Technical Contents

Engineering Guide: Sheet Metal Squares

Engineering Insight Precision Fundamentals in Sheet Metal Squares

In high-stakes sheet metal fabrication, the humble square transcends its basic geometric form to become a critical vector of dimensional integrity. Precision in these foundational tools directly dictates the accuracy of layout, bending, and assembly operations across aerospace, medical device, and advanced electronics manufacturing. A deviation of mere microns in the square’s reference edge or perpendicularity propagates exponentially through subsequent processes, potentially compromising entire production runs. At Wuxi Lead Precision Machinery, we engineer sheet metal squares not as simple shop aids, but as calibrated metrology instruments essential for maintaining tolerances demanded by Tier 1 suppliers and regulated industries. Material selection is paramount; our aerospace-grade 440C stainless steel blanks undergo stringent stress-relieving and cryogenic stabilization to eliminate internal stresses that cause drift over time and temperature fluctuations. The grinding and lapping sequence employs proprietary multi-axis CNC processes achieving sub-micron surface finishes, ensuring consistent contact geometry against critical workpiece edges.

Our commitment to uncompromising precision is validated through rigorous real-world application. Lead Precision squares were specified for the structural steel alignment during Beijing Olympic venue construction, where thermal expansion variances across massive spans required tools holding perpendicularity within 0.0002 inches per foot across ambient shifts. Similarly, our military-grade fabrication squares undergo NATO STANAG 4427 environmental testing, maintaining certification after exposure to extreme humidity, salt fog, and thermal cycling from -55°C to +125°C. This heritage informs every production run, ensuring traceable NIST-certified accuracy for clients where failure is not an option.

The table below defines the performance benchmarks achievable with Lead Precision’s engineered solutions, contrasting standard commercial offerings with our high-end fabrication series:

| Specification | Commercial Grade Square | Lead Precision Fabrication Series |

|---|---|---|

| Perpendicularity Tolerance | ≤ 0.001 inch/ft | ≤ 0.0002 inch/ft (Class AA) |

| Surface Flatness (Reference Edge) | 0.0005 inch | 0.00005 inch (50 nm) |

| Material Stability | Tool Steel (Minimal Stress Relief) | Cryogenically Treated 440C Stainless Steel |

| Thermal Drift Coefficient | 8-10 ppm/°C | ≤ 2.5 ppm/°C |

These specifications translate directly to reduced scrap rates, elimination of secondary alignment operations, and accelerated throughput in complex sheet metal assembly cells. Consider an aircraft wing rib fabrication line: using a square meeting our Fabrication Series tolerances ensures every bend angle aligns within 0.05° across hundreds of identical parts, preventing costly shimming during final assembly. For medical enclosure manufacturers, the ultra-fine surface finish prevents micro-gouging on polished stainless steel housings during layout. Precision in the square is not an incremental cost; it is the bedrock of dimensional certainty throughout the fabrication value stream. Wuxi Lead Precision Machinery delivers this certainty through metallurgical expertise, aerospace-grade process control, and a legacy forged in the world’s most demanding production environments. Contact our engineering team to specify squares meeting your exact thermal, material, and tolerance requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-precision industrial applications. Our technical capabilities are built around state-of-the-art 5-axis CNC machining systems, enabling us to produce complex sheet metal squares with exceptional accuracy, consistency, and repeatability. These multi-axis platforms allow simultaneous machining from multiple angles, minimizing setup changes and ensuring tight geometric alignment across all faces of the component. This level of control is critical when manufacturing sheet metal squares used in aerospace, medical equipment, and high-end automation systems where dimensional integrity directly impacts performance.

All sheet metal squares are fabricated using premium-grade materials, including stainless steel, aluminum alloys, and cold-rolled carbon steel, selected based on customer specifications and environmental requirements. Our 5-axis CNC centers integrate high-speed cutting tools with dynamic toolpath optimization, ensuring clean edges, minimal burring, and superior surface finish. This capability supports intricate features such as precision-machined corners, alignment slots, mounting holes, and interface cutouts—all executed within a single setup to reduce cumulative error and improve overall part symmetry.

Quality assurance is embedded throughout the production cycle. Each sheet metal square undergoes comprehensive inspection via coordinate measuring machine (CMM) technology, providing full 3D validation of critical dimensions, flatness, squareness, and positional tolerances. Our CMM systems are calibrated to international standards (ISO 17025) and operated by certified metrology technicians, ensuring traceability and compliance with stringent industry regulations. Data from each inspection is documented and available with the final delivery, supporting full quality traceability for audit and integration purposes.

We maintain strict environmental and operational controls within our facility to ensure thermal stability and vibration isolation during machining and inspection processes. This controlled environment contributes directly to maintaining micron-level tolerances across production batches. In addition to CMM verification, first-article inspections and in-process checks are conducted to identify and correct deviations in real time, ensuring consistency from prototype to volume production.

The following table outlines the standard technical specifications and achievable tolerances for our sheet metal square fabrication services:

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm |

| Angular Accuracy | ±0.1° | ±0.05° |

| Flatness | 0.05 mm/m² | 0.02 mm/m² |

| Squareness (Corner Angle) | ±0.15° | ±0.08° |

| Hole Position Tolerance | ±0.08 mm | ±0.03 mm |

| Surface Roughness (Ra) | 3.2 μm | 1.6 μm |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC technology with rigorous quality control protocols to deliver sheet metal squares that meet the most demanding engineering requirements. Our integrated approach ensures every component performs reliably in critical assembly environments.

Material & Finish Options

Material Selection for Precision Sheet Metal Squares

Selecting the optimal material for sheet metal squares is critical in high-tolerance fabrication. At Wuxi Lead Precision Machinery, we prioritize mechanical properties, environmental resistance, and cost efficiency to ensure your components meet exacting industrial standards. Below, we detail key considerations for aluminum, steel, and titanium, along with anodizing finishes for enhanced performance.

Aluminum alloys dominate aerospace and electronics due to their high strength-to-weight ratio and corrosion resistance. Grade 6061-T6 offers excellent weldability and moderate strength, ideal for structural frames, while 7075-T6 provides superior hardness for high-stress applications like drone chassis. Aluminum’s natural oxide layer resists rust, but anodizing significantly boosts surface durability and aesthetic control. Avoid aluminum in high-abrasion or extreme-temperature settings above 150°C, where thermal expansion may compromise precision.

Carbon steel remains indispensable for heavy machinery and construction. Cold-rolled 1018 steel delivers cost-effective strength and machinability for brackets and enclosures, whereas 304 stainless steel excels in corrosive environments like marine hardware or medical equipment. Note that carbon steel requires protective finishes to prevent oxidation, adding process steps. Stainless grades mitigate this but increase material costs by 30–50% versus mild steel. For load-bearing squares under 200 MPa stress, steel often provides the most economical solution.

Titanium Grade 2 is reserved for mission-critical sectors like aerospace and defense, where its exceptional strength-to-weight ratio and resistance to saltwater/chemical corrosion justify premium pricing. It maintains integrity up to 400°C but demands specialized CNC tooling due to low thermal conductivity and work-hardening tendencies. Titanium is impractical for non-critical applications given its cost—typically 5–8× that of aluminum—and complex machining requirements.

Anodizing Finish Specifications

Anodizing is essential for aluminum squares requiring wear resistance or electrical insulation. Type II (sulfuric acid) anodizing creates a porous layer for dyeing and moderate protection, while Type III (hard coat) yields thicker, harder surfaces for industrial tooling. Key parameters:

| Property | Type II Anodizing | Type III Anodizing |

|---|---|---|

| Thickness Range | 5–25 μm | 25–100 μm |

| Hardness (HV) | 200–300 | 500–700 |

| Wear Resistance | Moderate | High |

| Electrical Insulation | Yes | Yes |

| Typical Use Cases | Decorative panels | Hydraulic fittings |

For steel squares, powder coating or zinc plating better addresses corrosion concerns, as anodizing applies exclusively to aluminum. Always align material and finish choices with your operational environment—Wuxi Lead’s engineering team validates these selections against ISO 2768 tolerances and client-specific fatigue requirements. Consult us early in the design phase to optimize manufacturability and lifecycle value.

Manufacturing Process & QC

Sheet Metal Square Manufacturing: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, the production of high-precision sheet metal squares follows a rigorously controlled process designed to ensure dimensional accuracy, structural integrity, and long-term reliability. Our end-to-end workflow integrates advanced engineering, iterative prototyping, and automated mass production, all aligned with a zero-defect philosophy. This disciplined approach ensures that every component meets exacting industrial standards.

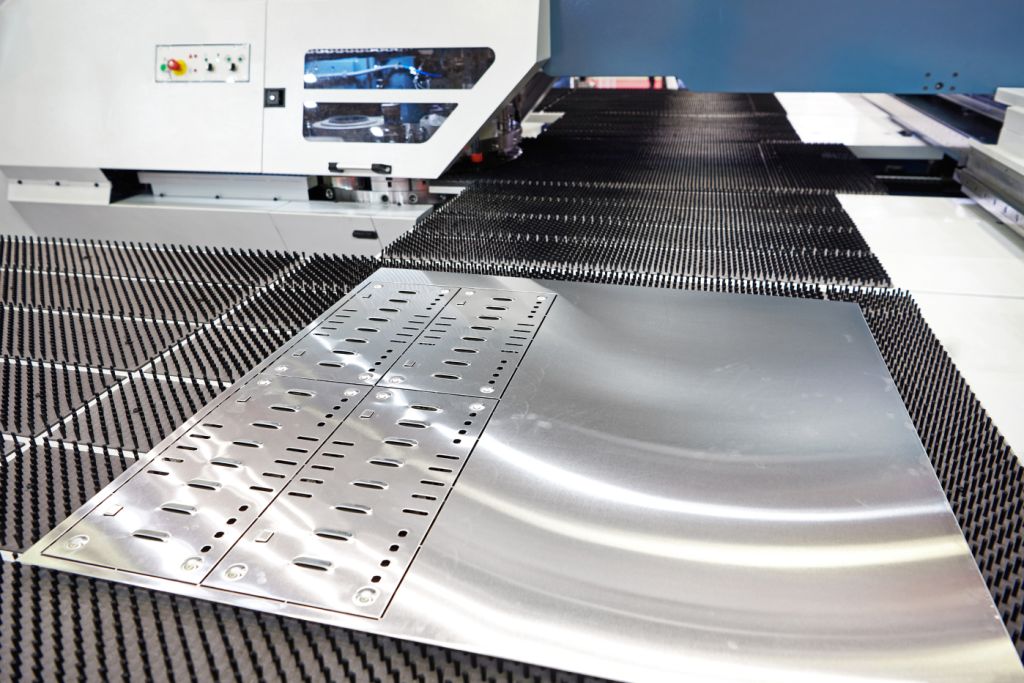

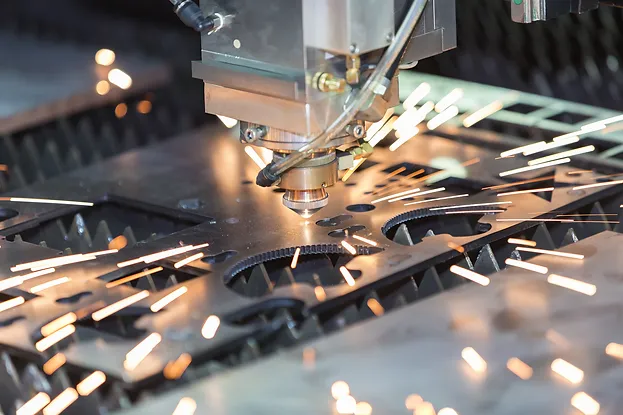

The process begins with precision design using 3D CAD software. Engineers analyze customer specifications including dimensional tolerances, material grade, and surface finish requirements. Finite element analysis (FEA) is applied to simulate mechanical stress and thermal behavior, ensuring structural performance under real-world operating conditions. Design for manufacturability (DFM) principles are embedded early to eliminate potential production bottlenecks and minimize material waste. Once the design is validated, it is translated into machine-readable CNC programs for laser cutting, bending, and welding operations.

Prototyping follows immediately after design finalization. A small batch of sheet metal squares is produced using the same equipment and materials intended for mass production. This phase allows for physical validation of fit, form, and function. Each prototype undergoes comprehensive metrology testing using coordinate measuring machines (CMM) and laser trackers to verify dimensional conformity. Any deviations are traced back to process parameters, and corrective actions are implemented before progression. Customer feedback is actively incorporated at this stage to ensure alignment with application-specific needs.

Once prototype approval is obtained, the process transitions to mass production. Our automated fabrication cells, equipped with fiber laser cutters, CNC press brakes, and robotic welding systems, ensure repeatability and throughput. In-process inspection stations are integrated at critical junctures—after cutting, bending, and assembly—to detect anomalies in real time. Statistical process control (SPC) monitors key variables such as bend angle, edge straightness, and weld penetration, enabling immediate adjustments. All finished units undergo 100% visual and dimensional inspection prior to packaging.

Our zero-defect commitment is enforced through a closed-loop quality management system compliant with ISO 9001:2015. Non-conforming parts are quarantined, root causes analyzed, and process improvements documented to prevent recurrence. Traceability is maintained via serialized part marking and digital production logs.

The following table outlines key production specifications for our standard sheet metal squares:

| Parameter | Specification |

|---|---|

| Material Thickness | 0.8 mm – 6.0 mm |

| Dimensional Tolerance | ±0.1 mm (cutting), ±0.2° (bending) |

| Surface Roughness | Ra ≤ 1.6 µm (after finishing) |

| Edge Straightness | ≤ 0.15 mm per 100 mm |

| Squareness Tolerance | ±0.1° (corner angle) |

| Production Capacity | Up to 5,000 units per week |

| Quality Standard | ISO 2768-m, ISO 9013 (thermal cutting) |

Through seamless integration of precision engineering, iterative validation, and automated quality control, Wuxi Lead delivers sheet metal squares that consistently meet the demands of high-end industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Square Performance

In the demanding landscape of precision sheet metal fabrication, the dimensional accuracy and geometric integrity of critical components like squares directly impact assembly success, structural reliability, and final product performance. Wuxi Lead Precision Machinery stands as your dedicated engineering partner, leveraging over 15 years of specialized expertise and ISO 9001-certified processes to deliver sheet metal squares meeting the most stringent aerospace, medical, and industrial automation requirements. We understand that a square is never merely a shape; it is a foundational element where tolerance stacking, edge consistency, and material stability dictate system functionality. Our integrated approach combines advanced CNC punching, laser cutting, and precision bending technologies with rigorous metrology protocols to eliminate common fabrication pitfalls such as angular deviation, surface distortion, and inconsistent corner radii.

Our commitment transcends basic manufacturing. We collaborate during the design phase to optimize material selection, grain direction, and bend sequencing, ensuring manufacturability without sacrificing your performance targets. Every square undergoes comprehensive first-article inspection using Zeiss CMM systems, verifying critical parameters far beyond basic dimensional checks. This proactive engineering partnership minimizes scrap, accelerates time-to-market, and guarantees the geometric fidelity essential for seamless integration into complex sub-assemblies. When dimensional stability under thermal cycling or mechanical load is non-negotiable, our process control delivers repeatable results batch after batch.

The technical specifications achievable through our dedicated sheet metal square production line underscore this precision capability:

| Specification Parameter | Performance Capability | Measurement Standard |

|---|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm | ASTM A653 / EN 10130 |

| Angular Accuracy (Internal) | ±0.1° | ISO 2768-mK |

| Flatness Tolerance | ≤ 0.02 mm per 100 mm | ISO 2768-f |

| Edge Burr Height | ≤ 0.05 mm | ASME B46.1 |

| Surface Roughness (Ra) | ≤ 0.8 µm | ISO 1302 |

| Dimensional Repeatability | ±0.03 mm | Based on Cpk ≥ 1.67 |

Entrust your critical square components to a partner who views precision as an engineering imperative, not merely a specification. Wuxi Lead Precision Machinery provides the technical depth, process transparency, and unwavering quality focus required for mission-critical applications. We eliminate the risk of downstream assembly failures caused by inconsistent geometry, offering full traceability from raw material certification through final inspection documentation. Our dedicated engineering team is prepared to review your specific square component challenges, whether involving exotic alloys, ultra-thin gauges, or complex multi-bend configurations requiring secondary operations.

Initiate a technical dialogue that transforms your sheet metal square requirements into a guaranteed outcome. Contact our precision engineering team directly at [email protected] to request a confidential design review, discuss material optimization strategies, or receive a detailed quotation based on your exact performance criteria. Specify “Sheet Metal Square Precision Inquiry” in your subject line to ensure immediate routing to our specialist fabrication engineers. Let us demonstrate how Lead Precision becomes an extension of your quality assurance and engineering excellence. Your commitment to perfection demands a manufacturing partner of equal resolve. Reach out today.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.