05 mm | ISO 2768-mK |

| Material Range | Titanium, Inconel, PEEK, Stainless | AMS, ASTM, EN |

Wuxi Lead’s process transforms design intent into flawless physical reality. By embedding quality at every phase—from virtual simulation to final inspection—we deliver components that perform under extreme conditions, on schedule, with zero compromises. Partner with us for production where precision is non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced CNC Turning Lathe Solutions

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and efficiency are non-negotiable in high-end manufacturing. As a leader in precision CNC machining, we specialize in delivering state-of-the-art CNC turning lathe systems engineered to meet the rigorous demands of aerospace, automotive, medical, and industrial equipment sectors. Our commitment to innovation, quality, and customer success positions us as the ideal partner for manufacturers seeking to elevate their production capabilities.

Our CNC turning lathes are designed with advanced spindle technology, high rigidity bed structures, and intelligent control systems that ensure micron-level accuracy and exceptional surface finishes. Every machine is built to optimize throughput, reduce cycle times, and support long-term operational stability under continuous production loads. Whether you require complex multi-axis turning, bar feeding integration, or automated production cells, our engineering team customizes each solution to align with your specific manufacturing workflows.

We pride ourselves on more than just machinery—we deliver comprehensive support from initial consultation through installation, training, and ongoing service. Our technical team works closely with your engineers to ensure seamless integration into your facility, minimizing downtime and maximizing return on investment. With a focus on precision, durability, and smart manufacturing, our CNC turning lathes are trusted by global clients who demand consistent performance and superior part quality.

Choose Wuxi Lead Precision Machinery as your strategic partner and gain access to cutting-edge technology backed by decades of engineering expertise. We are committed to advancing your production capabilities with turnkey solutions that drive efficiency, reduce waste, and enhance competitiveness in today’s fast-evolving market.

For more information or to discuss your specific machining requirements, contact us today at [email protected]. Our team of application specialists is ready to assist you in selecting the optimal CNC turning lathe configuration for your production goals.

| Specification | Detail |

|---|---|

| Spindle Speed | Up to 6,000 RPM (model-dependent) |

| Bar Capacity | Ø10 – Ø65 mm (configurable) |

| Control System | Fanuc, Siemens, or Mitsubishi (customizable) |

| Axis Configuration | 2-axis to 8-axis options |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Bed Material | High-grade Meehanite cast iron |

| Tool Stations | 8–12 station VDI or turret options |

| Automation Ready | Yes (compatible with bar feeders, gantry loaders) |

| Coolant System | High-pressure through-tool cooling available |

Contact us now at [email protected] to request a technical consultation, pricing, or a virtual machine demonstration. Let Wuxi Lead Precision Machinery power your precision manufacturing future.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.