Technical Contents

Engineering Guide: Milling Cnc

Engineering Insight Precision in CNC Milling

In high-stakes manufacturing sectors like aerospace, medical device production, and defense, the term “precision” transcends mere specification; it defines product viability, safety, and ultimate success. Sub-micron tolerances are not academic exercises but absolute requirements where component failure is unacceptable. At Wuxi Lead Precision Machinery, we engineer CNC milling systems specifically to meet and exceed these demanding standards, understanding that dimensional accuracy directly impacts performance, longevity, and regulatory compliance. Our machines are built for environments where a single micron of deviation can cascade into catastrophic system failure or costly field recalls.

Our commitment to precision is forged in real-world crucibles. Lead Precision has delivered mission-critical components for the Beijing Winter Olympics timing infrastructure, where split-second accuracy depended on flawless mechanical parts. Equally significant is our work supplying precision-machined elements for advanced military platforms, adhering to stringent MIL-STD requirements where reliability under extreme conditions is non-negotiable. This experience shapes our engineering philosophy: precision must be inherent in the machine’s structure, control, and process, not merely an aspiration.

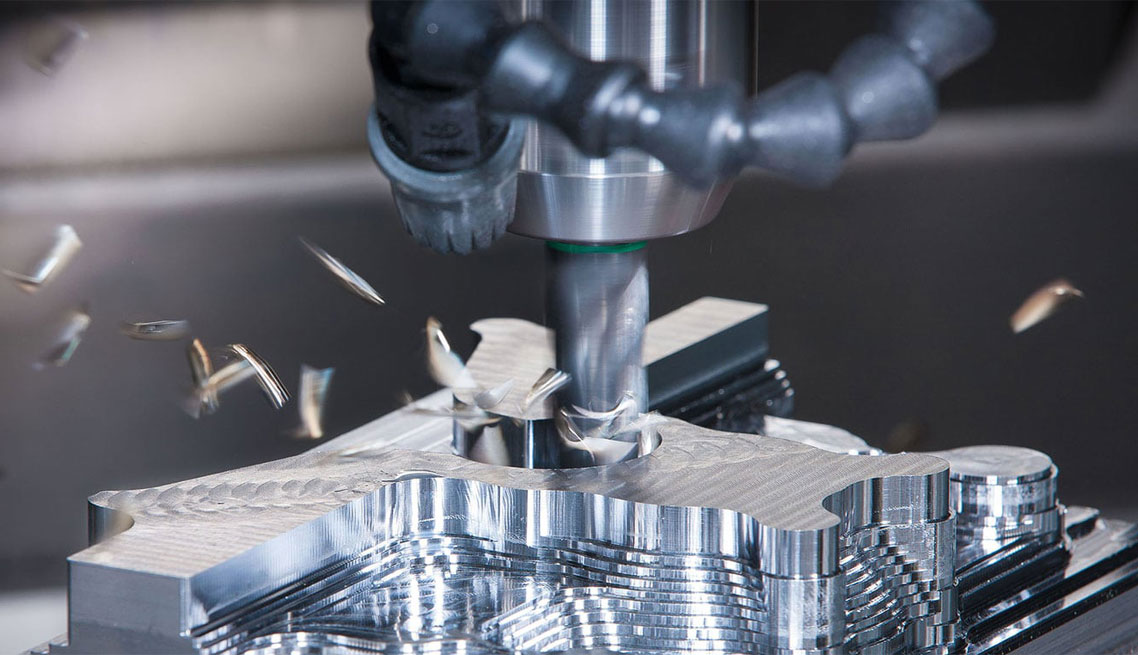

True precision in CNC milling manifests through rigorous machine design and intelligent process integration. It requires exceptional thermal stability to counteract environmental fluctuations, ultra-rigid kinematics to prevent deflection during aggressive cuts, and sophisticated motion control to ensure path fidelity. Crucially, it demands continuous verification – not just during initial calibration but throughout the production lifecycle. At Lead Precision, we integrate real-time thermal compensation, laser interferometer validation protocols, and closed-loop feedback systems as standard, ensuring that the part leaving the machine matches the CAD model exactly, batch after batch. This capability directly reduces scrap rates, minimizes post-process inspection bottlenecks, and accelerates time-to-market for our clients’ most complex products.

The tangible outcomes of this precision engineering are reflected in the consistent performance of our flagship milling platforms. The following specifications represent the baseline capabilities achievable across our production fleet, engineered for industries where compromise is not an option.

| Specification | Performance Value | Industry Relevance |

|---|---|---|

| Positioning Accuracy (X/Y/Z) | ≤ ±1.5 µm | Critical for aerospace turbine blades |

| Repeatability (3σ) | ≤ 0.8 µm | Essential for medical implant batches |

| Spindle Runout (at nose) | ≤ 0.5 µm | Ensures perfect surface finish |

| Thermal Drift Compensation | < 2 µm over 8 hours | Maintains accuracy in variable shops |

| Interpolation Accuracy | ≤ ±2.0 µm (circular) | Guarantees complex 3D contour fidelity |

For manufacturers navigating increasingly complex component requirements, partnering with a supplier whose engineering DNA is proven in Olympic and military applications provides tangible security. Wuxi Lead Precision Machinery delivers not just machines, but validated, repeatable precision – the foundational element for competitive advantage in tomorrow’s high-value manufacturing landscape. Your critical components demand nothing less.

Precision Specs & Tolerances

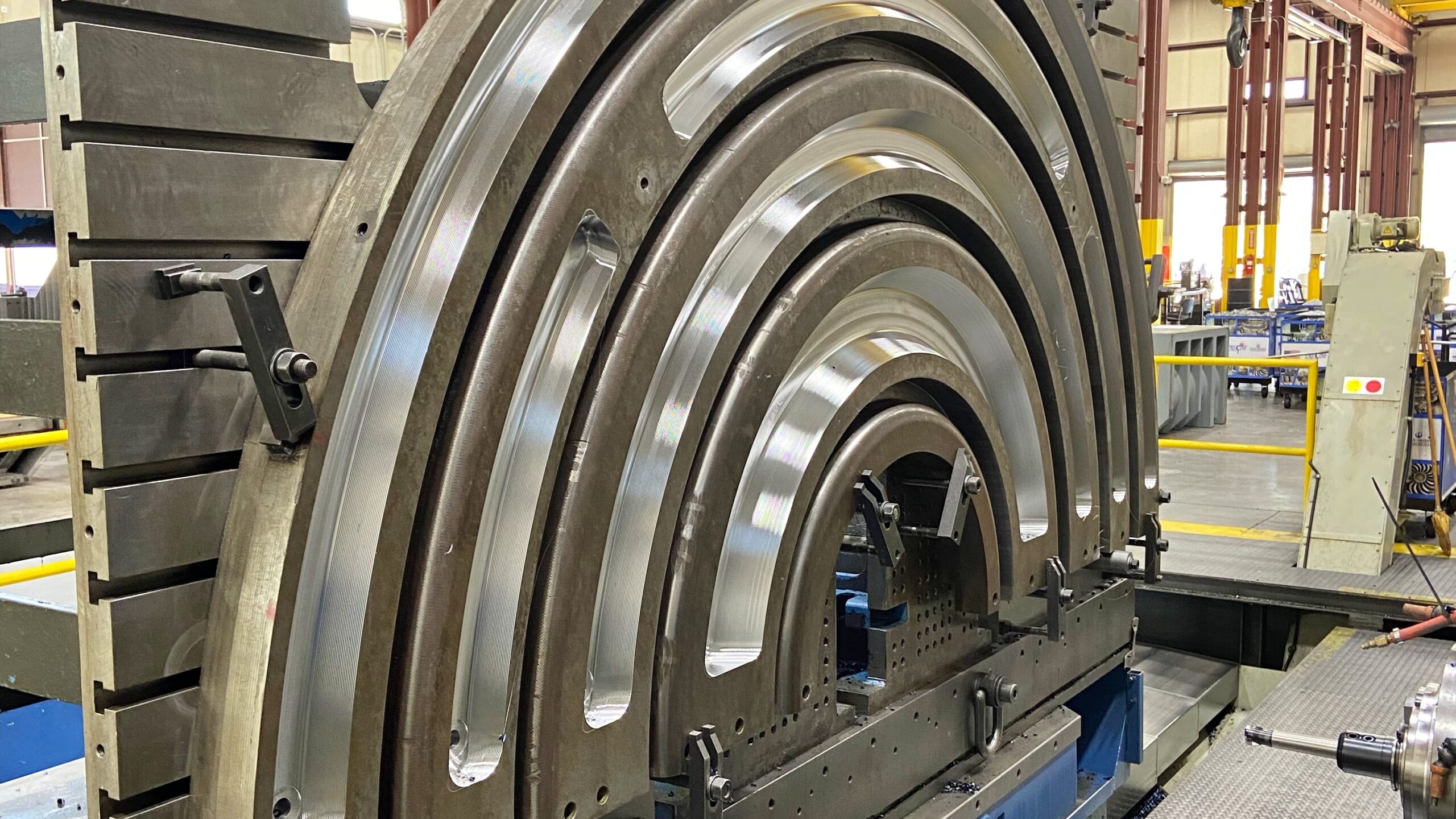

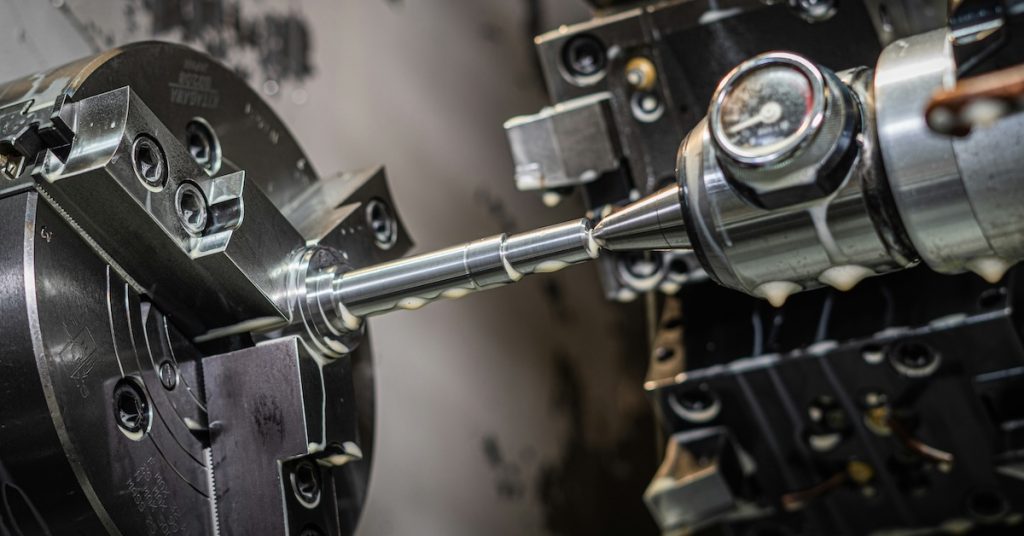

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, anchored by state-of-the-art 5-axis CNC systems. These multi-axis platforms enable complex part geometries to be produced in a single setup, reducing cycle times and enhancing dimensional accuracy. Our 5-axis CNC machines integrate high-speed spindles, dynamic tool path control, and real-time feedback systems to maintain precision across intricate contours and deep cavities. This level of machining flexibility supports industries requiring tight tolerances and superior surface finishes, including aerospace, medical device manufacturing, and high-performance automotive engineering.

Our machining centers utilize simultaneous 5-axis motion, allowing the cutting tool to remain tangential to the workpiece surface at all times. This results in reduced tool wear, improved surface quality, and the ability to machine undercuts and compound angles without re-fixturing. With a focus on repeatability and process stability, our equipment is maintained to OEM specifications and calibrated regularly to ensure peak performance. Advanced CAM software enables optimized tool paths, minimizing air cutting and maximizing material removal rates while preserving accuracy.

Quality control is integral to our production workflow. Every machined component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM) to verify geometric conformity. Our CMM systems are equipped with tactile probing and high-resolution scanning capabilities, enabling full 3D validation of critical dimensions, form, and positional tolerances. Inspection reports are fully documented and traceable, meeting ISO 9001 and customer-specific quality standards. This metrology-backed approach ensures that every part shipped meets the exact specifications required for mission-critical applications.

We specialize in low-to-medium volume production runs where precision, complexity, and material integrity are paramount. Our technical team collaborates closely with clients during the design-for-manufacturability phase to optimize part geometry, reduce assembly steps, and eliminate potential failure points before machining begins. Materials commonly processed include aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and engineering plastics such as PEEK and PTFE.

The following table outlines our standard machining capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machine Types | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Table Size (Max) | 1,200 mm × 800 mm |

| Travel (X/Y/Z) | 1,000 mm / 600 mm / 500 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Standard Tolerance (Machining) | ±0.01 mm |

| Tight Tolerance Capability | ±0.005 mm |

| Surface Finish (Typical) | Ra 0.8 µm |

| Fine Surface Finish Capability | Ra 0.4 µm |

| Inspection Equipment | Zeiss CMM with PC-DMIS Software |

| Max Workpiece Weight | 1,200 kg |

Wuxi Lead Precision Machinery combines cutting-edge technology with rigorous quality assurance to deliver components that meet the highest standards in precision engineering.

Material & Finish Options

Material Selection for Precision CNC Milling: Aluminum, Steel, Titanium & Anodizing

Material choice fundamentally impacts the performance, cost, and manufacturability of precision CNC milled components. At Wuxi Lead Precision Machinery, our engineering team prioritizes matching material properties to your specific application demands, balancing strength, weight, corrosion resistance, thermal characteristics, and machinability. This guide outlines critical considerations for Aluminum, Steel, and Titanium, along with essential insights on Anodizing finishes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate aerospace, automotive, and electronics due to their exceptional strength-to-weight ratio, excellent thermal and electrical conductivity, and inherent corrosion resistance. 6061 offers superior weldability and moderate strength, while 7075 delivers higher strength for demanding structural applications. Aluminum machines exceptionally well, allowing high feed rates and excellent surface finishes with proper tooling and coolant strategies. Chip evacuation is critical to prevent built-up edge and maintain dimensional accuracy. Its lower density significantly reduces part weight compared to steel or titanium.

Steel alloys, including 4140, 4340, and 17-4 PH stainless, provide superior strength, hardness, and wear resistance essential for tooling, heavy machinery, and high-stress components. Carbon steels offer high strength at lower cost but require protective finishes for corrosion resistance. Stainless steels like 17-4 PH provide excellent corrosion resistance and can be precipitation hardened. Machining steel demands robust tooling, lower speeds than aluminum, and careful attention to heat management to avoid work hardening and tool wear. Achieving tight tolerances often requires stress-relieving heat treatments before final machining.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), are critical for extreme environments in aerospace and medical implants due to their outstanding strength-to-weight ratio, exceptional corrosion resistance, and biocompatibility. However, titanium presents significant machining challenges: low thermal conductivity causes heat concentration at the cutting edge, high chemical reactivity risks galling, and its springiness can lead to chatter and poor surface finish. Success requires rigid setups, sharp carbide tools with specialized geometries, controlled feeds and speeds, and ample coolant to manage heat and ensure chip breakage.

Anodizing is the premier surface finish for aluminum components, significantly enhancing corrosion and wear resistance while providing excellent electrical insulation. Type II (Sulfuric Acid) anodizing creates a durable, dyeable oxide layer typically 0.0002″ to 0.001″ thick. Type III (Hardcoat) anodizing produces a much thicker (0.001″ to 0.003″+), extremely hard, and wear-resistant surface, often used for functional parts requiring longevity. Both types improve adhesion for paints and adhesives. Precise dimensional control during anodizing is paramount for tight-tolerance parts; our process includes strict pre-treatment and masking protocols to maintain critical features.

Key Material Properties for CNC Milling

| Property | Aluminum 6061-T6 | Steel 4140 | Titanium Ti-6Al-4V |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 7.85 | 4.43 |

| Tensile Strength (MPa) | 310 | 655 | 900 |

| Thermal Conductivity (W/m·K) | 167 | 42.7 | 7.2 |

| Machinability Rating | Excellent (100%) | Good (65%) | Poor (30-40%) |

| Primary CNC Challenge | Chip evacuation | Heat management | Heat concentration |

Selecting the optimal material requires deep understanding of both the end-use environment and the nuances of the CNC milling process. Wuxi Lead Precision Machinery leverages decades of experience machining these critical materials. Our engineering team collaborates closely with clients during the design phase to recommend the ideal material and finishing process, ensuring manufacturability, performance, and cost-efficiency for your high-precision components. Contact us for a detailed material suitability assessment for your next project.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the CNC milling production process begins with a rigorously engineered design phase. Our engineering team collaborates closely with clients to translate technical drawings, 3D CAD models, and performance requirements into manufacturable designs. Using advanced software such as Siemens NX, SolidWorks, and Autodesk PowerMill, we conduct comprehensive design for manufacturability (DFM) analysis. This ensures optimal material usage, tool accessibility, and structural integrity while minimizing machining time and cost. Tolerances, surface finishes, and critical dimensions are defined at this stage with micron-level precision. Every design undergoes internal validation and cross-functional review to eliminate potential flaws before any material is cut.

Prototyping: Validating Performance and Fit

Once the design is finalized, we proceed to prototype manufacturing using high-accuracy 3-axis, 4-axis, and 5-axis CNC milling centers. Prototypes are produced in small batches to verify form, fit, and function under real-world conditions. This stage is critical for detecting design inconsistencies, assembly issues, or performance deviations. We employ coordinate measuring machines (CMM), optical comparators, and laser scanning to validate geometric accuracy and dimensional compliance. Feedback from prototype testing is systematically analyzed and incorporated into design or process adjustments. Our closed-loop prototyping methodology ensures that all iterations are traceable and documented, reducing risk in full-scale production.

Mass Production: Scalable Precision with Zero Defects

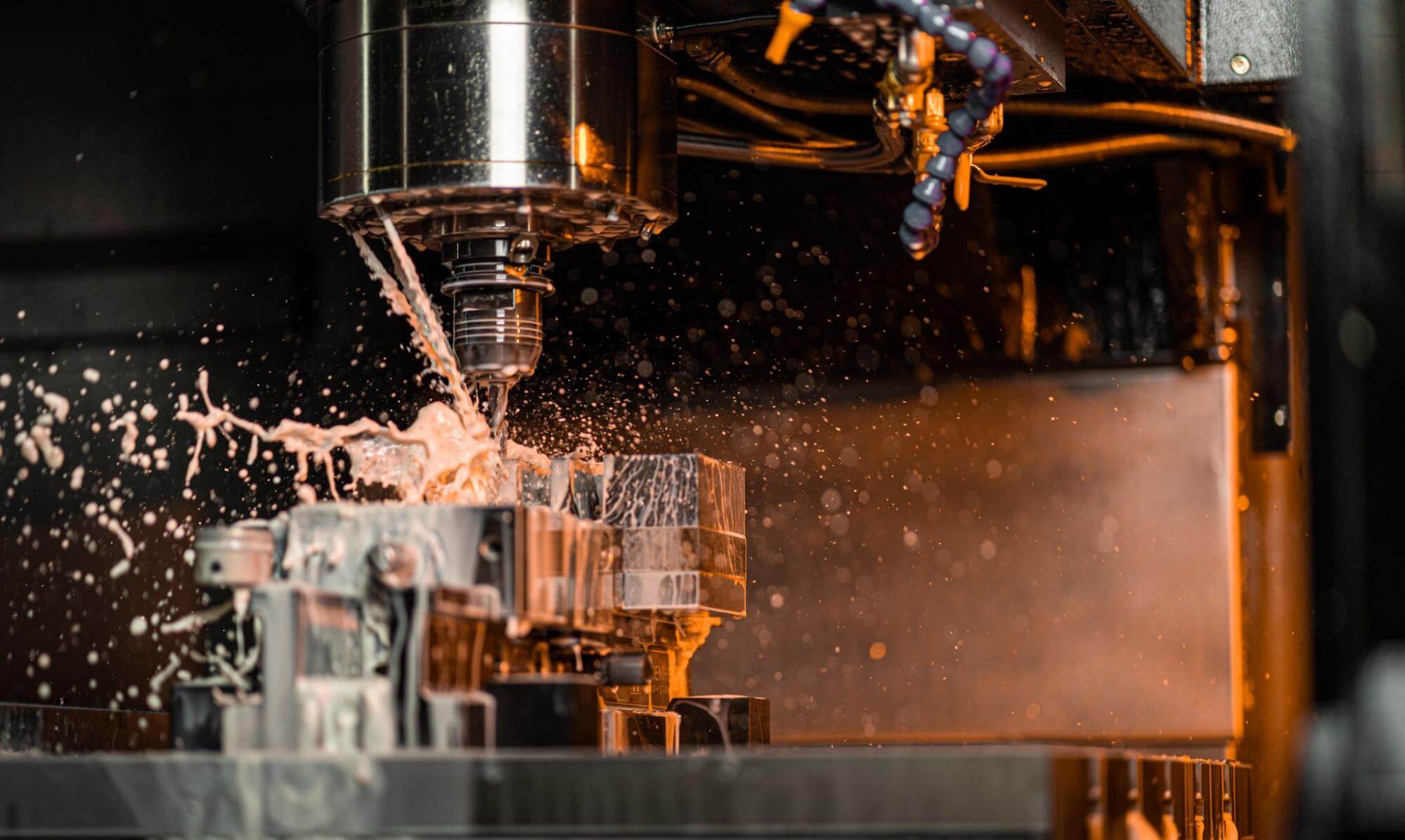

With prototype approval, we transition to mass production using automated CNC machining cells equipped with robotic loading, in-process probing, and real-time tool monitoring. Production runs are executed under strict ISO 9001-certified quality management protocols. Every component is machined from premium-grade materials including aluminum alloys, stainless steel, titanium, and engineering plastics, selected based on application demands. Our process control system integrates Statistical Process Control (SPC) and First Article Inspection (FAI) to maintain consistency across batches. Each part undergoes 100% visual inspection and selective metrology sampling to guarantee compliance with specified tolerances and surface finishes.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Machining Axes | 3-axis, 4-axis, 5-axis |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Standard Tolerances | ±0.01 mm (standard), ±0.005 mm (precision) |

| Surface Finish (Ra) | 0.8–3.2 μm (standard), down to 0.4 μm (polished) |

| Materials | Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 5, PEEK, Delrin |

| Production Capacity | 1–10,000+ units per order |

| Quality Standards | ISO 9001:2015, GD&T, AS9100 (aerospace support) |

Through seamless integration of design intelligence, iterative prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers CNC milled components with zero defects and uncompromising quality. Our process is engineered not just to meet specifications, but to exceed the reliability demands of aerospace, medical, and high-performance industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Partnership with Lead Precision

In the demanding realm of precision CNC milling, component integrity and process reliability are non-negotiable. Selecting a machining partner transcends simple procurement; it requires aligning with an engineering extension of your own operation. Wuxi Lead Precision Machinery delivers this critical integration, transforming complex design challenges into certified, high-performance components. We operate at the convergence of advanced technology, rigorous quality protocols, and deep application expertise, ensuring your most exacting milling requirements are met consistently and efficiently. Our commitment extends beyond machine operation to becoming a strategic asset in your supply chain, mitigating risk and accelerating time-to-market.

Our facility leverages a modern fleet of multi-axis CNC milling centers, meticulously maintained and operated by certified engineers. This foundation enables us to handle intricate geometries, demanding materials, and the tightest tolerances expected in aerospace, medical device, and advanced industrial sectors. We understand that your success hinges on dimensional accuracy, surface finish consistency, and unwavering repeatability—metrics we engineer into every process step. Partnering with Lead Precision means gaining access to robust production capabilities backed by ISO 9001:2015 certified quality management systems and comprehensive in-process inspection protocols.

The technical capability of our equipment forms the bedrock of our service. The following specifications represent our core high-precision milling capacity for demanding applications:

| Capability | Specification Detail |

|---|---|

| Machine Types | 3-Axis, 4-Axis, 5-Axis Simultaneous Milling Centers |

| Maximum Work Envelope | 1200 x 800 x 600 mm (X, Y, Z) |

| Typical Positioning Accuracy | ± 0.003 mm |

| Repeatability | ± 0.0015 mm |

| Spindle Speed Range | 20 – 24,000 RPM |

| Core Materials Processed | Aluminum Alloys, Titanium, Stainless Steels (incl. 17-4PH, 316L), Inconel, Tool Steels, Engineering Plastics |

| Standard Tolerances | ± 0.01 mm (Machining), Tighter achievable per drawing |

This technical proficiency, combined with our proactive engineering collaboration, ensures optimal manufacturability from the earliest design stages. We engage deeply to understand your functional requirements, material constraints, and volume needs, providing actionable feedback to enhance part performance and reduce overall production costs. Our structured project management guarantees transparent communication, on-time delivery, and full traceability for every component produced.

The competitive advantage in precision manufacturing lies not just in capability, but in the reliability and partnership ethos of your supplier. Wuxi Lead Precision Machinery is engineered to deliver both. We invite you to submit your most challenging milling projects for evaluation. Contact our engineering team directly at [email protected] to initiate a technical consultation. Provide your part drawings, material specifications, and volume requirements. Our specialists will respond within 24 business hours with a detailed capability assessment and a clear path forward. Partner with precision—partner with Lead. Your next breakthrough component begins with an email to [email protected].

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.