Technical Contents

Engineering Guide: Cnc Aluminum Milling Machine

Engineering Insight Precision in CNC Aluminum Milling

Aluminum’s prevalence in aerospace, medical, and high-performance automotive sectors stems from its strength-to-weight ratio and thermal conductivity. Yet its softness, thermal expansion, and chip adhesion characteristics demand exceptional machine precision to avoid dimensional drift, surface imperfections, or costly rework. In critical applications like flight control components or surgical implants, tolerances below ±0.005 mm are non-negotiable. Even minor deviations in aluminum milling can compromise part integrity, assembly fit, or functional performance, directly impacting safety and lifecycle costs. At Wuxi Lead Precision Machinery, we engineer CNC aluminum milling systems where precision isn’t a specification—it’s the foundation of every spindle rotation and axis movement.

Our engineering prioritizes thermal stability and dynamic rigidity. Aluminum milling generates significant heat, inducing thermal growth that distorts workpieces and machine structures. Lead’s proprietary thermal compensation algorithms, integrated with real-time sensor networks, actively counteract thermal drift across all axes. Combined with FEM-optimized cast iron frames and direct-drive linear motors, this ensures consistent volumetric accuracy even during extended production runs. Rigidity is equally critical; aluminum’s tendency to deflect under cutting forces requires machines with minimal structural compliance. Our designs achieve this through reinforced column geometries and high-stiffness ball screws, eliminating chatter and maintaining surface finishes below Ra 0.8 µm.

The following specifications define our benchmark for aluminum milling excellence:

| Critical Parameter | Lead Precision Standard | Industry Typical | Measurement Standard |

|---|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±1.5 µm | ±3–5 µm | ISO 230-2:2014 |

| Repeatability (3σ) | ≤0.8 µm | ≤2.0 µm | ISO 230-2:2014 |

| Spindle Runout (at tool) | ≤0.5 µm | ≤1.5 µm | VDI/DGQ 3441 |

| Thermal Growth Compensation | 95% reduction (0–40°C) | 70–80% | Custom internal test |

This commitment transcends theoretical standards. Lead Precision machinery has delivered mission-critical components for the Beijing Winter Olympics timing systems, where nanosecond synchronization demanded micron-perfect aluminum housings. Similarly, our machines produce certified military-grade communication enclosures operating in extreme environments, adhering to MIL-STD-810G vibration and thermal shock requirements. These projects validate our machines’ ability to sustain precision under relentless operational demands—where failure is not an option.

For manufacturers scaling aluminum production, investing in a platform engineered for uncompromised precision eliminates hidden costs: scrap reduction, secondary operations, and warranty claims. At Wuxi Lead, every CNC aluminum milling machine undergoes 72-hour continuous-load validation with laser interferometer certification. We don’t just meet tolerance sheets; we ensure your parts perform identically from the first to the millionth cycle. Your application’s precision ceiling should be defined by design—not by machine limitations.

Precision Specs & Tolerances

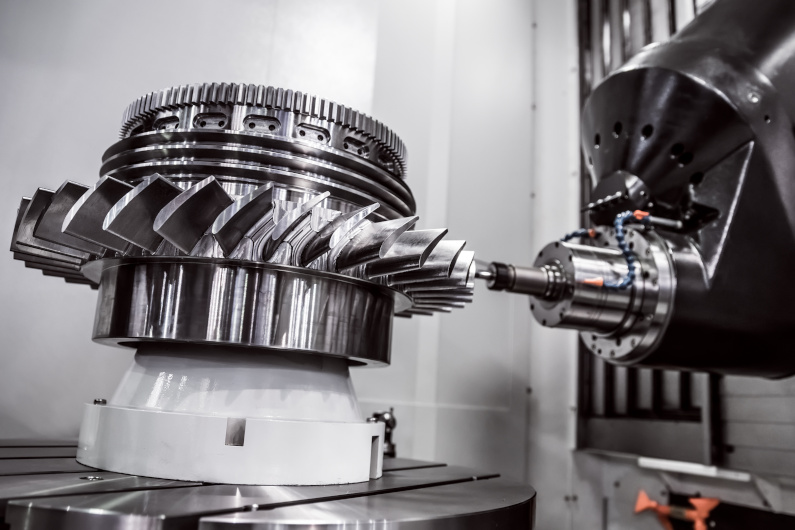

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, with a specialized focus on aluminum components for high-performance industries such as aerospace, automotive, medical, and industrial automation. Our facility is equipped with state-of-the-art 5-axis CNC milling machines, enabling the production of complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup times and part handling while ensuring superior dimensional consistency across high-mix, low-volume, and high-volume production runs.

Our 5-axis CNC aluminum milling machines are engineered for rigidity, speed, and precision, supporting a wide range of aluminum alloys including 6061, 7075, 2024, and 5052. This flexibility allows us to meet diverse mechanical and thermal requirements across client applications. Advanced tooling systems, high-speed spindles, and real-time adaptive control ensure optimal material removal rates and surface integrity, particularly critical when machining thin-walled or intricate aluminum structures. All machines are maintained under strict calibration schedules and monitored through continuous performance tracking to ensure operational excellence.

Quality is embedded into every stage of our manufacturing process. Each component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), providing metrology-grade verification of critical dimensions, geometric tolerances, and surface characteristics. Our CMM systems are certified to international standards and operated by trained quality engineers, ensuring traceability and compliance with ISO 9001:2015 requirements. In addition to first-article inspection, we implement in-process and final inspections to guarantee consistency across production batches.

The following table outlines the standard technical tolerances we achieve on our 5-axis CNC aluminum milling platforms under controlled conditions:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.010 mm |

| Angular Tolerances | ±0.1° | ±0.05° |

| Positional Accuracy | ±0.020 mm | ±0.008 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished finishes) |

| Geometric Tolerances (GD&T) | ±0.025 mm | ±0.010 mm |

| Feature-to-Feature Alignment | ±0.030 mm | ±0.012 mm |

| Hole Diameter Tolerance | H7 | H6 |

These capabilities are supported by integrated CAD/CAM programming, real-time tool wear compensation, and environmental controls within the machining area to minimize thermal drift. Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality assurance, and engineering expertise to deliver aluminum-milled components that meet the most demanding technical specifications. Our 5-axis CNC milling services are designed for clients who require precision, repeatability, and scalability in mission-critical applications.

Material & Finish Options

Material Selection for Precision CNC Aluminum Milling Applications

Material selection critically defines the performance envelope, manufacturability, and lifecycle cost of components produced on high-end CNC aluminum milling machines. At Wuxi Lead Precision Machinery, our engineering team emphasizes that optimal material choice aligns with the part’s functional requirements, environmental exposure, and production efficiency. Aluminum alloys dominate aerospace, automotive, and medical sectors due to their exceptional strength-to-weight ratio and thermal conductivity. Steel remains indispensable for high-wear tooling and structural applications demanding ultimate durability. Titanium, while challenging to machine, is essential for critical aerospace and medical implants where unparalleled strength-to-weight and biocompatibility are non-negotiable. Understanding the distinct machining characteristics of each material is paramount for achieving tight tolerances and surface finishes on modern CNC platforms.

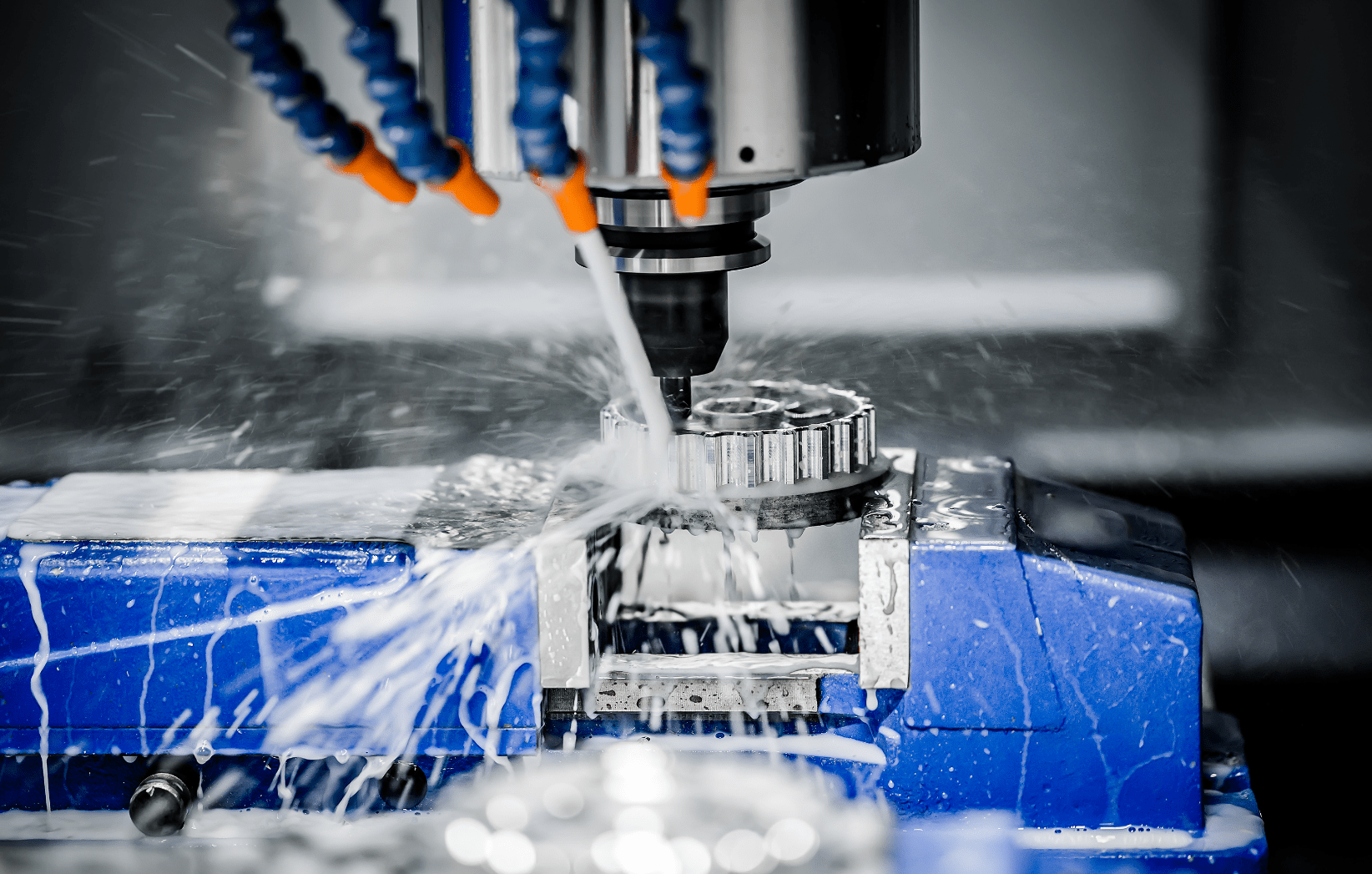

Aluminum alloys like 6061-T6 offer excellent machinability and weldability, making them ideal for prototypes and low-to-medium stress components. For higher strength demands, 7075-T6 provides superior mechanical properties but requires precise toolpath strategies and rigid machine setups to manage chip evacuation and prevent work hardening. Steel grades such as 4140 and 17-4 PH necessitate robust machine structures, high-torque spindles, and optimized coolant delivery to handle their toughness and heat generation during milling. Titanium alloys (e.g., Ti-6Al-4V) present significant challenges with low thermal conductivity and high chemical reactivity, demanding specialized tooling, slower feed rates, and exceptional machine stability to avoid galling and maintain dimensional accuracy. Our high-rigidity CNC milling centers are engineered specifically to manage these thermal and vibrational constraints across all material classes.

Surface finishing, particularly anodizing, is intrinsically linked to the base material’s properties. Aluminum is uniquely suited for anodizing, which enhances corrosion resistance, wear performance, and aesthetic options. Type II (sulfuric acid) anodizing provides a standard decorative and protective layer, while Type III (hardcoat) anodizing delivers significantly thicker, harder coatings (50+ microns) essential for high-wear applications. Material composition directly impacts anodizing results; for instance, 7075’s higher zinc content requires tighter process control to achieve consistent dye absorption and coating hardness compared to 6061. Steel components typically utilize plating or passivation, while titanium benefits from specialized anodizing for color coding or enhanced biocompatibility in medical devices. Post-mill cleaning and surface preparation are critical steps we integrate to ensure flawless anodizing adhesion and quality.

The following table summarizes key material properties and machining considerations relevant to precision CNC milling:

| Material Group | Key Properties & Machining Notes | Typical Applications |

|---|---|---|

| Aluminum Alloys (6061-T6, 7075-T6) | High thermal conductivity; Excellent machinability (6061); High strength but prone to work hardening (7075); Requires effective chip control and coolant | Enclosures, brackets, aerospace fittings |

| Steel (4140, 17-4 PH) | High strength/toughness; Generates significant heat; Requires rigid setup, high torque, optimized cutting parameters; Excellent for post-mill heat treatment | Tooling, hydraulic components, shafts |

| Titanium (Ti-6Al-4V) | Low thermal conductivity; High chemical reactivity; Demands slow feeds/speeds, sharp tooling, high stability; Prone to galling if parameters incorrect | Aircraft structural parts, medical implants |

Material selection is not merely a technical specification but a strategic decision impacting cost, lead time, and part performance. Wuxi Lead Precision Machinery leverages decades of metallurgical and CNC process expertise to guide clients toward the optimal material-finish combination for their specific application, ensuring components meet the highest standards of precision and reliability. Consult our engineering team early in the design phase to maximize manufacturability and performance.

Manufacturing Process & QC

The production process for a high-performance CNC aluminum milling machine at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure precision, repeatability, and zero defects—core principles that define our commitment to excellence in advanced manufacturing.

Design begins with a comprehensive analysis of functional requirements, material behavior, and operational environment. Our engineering team employs finite element analysis (FEA) and computational fluid dynamics (CFD) to simulate thermal expansion, vibration resistance, and structural integrity under load. Every geometric feature of the machine frame, spindle housing, and guideway system is optimized for stiffness, damping, and minimal thermal distortion. The design integrates modular architecture to support scalability and serviceability, ensuring long-term reliability. All components are modeled in 3D CAD with geometric dimensioning and tolerancing (GD&T) applied to critical interfaces, enabling seamless transition to prototyping.

Prototyping is executed using our in-house 5-axis CNC machining centers, allowing full-scale fabrication of structural and dynamic components from aerospace-grade aluminum alloys. These prototypes undergo rigorous validation, including laser tracker-based volumetric accuracy measurement, dynamic runout testing, and thermal stability monitoring over 72-hour cycles. Functional testing includes dry-run motion profiling, tool change sequence verification, and spindle load analysis. Any deviation beyond micrometer-level thresholds triggers immediate design refinement. This closed-loop iteration ensures that only fully validated designs advance to mass production.

Mass production is conducted in a climate-controlled facility with automated process control and real-time quality monitoring. Each machine is built on a serialized assembly line where every operation is documented via a digital work instruction system. Critical fastening sequences use torque-controlled robots, while linear guideways and ball screws are preloaded and calibrated using laser interferometry. Final assembly includes a 24-hour continuous burn-in cycle under simulated production load, followed by a full-axis dynamic accuracy verification. Only units achieving sub-micron repeatability and ISO 230-2 compliance are released for shipment.

Throughout the entire production lifecycle, traceability is maintained through a barcode-linked quality management system. Every component, fastener, and calibration record is archived for full auditability. This end-to-end control system, combined with our zero-defect philosophy, ensures that every CNC aluminum milling machine delivered meets the highest standards of precision and performance.

| Specification | Value |

|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.005 mm |

| Repeatability (3σ) | ±0.003 mm |

| Spindle Speed Range | 8,000 – 24,000 rpm |

| Rapid Traverse Rate (X/Y/Z) | 60 / 60 / 50 m/min |

| Table Size (T-slots) | 1,200 × 600 mm |

| Control System | Fanuc 31i-B5 or Siemens 840D sl |

| Volumetric Compensation | Standard (laser-calibrated) |

| Thermal Compensation | Real-time sensor-based |

| Machine Weight | 8,500 kg |

| Power Requirement | 380V, 50/60 Hz, 3-phase |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Aluminum Excellence

Elevate your manufacturing capabilities by aligning with Wuxi Lead Precision Machinery, your dedicated partner in high-performance CNC aluminum milling solutions. We understand the critical demands of aerospace, medical device, and advanced electronics production where micron-level precision, material integrity, and repeatability are non-negotiable. Our engineering team doesn’t just supply machines; we integrate deeply with your production goals, providing tailored process validation, rigorous quality assurance protocols, and lifecycle support that minimizes downtime and maximizes your return on investment. When you choose Lead Precision, you gain a strategic ally committed to advancing your competitive edge through demonstrable technical superiority and unwavering reliability.

Our commitment to precision is quantifiable. Every CNC aluminum milling machine we engineer adheres to stringent international standards, ensuring consistent performance under the most demanding production conditions. The specifications below reflect the core capabilities embedded in our standard high-end configurations, designed specifically for complex aluminum alloys requiring exceptional surface finishes and tight tolerances. These machines form the foundation upon which we build your custom solution.

Lead Precision CNC Aluminum Milling Machine Core Specifications

| Specification Category | Performance Metric | Industry Standard Comparison |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ±0.003 mm | Exceeds ISO 230-2 Class A |

| Repeatability (X/Y/Z) | ±0.002 mm | Surpasses ISO 230-2 Class A |

| Spindle Speed Range | 20,000 – 42,000 RPM | Optimized for high-speed aluminum |

| Maximum Rapid Traverse | 60 m/min | Enhances non-cutting cycle time |

| Control System | Fanuc 31i-B5 / Siemens 840D sl | Industry-leading stability & interface |

| Tool-to-Tool Change Time | ≤ 1.2 seconds | Minimizes non-productive time |

| Thermal Compensation | Full 3D Active System | Ensures dimensional stability over shifts |

| Core Construction Material | Meehanite MHT 300 Cast Iron | Superior vibration damping |

These specifications are not merely theoretical benchmarks. They are rigorously validated through our in-house metrology lab using calibrated laser interferometers and ballbar systems, providing documented proof of machine capability before shipment. We subject every unit to extended aluminum milling trials under simulated production loads, verifying thermal stability and surface finish consistency critical for your end-use applications. This empirical validation process eliminates guesswork and ensures your machine performs to specification from day one of operation.

Moving beyond equipment supply, Lead Precision delivers comprehensive partnership. Our application engineers collaborate with your team during feasibility studies, optimizing toolpaths, fixture design, and coolant strategies specifically for your aluminum components. We provide detailed machine capability studies (Cp/Cpk) and ongoing process support, transforming your milling operation into a predictable, high-yield asset. This proactive engineering engagement is fundamental to achieving your quality targets and production throughput goals.

Initiate your precision advantage today. Contact our engineering sales team directly at [email protected] to schedule a confidential technical consultation. Provide your specific component challenges, volume requirements, and quality targets. We will respond within 24 business hours with a preliminary capability assessment and arrange a virtual or onsite demonstration focused exclusively on solving your manufacturing constraints. Partner with Wuxi Lead Precision Machinery – where engineering excellence meets actionable results. Your next breakthrough in aluminum machining starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.