Technical Contents

Engineering Guide: Injection Molding Best Practices

Engineering Insight: Injection Molding Best Practices – The Role of Precision in High-Performance Manufacturing

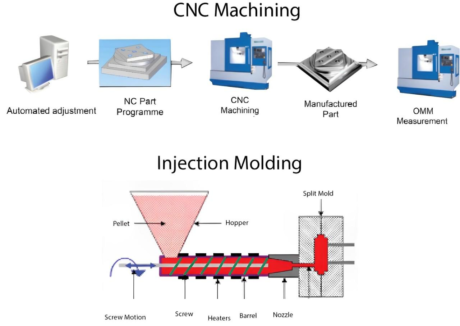

In the realm of custom metal manufacturing, injection molding stands as a cornerstone process for producing complex, high-volume components with exceptional repeatability. However, the success of any injection molding operation hinges on one critical factor: precision. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations can compromise part integrity, performance, and longevity—especially in mission-critical applications.

Precision in injection molding is not merely about achieving tight tolerances. It encompasses the entire manufacturing ecosystem: mold design accuracy, material consistency, thermal control, machine calibration, and real-time process monitoring. A high-precision mold ensures uniform filling, minimizes flash, reduces post-processing requirements, and enhances part-to-part consistency. This level of control is essential when manufacturing components for industries such as aerospace, defense, and high-performance sports equipment—sectors where Wuxi Lead has demonstrated proven expertise.

Our involvement in engineering components for Olympic-grade equipment and military-grade systems underscores our commitment to precision. These applications demand materials and geometries that perform under extreme conditions—whether subjected to high impact, thermal cycling, or prolonged stress. For such cases, standard molding practices are insufficient. Instead, we employ advanced simulation software, high-stiffness mold steels, and closed-loop control systems to ensure every cycle meets exacting specifications.

Material selection also plays a pivotal role. At Wuxi Lead, we specialize in processing high-performance alloys and engineered composites tailored for structural integrity and thermal stability. Our engineers work closely with clients to optimize wall thickness, gate placement, and cooling channel design—factors that directly influence warpage, sink marks, and cycle time.

To illustrate the capabilities that define our best practices, consider the following technical specifications achieved across recent high-precision molding projects:

| Parameter | Specification Range |

|---|---|

| Tolerance Control | ±0.005 mm to ±0.02 mm |

| Surface Finish (Ra) | 0.1 µm to 0.8 µm |

| Mold Material | H13, S136, 2344, or Custom Alloy |

| Clamping Force | 150 to 2,500 Tons |

| Process Repeatability (CpK) | ≥1.67 |

| Cycle Time Optimization | Up to 30% reduction vs. standard |

| Material Compatibility | PEEK, PA, PPS, Metal-Polymer Composites |

These benchmarks reflect not only machine capability but also the depth of engineering insight applied at every stage. From initial prototyping to full-scale production, Wuxi Lead integrates metrology-grade inspection, in-mold pressure sensing, and DOE (Design of Experiments) methodologies to validate and refine the molding process.

In high-end manufacturing, precision is not an option—it is a requirement. At Wuxi Lead Precision Machinery, our legacy in delivering components for Olympic and military applications is built on this principle. By adhering to the highest standards of injection molding best practices, we ensure that every part we produce meets the demands of performance, reliability, and innovation.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Injection Molding Excellence

Wuxi Lead Precision Machinery delivers the foundational precision required for high-performance injection molding tooling and components. Our custom metal manufacturing capabilities directly address the demanding tolerances and complex geometries inherent in modern mold design, ensuring optimal part consistency, reduced cycle times, and extended tool life. We recognize that the accuracy of the mold cavity and core directly dictates the quality and repeatability of the final plastic part; therefore, our entire process chain is engineered for micron-level control.

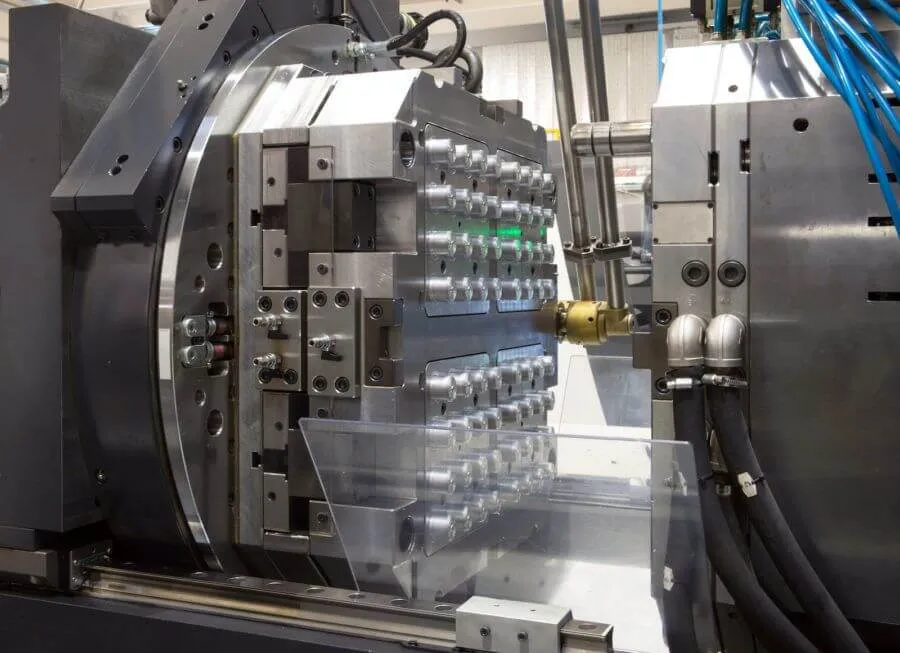

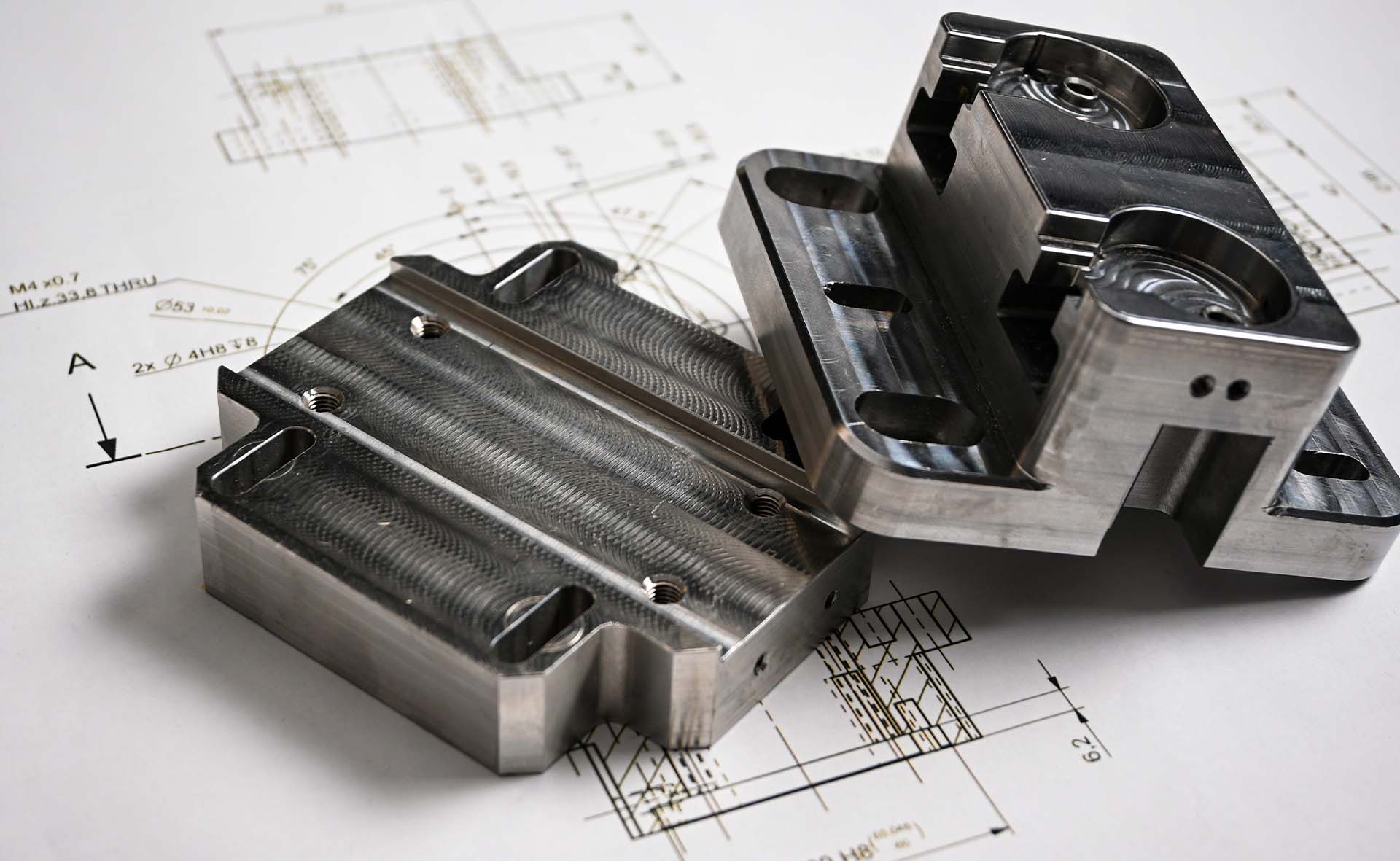

Our core manufacturing strength lies in advanced multi-axis machining. We deploy state-of-the-art 5-axis CNC milling and turning centers, specifically selected for their rigidity, thermal stability, and sub-micron positioning accuracy. This technology enables the complete machining of complex mold bases, cavities, cores, and intricate slide mechanisms in a single setup. Eliminating multiple fixturing stages significantly reduces cumulative error potential and geometric deviations, which is critical for maintaining tight tolerances across multi-cavity molds or parts requiring undercuts. The simultaneous 5-axis motion allows for optimal tool engagement angles, producing superior surface finishes directly off the machine. This minimizes secondary polishing requirements and ensures consistent thermal transfer characteristics within the mold, directly impacting part quality and production stability.

Rigorous quality control is non-negotiable in our process. Every critical component undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMMs) operating within a climate-controlled metrology lab. Our CMMs, certified to ISO/IEC 17025 standards, provide full 3D geometric dimensioning and tolerancing (GD&T) verification against the original CAD model. This traceable measurement process captures not only dimensional accuracy but also complex form, profile, orientation, and location tolerances essential for mold functionality. Real-time data from CMM inspection feeds directly back into our process control systems, enabling immediate corrective actions and continuous process refinement. This closed-loop quality system guarantees that every mold component meets the stringent specifications required for high-volume, zero-defect injection molding production.

The following table details our standard and precision tolerance capabilities for critical mold features, achievable through our integrated CNC and CMM processes:

| Feature Category | Standard Capability | Precision Capability | Primary Verification Method |

|---|---|---|---|

| Dimensional (Linear) | ±0.010 mm | ±0.005 mm | CMM, High-Precision Micrometers |

| Geometric (GD&T) | ±0.015 mm | ±0.008 mm | CMM (Full 3D Analysis) |

| Surface Finish (Cavity) | Ra 0.4 µm | Ra 0.1 µm | Profilometer, Visual Comparison |

| Material Density Check | As per Spec | As per Spec + 0.5% | Archimedes Principle, CMM Volume Calc |

These capabilities are not theoretical benchmarks but proven standards consistently achieved across our production floor. They form the bedrock of reliable mold performance, directly translating to our clients’ success through reduced scrap rates, minimized downtime, and superior end-part quality in their injection molding operations.

Material & Finish Options

Material selection is a critical phase in the injection molding process, particularly when producing high-precision metal components for demanding industries such as aerospace, medical, and automotive. At Wuxi Lead Precision Machinery, we emphasize the importance of aligning material properties with functional requirements, environmental exposure, and production volume. Aluminum, steel, and titanium each offer distinct advantages depending on the application, and understanding their mechanical behavior ensures optimal performance and cost-efficiency.

Aluminum is widely favored for mold construction due to its excellent thermal conductivity, lightweight nature, and ease of machining. It enables faster cycle times by facilitating rapid heat dissipation, making it ideal for low- to medium-volume production runs. While not as hard as steel, modern aluminum alloys such as 7075-T6 provide sufficient durability for thousands of cycles when properly maintained. This makes aluminum a cost-effective solution for prototyping and bridge tooling.

Steel remains the standard for high-volume injection molding applications. Hardened tool steels like P20, H13, and S136 offer superior wear resistance, dimensional stability, and longevity under continuous operation. These alloys can withstand the abrasive nature of filled polymers and elevated processing temperatures, ensuring consistent part quality over hundreds of thousands of cycles. For corrosive environments or optical-grade components, stainless variants provide enhanced resistance to rust and pitting.

Titanium is less commonly used in standard mold bases but finds niche applications in specialized inserts or cores where extreme strength-to-density ratios and corrosion resistance are paramount. While costly and challenging to machine, titanium excels in environments involving high stress, elevated temperatures, or exposure to aggressive chemicals. Its biocompatibility also makes it suitable for medical molding applications requiring sterile, non-reactive tooling.

Surface finishes further influence mold performance and part quality. Anodizing, particularly hard anodizing, is a key finishing process for aluminum molds. This electrochemical treatment creates a durable, corrosion-resistant oxide layer that enhances surface hardness up to 60 HRC, significantly improving wear resistance. Type III anodizing (hard coat) is recommended for molds subjected to repeated ejection cycles or abrasive materials. The process also allows for precise dimensional control and can be combined with sealing treatments for improved lubricity and reduced friction.

Below is a comparative overview of the three primary materials used in precision mold manufacturing:

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Best Use Case |

|---|---|---|---|---|

| Aluminum 7075-T6 | 150 HB | 130 | Moderate (improved with anodizing) | Prototyping, low-volume production |

| P20 Steel | 28–32 HRC | 30 | Low | Medium- to high-volume tooling |

| H13 Steel | 48–52 HRC | 35 | Moderate | High-stress, high-temp molding |

| Titanium Grade 5 | 36 HRC | 7 | Excellent | Specialized inserts, medical tools |

Selecting the right material and finish is not a one-size-fits-all decision. At Wuxi Lead Precision Machinery, we work closely with clients to evaluate project-specific needs and recommend solutions that balance performance, longevity, and cost.

Manufacturing Process & QC

Injection Molding Production Process: Achieving Zero Defects from Concept to Volume

The path to flawless injection molded components demands a rigorously controlled sequence from initial concept through to high-volume manufacturing. At Wuxi Lead Precision Machinery, we implement a disciplined three-phase methodology proven to eliminate defects and ensure consistent part quality for demanding industrial applications. This structured approach is non-negotiable for meeting the exacting tolerances and reliability standards expected in custom metal manufacturing supply chains.

The Design for Manufacturability (DFM) phase is the critical foundation. Our engineering team collaborates closely with clients during the earliest stages, utilizing advanced simulation software to analyze flow, cooling, and potential stress points within the proposed geometry. We scrutinize wall thickness transitions, gate location, and ejection strategies to preempt warpage, sink marks, or knit lines. Material selection is validated against thermal and mechanical requirements, ensuring compatibility with the intended service environment. This proactive analysis prevents costly revisions later, embedding quality into the part’s DNA before tooling begins. Skipping thorough DFM inevitably leads to defects that are expensive or impossible to correct downstream.

Prototyping transitions validated designs into physical reality under controlled conditions. We employ rapid tooling or soft tooling to produce initial parts using the exact material and process parameters planned for production. This stage is not merely about form and fit; it is a rigorous validation of the DFM predictions. Parts undergo comprehensive metrology, including CMM inspection and material property testing, against the original specifications. Process parameters are fine-tuned using Design of Experiments (DOE) to identify the optimal, robust processing window. Any deviations trigger immediate root cause analysis and parameter adjustment. This phase provides statistically validated proof that the design and process can consistently yield zero-defect parts.

Mass production leverages the insights from DFM and prototyping to execute with unwavering precision. Process parameters are locked down and monitored in real-time using integrated sensors tracking cavity pressure, melt temperature, and cooling rates. Statistical Process Control (SPC) charts are continuously analyzed to detect any drift before it impacts quality. Our automated systems enforce strict adherence to the validated process window, with automatic machine lockouts triggered by out-of-spec conditions. Regular in-process inspections and final audits against critical-to-quality (CTQ) characteristics provide multi-layered assurance. This closed-loop system, combined with our stringent maintenance protocols for molds and machines, guarantees that every part produced meets the zero-defect standard required for mission-critical components.

Critical Process Parameter Control for Zero Defects

| Parameter | Typical Range | Wuxi Lead Precision Control Target | Measurement Frequency | Critical Defect Prevented |

|---|---|---|---|---|

| Cavity Pressure | 80-120 MPa | ± 3 MPa | Real-time per shot | Short shots, flash, sinks |

| Melt Temperature | Material Specific | ± 5°C | Continuous | Degradation, poor flow |

| Cooling Time | 15-30 seconds | Optimized ± 0.5s | Per cycle | Warpage, dimensional drift |

| Injection Speed | Part Dependent | Profile ± 2% | Per stage | Weld lines, jetting |

| Gate Seal Time | Calculated | Validated ± 0.2s | DOE validated | Sinks, voids, dimensional |

This integrated process, executed with engineering discipline and advanced monitoring, transforms the aspiration of zero defects into a measurable, sustainable reality for our clients’ most challenging injection molding requirements.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Injection Molding Excellence

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and performance are non-negotiable in high-end custom metal manufacturing. As a trusted leader in advanced injection molding solutions, we specialize in delivering engineered systems that meet the exacting demands of aerospace, medical, automotive, and industrial applications. Our commitment to innovation, quality, and technical mastery positions us as the ideal partner for manufacturers seeking to elevate their production capabilities.

Choosing the right partner in injection molding goes beyond equipment—it’s about collaboration, expertise, and long-term support. At Lead Precision, we offer more than machines; we deliver comprehensive process optimization, from mold design and material selection to cycle efficiency and quality assurance. Our engineering team works closely with clients to analyze production goals, identify bottlenecks, and implement custom-tailored solutions that maximize uptime, reduce waste, and enhance part consistency.

Our state-of-the-art manufacturing facilities in Wuxi, China, are equipped with advanced CNC machining centers, real-time monitoring systems, and rigorous quality control protocols. Every component we produce adheres to international standards, including ISO 9001 and CE certification, ensuring compliance and performance across global markets. Whether you require high-cavitation molds, hot runner integration, or fully automated molding cells, our team has the technical depth to deliver precision at scale.

We pride ourselves on transparency, responsiveness, and technical partnership. From initial consultation to post-installation support, our engineers provide continuous guidance to ensure seamless integration into your production environment. Our clients benefit from reduced lead times, improved repeatability, and long-term cost savings—critical advantages in today’s competitive manufacturing landscape.

Below are key specifications that define the performance and reliability of our injection molding systems:

| Specification | Detail |

|---|---|

| Clamping Force Range | 80 to 3,500 Tons |

| Injection Pressure | Up to 2,500 Bar |

| Screw Diameter Range | 30 mm to 120 mm |

| Shot Weight (PS) | 150 g to 6,800 g |

| Control System | Advanced PLC with Touch HMI |

| Automation Integration | Full robot interface (6-axis compatible) |

| Energy Efficiency | Variable Pump or Servo-Drive Options |

| Mold Compatibility | Standard and Custom Hot Runner Systems |

| Precision Tolerance | ±0.01 mm |

| Industry Compliance | ISO 9001, CE, ROHS |

Elevate your manufacturing output with a partner who understands the science and art of precision molding. At Wuxi Lead Precision Machinery, we don’t just build machines—we build performance, trust, and long-term value.

Contact us today at [email protected] to schedule a technical consultation or request a customized solution for your production needs. Let Lead Precision be the foundation of your next breakthrough in injection molding excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.