Technical Contents

Engineering Guide: Injection Molding Quotes

Engineering Insight Precision as the Foundation of Injection Molding Quotes

In high-stakes custom metal manufacturing, particularly for injection molding tooling and components, the accuracy embedded within a quotation is not merely a cost indicator—it is the first critical engineering assessment of project viability. Generic quotes focusing solely on price per unit obscure the fundamental reality: dimensional precision dictates functional performance, assembly integrity, and long-term reliability. A variance of ±0.05mm may suffice for a consumer plastic housing but becomes catastrophic in aerospace hydraulic manifolds or medical implant interfaces where micro-movements induce failure. At Wuxi Lead Precision Machinery, we treat every quote as an engineering commitment. Our quoting process rigorously evaluates geometric complexity, material behavior under thermal cycling, gate location impact on residual stress, and the achievable tolerance stack-up across multi-cavity tools. This depth prevents costly downstream revisions, mold reworks, or field failures—risks often hidden in superficially attractive low-cost proposals.

True precision quoting demands proven capability, not theoretical promises. Our facility operates under AS9100 and ISO 13485 standards, with CNC machining centers maintained to sub-micron repeatability. This technical foundation allows us to quantify achievable tolerances during quoting, not guess. For instance, quoting a medical connector housing requires confirming we can hold ±0.005mm on critical sealing surfaces across 50,000 cycles—a specification validated by our in-house metrology lab’s Zeiss CONTURA systems. Underestimating such requirements leads to non-conformance; over-engineering inflates costs unnecessarily. Our engineers dissect 3D CAD models to identify features demanding tight control versus those suitable for standard tolerances, optimizing both performance and value. This granular analysis is why global clients trust us for mission-critical applications, including pressure housings for the Beijing Winter Olympics infrastructure and precision actuators in Tier-1 military supply chains. These projects demanded zero-defect tooling under extreme environmental conditions—proof our quoting accuracy translates to real-world resilience.

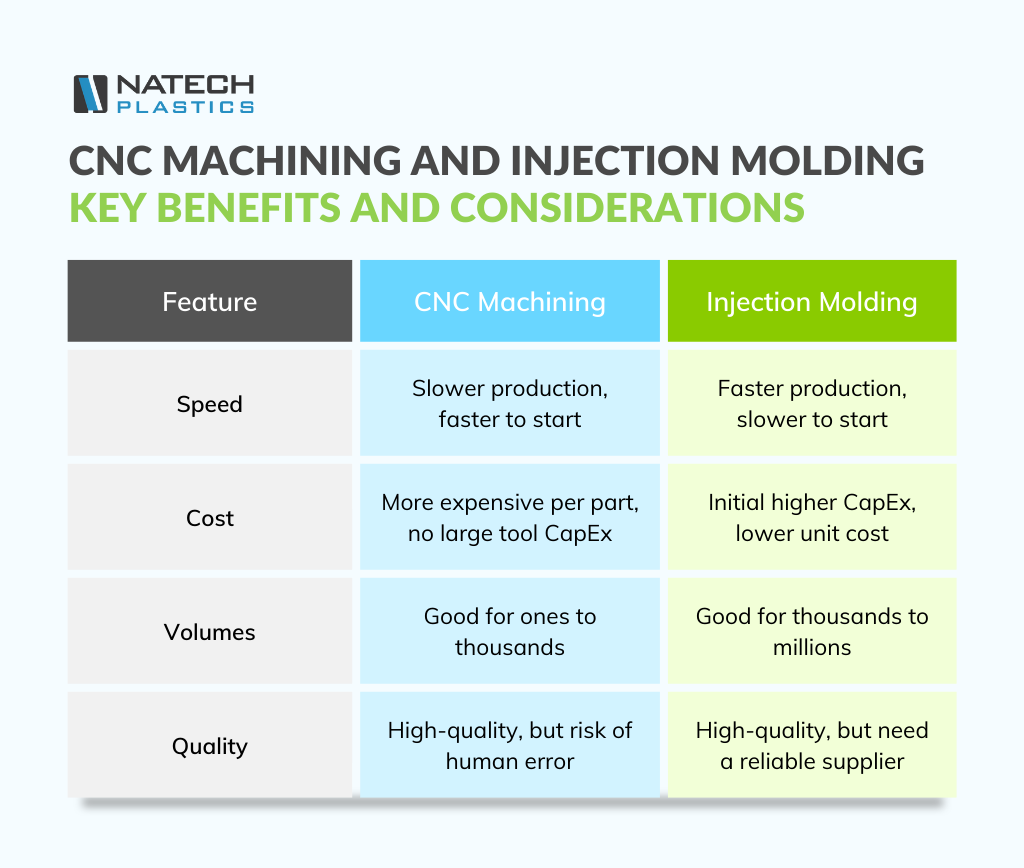

The following table outlines core capabilities directly influencing quote feasibility and precision outcomes for metal injection molding (MIM) and precision machined components:

| Specification Category | Capability Range | Industry Relevance |

|---|---|---|

| Linear Tolerance (MIM Sintered) | ±0.3% to ±0.1% of dimension | Critical for mating surfaces in automotive sensors |

| Geometric Tolerance (GD&T) | ±0.002mm to ±0.010mm (machined) | Essential for aerospace hydraulic components |

| Surface Roughness (Ra) | 0.2µm to 1.6µm (machined) | Required for medical implant biocompatibility |

| Material Options | 17-4PH, 316L, Inconel 718, Ti-6Al-4V | Determines thermal stability in high-temp tools |

| Max Part Weight (MIM) | 250 grams | Enables complex structural brackets |

| Secondary Operations | CNC milling, laser welding, plating | Ensures final assembly precision |

A precise quote is the blueprint for success. It aligns client expectations with physical reality, mitigates risk through engineering foresight, and establishes trust via demonstrable capability. At Wuxi Lead Precision Machinery, decades of refining Olympic-grade and military-specification components ensure our quotes reflect not just cost, but the uncompromising precision your application demands. We engineer certainty from the first specification sheet.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the rigorous demands of high-performance industries such as aerospace, medical, automotive, and industrial automation. Our technical capabilities are built around precision engineering, state-of-the-art equipment, and a quality-driven manufacturing culture. At the core of our production floor lies a fleet of 5-axis CNC machining centers, enabling us to execute complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly enhancing machining efficiency and part integrity—particularly for intricate injection molded tooling components and high-tolerance metal parts.

Our 5-axis technology eliminates the need for multiple setups, reducing cumulative error and improving repeatability. This capability is essential when producing molds, inserts, and cores used in high-pressure injection molding applications, where dimensional stability and surface precision directly impact final product quality. Advanced toolpath strategies and high-speed machining ensure minimal material stress and optimal thermal control, preserving the metallurgical properties of premium alloys such as tool steels, stainless steels, aluminum, and titanium.

Quality assurance is fully integrated into our manufacturing workflow. Every critical component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring compliance with the tightest tolerances and geometric specifications. Our CMM system supports both contact and non-contact probing, enabling high-resolution verification of complex contours, hole patterns, and form deviations. All inspection data is documented and traceable, meeting ISO 9001 standards and client-specific quality requirements.

We maintain full in-house control from design support and material sourcing to final inspection and packaging. This vertical integration ensures rapid iteration, consistent quality, and on-time delivery—key factors when responding to injection molding quote requests that demand precision, reliability, and technical expertise.

The following table outlines our standard machining tolerances, reflecting our commitment to precision and repeatability across production runs.

| Feature | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 500 mm length |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed or honed finishes |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Per GD&T standards |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm | Verified on granite surface plate |

| Surface Roughness | Ra 1.6 µm | Ra 0.4 µm | Machined; finer with polishing |

| Angular Tolerance | ±0.05° | ±0.02° | 5-axis simultaneous control |

All tolerances are achievable under controlled environmental conditions and are validated through our CMM inspection protocol. Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous quality assurance to deliver injection molding components that meet the highest standards of precision and performance.

Material & Finish Options

Material Selection for Injection Molding Tooling: Precision Engineering Impact

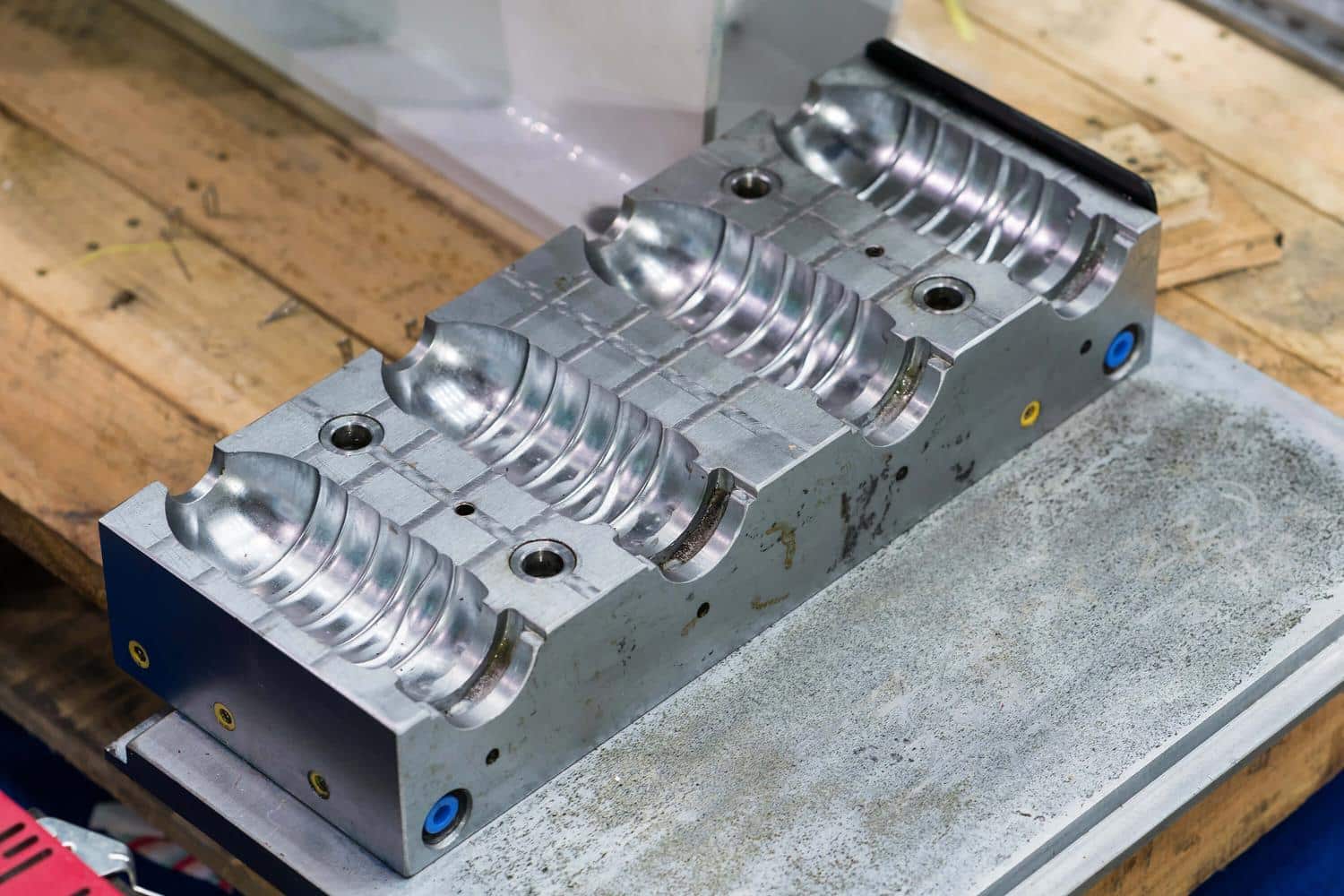

Material selection for injection molding tooling is not merely a cost decision; it directly determines mold longevity, part quality, production efficiency, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your specific application demands to optimize performance and value. Aluminum alloys offer rapid prototyping and low-volume production advantages due to excellent machinability and thermal conductivity. However, their lower hardness limits mold life, typically to 100,000 cycles or fewer, making them unsuitable for abrasive resins or high-wear applications. Steel remains the dominant choice for high-volume production. Tool steels like P20, H13, and S136 provide exceptional hardness, wear resistance, and thermal stability. Properly heat-treated and maintained steel molds reliably achieve 500,000 to over 1,000,000 cycles, even with challenging engineering plastics. Titanium alloys represent the pinnacle for extreme applications demanding ultra-high strength-to-weight ratio, exceptional corrosion resistance, and non-magnetic properties. While significantly more expensive and challenging to machine, titanium molds excel in highly corrosive environments or specialized aerospace and medical components where steel would degrade prematurely.

Surface finish, particularly anodizing, is critical for mold release, surface finish replication, and wear resistance. Standard sulfuric acid anodizing (Type II) provides moderate corrosion protection and aesthetic options. For demanding injection molding, hard anodizing (Type III) is essential. This process creates a thick, dense, wear-resistant aluminum oxide layer, typically 25-50μm thick, significantly enhancing surface hardness to 500-900 HV. Hard anodizing drastically reduces galling and improves release properties for sticky resins like POM or certain nylons, directly extending mold life and reducing downtime for cleaning. It is a standard recommendation for aluminum mold components subjected to high wear.

The following table summarizes key material specifications for injection molding tooling:

| Material | Key Properties | Typical Applications | Mold Life Expectancy |

|---|---|---|---|

| Aluminum Alloys | High thermal conductivity, Excellent machinability, Lower hardness (100-150 HB) | Prototyping, Low-volume production, Non-abrasive resins | < 100,000 cycles |

| Tool Steel (H13) | High hardness (48-52 HRC), Excellent toughness, Thermal fatigue resistance | High-volume production, Engineering plastics, Hot-runner systems | 500,000 – 1,000,000+ cycles |

| Titanium Alloys | Exceptional strength-to-weight, Superior corrosion resistance, Non-magnetic | Extreme environments, Medical implants, Aerospace components | Highly application-dependent; corrosion resistance extends life vs steel |

Selecting the optimal material and finish requires analyzing resin type, part geometry, required surface finish, production volume, and environmental factors. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and metallurgical knowledge to guide clients toward the most cost-effective, durable solution. We rigorously evaluate material certifications and implement precise heat treatment protocols to ensure the specified properties are met. Partnering with us ensures your mold investment delivers maximum performance and return, transforming material selection from a cost center into a strategic advantage for your manufacturing success. Contact our engineering team for a detailed analysis tailored to your specific quote requirements.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the injection molding process begins with an engineering-centric design phase, where precision and manufacturability are prioritized from the outset. Our team of senior CNC engineers collaborates directly with clients to analyze part geometry, material requirements, and functional performance under real-world conditions. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize wall thickness, gate locations, and cooling channels to prevent warpage, sink marks, and residual stress. This stage includes Design for Manufacturing (DFM) reviews to ensure that every component is not only functional but also cost-efficient to produce at scale. Our engineers apply decades of experience in custom metal manufacturing to anticipate potential defects before tooling begins, reducing risk and accelerating time to market.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC-machined molds or soft tooling, depending on the complexity and urgency. These prototype molds allow for the production of functional parts in the actual target material—typically high-grade aluminum, stainless steel, or tool steel—enabling accurate testing of fit, form, and function. Each prototype undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to validate dimensional accuracy and surface integrity. This phase is critical for identifying any micro-defects or process inconsistencies. Client feedback is integrated swiftly, and iterative refinements are made until zero-defect performance is consistently achieved. The result is a fully validated process ready for seamless transition to mass production.

Mass Production: Consistency Through Automation and Control

With design and prototyping complete, we initiate full-scale production using hardened steel molds built for longevity and repeatability. Our automated injection molding cells operate under strict environmental and process controls, with real-time monitoring of temperature, pressure, and cycle time. Each production run is supported by Statistical Process Control (SPC) systems that detect deviations before they impact quality. In-line inspection stations and 100% critical dimension checks ensure every component meets exacting tolerances. Our facility in Wuxi is certified to ISO 9001 standards, and every batch is traceable, with full documentation provided to the client.

Process Specifications Overview

| Parameter | Specification |

|---|---|

| Material Options | Aluminum alloys, Stainless Steel, Tool Steel |

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.2 µm to Ra 1.6 µm (polished/matte) |

| Tooling Life | 100,000 to 1,000,000 cycles (hardened steel) |

| Prototype Lead Time | 7–14 days |

| Mass Production Cycle Time | 30 seconds to 3 minutes per part (varies by size) |

| Quality Standards | ISO 9001, SPC, Full First Article Inspection |

Through this disciplined progression—from engineered design to validated prototyping and controlled mass production—Wuxi Lead Precision Machinery guarantees zero-defect output, on time, every time.

Why Choose Wuxi Lead Precision

Elevate Your Injection Molding Precision with Lead Precision Engineering

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical injection molding projects requiring uncompromising metal component accuracy. We transcend conventional manufacturing by integrating advanced CNC machining, rigorous material science expertise, and closed-loop quality validation. Our facility operates under ISO 9001:2015 and IATF 16949 standards, ensuring every mold base, cavity, and core meets aerospace, medical, and high-volume industrial specifications. When dimensional stability at ±0.005mm tolerances or hardened tool steel longevity under 1 million+ cycles defines success, our engineered solutions eliminate production bottlenecks and scrap costs inherent in substandard tooling.

Our technical capabilities are engineered for complex metal fabrication demands. The following specifications demonstrate our precision infrastructure:

| Capability | Specification Range | Material Compatibility |

|---|---|---|

| Machining Tolerance | ±0.002mm to ±0.005mm | P20, H13, S7, Stainless 420, Inconel |

| Surface Finish | Ra 0.05µm to Ra 0.4µm (mirror polish) | Aluminum 7075, Titanium Grade 5 |

| Max Work Envelope | 1200 x 800 x 650mm | Copper Alloys, Tool Steels |

| Hardness Range | HRC 28-58 (post-heat treatment) | Pre-hardened Steels (up to 40HRC) |

| Secondary Operations | EDM, Welding, Coating, Metrology | Full Material Traceability |

This precision foundation enables proactive risk mitigation from day one. We implement Design for Manufacturing (DFM) analysis before quoting, identifying potential sink marks, weld lines, or ejection challenges in your part geometry. Our engineers collaborate to optimize gate locations, cooling channels, and venting—translating theoretical designs into production-ready tooling. Real-time cavity pressure monitoring and automated SPC data logging during trials guarantee process stability before full-scale production. Unlike transactional suppliers, we provide comprehensive documentation: mold flow analysis reports, first-article inspection (FAI) per AS9102, and full 3D metrology datasets for your quality archives.

Partnering with Lead Precision means embedding engineering accountability into your supply chain. We accept only projects where our precision capabilities directly impact your product’s performance lifecycle—refusing to compete on price alone. Our quoting process includes a technical consultation to align material selection, tolerance stack-ups, and secondary operations with your functional requirements. This prevents costly redesigns and accelerates time-to-market for complex assemblies.

Initiate your precision partnership by contacting our engineering team directly at [email protected]. Include your CAD files, material specifications, and annual volume requirements for a validated quote within 48 hours. Our senior process engineers will outline specific recommendations for mold longevity, cycle time reduction, and cost-per-part optimization—no generic templates. For urgent prototyping needs, reference “RUSH-QUOTE” in your email subject line to activate our 72-hour trial mold service. Trust Wuxi Lead Precision Machinery to transform injection molding from a production step into a competitive advantage. Precision engineered. Performance guaranteed.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.