Technical Contents

Engineering Guide: 3D Printing Of Metal Components

Engineering Insight Precision Imperatives in Metal Additive Manufacturing

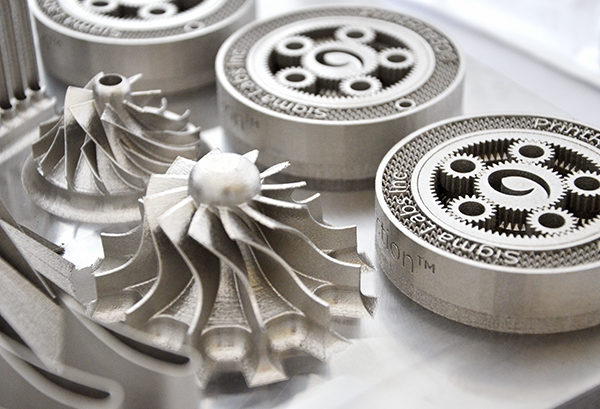

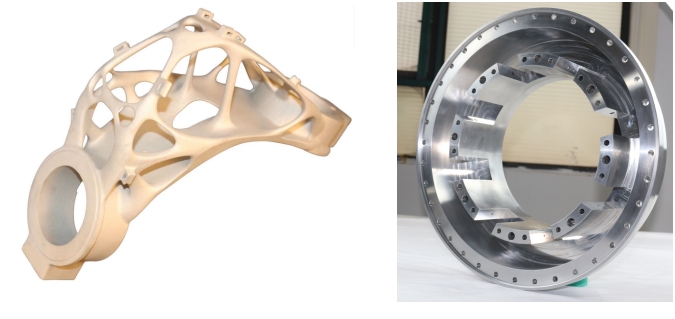

Achieving micron-level precision in metal additive manufacturing is not merely advantageous—it is non-negotiable for critical aerospace, defense, and high-performance industrial applications. Sub-millimeter deviations in turbine blades, medical implants, or satellite components directly compromise structural integrity, fatigue life, and operational safety. Conventional subtractive methods often struggle with the geometric complexity demanded by modern engineering, while poorly controlled additive processes introduce porosity, residual stress, and surface roughness that undermine part reliability. At Wuxi Lead Precision Machinery, we treat dimensional accuracy and material homogeneity as foundational requirements, not optional outcomes. Our engineering protocols prioritize closed-loop monitoring, thermal management, and post-processing validation to ensure every printed component meets stringent AS9100 and MIL-STD tolerances. Precision begins with material science—optimizing powder characteristics and laser parameters—and culminates in metrology-grade verification. Without this end-to-end control, additive manufacturing risks becoming an expensive prototyping tool rather than a certified production solution.

Wuxi Lead’s expertise in high-stakes metal 3D printing is empirically validated through mission-critical projects. We engineered flight-certified titanium ducts for next-generation commercial aircraft where thermal expansion tolerances demanded consistency within ±15 microns across 400mm spans. Our collaboration on Olympic-caliber bobsled runners required surface finishes below Ra 0.8µm to minimize ice friction—achieving podium results through iterative laser parameter tuning. Most significantly, our military-grade component production for naval propulsion systems adheres to zero-defect mandates under MIL-STD-883, where internal voids exceeding 50µm are categorically rejected. This real-world experience proves that precision in metal AM is governed by process maturity, not machine capability alone. We deploy in-situ melt pool monitoring and AI-driven distortion compensation to preempt deviations, ensuring first-article success rates exceed 92% for complex geometries.

Our certified production environment integrates additive and subtractive technologies to deliver uncompromised precision. The following specifications reflect our industrial-scale metal AM capabilities for demanding sectors:

| Parameter | Specification | Industry Relevance |

|---|---|---|

| Layer Thickness | 20–50 µm | Enables fine feature resolution |

| Build Volume | Ø350 x 400 mm (EOS M 400) | Accommodates aerospace assemblies |

| Dimensional Accuracy | ±25 µm over 100 mm | Meets aerospace casting standards |

| Surface Roughness (as-built) | Ra 12–15 µm | Reduces post-processing time by 40% |

| Material Density | >99.95% (Ti-6Al-4V, Inconel 718) | Eliminates fatigue-critical porosity |

| Certification | ISO 13485, AS9100D, NADCAP | Validates compliance for regulated sectors |

True precision engineering transcends machine specifications—it demands an ecosystem of material science, process validation, and domain expertise. Wuxi Lead’s proven record in Olympic and defense applications demonstrates our capacity to transform additive manufacturing from a novelty into a trusted production pillar. When failure is not an option, precision must be engineered into every micron of the build. Contact our applications team to discuss how our certified metal AM processes can meet your most exacting requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the production of precision metal components, combining state-of-the-art 5-axis CNC machining with rigorous quality assurance protocols to meet the most demanding industrial requirements. Our expertise in custom metal manufacturing enables us to support complex geometries, tight tolerances, and high repeatability across a wide range of alloys, including stainless steel, aluminum, titanium, and high-performance superalloys. This ensures that every component we produce meets the exact specifications required by industries such as aerospace, medical devices, automotive, and energy.

At the core of our manufacturing process is our 5-axis CNC machining technology. Unlike conventional 3-axis systems, our 5-axis machines allow simultaneous movement across five planes, enabling the machining of intricate features in a single setup. This reduces cycle time, minimizes human error, and enhances surface finish consistency. The ability to approach parts from multiple angles ensures optimal tool positioning, which is particularly critical when producing organic shapes, undercuts, and internal cavities typical in high-performance applications. Our CNC systems are integrated with advanced CAD/CAM software, allowing seamless translation from digital design to physical part with exceptional accuracy.

Quality control is embedded into every stage of production. Each component undergoes comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring dimensional conformity to the tightest tolerances. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, providing traceable and repeatable measurement data. In addition to final part inspection, in-process checks are conducted to detect deviations early, ensuring consistent quality throughout the production run. This level of scrutiny supports compliance with ISO 9001 standards and customer-specific quality requirements.

The following table outlines the standard tolerances we consistently achieve across various machining parameters:

| Feature | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.01 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Hole Diameter (Drilled) | ±0.01 mm | ±0.005 mm |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm |

These tolerances reflect our commitment to precision and repeatability. Whether producing low-volume prototypes or high-volume production runs, Wuxi Lead Precision Machinery ensures that every metal component meets the highest standards of performance and reliability. Our technical capabilities are designed not only to meet but exceed the expectations of global OEMs and engineering firms relying on mission-critical metal parts.

Material & Finish Options

Material Selection for Metal 3D Printing: Performance-Driven Choices

Selecting the optimal material for metal additive manufacturing (AM) is critical for achieving functional part performance, cost efficiency, and production viability. At Wuxi Lead Precision Machinery, our engineering expertise ensures material choices align precisely with your application’s mechanical, thermal, and environmental demands. Aluminum, steel, and titanium alloys dominate high-performance sectors, each offering distinct advantages and processing considerations. Understanding these nuances prevents costly redesigns and ensures first-pass success in complex builds.

Aluminum alloys, particularly AlSi10Mg, are favored for lightweight structural components requiring good thermal conductivity and moderate strength. Ideal for aerospace brackets, heat exchangers, and automotive prototypes, this material offers excellent printability and a favorable strength-to-weight ratio. However, its lower melting point necessitates precise laser parameter control to avoid distortion. Post-processing like Hot Isostatic Pressing (HIP) is often recommended to eliminate internal porosity for critical applications. Aluminum’s susceptibility to corrosion means surface finishing is frequently essential.

Stainless steel variants, such as 316L and 17-4PH, deliver superior strength, hardness, and corrosion resistance across demanding environments. 316L excels in chemical and marine applications due to its molybdenum content, while 17-4PH provides exceptional strength after precipitation hardening, making it suitable for aerospace fittings and oil & gas tooling. These alloys demonstrate robust printability but require stringent inert gas control to prevent oxidation. Achieving fine surface finishes often involves extensive machining or polishing post-print due to inherent layer lines.

Titanium alloys, primarily Ti6Al4V (Grade 5), are the benchmark for high-strength, low-weight applications in extreme conditions. Widely used in aerospace structural components, medical implants, and motorsport parts, titanium offers outstanding biocompatibility, fatigue resistance, and performance at elevated temperatures. Its high reactivity demands ultra-pure argon environments during printing to avoid embrittlement. While printability is moderate, the material’s cost necessitates minimizing support structures through strategic build orientation. Near-net-shape printing significantly reduces the expensive raw material waste typical of subtractive methods.

Anodizing is a vital surface treatment exclusively applicable to aluminum AM parts. This electrochemical process creates a durable, corrosion-resistant oxide layer, enhancing wear resistance and enabling color coding for identification. Critical for aerospace and consumer electronics, successful anodizing on 3D printed aluminum requires meticulous pre-treatment to address surface roughness from the powder bed fusion process. Standard Type II sulfuric acid anodizing is common, while Type III (hardcoat) offers superior abrasion resistance for high-wear components. Ensure your AM partner integrates surface preparation protocols specifically for additively manufactured substrates.

Material performance characteristics guide strategic selection. Refer to the comparative specifications below:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Elongation (%) | Printability Rating | Key Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 270-350 | 8-12 | ★★★★☆ | Lightweight brackets, heat sinks |

| 316L Stainless | 8.0 | 550-650 | 35-45 | ★★★★☆ | Marine components, chemical pumps |

| 17-4PH Stainless | 7.8 | 1000-1300 | 10-15 | ★★★☆☆ | Aerospace fittings, valve parts |

| Ti6Al4V | 4.43 | 900-1000 | 10-16 | ★★★☆☆ | Aircraft brackets, medical implants |

Material selection transcends basic properties; it integrates printability, post-processing requirements, and lifecycle costs. Wuxi Lead Precision Machinery leverages deep metallurgical knowledge and process validation to match your performance targets with the optimal AM material and finishing strategy, ensuring components meet stringent industry standards while maximizing production efficiency. This precision engineering approach delivers tangible strategic advantage.

Manufacturing Process & QC

The production process for high-precision metal 3D printed components at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure dimensional accuracy, material integrity, and zero-defect deliverables tailored to aerospace, medical, and industrial applications.

Design begins with a comprehensive analysis of functional requirements, environmental conditions, and performance metrics. Our engineering team utilizes advanced CAD and simulation software to optimize part geometry, topology, and support structures. Finite element analysis (FEA) and computational fluid dynamics (CFD) are applied to predict thermal behavior, stress distribution, and fatigue life, ensuring the design is not only printable but also fit for purpose. Material selection is determined during this stage, with options including Inconel 718, Ti-6Al-4V, 316L stainless steel, and AlSi10Mg, based on corrosion resistance, strength-to-weight ratio, and operational temperature.

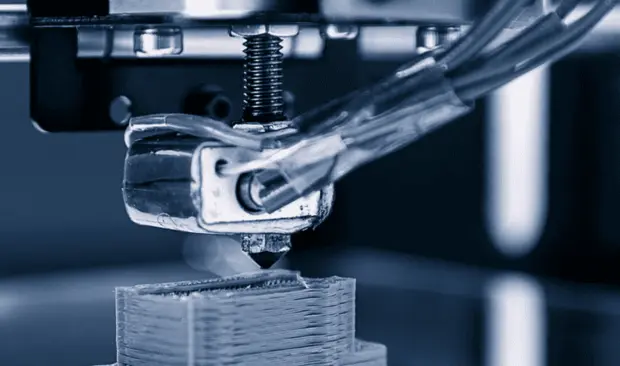

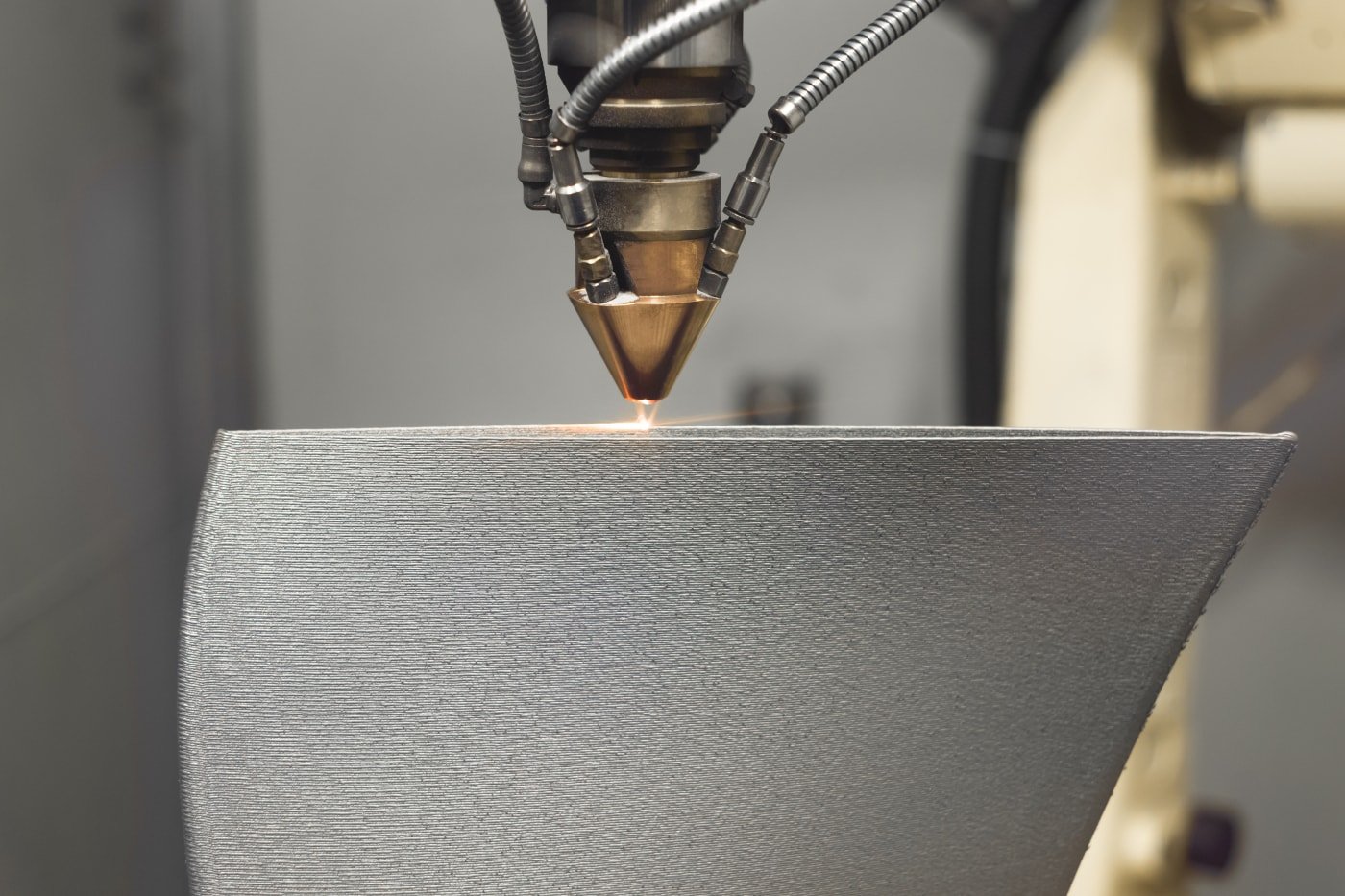

Prototyping is executed using state-of-the-art metal additive manufacturing systems, primarily laser powder bed fusion (LPBF). This stage validates the design under real-world conditions. Each prototype undergoes full metrological inspection using coordinate measuring machines (CMM) and 3D scanning to verify geometric accuracy within ±0.02 mm. Non-destructive testing (NDT), including micro-CT scanning and dye penetrant inspection, confirms internal integrity and absence of porosity. Feedback from prototyping is integrated into the design through iterative refinement, ensuring optimal printability and performance before transitioning to volume production.

Mass Production leverages our industrial-scale metal 3D printing fleet, operating under strict environmental and process controls. Each build is monitored in real time using in-situ sensors for melt pool stability, layer adherence, and thermal gradients. Our production workflow incorporates automated powder handling, controlled atmosphere chambers, and post-processing sequences including stress relieving, hot isostatic pressing (HIP), and precision machining. All components are subject to 100% inspection per AS9100 and ISO 13485 standards, with full traceability from raw material to final shipment.

Our zero-defect philosophy is enforced through statistical process control (SPC), first-article inspection (FAI), and continuous monitoring of key performance indicators. Every batch is documented with material certificates, process logs, and quality reports, ensuring compliance with the most stringent industry requirements.

Key production specifications are summarized below:

| Parameter | Capability |

|---|---|

| Build Volume | Up to 500 x 500 x 400 mm |

| Layer Thickness | 20–60 µm |

| Positional Accuracy | ±0.02 mm per 100 mm |

| Surface Roughness (as-printed) | Ra 8–15 µm |

| Post-Processing Options | HIP, CNC machining, polishing, coating |

| Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, CoCr |

| Quality Standards | ISO 9001, AS9100, ISO 13485 |

This integrated approach ensures that every metal component produced meets the highest benchmarks in reliability, repeatability, and performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Additive Success

The transition from prototyping to serial production of metal 3D printed components demands more than advanced machinery—it requires a partner with unwavering precision, scalable infrastructure, and deep metallurgical expertise. At Wuxi Lead Precision Machinery, we bridge this gap for aerospace, medical implant, and energy sector leaders who cannot compromise on part integrity or delivery timelines. Our ISO 9001:2015 and AS9100D certified facility in Wuxi integrates industrial-grade metal additive systems with legacy CNC finishing capabilities, ensuring every component meets stringent regulatory and performance benchmarks. Unlike generalist suppliers, we specialize in low-volume, high-complexity builds where tolerances below ±0.02mm and material properties matching forged equivalents are non-negotiable.

Our end-to-end workflow begins with design for additive manufacturing (DfAM) consultation, where our engineers optimize topology, support structures, and thermal management protocols to eliminate post-processing bottlenecks. We deploy EOS M 400-4 and SLM Solutions S500 systems for titanium, Inconel, and maraging steel builds, followed by in-house heat treatment, HIP, and 5-axis milling to achieve surface finishes down to Ra 0.8µm. This vertical integration prevents quality drift between vendors—a critical vulnerability in high-stakes applications. Below are core capabilities enabling zero-defect production:

| Parameter | Specification | Industry Relevance |

|---|---|---|

| Build Volume | Up to Ø400 x 400 mm | Large turbine blades, orthopedic frames |

| Layer Thickness | 20–60 µm | Precision fluid dynamics components |

| Positional Accuracy | ±0.02 mm | Aerospace hydraulic manifolds |

| Material Range | Ti6Al4V, Inconel 718, 17-4PH, CoCr | Medical/energy sector compliance |

| Post-Processing | HIP, stress-relieving, micro-machining | Fatigue-critical part longevity |

| Traceability | Full lot tracking per AS9100 | FAA/EU MDR audit readiness |

Partnering with Lead Precision means embedding our process engineers within your NPI team from concept to PPAP. We deploy real-time melt pool monitoring and in-situ CT scanning to validate internal integrity—data you own and leverage for regulatory submissions. Our facility operates under strict ITAR-compliant data protocols, with dedicated cleanrooms for biomedical builds. When a Tier 1 aerospace client faced 18-month delays from their incumbent supplier, our rapid qualification process delivered flight-certified brackets in 9 weeks, avoiding $2.3M in production downtime.

Do not let fragmented supply chains jeopardize your next breakthrough. Contact our engineering team at [email protected] to receive a custom capability assessment within 24 hours. Specify your target material, critical tolerances, and annual volume—we will respond with a validated production timeline, sample lead time, and DfAM optimization report. For urgent RFQs, include project code METAL-ADDITIVE-2024 to fast-track technical review. Lead Precision: Where additive ambition meets industrial execution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.