Technical Contents

Engineering Guide: Cnc Machining For Prototyping

Engineering Insight: CNC Machining for Prototyping

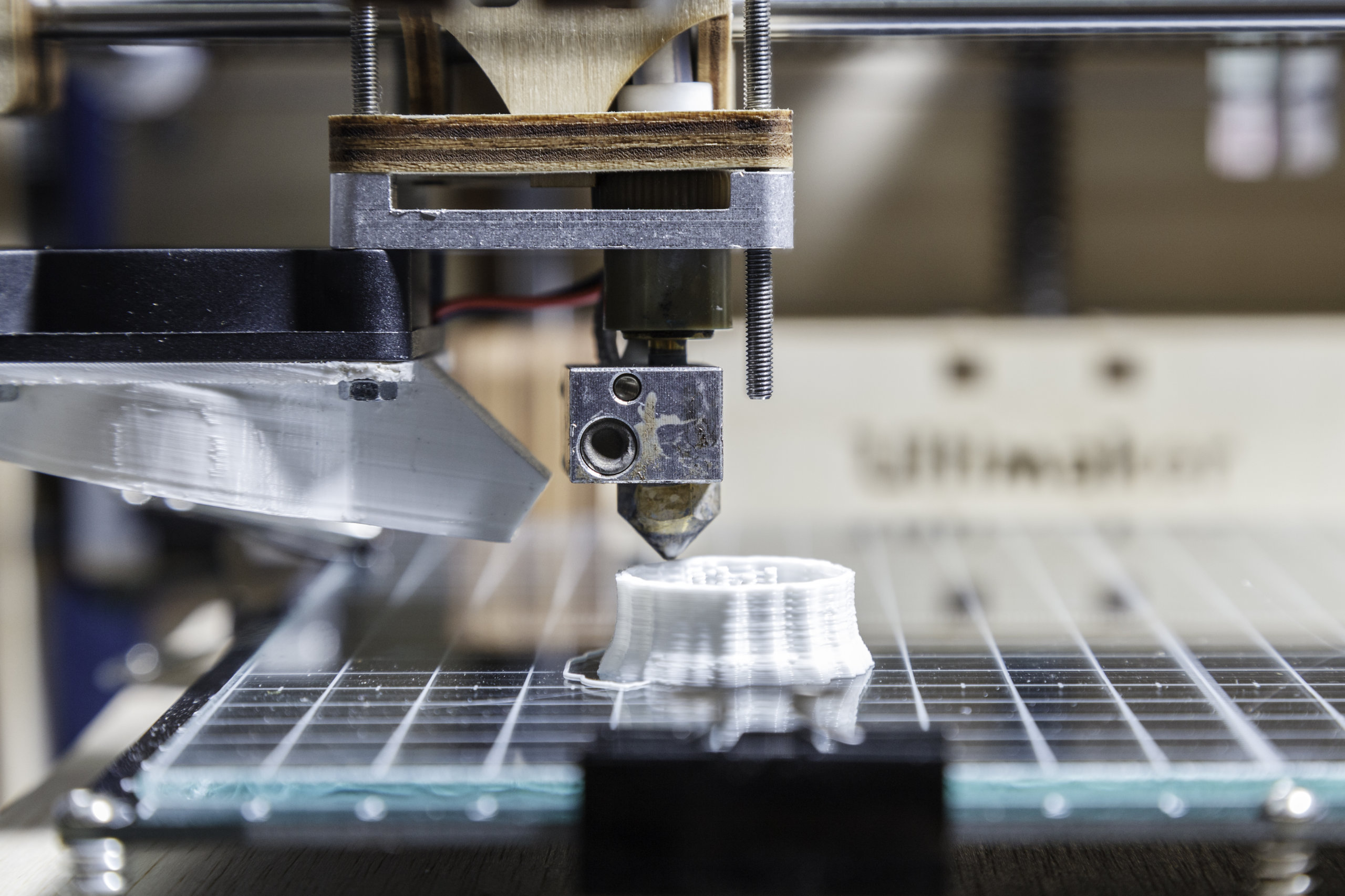

In the realm of advanced manufacturing, precision is not merely a performance metric—it is the foundation upon which innovation, reliability, and scalability are built. When it comes to prototyping, especially for industries such as aerospace, defense, medical devices, and high-performance automotive, even micron-level deviations can compromise functionality, safety, and compliance. CNC machining remains the gold standard for high-fidelity prototyping due to its unmatched accuracy, repeatability, and material versatility.

At Wuxi Lead Precision Machinery, we understand that a prototype is far more than a preliminary model. It is a critical validation step that informs design integrity, manufacturing feasibility, and time-to-market. Our CNC machining processes are engineered to deliver tolerances as tight as ±0.002 mm, ensuring that every prototype mirrors the final production part in both form and function. This level of precision enables engineers to conduct accurate testing, secure regulatory approvals, and iterate with confidence.

Our expertise in precision CNC machining has been rigorously tested through high-stakes projects, including components developed for Olympic-grade equipment and mission-critical military systems. These applications demand absolute reliability under extreme conditions, where failure is not an option. By applying the same stringent standards to every prototyping project, we ensure that our clients receive parts that are not only dimensionally accurate but also structurally and thermally stable across a wide range of operational environments.

Material selection plays a pivotal role in achieving precision during prototyping. We work with a broad spectrum of engineering-grade metals and polymers, including aluminum 7075, titanium Grade 5, stainless steel 316L, and PEEK, all machined using multi-axis CNC centers equipped with in-process probing and thermal compensation systems. These technologies allow real-time adjustments, minimizing human error and environmental influence on dimensional outcomes.

Below is a summary of our standard prototyping capabilities:

| Specification | Capability |

|---|---|

| Positional Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 x 800 x 600 mm |

| Axis Configuration | 3-axis, 4-axis, 5-axis |

| Standard Surface Finish | Ra 0.8 μm (custom finishes available) |

| Lead Time (Typical) | 5–10 working days |

| Materials Supported | Aluminum, Titanium, Stainless Steel, Brass, PEEK, Delrin, Polycarbonate |

Wuxi Lead Precision Machinery combines decades of engineering experience with state-of-the-art infrastructure to deliver prototypes that meet the most demanding technical requirements. Whether supporting R&D teams in multinational corporations or agile startups pushing the boundaries of innovation, our mission is to provide precision you can prototype on—consistently, reliably, and at scale.

Precision Specs & Tolerances

Technical Capabilities for Precision Prototyping

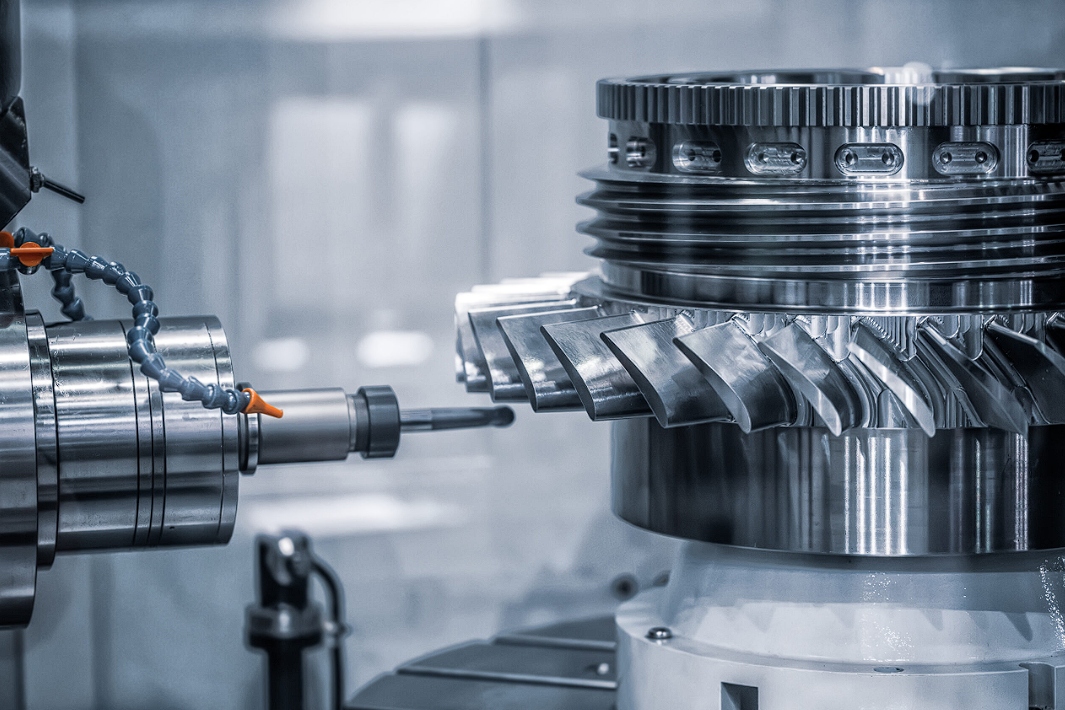

Wuxi Lead Precision Machinery delivers advanced CNC machining solutions engineered specifically for high-fidelity prototyping. Our capabilities bridge the gap between conceptual design and production readiness, ensuring prototypes meet stringent functional and dimensional requirements. Central to this is our fleet of state-of-the-art 5-axis CNC machining centers, featuring dual-table configurations and high-torque spindles. These systems enable simultaneous multi-axis movement, eliminating the need for multiple setups and preserving critical datums across complex geometries. This approach minimizes cumulative error while accelerating lead times—typically reducing prototype delivery by 30% compared to conventional 3-axis processes. Material versatility spans aerospace-grade aluminum alloys, medical titanium, stainless steel 316L, and engineering plastics like PEEK, all processed under strict environmental controls to prevent thermal distortion.

Quality assurance is non-negotiable in prototyping, where validation accuracy dictates downstream success. Every component undergoes comprehensive inspection using Zeiss CONTURA CMM systems, calibrated to ISO 17025 standards. Our metrology lab executes full GD&T analysis, generating detailed inspection reports with traceable measurement data for every feature. This includes first-article inspection (FAI) per AS9102 standards for aerospace clients and biocompatibility documentation for medical prototypes. In-process checks at critical machining stages ensure deviations are corrected before final finishing, guaranteeing that surface integrity and dimensional stability align with design intent.

Our precision tolerances reflect the demands of industries where prototype performance must mirror production reality. The table below outlines achievable specifications under controlled conditions:

| Feature Type | Tolerance Range | Surface Finish (Ra) |

|---|---|---|

| Critical Dimensions | ±0.005 mm | 0.4–0.8 µm |

| General Dimensions | ±0.025 mm | 1.6–3.2 µm |

| Threads (Machined) | 6H/6g | 1.6 µm |

| Flatness/Parallelism | 0.01 mm/m | 0.8–1.6 µm |

| Hole Positional | ±0.01 mm | 1.6 µm |

These tolerances are consistently achieved through rigid machine tool construction, in-process probing for tool wear compensation, and climate-controlled machining environments maintained at 20±1°C. For prototypes requiring micro-features or optical surfaces, we deploy specialized toolpaths and diamond-turned finishing cycles to achieve sub-micron repeatability. Our engineering team collaborates directly with clients during DFM analysis to identify tolerance-critical zones, optimizing machining strategies to balance precision with cost efficiency. This proactive approach prevents over-engineering while ensuring prototypes reliably validate assembly, fit, and functional performance.

Wuxi Lead’s integrated technical capability—from 5-axis machining to metrology-grade validation—provides the foundation for prototypes that accelerate design iteration and de-risk production scaling. We treat every prototype as a production-part surrogate, applying the same rigor that defines our volume manufacturing processes. This commitment ensures your design transitions seamlessly from validation to full-scale realization.

Material & Finish Options

Material selection is a critical decision in CNC machining for prototyping, directly influencing performance, durability, and cost. At Wuxi Lead Precision Machinery, we guide engineering teams through optimal material choices based on functional requirements, environmental exposure, and post-processing needs. Among the most widely used metals in high-precision prototyping are aluminum, steel, and titanium—each offering distinct mechanical properties and compatibility with finishing processes such as anodizing.

Aluminum stands out for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 is a common choice for prototypes requiring weldability and moderate strength, while 7075-T6 offers superior strength for aerospace and defense applications. Aluminum is highly receptive to anodizing, a process that enhances surface hardness and corrosion resistance. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat anodizing) delivers thick, wear-resistant surfaces ideal for functional prototypes. The natural oxide layer formed during anodizing also allows for color dyeing, enabling visual differentiation in multi-part assemblies.

Steel, particularly in grades such as 304 stainless, 316 stainless, and 4140 alloy steel, is selected when high strength, wear resistance, and structural integrity are paramount. 304 and 316 stainless steels offer excellent corrosion resistance, making them suitable for medical, food processing, and marine environments. 4140, a chromium-molybdenum alloy steel, is often used in high-stress mechanical components due to its toughness and fatigue resistance. Unlike aluminum, steel does not respond to anodizing. Instead, it is typically finished with passivation, electropolishing, or coatings such as zinc plating or powder coating to enhance durability and appearance.

Titanium, specifically Grade 5 (Ti-6Al-4V), is favored in aerospace, medical, and high-performance automotive sectors for its exceptional strength-to-density ratio and biocompatibility. It maintains integrity at elevated temperatures and resists corrosion in harsh environments, including seawater and chlorides. However, titanium’s low thermal conductivity and high chemical reactivity require specialized CNC tooling and slower machining parameters. While titanium can be anodized, the process differs from aluminum and is primarily used for color coding or mild surface protection rather than wear resistance.

Below is a comparison of key mechanical and finishing properties:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 310 (6061-T6) | 2.7 | 6061, 7075 | Yes (Type II & III) | Enclosures, heat sinks, UAVs |

| Stainless Steel | 505 (304) | 8.0 | 304, 316, 4140 | No | Medical devices, structural parts |

| Titanium | 900 (Ti-6Al-4V) | 4.4 | Gr2, Gr5 | Yes (decorative) | Aerospace, implants, racing parts |

Selecting the right material begins with understanding the prototype’s operational environment and mechanical demands. At Wuxi Lead Precision Machinery, we support clients in matching material properties with precision CNC capabilities and surface treatments to deliver prototypes that meet both form and function.

Manufacturing Process & QC

Precision CNC Machining Production Process: From Design to Zero-Defect Production

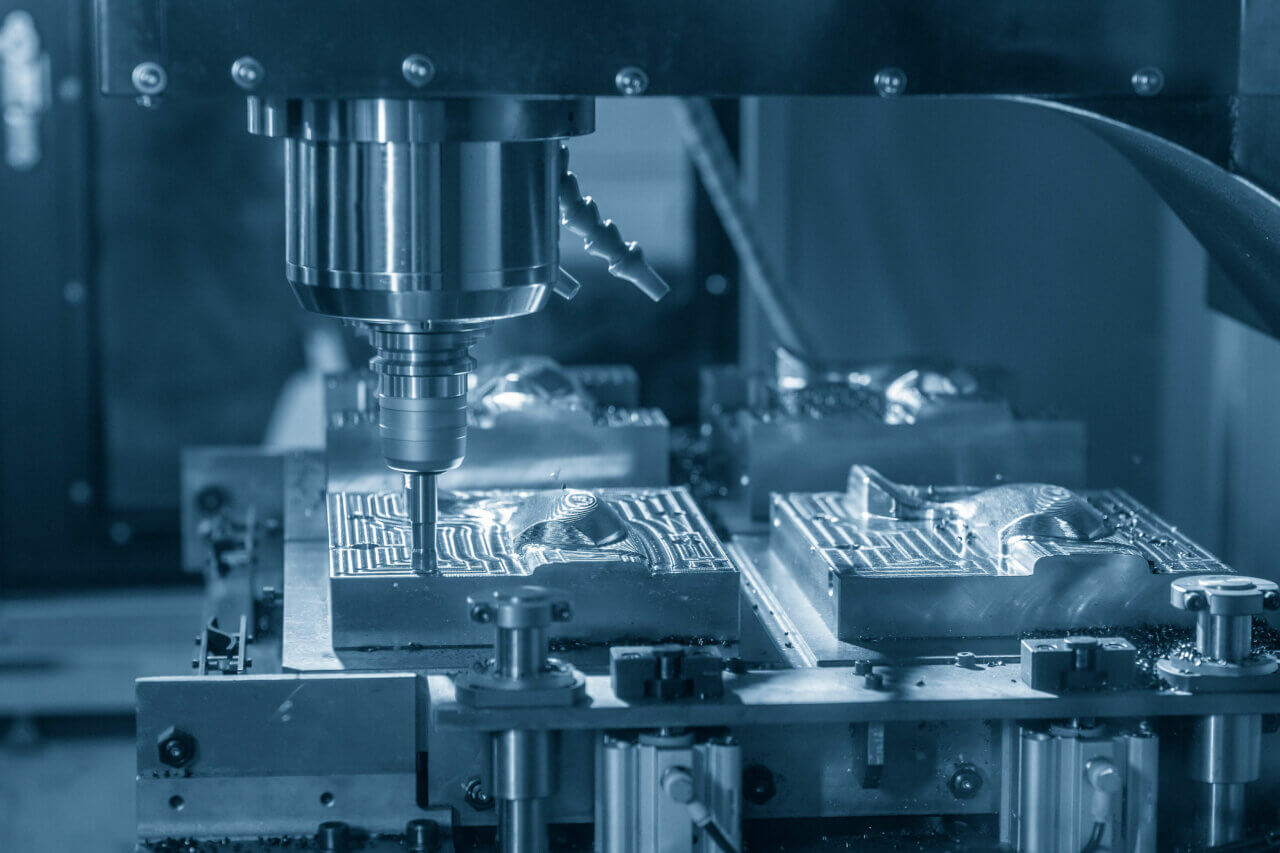

The transition from prototype to full-scale production is where theoretical design meets manufacturing reality. At Wuxi Lead Precision Machinery, we execute a rigorously controlled, three-phase process ensuring dimensional accuracy and functional integrity are preserved from the initial concept through high-volume output. This seamless integration is fundamental to achieving true zero-defect manufacturing for demanding industrial applications.

Design phase success hinges on collaborative engineering. Our technical team conducts in-depth Design for Manufacturability (DFM) analysis alongside client engineers, identifying potential machining constraints, material limitations, and geometric complexities early. This proactive review optimizes part geometry for CNC efficiency, minimizes stress points affecting dimensional stability, and selects the optimal material grade for both prototype validation and production lifecycle requirements. Critical tolerances and surface finishes are defined with production feasibility as the core principle, preventing costly redesigns later. This stage establishes the unambiguous blueprint for all subsequent phases.

Prototyping is not merely a validation step; it is the critical proving ground for the production process. Utilizing our high-precision 5-axis DMG MORI and Makino machining centers, we manufacture functional prototypes under conditions mirroring planned production. Every operation undergoes rigorous first-article inspection using calibrated Zeiss CMMs and optical comparators, verifying conformance to the DFM-optimized specifications. Material behavior under machining stress, thermal compensation strategies, and fixture repeatability are validated. This phase confirms the design’s manufacturability and fine-tunes the exact CNC programs, tooling, and inspection protocols that will be locked for mass production, eliminating guesswork.

The transition to mass production leverages the validated prototype process without deviation. Our integrated manufacturing execution system (MES) ensures the identical CNC programs, tooling assemblies, workholding, and inspection routines proven during prototyping are deployed on the production floor. Real-time statistical process control (SPC) monitors critical dimensions on every part, with automatic machine tool compensation maintaining tolerances. Comprehensive first-article and in-process inspections per AS9102 or client-specific standards are mandatory. This closed-loop system, built on the foundation of the prototype phase, guarantees consistent output meeting the stringent zero-defect target. Production scalability is achieved through process replication, not process re-engineering.

Key process capabilities ensuring zero-defect outcomes are maintained throughout all phases:

| Parameter | Capability | Verification Method |

|---|---|---|

| Positional Tolerance | ±0.005 mm | Zeiss CONTURA CMM |

| Surface Finish | Ra 0.4 µm (as-machined) | Mitutoyo Surftest SJ-410 |

| Material Range | Aluminum 7075-T6 to Inconel 718 | Certified Mill Test Reports |

| Max Work Envelope | 1200 x 800 x 650 mm | Laser Tracker Calibration |

| Process Control | Real-time SPC with Cpk ≥ 1.67 | Minitab Statistical Analysis |

This disciplined progression from intelligent design through validated prototyping to rigorously controlled production is the cornerstone of Wuxi Lead’s zero-defect philosophy. We eliminate the traditional prototype-to-production gap, delivering parts that perform identically in the field as they did in the initial validation, significantly reducing client risk and time-to-market.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC Machining Excellence in Prototyping

At Wuxi Lead Precision Machinery, we understand that prototyping is not just a phase—it’s the foundation of innovation. Every breakthrough product begins with a precise, reliable, and rapidly produced prototype. As a trusted leader in high-precision CNC machining, we specialize in transforming conceptual designs into functional, real-world prototypes with exceptional accuracy and speed. Our advanced manufacturing capabilities, combined with decades of engineering expertise, position us as the ideal partner for global OEMs, R&D teams, and engineering firms seeking to accelerate product development without compromising quality.

Our state-of-the-art facility in Wuxi, China, is equipped with multi-axis CNC machining centers, high-speed milling systems, and precision turning equipment, all calibrated to maintain tolerances as tight as ±0.002 mm. We support a wide range of engineering-grade materials, including aluminum alloys, stainless steel, titanium, brass, and high-performance plastics such as PEEK and Delrin. Whether you require a single prototype or low-volume bridge production, our agile manufacturing workflow ensures rapid turnaround times—often as fast as 5 to 7 days for standard parts—without sacrificing repeatability or finish quality.

What sets Lead Precision apart is our end-to-end engineering support. From design for manufacturability (DFM) analysis to material selection and surface finishing options, our team collaborates closely with clients to optimize every aspect of the prototyping process. We offer a variety of post-processing services, including anodizing, powder coating, passivation, and precision polishing, ensuring your prototype meets both functional and aesthetic requirements.

Our commitment to quality is reinforced by ISO 9001:2015 certification and rigorous in-process inspection protocols using coordinate measuring machines (CMM) and optical comparators. Every component we produce undergoes comprehensive dimensional and surface verification to guarantee compliance with your specifications.

Below are key technical capabilities that define our CNC prototyping services:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.002 mm |

| Max Work Envelope (XYZ) | 1200 x 800 x 650 mm |

| Spindle Speed (Milling) | Up to 24,000 RPM |

| Turning Diameter | Up to Ø320 mm |

| Lead Time (Standard) | 5–7 days |

| Supported File Formats | STEP, IGES, DWG, DXF, PDF |

| Quality Standards | ISO 9001:2015, First Article Inspection (FAI), PPAP |

When speed, precision, and reliability matter most, Wuxi Lead Precision Machinery delivers. We are not just a service provider—we are an extension of your engineering team, committed to helping you de-risk development and bring products to market faster.

Contact us today to start your next prototyping project. Email us at [email protected] and receive a free quote with DFM feedback within 4 hours. Let Lead Precision be your strategic partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.