Technical Contents

Engineering Guide: H Molding

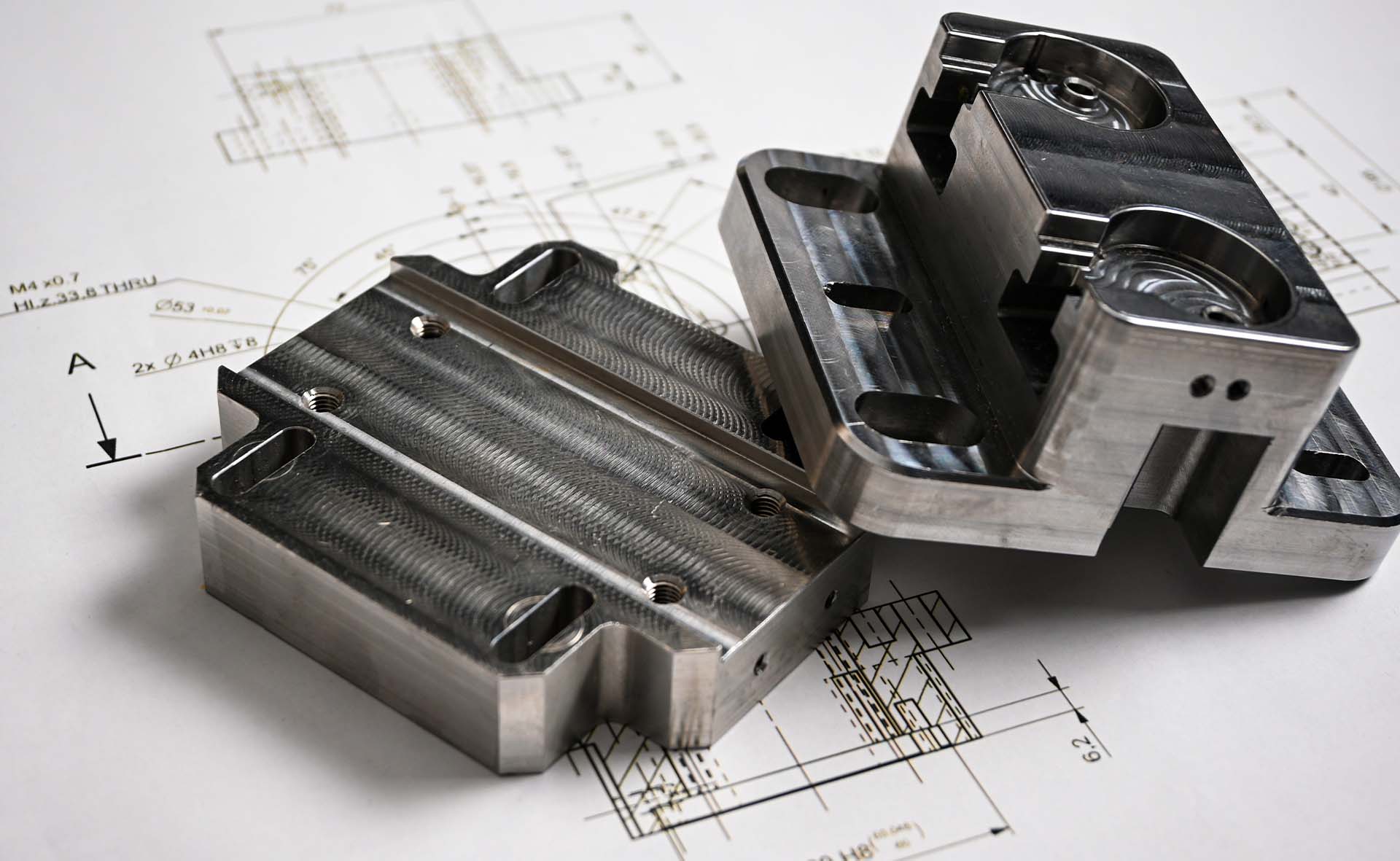

Engineering Insight: The Critical Role of Precision in H Molding

In the realm of custom metal manufacturing, H molding represents a specialized process critical to producing high-strength, dimensionally stable structural components. Named for its characteristic cross-sectional profile resembling the letter “H”, this molding technique is widely employed in aerospace, defense, transportation, and high-load architectural applications. At Wuxi Lead Precision Machinery, we recognize that the integrity and performance of H-molded parts are directly tied to the precision of their manufacturing. Even minor deviations in wall thickness, flange alignment, or material consistency can compromise structural reliability, especially under dynamic or extreme operating conditions.

Precision in H molding is not merely a quality objective—it is an engineering necessity. Components used in mission-critical systems, such as military vehicle frames or support structures in Olympic-grade sporting facilities, must adhere to exacting tolerances and material standards. At Lead Precision, our decades of experience in high-end metal fabrication have enabled us to master the control of thermal expansion, die alignment, and material flow during the molding process. Our in-house engineering team leverages finite element analysis (FEA) and real-time process monitoring to ensure every H-molded profile meets or exceeds international standards, including ISO 9001 and MIL-STD-810.

Our involvement in projects for Olympic infrastructure and military-grade equipment underscores our capability to deliver under the most stringent requirements. For example, H-molded support beams produced for a national Olympic stadium project required tolerances within ±0.1 mm over lengths exceeding 6 meters, alongside full traceability of aluminum alloy batches and non-destructive testing certification. Similarly, components developed for armored vehicle chassis demanded not only precision geometry but also enhanced impact resistance through controlled cooling rates and post-form heat treatment—all managed within our integrated production ecosystem.

The following table outlines key technical specifications achievable with our H molding process:

| Parameter | Standard Capability | High-Precision Option | Material Options |

|---|---|---|---|

| Cross-Sectional Tolerance | ±0.3 mm | ±0.1 mm | 6061, 6082, 7075 Aluminum, Q355 Steel |

| Maximum Length | 6,000 mm | 8,000 mm | Custom lengths on request |

| Wall Thickness Range | 3–15 mm | 2.5–18 mm (with approval) | Tolerance ±0.2 mm |

| Surface Finish | As-extruded (Ra ≤ 3.2 µm) | Machined (Ra ≤ 1.6 µm) | Anodizing, powder coating available |

| Production Volume | Prototype to 50,000 units/year | High-volume automation | Full QA documentation included |

At Wuxi Lead Precision Machinery, precision is more than a metric—it is our commitment to performance, safety, and long-term reliability. Our H molding solutions are engineered to support the most demanding industrial applications, backed by proven expertise in high-stakes manufacturing environments. When structural integrity cannot be compromised, our process ensures it is never left to chance.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Mission-Critical Applications

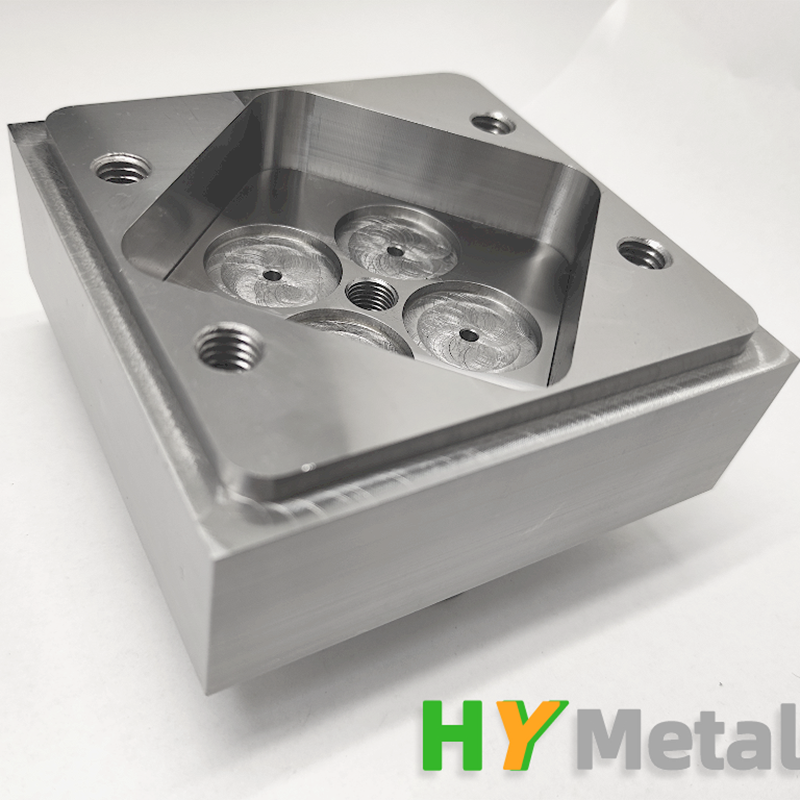

At Wuxi Lead Precision Machinery, our core strength lies in delivering uncompromising precision for the most demanding custom metal components, particularly within high-integrity molding applications requiring complex geometries and stringent tolerances. We leverage advanced manufacturing technology integrated with rigorous quality assurance protocols to ensure every part meets or exceeds the exacting standards of aerospace, medical, and semiconductor industries. Our foundation is built upon state-of-the-art five-axis CNC machining centers, representing the pinnacle of modern metal fabrication capability.

Our Haas and DMG MORI five-axis machining platforms provide the essential flexibility and accuracy required for intricate ‘h molding’ components. These systems perform true simultaneous five-axis interpolation, eliminating the need for multiple setups and significantly reducing cumulative error potential. This capability is critical for machining complex contoured surfaces, deep cavities, undercuts, and integrated features common in high-performance molding tools and cores. The expansive work envelope and high-torque spindles accommodate a wide range of material types, from aluminum alloys and titanium to hardened tool steels and exotic superalloys, ensuring material integrity is maintained throughout the process. Precision motion control guarantees micron-level repeatability, forming the bedrock of our dimensional accuracy.

Quality is not an afterthought but an integrated, measurable process at every stage. Comprehensive Coordinate Measuring Machine (CMM) inspection is mandatory for all critical features on high-tolerance components. Our Zeiss and Hexagon GLOBAL S CMMs, operating within a climate-controlled metrology lab, provide full 3D geometric dimensioning and tolerancing (GD&T) verification. Inspection routines are developed directly from customer CAD models, ensuring alignment with design intent. Data points are meticulously analyzed, generating detailed inspection reports traceable to international standards. This systematic approach to quality control provides absolute confidence in part conformance and process stability, mitigating risk for our clients’ end products.

The following table details the standard tolerance capabilities achievable under controlled production conditions for machined features. Specific project requirements may allow for tighter control based on material, geometry, and feature size.

| Feature Type | Standard Capability | High-Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.005 | CMM, Micrometer |

| Angular Tolerances (°) | ±0.05 | ±0.02 | CMM, Sine Bar |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | CMM |

| Profile of Surface | 0.02 mm | 0.01 mm | CMM |

This combination of advanced five-axis machining and metrology-grade inspection delivers components where precision directly translates to performance. Reduced assembly time, enhanced part reliability, and extended tool life are direct outcomes of our manufacturing fidelity. Partner with Wuxi Lead Precision Machinery to transform complex ‘h molding’ design challenges into reality with engineering excellence you can measure. Our technical team is prepared to discuss your specific tolerance requirements and material challenges to define the optimal manufacturing solution.

Material & Finish Options

Material selection is a critical factor in high-precision custom metal manufacturing, especially in applications involving H molding processes where dimensional accuracy, structural integrity, and environmental resistance are paramount. At Wuxi Lead Precision Machinery, we specialize in guiding engineering teams through the optimal material and finish choices based on performance requirements, cost efficiency, and production scalability. The three primary metals used in our H molding solutions—aluminum, steel, and titanium—each offer distinct mechanical and chemical properties that influence their suitability across aerospace, automotive, medical, and industrial equipment sectors.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly effective in applications requiring lightweight durability and thermal conductivity. 6061-T6 and 7075-T6 are among the most commonly specified alloys due to their balanced mechanical properties and weldability. When enhanced surface hardness and wear resistance are needed, anodizing is the preferred finishing process. Type II (sulfuric acid) anodizing provides a decorative and protective oxide layer, while Type III (hardcoat) anodizing delivers superior abrasion resistance for high-stress environments.

Steel offers unmatched tensile strength and rigidity, making it ideal for load-bearing H molding components exposed to high mechanical stress. We commonly work with stainless steel grades such as 304 and 316 for their corrosion resistance and hygienic surface properties, especially in medical and food processing applications. For structural or industrial tooling, carbon steels like 1045 or alloy steels such as 4140 are selected for their hardenability and fatigue resistance. While steel does not anodize, it can be treated with electroplating, passivation, or powder coating to enhance durability and appearance.

Titanium, particularly Grade 5 (Ti-6Al-4V), is the material of choice in extreme environments where strength, light weight, and resistance to oxidation and corrosion are essential. Commonly used in aerospace and defense applications, titanium maintains performance at elevated temperatures and in aggressive chemical conditions. Though more challenging to machine, its long-term reliability justifies the investment in high-value systems. Surface finishing for titanium typically includes acid pickling or laser texturing, though anodizing is also used for color coding and mild wear improvement.

The following table summarizes key mechanical and finishing characteristics of these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Finishes | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Type II/III Anodizing, Powder Coat | Enclosures, H frames, heat sinks |

| Steel 304 | 505–585 | 7.9 | Passivation, Electroplating | Medical devices, industrial parts |

| Steel 4140 | 655 | 7.85 | Hardening, Painting | Tooling, high-stress components |

| Titanium Ti-6Al-4V | 950 | 4.43 | Anodizing, Pickling | Aerospace, defense, motorsports |

Selecting the right material and finish begins with a clear understanding of operational demands. Wuxi Lead Precision Machinery supports clients with material certification, prototyping, and finish validation to ensure every H molding component meets exact engineering specifications.

Manufacturing Process & QC

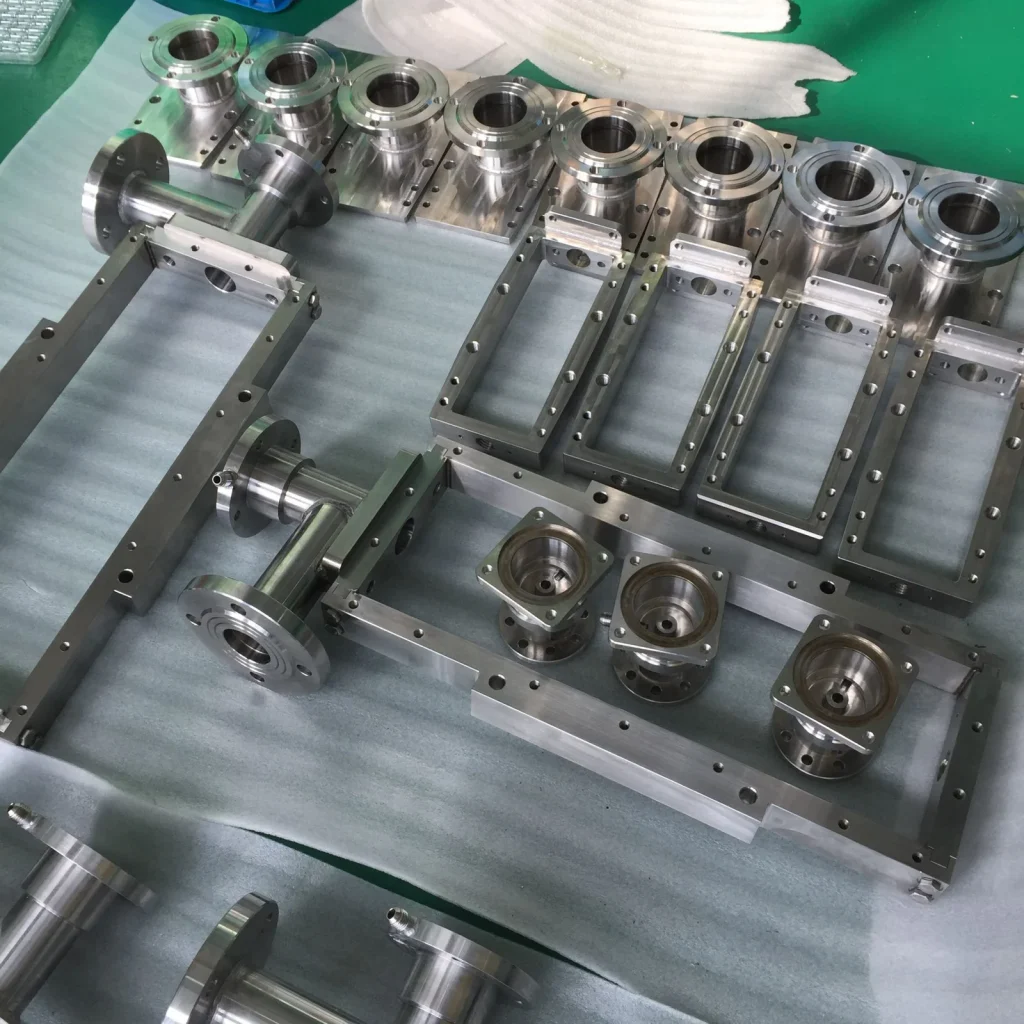

Precision Metal Manufacturing: The Zero Defects Production Process at Wuxi Lead

At Wuxi Lead Precision Machinery, our commitment to Zero Defects begins long before metal meets tool. We execute a rigorously controlled, three-phase production process—Design, Prototyping, and Mass Production—engineered to eliminate waste, ensure absolute conformance, and deliver components meeting the most demanding aerospace, medical, and industrial specifications. This integrated approach is fundamental to our role as a trusted partner in high-end custom metal manufacturing.

The Design phase is a collaborative engineering partnership. We work closely with clients to translate conceptual requirements into manufacturable realities, focusing on Design for Manufacturability (DFM) and Design for Assembly (DFA) principles from day one. Our senior engineers conduct thorough tolerance stack-up analysis and Finite Element Analysis (FEA) simulations to anticipate material behavior under load and thermal conditions. This proactive validation ensures geometric dimensioning and tolerancing (GD&T) align perfectly with functional intent, preventing costly downstream errors. Client sign-off on finalized CAD/CAM models and comprehensive process flow documentation is mandatory before progression.

Prototyping is not merely a formality; it is the critical validation step where theoretical design meets physical reality. Utilizing our advanced 5-axis CNC milling and precision casting capabilities, we produce functional prototypes matching final production intent. Every prototype undergoes rigorous metrology using calibrated Coordinate Measuring Machines (CMM) and optical comparators against the approved master model. Material properties are verified through certified third-party lab testing. This phase identifies potential micro-shrinkage, residual stress points, or surface finish anomalies invisible in simulation. Client feedback on prototype performance directly refines the production process plan, ensuring only validated parameters move forward.

Mass Production leverages full automation and real-time statistical process control (SPC) to institutionalize Zero Defects. Components are manufactured on state-of-the-art, IoT-enabled machinery with closed-loop feedback systems monitoring critical parameters like tool wear, coolant pressure, and thermal drift. Every production run implements 100% automated in-process inspection for key characteristics, supplemented by rigorous first-article and periodic CMM validation. Our ISO 9001-certified quality management system mandates traceability from raw material lot to finished part, with all data logged for immediate root-cause analysis should any deviation occur. Continuous operator training and poka-yoke (error-proofing) fixtures are standard.

This seamless integration of engineering rigor, physical validation, and data-driven production ensures consistent output. The table below outlines core process specifications guaranteeing dimensional and material integrity throughout.

| Parameter | Standard | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (standard) | CMM, Optical Comparator |

| Surface Roughness | Ra 0.4 µm (standard) | Profilometer, Visual Comparison |

| Material Certification | Full Mill Test Report | Lab Certificate Cross-Reference |

| Process Capability | Cpk ≥ 1.67 (all critical dims) | Real-time SPC Charting |

| Inspection Rate | 100% automated in-process | Vision Systems, SPC Data Logging |

Wuxi Lead Precision Machinery transforms complex metal manufacturing challenges into defect-free deliverables. By embedding quality at every stage—from collaborative design through validated prototyping to SPC-controlled mass production—we eliminate scrap, reduce total cost of ownership, and provide the unwavering reliability your high-stakes applications demand. Partner with us for precision that performs, guaranteed.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation are non-negotiable in high-end manufacturing. As a leader in custom metal fabrication and CNC machining, we specialize in delivering tailored solutions for industries where performance under extreme conditions is critical. From aerospace components to medical devices and advanced automation systems, our engineering team collaborates closely with global partners to transform complex designs into flawless, production-ready parts.

Our commitment begins with precision and ends with performance. Every component we produce adheres to the strictest international quality standards, including ISO 9001:2015 certification, ensuring consistent repeatability, tight tolerance control, and full traceability. With state-of-the-art CNC machining centers, multi-axis turning, and advanced inspection systems, we handle low-volume prototypes to high-volume production runs with equal mastery.

What sets us apart is our engineering-first approach. We don’t just manufacture parts—we optimize them. Our team of senior CNC engineers and manufacturing specialists work alongside your design and R&D departments to identify opportunities for material efficiency, cost reduction, and improved manufacturability—without compromising on strength, finish, or function. Whether you’re working with titanium, stainless steel, aluminum alloys, or exotic materials, our process expertise ensures optimal tool paths, reduced cycle times, and superior surface integrity.

We serve as a true extension of your engineering capability, providing comprehensive technical documentation, first-article inspection reports (FAIR), and real-time production updates. Our facility in Wuxi is equipped with automated material handling and in-process metrology, enabling rapid turnaround without sacrificing quality. For mission-critical applications, this level of control is not just an advantage—it’s a necessity.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier. You gain a strategic manufacturing ally with deep technical knowledge, scalable capacity, and a relentless focus on precision.

| Specification | Detail |

|---|---|

| Machining Capabilities | 3 to 5-axis CNC milling, CNC turning, multi-tasking machines |

| Tolerance Range | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 1200 x 800 x 600 mm (47 x 31 x 24″) |

| Materials Processed | Aluminum, Stainless Steel, Titanium, Inconel, Brass, Plastics |

| Surface Finishes | As-machined, anodizing, passivation, polishing, coating support |

| Quality Standards | ISO 9001:2015, FAIR, PPAP, Full CMM inspection |

| Lead Times | Prototype: 7–14 days; Production: 15–30 days (varies by volume) |

Contact us today to discuss your next project. Email us at [email protected] and let our engineering team provide a detailed manufacturability analysis and competitive quotation. At Lead Precision, we don’t just meet expectations—we redefine them.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.