Technical Contents

Engineering Guide: Plastic Mold Injection Machines

Engineering Insight: The Critical Role of Precision in Plastic Mold Injection Machines

In the realm of custom metal manufacturing for high-performance industries, the integration of plastic mold injection machines demands an uncompromising commitment to precision. These machines are not merely tools for shaping polymers—they are central to producing components that must meet exacting dimensional tolerances, surface finishes, and repeatability standards. At Wuxi Lead Precision Machinery, we understand that the success of a final product often hinges on the microscopic accuracy achieved during the injection molding phase. This understanding is forged through decades of engineering excellence and direct involvement in mission-critical applications, including components developed for Olympic-standard equipment and military-grade systems.

Precision in plastic mold injection is not a singular attribute but a convergence of factors: mold design integrity, thermal control, clamping force consistency, and real-time process monitoring. Even micron-level deviations can result in part warpage, flash, or incomplete filling—defects that are unacceptable in aerospace, defense, or high-end industrial automation. Our engineering approach treats each mold as a precision instrument, where cavity alignment, gate positioning, and cooling channel geometry are optimized using advanced simulation software and validated through iterative prototyping.

At Lead Precision, our experience with government and Olympic-tier projects has instilled a culture of zero-defect manufacturing. For instance, components used in precision-guided systems or high-stress mechanical assemblies require not only tight tolerances but also long-term material stability and structural integrity. Our plastic mold injection processes are designed to deliver consistent results across production runs, ensuring that every unit performs identically under operational stress.

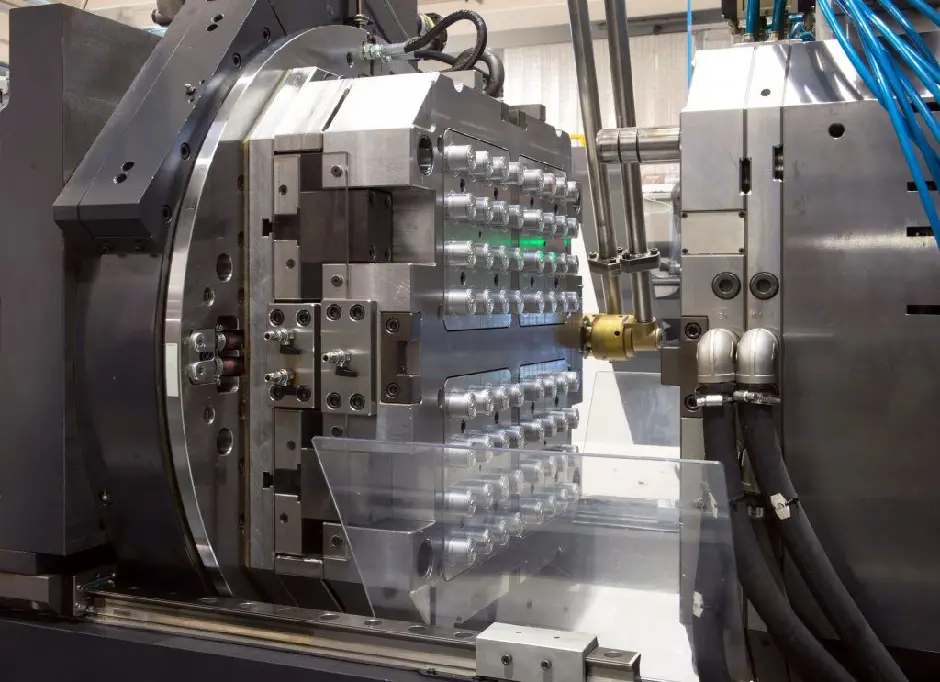

We specialize in integrating hybrid manufacturing solutions, where custom metal molds—crafted from high-grade tool steels or aluminum alloys—are paired with intelligent injection systems featuring closed-loop control, adaptive pressure regulation, and in-mold sensors. This synergy between precision metalwork and advanced polymer processing defines our competitive edge.

Below are key technical specifications that exemplify the capabilities of our plastic mold injection systems:

| Parameter | Specification |

|---|---|

| Clamping Force Range | 50 to 3,500 Tons |

| Injection Pressure | Up to 2,500 Bar |

| Screw Diameter Range | 25 mm to 120 mm |

| Shot Weight (PS) | 80 g to 6,800 g |

| Positioning Accuracy | ±0.01 mm |

| Repeatability | ±0.02 mm |

| Control System | Siemens / Mitsubishi CNC with IoT interface |

| Mold Tolerance (Cavity/Core) | ±0.005 mm |

| Surface Finish (Cavity) | Ra ≤ 0.05 µm (Mirror Polish Available) |

| Cycle Time Optimization | Adaptive cooling & packing algorithms |

These specifications reflect our dedication to engineering systems that meet the most demanding requirements. At Wuxi Lead Precision Machinery, we do not manufacture generic machines—we deliver precision solutions calibrated for performance, reliability, and integration into advanced manufacturing ecosystems.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineering for Injection Mold Excellence

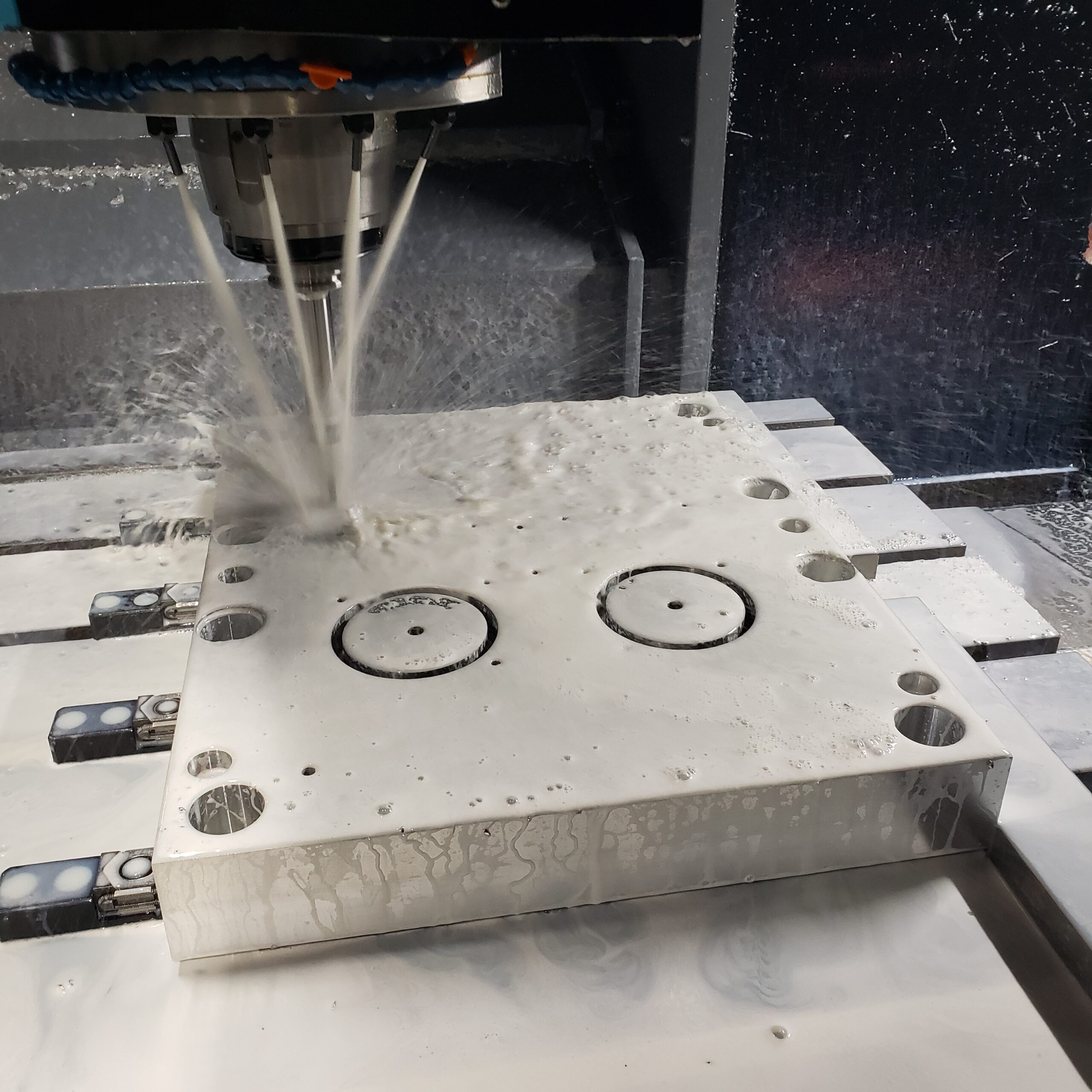

At Wuxi Lead Precision Machinery, we engineer plastic injection molds to exacting standards where micron-level accuracy directly impacts part quality, cycle time, and production longevity. Our integrated workflow leverages advanced 5-axis CNC machining and rigorous metrology to transform complex designs into high-performance tooling. Unlike conventional 3-axis systems, our DMG MORI and Hermle 5-axis CNC centers perform simultaneous multi-directional cutting. This eliminates manual repositioning, reduces cumulative error, and achieves undercuts, organic contours, and micro-textured surfaces in a single setup. Critical mold components—such as cavities, cores, lifters, and hot runner manifolds—benefit from uninterrupted tool paths that maintain geometric integrity while optimizing surface finish to Ra 0.2 µm. Material efficiency is maximized through adaptive high-speed machining strategies, minimizing waste on premium tool steels like P20, H13, and S136.

Quality assurance is non-negotiable. Every mold undergoes 100% dimensional validation via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), operating under ISO 10283-compliant environmental controls. Our CMM protocols measure critical features against 3D CAD models with traceable NIST-certified accuracy. This includes cavity wall thickness uniformity, ejector pin alignment, cooling channel positioning, and parting line flatness. Statistical process control (SPC) data is documented per batch, enabling proactive tolerance adjustments and full traceability from raw material to finished assembly.

The table below details achievable tolerance benchmarks for mold components, validated through our CMM inspection regime. These values reflect real-world production capability on hardened tool steels (38–52 HRC), not theoretical machine limits.

| Feature Category | Standard Tolerance | Tight Tolerance | Measurement Method |

|---|---|---|---|

| Cavity/ Core Dimensions | ±0.015 mm | ±0.005 mm | CMM (5-axis probe) |

| Parting Line Flatness | 0.02 mm/m | 0.008 mm/m | CMM + Laser Scan |

| Ejector Pin Alignment | ±0.01 mm | ±0.003 mm | CMM (Dynamic Test) |

| Cooling Channel Position | ±0.05 mm | ±0.02 mm | CMM (Internal Probe) |

| Surface Texture (Ra) | 0.8 µm | 0.2 µm | Profilometer |

Our technical edge lies in merging hardware precision with process intelligence. The 5-axis CNC’s real-time thermal compensation and collision avoidance systems ensure repeatability across 10,000+ hour tool life cycles. Combined with CMM-driven closed-loop feedback, this enables consistent production of molds for medical, automotive, and electronics applications—where 0.005 mm deviations can trigger part warpage or flash. Every mold shipped from Wuxi Lead includes a full inspection report with deviation heatmaps, certifying compliance to customer-specified GD&T callouts. This disciplined approach minimizes trial runs, accelerates time-to-market, and delivers molds engineered for 1 million+ cycles without rework. Precision isn’t theoretical here; it’s measured, validated, and guaranteed.

Material & Finish Options

Material Selection for High-Performance Plastic Injection Molds

Selecting the appropriate material for plastic injection molds is critical to ensuring durability, precision, and cost-efficiency in high-volume production environments. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the exacting demands of modern injection molding. Our expertise spans aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental exposure.

Aluminum is often the preferred choice for prototype molds and low- to medium-volume production. Its excellent thermal conductivity allows for faster cooling cycles, reducing cycle times and increasing throughput. Additionally, aluminum is easier to machine than steel or titanium, which translates to lower tooling costs and faster lead times. However, its lower hardness makes it less suitable for abrasive resins or long production runs exceeding 100,000 cycles.

Steel, particularly tool steels such as P20, H13, and S136, remains the industry standard for high-volume injection molding. These alloys offer superior hardness, wear resistance, and longevity, capable of withstanding millions of cycles. Stainless variants like S136 also provide excellent corrosion resistance, making them ideal for medical, optical, or food-grade applications where surface purity is paramount. While steel molds require longer machining times and higher initial investment, their extended service life often results in lower total cost of ownership over time.

Titanium, though less common in mold construction, is gaining traction in specialized applications requiring exceptional strength-to-density ratios and corrosion resistance. Its use is typically limited to core components or inserts exposed to extreme conditions, such as high-pressure or chemically aggressive environments. Due to its high cost and challenging machinability, titanium is not generally recommended for full mold bases but can significantly enhance performance in targeted areas.

Surface finish plays a pivotal role in part quality, ejection efficiency, and mold maintenance. Anodizing is a widely used finishing process for aluminum molds, enhancing surface hardness and corrosion resistance while allowing for color coding. Hard anodizing, in particular, can increase surface durability to near-steel levels, extending the life of aluminum molds in demanding applications. For steel molds, polishing, texturing, and nitriding are more common, though anodizing may still be applied to aluminum components within hybrid mold assemblies.

Below is a comparative overview of key material properties relevant to plastic injection mold performance.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Corrosion Resistance | Machinability |

|---|---|---|---|---|---|

| Aluminum (7075) | 15–20 | 130 | 10,000 – 100,000 | Moderate | Excellent |

| P20 Steel | 28–32 | 30 | 500,000 – 1,000,000 | Low | Good |

| H13 Steel | 48–52 | 36 | 1,000,000+ | Moderate | Fair |

| S136 Stainless | 50–54 | 22 | 1,000,000+ | High | Fair |

| Titanium (Ti-6Al-4V) | 36–40 | 7 | 500,000+ (inserts only) | Very High | Poor |

Material and finish selection must align with production goals, resin type, and part specifications. Wuxi Lead Precision Machinery provides engineering support to help clients optimize these choices for performance, longevity, and cost-effectiveness in their injection molding operations.

Manufacturing Process & QC

Precision Plastic Mold Injection: The Zero Defects Production Process

At Wuxi Lead Precision Machinery, achieving zero defects in plastic mold injection is non-negotiable. Our integrated production process transforms conceptual designs into flawless mass-produced components through rigorously controlled engineering phases. This systematic approach ensures dimensional accuracy, material integrity, and functional reliability demanded by aerospace, medical, and automotive sectors. We eliminate variability at every stage, preventing costly rework and supply chain disruption for our clients.

Design Phase: Engineering Perfection Before Metal Cutting

The foundation of zero defects begins with computational precision. Our engineering team utilizes advanced CAD/CAM suites and Moldflow simulation software to model mold geometry, analyze polymer flow dynamics, and predict potential warpage or sink marks. Critical to this stage is Design for Manufacturability (DFM) collaboration, where we identify and resolve tolerance stack issues, gate positioning conflicts, and cooling channel inefficiencies before tooling commences. This virtual validation ensures the mold design inherently supports consistent part quality under production parameters, directly targeting defect prevention at the source.

Prototyping Phase: Validating the Virtual to Physical Transition

Physical validation occurs through rapid prototyping using selective laser melting (SLM) for conformal-cooled metal inserts or high-strength polymer molds. This phase is not merely about form fit function; it is a critical diagnostic step. We conduct first-article inspections against the original CAD model using coordinate measuring machines (CMM), verifying critical dimensions, surface finishes, and material properties. Process parameters are meticulously refined through Design of Experiments (DOE), establishing the exact injection pressure, temperature profiles, and cooling times required for repeatability. Only when prototype parts meet all specifications within ±0.005mm tolerance is the process locked for production.

Mass Production Phase: Sustained Excellence Through Closed-Loop Control

Transitioning to high-volume manufacturing, our zero defects mandate relies on real-time process monitoring and statistical process control (SPC). Each machine integrates cavity pressure sensors and vision systems that continuously measure part dimensions, weight, and cosmetic quality against predefined control limits. Any deviation triggers immediate machine lockout and alerts our engineering team, preventing defective parts from progressing. Our production ecosystem links machine data directly to our quality management system, enabling predictive maintenance and instantaneous parameter adjustments. This closed-loop system, combined with operator training certified to ISO 9001 standards, guarantees sustained output where every cycle meets specification.

The following table outlines key capabilities enabling this zero-defects process within our plastic injection production ecosystem:

| Specification Category | Capability Range | Measurement Standard | Critical Impact |

|---|---|---|---|

| Clamping Force | 500 – 4,500 Tons | ISO 10077 | Ensures mold integrity under high pressure |

| Shot Weight Accuracy | ±0.15% | ASTM D3641 | Eliminates material inconsistency defects |

| Temperature Control | ±0.5°C | ISO 294-4 | Prevents viscosity-induced flow variations |

| Cavity Pressure Monitoring | Real-time per cavity | ISO 294-5 | Detects packing issues before part ejection |

| In-Process Gauging | 100% automated | AS9100 Rev D | Guarantees dimensional compliance per cycle |

This end-to-end process, from virtual design validation through intelligent mass production, embodies Wuxi Lead’s commitment to delivering only perfect components. We transform complex plastic injection challenges into guaranteed outcomes.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery to elevate your plastic mold injection capabilities with precision-engineered solutions tailored to your production demands. As a trusted leader in custom metal manufacturing, we specialize in delivering high-performance plastic mold injection machines designed for reliability, repeatability, and long-term operational efficiency. Whether you are producing complex medical components, automotive parts, or consumer electronics housings, our engineering team collaborates closely with you to develop systems that meet exacting technical and quality standards.

Our machines are built on decades of metallurgical expertise and advanced CNC fabrication processes, ensuring robust construction and thermal stability under continuous operation. We integrate premium-grade components from globally certified suppliers, including high-response servo-hydraulic systems, hardened steel platens, and intelligent control units with real-time monitoring. Every machine is assembled, tested, and calibrated in our Wuxi-based facility under strict ISO-compliant protocols, guaranteeing seamless integration into your existing production environment.

What sets us apart is our commitment to customization. Off-the-shelf solutions often fail to address unique material flow dynamics, cycle time constraints, or mold complexity. At Lead Precision, we design each machine around your specific application—adjusting clamp force, injection speed, shot weight, and automation compatibility to match your product requirements. Our engineers work with your technical team to simulate mold filling, optimize gate placement, and ensure minimal part warpage or flash, reducing scrap rates and improving throughput from day one.

We understand that downtime is costly. That’s why each system includes remote diagnostics, predictive maintenance alerts, and full documentation in multiple languages. Our after-sales support network spans Asia, Europe, and North America, providing rapid response times and on-site service when needed. Training programs are also available to ensure your operators and maintenance personnel are fully equipped to maximize machine performance.

Below are the standard technical specifications for our flagship series of plastic mold injection machines. Custom configurations beyond these ranges are available upon request.

| Specification | Value |

|---|---|

| Clamp Force Range | 800 kN – 6,500 kN |

| Screw Diameter | 30 mm – 80 mm |

| Injection Pressure | Up to 2,200 bar |

| Shot Weight (PS) | 280 g – 3,800 g |

| Platen Size | 700 mm × 700 mm – 1,800 mm × 1,800 mm |

| Minimum Mold Height | 250 mm – 600 mm |

| Maximum Mold Height | 700 mm – 1,200 mm |

| Control System | LeadSmart 5.0 (Touchscreen HMI + IoT-ready) |

| Power Supply | 380V / 50Hz (custom voltages available) |

| Machine Footprint | Custom modular design |

For engineering consultation or to request a detailed proposal, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your strategic partner in precision injection molding.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.