Technical Contents

Engineering Guide: Rubber Liquid Mold

Engineering Insight: Rubber Liquid Silicone Molding Demands Absolute Precision

In high-performance rubber liquid silicone molding (LSR), dimensional accuracy is not merely desirable—it is a non-negotiable requirement for functional integrity and regulatory compliance. Components destined for aerospace seals, medical implants, or critical automotive systems operate under extreme conditions where deviations measured in microns can trigger catastrophic seal failure, fluid leakage, or compromised biocompatibility. The inherent challenges of LSR processing—material flow dynamics, thermal expansion during curing, and complex cavity geometries—demand mold tooling engineered to exceptional tolerances. Conventional manufacturing approaches often fall short, introducing inconsistencies that propagate through production, leading to scrap rates that erode profitability and jeopardize client timelines. Precision at the mold foundation is the sole determinant of consistent, high-yield part quality.

At Wuxi Lead Precision Machinery, we engineer LSR molds where micron-level control is standard practice, not an aspiration. Our process begins with advanced simulation to predict material behavior and optimize gate design, ensuring uniform fill and minimal internal stress. This is executed through multi-axis CNC machining and wire EDM capabilities operating within controlled environmental chambers, maintaining tolerances unattainable by standard workshops. Critical cavity surfaces achieve mirror finishes (Ra ≤ 0.025 µm) through specialized polishing protocols, eliminating knit lines and ensuring flawless part release. Thermal management channels are machined with positional accuracy of ±0.005 mm, guaranteeing uniform curing and preventing post-mold shrinkage variations. Every stage—from material certification of H13 or 420SS tool steel to final metrology using Zeiss CMM systems—adheres to stringent ISO 9001 and IATF 16949 protocols. This systematic rigor transforms theoretical design into production reality.

Our commitment to zero-failure performance is validated through demanding applications. Lead Precision molds consistently meet the exacting specifications required for components used in Olympic-grade athletic equipment and mission-critical military hardware, where failure is inconceivable. These projects demand traceability to individual tooling features and validation under conditions simulating decades of service life—all achieved through our precision-first engineering philosophy.

The table below outlines key specifications achievable in our LSR mold manufacturing:

| Parameter | Lead Precision Standard | Typical Industry Benchmark |

|---|---|---|

| Linear Dimension Tolerance | ±0.005 mm | ±0.025 mm |

| Surface Roughness (Cavity) | Ra ≤ 0.025 µm | Ra ≤ 0.1 µm |

| Cavity Position Accuracy | ±0.003 mm | ±0.01 mm |

| Thermal Channel Position | ±0.005 mm | ±0.02 mm |

| Material Hardness (Core) | 52-54 HRC (Verified) | 48-52 HRC (Typical) |

| Metrology Standard | ISO 2768-mK / ASME Y14.5 | ISO 2768-fK |

Precision in LSR molding transcends technical capability; it is a commitment to the operational success and safety of the end product. Wuxi Lead Precision Machinery delivers molds engineered for uncompromising performance in the world’s most demanding sectors. Partner with us to transform your critical LSR component requirements into reality—where every micron matters and excellence is measurable. Contact our engineering team to discuss your specific application challenges and validation protocols.

Precision Specs & Tolerances

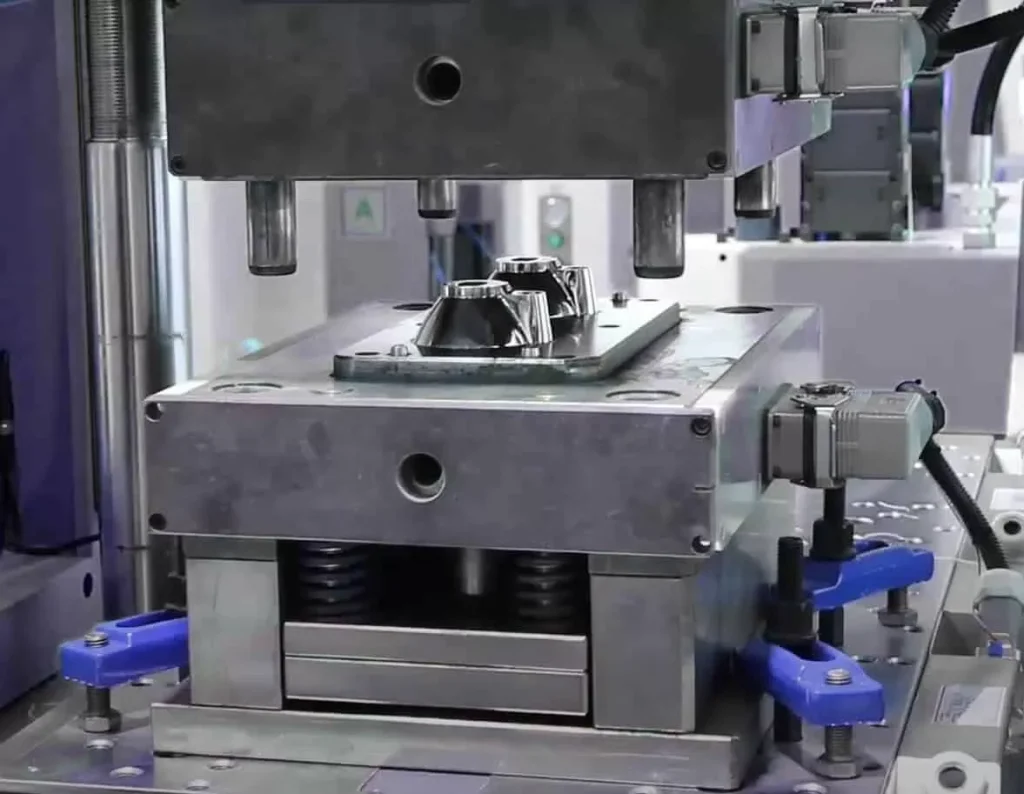

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to support high-precision applications such as rubber liquid mold production. Our facility integrates state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, providing unparalleled flexibility in contouring intricate mold cavities and cores. This level of precision is critical for rubber liquid molding, where dimensional consistency directly impacts final product integrity, sealing performance, and assembly compatibility.

Our 5-axis CNC platforms are operated by certified machinists with extensive experience in mold-specific alloys, including hardened tool steels, stainless steels, and aluminum composites. Each machining cycle is supported by advanced CAM software, ensuring optimized toolpaths, minimized cycle times, and reduced risk of human error. High-speed machining techniques are employed to maintain tight tolerances while preserving material integrity, especially during deep cavity milling and thin-wall feature fabrication common in liquid mold designs.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes comprehensive CMM (Coordinate Measuring Machine) inspection to validate conformance to design specifications. Our Zeiss and Hexagon CMM systems provide micron-level measurement accuracy across three-dimensional datums, enabling full geometric dimensioning and tolerance (GD&T) verification. This metrology-backed validation ensures that each mold base, insert, or electrode meets the stringent requirements of rubber overmolding, injection transfer, and compression molding processes.

In addition to dimensional accuracy, surface finish consistency is rigorously controlled. We utilize in-process probing and post-machining profilometry to verify surface textures, ensuring optimal release characteristics and minimizing post-processing requirements. All inspection data is documented and provided with the final shipment, supporting full traceability for regulated industries such as automotive, medical, and aerospace.

The following table outlines our standard machining tolerances and surface capabilities for rubber liquid mold components:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Hole Diameter | ±0.01 mm | ±0.008 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm (polished) |

| Angular Tolerance | ±0.05° | ±0.02° |

| Cavity Depth Consistency | ±0.01 mm | ±0.005 mm |

These technical capabilities position Wuxi Lead Precision Machinery as a trusted partner for OEMs and mold makers requiring precision-engineered metal components for rubber liquid molding applications. Our combination of 5-axis CNC technology, rigorous CMM-based quality control, and deep domain expertise ensures consistent delivery of high-performance molds that meet the most demanding specifications.

Material & Finish Options

Material Selection for High-Performance Rubber Liquid Molds

Material selection is a critical engineering decision directly impacting the performance, longevity, and cost-efficiency of rubber liquid injection molds. At Wuxi Lead Precision Machinery, we prioritize matching the optimal substrate to your specific compound chemistry, production volume, and thermal requirements. The primary contenders—aluminum, steel, and titanium—each offer distinct advantages and limitations within the demanding environment of liquid rubber processing.

Aluminum alloys, particularly 7075-T6 and 6061-T6, excel in rapid prototyping and medium-volume production due to their superior thermal conductivity. This property significantly reduces cycle times by facilitating faster heat transfer during curing, directly boosting throughput. Aluminum’s machinability allows for complex geometries and intricate details with high precision. However, its lower hardness and wear resistance compared to steel necessitate careful evaluation for highly abrasive compounds or very high-volume runs exceeding several hundred thousand cycles. Surface treatments become essential for extended life.

Tool steels, such as H13 and S7, are the industry standard for high-volume, long-life production molds. Their exceptional hardness, wear resistance, and ability to withstand repeated thermal cycling make them indispensable for demanding applications involving abrasive fillers or millions of cycles. While thermal conductivity is lower than aluminum, requiring potentially longer cycle times, proper mold design and cooling channel optimization mitigate this. Steel molds demand precise heat treatment and stress-relieving processes during manufacturing to prevent distortion—a core competency of our CNC engineering team.

Titanium alloys represent the pinnacle for extreme applications, offering an unparalleled strength-to-weight ratio and exceptional corrosion resistance against aggressive liquid rubber formulations. Its biocompatibility is crucial for medical-grade silicone molding. Thermal conductivity is moderate, better than steel but less than aluminum. The primary constraint is significantly higher material and machining costs, justifying its use only for the most demanding, specialized, or ultra-high-value production scenarios where its unique properties are non-negotiable.

Surface finishing, particularly hard anodizing for aluminum molds, is not optional—it is integral to performance. A dense, hard anodized layer (typically Type III, 50-75µm) dramatically enhances surface hardness, wear resistance, and release properties, effectively bridging the longevity gap between aluminum and steel for many applications. Proper anodizing prevents compound adhesion, reduces cleaning frequency, and maintains dimensional stability over the mold’s operational life. We specify and verify anodizing parameters rigorously to ensure consistent, high-integrity finishes.

The optimal material choice balances technical requirements with total cost of ownership. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and deep process knowledge to guide clients through this selection, ensuring the mold substrate and finish deliver maximum value and reliability for your specific rubber liquid molding operation.

| Material | Hardness Range (HRC) | Thermal Conductivity (W/m·K) | Max Continuous Temp (°C) | Best Suited For |

|---|---|---|---|---|

| Aluminum 7075 | 15-20 (Base) | 130-150 | 150 | Prototyping, Medium volume, Fast cycles |

| H13 Tool Steel | 48-52 (Hardened) | 28-36 | 600 | High volume, Abrasive compounds, Long life |

| Titanium Gr5 | 32-36 (Base) | 7-10 | 600 | Extreme corrosion, Medical, Specialized |

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The production process for rubber liquid molds begins with a comprehensive design phase, where engineering precision meets application-specific requirements. At Wuxi Lead Precision Machinery, our design team utilizes advanced CAD/CAM software to develop 3D models based on client specifications, including part geometry, material behavior, and production volume. Finite Element Analysis (FEA) is integrated to simulate mold performance under operational conditions, ensuring optimal thermal distribution, stress resistance, and flow dynamics for liquid rubber compounds. This digital prototyping reduces physical iterations and mitigates risks early in development. All designs adhere to international standards such as ISO 2768 and DIN 16901, ensuring compatibility and interchangeability across global manufacturing environments. Client collaboration is continuous, with detailed design reviews and approval checkpoints before transitioning to prototyping.

Prototyping: Validating Performance Before Scale

Once the digital model is finalized, a functional prototype is produced using high-precision CNC machining, EDM, and surface finishing techniques. This stage serves as a physical validation of the mold’s structural integrity, dimensional accuracy, and filling behavior with liquid silicone or synthetic rubber. Prototypes are tested under real production parameters, including injection pressure, curing temperature, and ejection cycles. Data collected during testing is analyzed to refine cooling channel layout, gate design, and parting line accuracy. At Wuxi Lead, we implement First Article Inspection (FAI) reports per AS9102 standards, documenting critical dimensions, material certifications, and process capability indices (Cp/Cpk). Only after full client approval and zero-defect validation does the mold proceed to mass production.

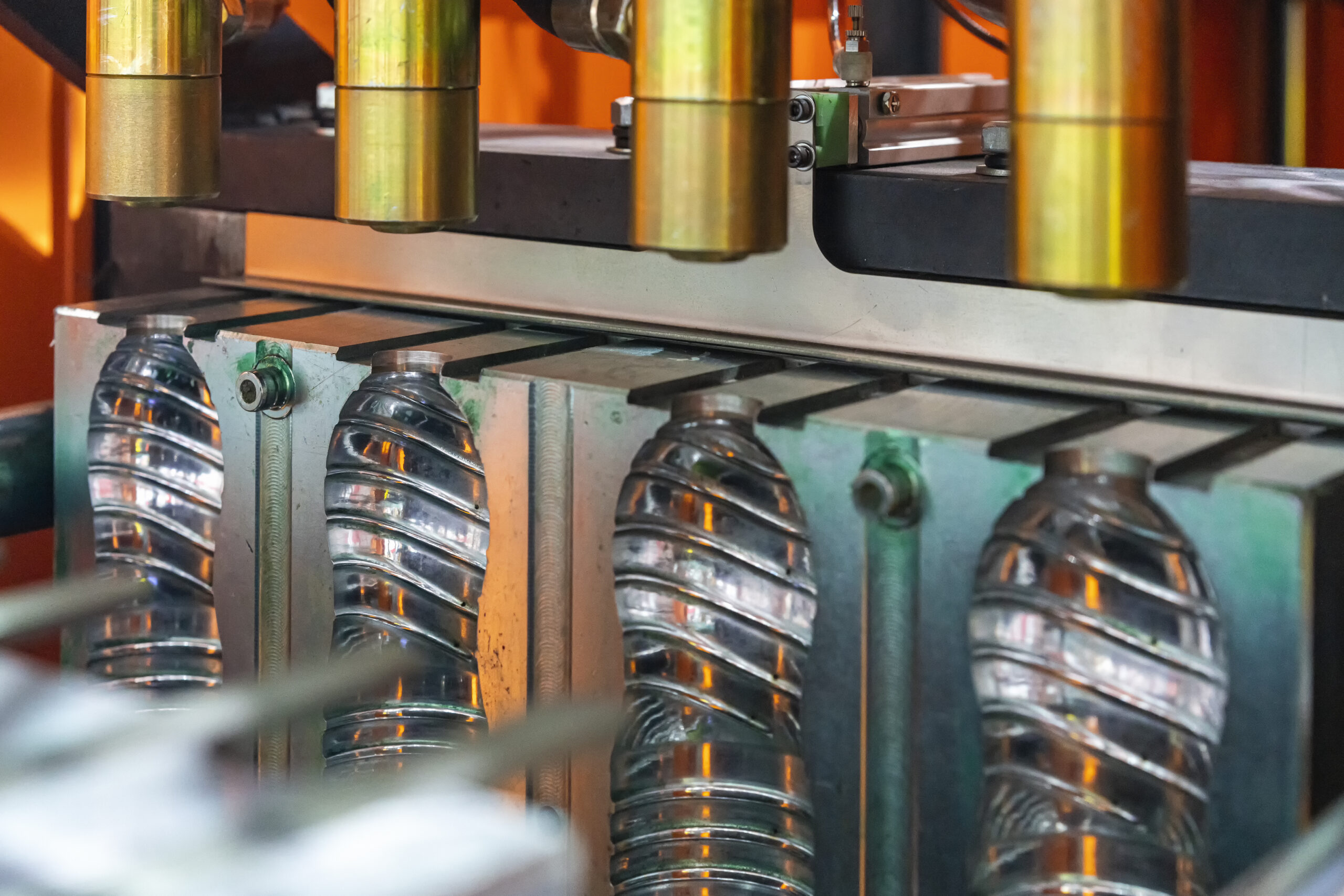

Mass Production: Consistency Through Automation and Control

Mass production is executed on fully automated molding lines integrated with real-time monitoring systems. Each mold undergoes rigorous pre-production calibration to ensure uniform cavity pressure, temperature control, and cycle timing. Our production cells are equipped with in-mold sensors and vision inspection systems that detect deviations at micron-level tolerances. Statistical Process Control (SPC) is applied throughout the run, enabling predictive maintenance and immediate corrective actions. Every component is traceable via QR-coded batch logs, linking material lots, machine settings, and quality inspections. This closed-loop quality system ensures zero-defect output across high-volume runs.

Typical Mold Specifications

| Parameter | Specification |

|---|---|

| Material | H13, S136, or 420 Stainless Steel (polished to Ra ≤ 0.2 µm) |

| Tolerance | ±0.005 mm (cavity/core dimensions) |

| Surface Finish | Mirror polish (SPI A1) or textured per request |

| Gate Type | Pin-point, edge, or submarine |

| Runner System | Cold or cold-to-hot (optimized for liquid rubber) |

| Cycle Time | 30–90 seconds (application-dependent) |

| Production Volume Capacity | 100,000 to 10 million cycles (lifespan) |

| Quality Standard | ISO 9001:2015, PPAP Level 3, 100% Cpk ≥ 1.33 |

Through seamless integration of design intelligence, validated prototyping, and defect-proof manufacturing systems, Wuxi Lead Precision Machinery delivers rubber liquid molds that set industry benchmarks in reliability and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineered Excellence for Rubber Liquid Mold Manufacturing

In the high-stakes realm of rubber liquid mold production, precision failures translate directly to production downtime, material waste, and compromised product integrity. Wuxi Lead Precision Machinery stands as your definitive engineering partner, merging decades of specialized CNC expertise with rigorous quality protocols to eliminate these risks. We do not merely manufacture molds; we engineer production certainty. Our facility operates under ISO 9001-certified processes, deploying advanced multi-axis milling, wire EDM, and surface grinding technologies to achieve micron-level accuracy critical for complex liquid silicone rubber (LSR) and polyurethane applications. Every mold undergoes stringent validation against thermal cycling, pressure tolerance, and flow dynamics to ensure seamless integration into your high-volume manufacturing lines.

The technical demands of rubber liquid molding require more than standard tooling capabilities. Sub-micron surface finishes prevent adhesion issues, while optimized cooling channel geometries directly impact cycle times and part consistency. Our engineering team collaborates with you from initial concept through final validation, applying finite element analysis (FEA) to anticipate material behavior under injection pressures exceeding 1500 bar. This proactive approach mitigates costly revisions and accelerates time-to-market for medical, automotive, and consumer electronics components where tolerances cannot exceed ±0.005mm.

Below are core specifications defining our production capability for rubber liquid molds:

| Specification | Capability | Industry Standard |

|---|---|---|

| Tolerance Control | ±0.002 mm (critical features) | ±0.01 mm |

| Surface Finish (Ra) | 0.05 – 0.2 µm | 0.8 µm |

| Material Options | 420SS, H13, DIN 1.2344, Custom Alloys | P20 Steel |

| Max Mold Size | 1200 x 800 x 600 mm | 800 x 500 x 400 mm |

| Lead Time (Complex) | 15–25 working days | 30–45 days |

This performance is sustained through our zero-defect manufacturing philosophy. Each mold cavity is verified using Zeiss CMM systems with 2.5 + L/300 µm accuracy, while in-house metallurgical labs ensure material homogeneity and hardness consistency. We prioritize intellectual property security with NDAs and segregated project workcells, recognizing that your mold designs represent strategic assets. Our clients achieve 99.2% first-pass yield rates in production – a metric that directly impacts your bottom line through reduced scrap and unplanned maintenance.

Partnering with Lead Precision means accessing a dedicated engineering resource, not just a vendor. Our team speaks your technical language, providing actionable data on mold wear analysis, process optimization, and lifecycle management to extend tool longevity beyond 500,000 cycles. We invest in understanding your end-product requirements to preemptively solve challenges before metal is cut.

Initiate a precision advantage for your rubber liquid molding operations. Contact our engineering sales team at [email protected] with your project specifications and timeline. We will respond within 4 business hours with a detailed capability assessment and feasibility study – no generic quotations, only engineered solutions. Let Lead Precision become the silent partner ensuring your production runs with uncompromised reliability. Your next high-yield mold begins with one email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.