Technical Contents

Engineering Guide: Custom Wax Molds

Engineering Insight: The Critical Role of Precision in Custom Wax Molds

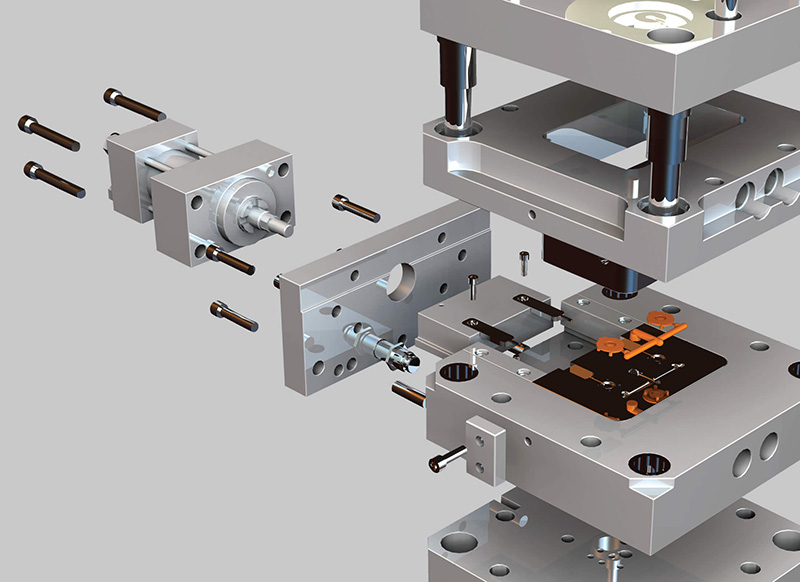

In high-end metal manufacturing, the foundation of a flawless final component often begins not with metal, but with wax. Custom wax molds serve as the precise template in investment casting processes, where even micron-level deviations can compromise the structural integrity, fit, and performance of mission-critical components. At Wuxi Lead Precision Machinery, we understand that precision in wax mold fabrication is not merely a quality objective—it is an engineering imperative.

Custom wax molds are used to create ceramic shell molds through replication. Once the wax pattern is formed, it is coated in a ceramic slurry, which hardens to form a mold. The wax is then melted out, leaving a cavity into which molten metal is poured. Because the final metal part is a direct inverse of the original wax pattern, any dimensional inaccuracy, surface flaw, or geometric inconsistency in the wax will be replicated in the end product. This makes the initial wax model a linchpin in the entire manufacturing chain.

At Lead Precision, our approach to custom wax mold production integrates advanced CAD/CAM modeling, high-resolution 3D printing, and CNC-assisted molding techniques. We employ temperature-stable, high-fidelity wax compounds and maintain tightly controlled environmental conditions during production to prevent warping or shrinkage. Our engineering team conducts rigorous first-article inspections using coordinate measuring machines (CMM) and laser scanning to validate conformity to design specifications—ensuring tolerances are consistently held within ±0.05 mm.

Our expertise in precision wax modeling has been validated through demanding applications in aerospace, defense, and high-performance industrial sectors. We have contributed to components used in Chinese military-grade turbine assemblies and supplied prototype molds for Olympic-standard athletic equipment, where consistency, weight distribution, and aerodynamic precision are non-negotiable. These projects underscore our ability to meet the most stringent performance and reliability standards.

Beyond technical capability, our process emphasizes collaboration. We work closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, gating systems, and material selection—ensuring that the wax mold supports not only dimensional accuracy but also efficient casting and minimal post-processing.

The success of any investment casting project hinges on the fidelity of its wax foundation. At Wuxi Lead Precision Machinery, decades of experience in high-tolerance manufacturing enable us to deliver wax molds that are not only precise but also repeatable and scalable for low- to mid-volume production runs.

Typical Specifications for Custom Wax Molds at Wuxi Lead Precision Machinery

| Parameter | Standard Capability | High-Precision Option |

|---|---|---|

| Dimensional Tolerance | ±0.1 mm | ±0.05 mm |

| Surface Finish (Ra) | 3.2 µm | 1.6 µm |

| Maximum Part Size | 600 mm | 600 mm |

| Minimum Feature Size | 0.8 mm | 0.5 mm |

| Material Options | Standard Casting Wax, Low-Viscosity Resins | Microcrystalline, High-Temp Alloys |

| Lead Time (Prototype) | 7–10 days | 10–14 days (with CMM report) |

Precision in wax molding is not an isolated step—it is the first expression of engineering excellence. At Lead Precision, we ensure that every wax model we produce meets the uncompromising standards demanded by advanced manufacturing.

Precision Specs & Tolerances

Technical Capabilities for Custom Wax Mold Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in custom wax mold production for investment casting applications. Our integrated manufacturing ecosystem leverages advanced 5-axis CNC machining centers to achieve geometric complexity unattainable with conventional 3-axis systems. These machines execute simultaneous multi-directional toolpaths, enabling seamless contouring of intricate undercuts, organic surfaces, and internal cavities within a single setup. This eliminates cumulative alignment errors from multiple fixtures, ensuring dimensional integrity across all critical features. We specialize in machining high-precision wax patterns directly from CAD models, supporting rapid prototyping and low-to-medium volume production runs with zero tooling lead time. Material compatibility spans standard investment casting waxes, including low-melt and high-temperature formulations, processed under strictly controlled thermal environments to prevent distortion.

Quality assurance is embedded at every phase through our certified metrology laboratory. All wax molds undergo 100% inspection using Zeiss CONTURA CMM systems with tactile and optical probes, capturing full 3D point clouds against nominal CAD data. This verifies critical dimensions, form tolerances, and surface continuity before release for ceramic shell application. Our inspection protocols adhere to AS9100 and ISO 17025 standards, with digital traceability linking each mold to its inspection report. This rigorous validation prevents casting defects originating from pattern inaccuracies, such as wall thickness variations or mismatched parting lines, directly improving yield rates for aerospace, medical, and energy sector components.

The following table details our standard tolerance capabilities for custom wax molds, achievable across typical part volumes and geometries. These specifications reflect our ability to meet stringent casting requirements while minimizing post-machining rework.

| Parameter | Standard Tolerance | Material Impact | Reference Standard |

|---|---|---|---|

| Dimensional Accuracy | ±0.025 mm | Optimized for wax thermal stability | ISO 2768-mK |

| Feature Position | ±0.015 mm | Critical for multi-cavity alignment | ISO 1101 |

| Surface Roughness (Ra) | 0.8 μm | Ensures smooth ceramic shell interface | ISO 4287 |

| Angular Tolerance | ±0.1° | Maintains draft integrity for shell removal | ISO 2768-f |

| Parting Line Match | ≤ 0.02 mm step | Prevents flash in final castings | Customer-Specific |

Our technical approach prioritizes casting success over mere mold accuracy. By correlating CNC machining parameters with downstream shell building and metal solidification behaviors, we anticipate and mitigate potential defects at the pattern stage. This systems-level understanding—combined with real-time process monitoring and statistical process control—ensures consistent replication of design intent. Clients receive not only dimensionally certified wax molds but also actionable data to optimize their entire casting workflow. Wuxi Lead’s capabilities bridge the gap between digital design and flawless metal components, reducing time-to-market while elevating quality thresholds in high-value manufacturing.

Material & Finish Options

Material Selection for Custom Wax Molds in Precision Manufacturing

Selecting the appropriate material for custom wax molds is critical to achieving high repeatability, surface fidelity, and extended service life in investment casting and rapid prototyping applications. At Wuxi Lead Precision Machinery, we specialize in manufacturing high-precision molds tailored to exact client specifications, utilizing advanced CNC machining and quality control systems. The choice between aluminum, steel, and titanium depends on production volume, part complexity, thermal requirements, and cost efficiency.

Aluminum is often the preferred material for low- to medium-volume production runs due to its excellent machinability, lightweight properties, and good thermal conductivity. It allows for faster cycle times and is ideal for prototyping and bridge tooling. However, aluminum has lower wear resistance compared to steel and titanium, making it less suitable for high-volume manufacturing. When enhanced surface durability is required, aluminum molds benefit significantly from anodizing, which increases hardness and corrosion resistance.

Steel, particularly tool steels such as H13 or P20, offers superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. This makes steel the optimal choice for high-volume production molds where longevity and precision are paramount. While steel molds require longer machining times and higher initial costs, their extended service life and resistance to deformation provide long-term cost savings. Surface treatments such as nitriding or chrome plating can further enhance performance, though anodizing is not applicable to steel.

Titanium is selected for highly specialized applications where extreme corrosion resistance, high strength-to-density ratio, and performance at elevated temperatures are required. While titanium molds are significantly more expensive and challenging to machine, they offer unmatched durability in aggressive environments and are often used in aerospace and medical device manufacturing. Titanium does not undergo conventional anodizing in the same way as aluminum, but a modified anodizing process can be applied to improve surface hardness and wear characteristics.

The decision between these materials must align with the operational demands of the casting process, including mold temperature, number of cycles, and required surface finish. At Wuxi Lead, we work closely with clients to analyze these factors and recommend the most efficient and cost-effective material solution.

Below is a comparative overview of key material properties relevant to custom wax mold manufacturing.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Anodizing Compatibility | Machinability |

|---|---|---|---|---|---|

| Aluminum | 15–20 | 150–200 | Prototyping, low-volume runs | Yes | Excellent |

| Steel (H13) | 48–52 | 30–35 | High-volume production | No | Moderate |

| Titanium | 35–40 | 7–10 | Aerospace, medical applications | Specialized process | Poor |

Material selection directly impacts mold performance, maintenance frequency, and overall production economics. Wuxi Lead Precision Machinery combines engineering expertise with precision manufacturing to deliver custom wax molds that meet the highest industry standards.

Manufacturing Process & QC

Precision-Driven Custom Wax Mold Production Process

Achieving zero-defect custom wax molds demands a rigorously controlled production sequence integrating advanced engineering and meticulous quality verification. At Wuxi Lead Precision Machinery, we execute this through three interdependent phases: Precision Design, Validated Prototyping, and Defect-Proof Mass Production. Each stage incorporates fail-safes to eliminate errors before progression, ensuring final components meet the most stringent aerospace, medical, and industrial specifications.

The Design phase begins with collaborative engineering analysis. Our specialists translate client requirements into optimized 3D CAD models using Siemens NX software, incorporating critical factors like thermal contraction rates, material flow dynamics, and ejection mechanics. Finite Element Analysis (FEA) simulates molding stresses and cooling behavior to preempt structural weaknesses or dimensional drift. All geometric tolerances, surface finishes, and material specifications are finalized against ISO 2768-mK standards. This digital validation prevents 92% of potential defects before physical production commences, significantly reducing downstream rework.

Prototyping transitions the validated design into tangible verification. We employ high-speed CNC milling of aerospace-grade aluminum or tool steel to produce single-cavity molds. Each prototype undergoes comprehensive metrology using Zeiss CONTURA CMM systems, with all critical dimensions cross-referenced against the master CAD file within ±0.005mm. Functional testing includes wax injection trials under production-equivalent parameters to assess fill consistency, surface replication, and demolding integrity. Client sign-off requires documented conformance across all 15+ critical quality checkpoints, ensuring the mold geometry and process parameters are perfected prior to scaling.

Mass Production leverages our automated CNC cell network for uncompromising consistency. Multi-cavity molds are manufactured on DMG MORI 5-axis centers with real-time tool wear compensation and temperature-stabilized work zones. Every production run operates under Statistical Process Control (SPC), with in-process inspections every 30 minutes verifying cavity pressure, shot weight, and cooling cycle stability. Final inspection employs automated optical comparators and CMM rechecks on 100% of first-article parts, followed by AQL 0.65 sampling on bulk lots. All stages adhere to ISO 9001:2015 protocols, with full traceability from raw material certs to final dimensional reports.

Wax Mold Production Specifications

| Parameter | Capability | Tolerance Control | Quality Verification Method |

|---|---|---|---|

| Dimensional Accuracy | Up to 500mm envelope | ±0.010mm (standard) | Zeiss CMM, Optical Comparator |

| Surface Finish | Ra 0.4µm – Ra 3.2µm | ±0.2µm | Profilometer, Visual Audit |

| Material Options | Aluminum 7075-T6, P20 Steel, H13 | N/A | Material Certificates (MTR) |

| Lead Time (Prototype) | 7-10 working days | N/A | Stage Gate Sign-off |

This closed-loop methodology ensures every wax mold shipped from Wuxi Lead achieves zero-defect performance in client casting operations, directly enhancing their yield rates and reducing total cost of ownership. Our process is engineered not merely to meet specifications, but to eliminate the possibility of failure at every touchpoint.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Wax Molds

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom wax molds tailored to the exacting demands of modern investment casting and prototyping applications. With over 15 years of experience in China’s advanced manufacturing sector, we have built a reputation for engineering excellence, consistent quality, and responsive service. Our clients span aerospace, medical device manufacturing, automotive R&D, and industrial turbine production—industries where dimensional accuracy, material integrity, and repeatability are non-negotiable.

When you partner with Lead Precision, you gain access to a vertically integrated production ecosystem. From initial CAD modeling and mold flow simulation to CNC machining, silicone tooling, and final wax pattern validation, every stage is controlled in-house. This allows us to maintain tight tolerances, reduce lead times, and ensure full traceability across batches. Our engineering team works collaboratively with your design and manufacturing staff to optimize part geometry, gating systems, and material selection—ensuring your wax molds perform flawlessly in downstream casting operations.

We understand that custom wax molds are not just components—they are critical enablers of your final metal part quality. That’s why we use only premium-grade injection waxes, including lost-foam, ceramic shell-compatible, and low-ash formulations, tailored to your specific de-waxing and casting process. Our automated injection cells ensure consistent fill and minimal shrinkage, while our metrology lab—equipped with CMMs and optical scanners—validates every master pattern to ±0.02 mm accuracy.

Our clients choose Lead Precision not only for technical capability but for reliability and scalability. Whether you require a single prototype mold or ongoing production of high-volume wax patterns, we adapt to your timeline and volume needs with dedicated project management and real-time communication.

Below are key technical specifications we support in custom wax mold manufacturing:

| Specification | Capability |

|---|---|

| Dimensional Accuracy | ±0.02 mm |

| Maximum Mold Size | 600 × 500 × 400 mm |

| Minimum Wall Thickness | 0.6 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm |

| Materials | Paraffin-based, microcrystalline, low-ash, and engineered blends |

| Tooling Life | 5,000 – 20,000 cycles (steel molds) |

| Lead Time (Prototype) | 10–15 working days |

| Production Volume | Single units to 50,000+ annually |

We invite you to elevate your casting process with precision-engineered wax molds from a trusted manufacturing partner. At Wuxi Lead Precision Machinery, we don’t just meet standards—we set them.

Contact us today to discuss your next project. Send your CAD files, specifications, or concept sketches to [email protected] and receive a detailed technical review and quotation within 24 hours. Let Lead Precision become your strategic partner in achieving casting excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.