Technical Contents

Engineering Guide: Contracting Cnc Machining

Engineering Insight: The Critical Role of Precision in Contract CNC Machining

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which reliability, safety, and functionality are built. When engineering components for industries such as aerospace, defense, medical devices, and high-performance automation, even micron-level deviations can result in system failure, regulatory non-compliance, or costly field recalls. This is why precision in contract CNC machining must be approached not as a target, but as a disciplined standard.

At Wuxi Lead Precision Machinery, we understand that precision extends beyond the capabilities of advanced CNC equipment. It encompasses process control, material science, metrology, and the accumulated expertise of engineering teams who have delivered mission-critical components under the most demanding specifications. Our work on projects tied to Olympic-standard sporting equipment and military-grade hardware exemplifies this commitment. These applications demand repeatability, traceability, and adherence to international quality standards—benchmarks we meet consistently through integrated quality systems and real-time in-process inspection.

Precision machining begins with design for manufacturability (DFM). Our engineering team collaborates closely with clients during the prototyping phase, identifying potential stress points, optimizing tool paths, and selecting materials that balance strength, weight, and thermal stability. This proactive approach prevents costly redesigns and accelerates time-to-market. Once production begins, our CNC machining centers—equipped with high-resolution feedback systems and temperature-compensated controls—maintain tolerances down to ±0.002 mm, ensuring dimensional integrity across batch runs.

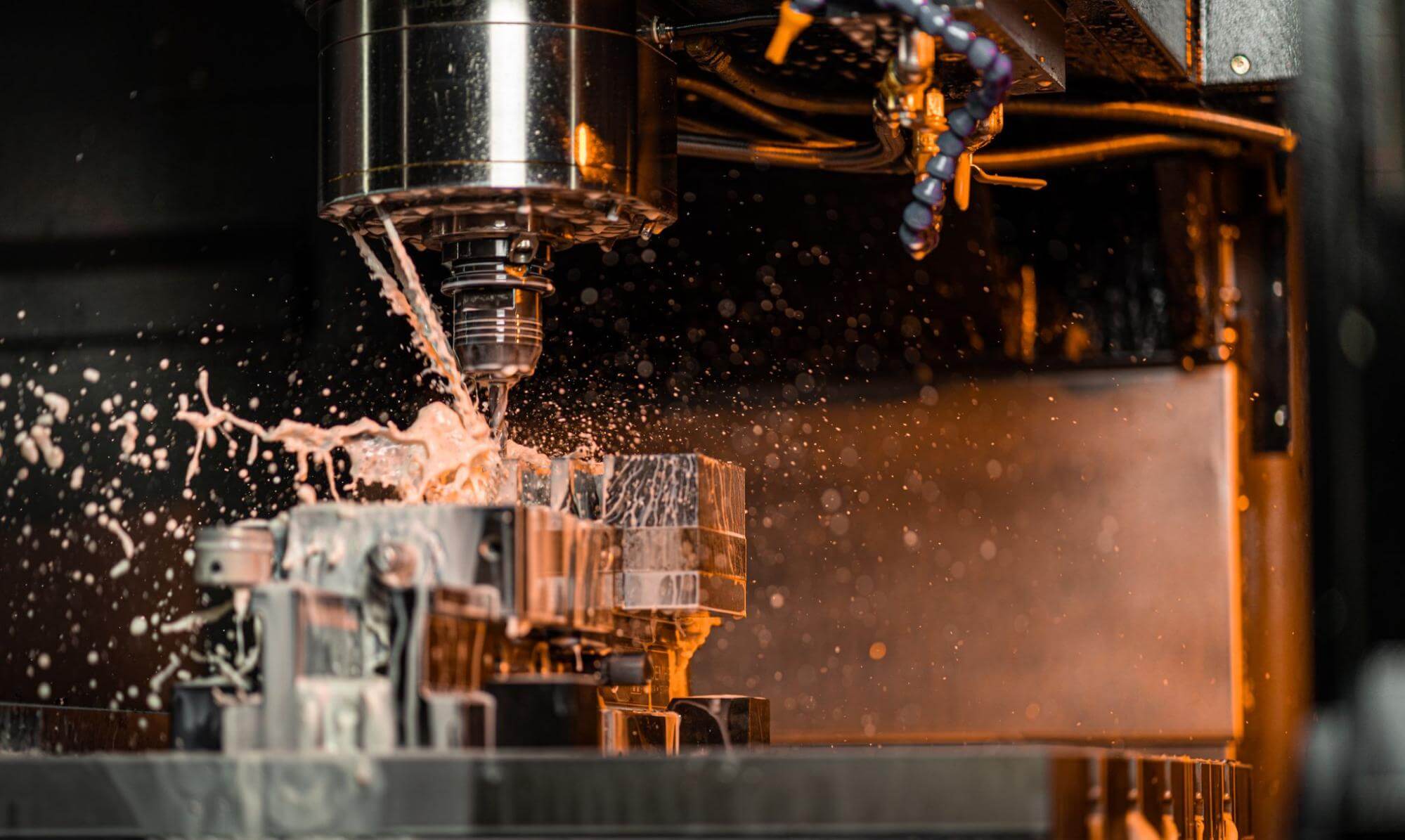

Another critical factor is material integrity. We specialize in machining difficult-to-process alloys such as titanium, Inconel, and hardened steels, where thermal expansion and tool wear present significant challenges. Our tooling strategies, coolant management, and spindle optimization protocols are fine-tuned to preserve surface finish and geometric accuracy, even in extended production cycles.

Below is a summary of our core machining capabilities, reflecting the precision standards we uphold for every client engagement.

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope (mm) | 1200 × 800 × 650 |

| Spindle Speed Range | 8,000 – 24,000 rpm |

| Surface Finish (Ra) | 0.2 – 1.6 µm |

| Materials Processed | Aluminum Alloys, Titanium, Inconel, Stainless Steel, Brass, Engineering Plastics |

| Quality Standards | ISO 9001:2015, ISO 13485 (Medical), Military-Grade Inspection Protocols |

Our experience with high-stakes projects has instilled a culture of zero tolerance for error. Whether supporting defense contractors requiring ITAR-compliant production or delivering components for precision medical instrumentation, Wuxi Lead Precision Machinery ensures every part meets exacting technical and regulatory demands.

In contract CNC machining, trust is earned through demonstrated capability. Precision is not claimed—it is proven, one component at a time.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Complex Demands

Wuxi Lead Precision Machinery delivers uncompromising precision through an integrated suite of advanced manufacturing and verification technologies. Our core strength lies in mastering complex geometries and stringent tolerances demanded by aerospace, medical, and high-performance industrial sectors. This capability is fundamentally enabled by our modern fleet of multi-axis CNC machining centers, coupled with rigorous, metrology-grade quality control processes implemented at every stage of production.

Our primary machining platform consists of state-of-the-art 5-axis CNC machining centers from leading global manufacturers. These systems feature high-torque spindles, rigid structural designs, and advanced control systems capable of true simultaneous five-axis interpolation. This allows for the efficient production of highly complex components—such as impellers, turbine blades, intricate housings, and organic medical implants—in a single setup. Eliminating multiple fixturing operations significantly reduces cumulative error, improves dimensional accuracy, enhances surface finish consistency, and shortens overall lead times. We routinely machine a wide range of materials including aerospace-grade aluminum alloys (e.g., 7075-T6), titanium (e.g., Ti-6Al-4V), stainless steels (e.g., 17-4 PH, 316L), and high-temperature superalloys (e.g., Inconel 718), optimizing cutting strategies and tooling for each specific material challenge.

Quality assurance is not an endpoint but an integrated process. Every critical dimension and feature is verified using our laboratory-grade Coordinate Measuring Machines (CMMs). These systems, calibrated to international standards (ISO 17025), provide traceable, three-dimensional measurement data with micron-level resolution. Our certified metrology technicians perform comprehensive first-article inspections (FAI) per AS9102 or client-specific requirements and conduct in-process checks to ensure conformance throughout the production run. This proactive approach, utilizing CAD model-based inspection routines, guarantees that components meet the exact specifications outlined in engineering drawings and prevents non-conforming product from progressing.

The following table details our standard and achievable tolerance capabilities across common material categories, reflecting the precision attainable through our optimized machining and inspection protocols. Achieving tight tolerance ranges consistently requires careful process planning, environmental control, and specialized tooling, all standard practice within our facility.

| Material Category | Standard Tolerance Range | Tight Tolerance Capability |

|---|---|---|

| Aluminum Alloys | ±0.010 mm (±0.0004″) | ±0.005 mm (±0.0002″) |

| Stainless Steels | ±0.012 mm (±0.0005″) | ±0.008 mm (±0.0003″) |

| Titanium Alloys | ±0.015 mm (±0.0006″) | ±0.010 mm (±0.0004″) |

| Engineering Plastics | ±0.025 mm (±0.0010″) | ±0.015 mm (±0.0006″) |

| High-Temp Superalloys | ±0.020 mm (±0.0008″) | ±0.012 mm (±0.0005″) |

These tolerances are verified using calibrated CMMs, optical comparators, and surface roughness testers as appropriate. Wuxi Lead Precision Machinery’s commitment to technical excellence ensures your most demanding precision machining requirements are met with reliability and repeatability, forming the bedrock of our partnership with global engineering leaders.

Material & Finish Options

Material selection is a critical factor in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of end components. At Wuxi Lead Precision Machinery, we specialize in machining high-tolerance parts from aluminum, steel, and titanium—each offering distinct mechanical properties suited to specific industrial applications. Understanding these materials enables engineers and procurement teams to make informed decisions that align with functional requirements and production goals.

Aluminum is widely favored in aerospace, automotive, and electronics industries due to its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is particularly popular for prototyping and structural components, offering good weldability and corrosion resistance. Its low density reduces part weight without sacrificing performance, making it ideal for applications where efficiency and mobility are paramount. However, aluminum’s lower hardness compared to steel and titanium may limit its use in high-wear environments.

Steel, particularly alloy and stainless grades such as 4140, 17-4 PH, and 304/316, provides superior strength, hardness, and wear resistance. These properties make steel the material of choice for tooling, heavy machinery, and components exposed to high stress or corrosive environments. Stainless steels also offer excellent resistance to oxidation and chemical exposure, critical in medical and food-grade applications. While steel is more challenging to machine than aluminum due to higher tool wear and cutting forces, our advanced CNC platforms are optimized to maintain tight tolerances and surface integrity.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional balance of strength, corrosion resistance, and biocompatibility at elevated temperatures. It is extensively used in aerospace, defense, and medical implant manufacturing. Despite its high cost and challenging machinability—due to low thermal conductivity and tendency to gall—titanium’s performance in extreme environments justifies its application in mission-critical systems. Our specialized tooling and cooling strategies ensure precise, burr-free results even with this demanding material.

Surface finishing further enhances material performance. Anodizing, primarily applied to aluminum, increases surface hardness and corrosion resistance while allowing for color coding and improved aesthetic quality. Type II (sulfuric acid) and Type III (hardcoat) anodizing are available depending on functional needs, with Type III providing thicker, wear-resistant layers suitable for industrial components.

Below is a comparative overview of key material properties:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | 2.7 | Aerospace, Electronics | Excellent |

| Stainless Steel | 304 | 515 | 8.0 | Medical, Food Processing | Moderate |

| Alloy Steel | 4140 | 655 | 7.85 | Tooling, Automotive | Moderate |

| Titanium | Ti-6Al-4V | 950 | 4.43 | Aerospace, Medical Implants | Poor to Moderate |

Selecting the right material involves balancing mechanical demands, environmental exposure, and production efficiency. Wuxi Lead Precision Machinery supports clients in this decision with material testing, DFMA analysis, and full-process traceability to ensure optimal outcomes.

Manufacturing Process & QC

Precision CNC Machining Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our production process is engineered for uncompromising quality in high-precision CNC machining. We eliminate defects at the source through a rigorously controlled workflow spanning design validation, iterative prototyping, and statistically monitored mass production. This integrated approach ensures every component meets aerospace, medical, and semiconductor industry standards—where failure is not an option.

Design begins with deep collaboration. Our engineering team conducts comprehensive Design for Manufacturability (DFM) analysis, scrutinizing CAD models for geometric feasibility, material suitability, and tolerance stack-up risks. We identify potential weaknesses early—such as thin walls prone to vibration or complex features requiring specialized tooling—reducing downstream rework by up to 70%. Client specifications are cross-referenced against ISO 2768 and AS9100 tolerancing standards, ensuring designs are not just functional but inherently producible at scale.

Prototyping transforms validated designs into physical proof. Using the same 5-axis DMG MORI and MAZAK equipment deployed in production, we machine initial units with full process documentation. Each prototype undergoes rigorous metrology: CMM scans verify critical dimensions, surface roughness testers confirm Ra values, and material composition is validated via spectroscopy. Crucially, we simulate production environmental stresses—thermal cycling for aerospace housings or pressure testing for medical fluidics—to expose latent flaws. Only when prototypes pass 100% of functional and dimensional checks do we approve the process for scale-up.

Mass production leverages statistical process control (SPC) to sustain zero defects. Every machine cell operates under real-time monitoring: tool wear sensors trigger automatic compensation, in-process probes verify feature alignment after each operation, and automated gaging feeds dimensional data into our SPC dashboard. We enforce capability indices (Cp/Cpk ≥ 1.67) on all critical features, with immediate process lockdown if trends approach tolerance limits. Final inspection employs multi-sensor CMMs and optical comparators, with full traceability from raw material certs to operator logs. This closed-loop system achieves sub-5 PPM defect rates across runs of 1 to 10,000+ units.

Our technical capabilities enable this precision:

| Parameter | Capability | Standard Compliance |

|---|---|---|

| Tolerance | ±0.0001″ (2.5 µm) | ISO 2768-m, ASME Y14.5 |

| Materials | Titanium, Inconel, PEEK, 440C | AMS, ASTM, ISO 6892 |

| Max Work Envelope | 2000 x 1000 x 800 mm | Custom fixturing support |

| Inspection | CMM, OGP SmartScope, XRF | ISO 10360, NIST-traceable |

Zero defects are not a goal—they are the non-negotiable outcome of engineering out variability at every phase. By converging design intelligence, prototype validation, and SPC-driven production, Wuxi Lead delivers components that perform flawlessly in the world’s most demanding applications. Your design integrity, our manufacturing certainty.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a global leader in high-end CNC machining, we specialize in providing tailored manufacturing solutions that meet the exacting demands of industries such as aerospace, medical devices, automation, and advanced industrial equipment. Our commitment to engineering excellence, combined with state-of-the-art technology and rigorous quality control, makes us the preferred partner for companies that require nothing less than perfection.

When you choose to partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem. Our facility in Wuxi, China, is equipped with advanced 3-, 4-, and 5-axis CNC machining centers, Swiss-type lathes, and multi-function turning-milling machines. Every process—from initial design consultation to final inspection—is managed in-house, ensuring seamless communication, faster turnaround times, and total traceability. Our team of experienced engineers works closely with clients to optimize part designs for manufacturability, reduce material waste, and ensure compliance with international standards such as ISO 9001:2015 and AS9100D.

We understand that in high-stakes industries, consistency and precision are non-negotiable. That’s why we invest heavily in metrology and process validation. Our quality assurance program includes first-article inspections, in-process checks, and full CMM reporting, ensuring every component meets your specifications—repeatable, every time. Whether you require low-volume prototypes or high-volume production runs, our scalable infrastructure allows us to adapt quickly without compromising on quality.

Our capabilities are designed to handle the most complex challenges in precision machining. Below is an overview of our core technical specifications:

| Capability | Specification |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis milling, turning, multi-axis Swiss machining, turn-mill |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Tolerance | As tight as ±0.002 mm |

| Surface Finish | Down to Ra 0.4 μm (polished finishes available) |

| Materials | Aluminum, stainless steel, titanium, brass, copper, PEEK, Delrin, and other engineered plastics |

| Secondary Operations | Deburring, anodizing, plating, passivation, heat treatment, laser marking |

| Quality Standards | ISO 9001:2015, AS9100D, RoHS compliant |

Partnering with Lead Precision means aligning with a manufacturer that values transparency, technical mastery, and on-time delivery. We serve clients across North America, Europe, and Asia, building trusted relationships through consistent performance and responsive support.

Take the next step toward precision manufacturing excellence. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a virtual factory tour. Let Wuxi Lead Precision Machinery be your strategic partner in bringing high-performance components to life—with precision you can count on.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.