Technical Contents

Engineering Guide: Sheet Metal Systems Inc

Engineering Insight Precision as the Non-Negotiable Foundation in Sheet Metal Fabrication

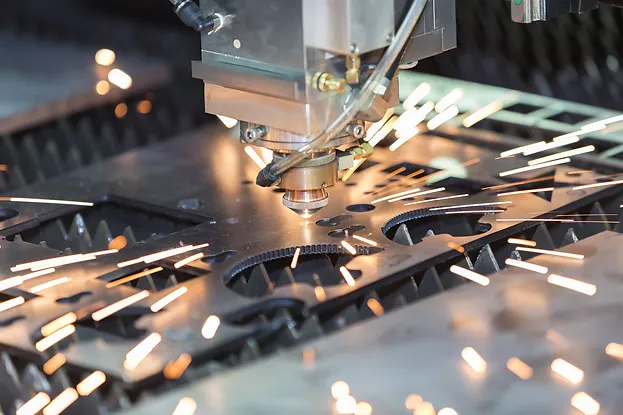

Precision in sheet metal fabrication transcends mere dimensional accuracy; it is the cornerstone of functional integrity, assembly efficiency, and long-term product reliability. For high-stakes applications across aerospace, defense, medical technology, and advanced automation, tolerances measured in hundredths of a millimeter directly impact system performance, safety, and lifecycle costs. Sub-millimeter deviations in critical components can cascade into catastrophic assembly failures, accelerated wear, or compromised operational parameters. Achieving this level of consistency demands more than advanced machinery; it requires an integrated engineering philosophy embedding metrology, material science, and process control at every stage – from initial laser cutting and forming through welding, finishing, and final inspection. True precision minimizes downstream rework, ensures seamless integration within complex assemblies, and ultimately defines the viability of the final product in demanding operational environments.

At Wuxi Lead Precision Machinery, our two-decade commitment to extreme precision is rigorously validated through partnerships on projects where failure is not an option. Our engineering protocols are forged in the crucible of supplying components for Olympic timing systems requiring microsecond synchronization and military-grade equipment demanding unwavering performance under extreme conditions. This experience instills a systemic approach: certified metrology labs operating 24/7, real-time process monitoring on CNC lasers and press brakes, and stringent material traceability from certified mills. We treat every customer project with the same uncompromising standards applied to these elite programs, understanding that consistent precision is the only acceptable baseline for mission-critical sheet metal systems.

The table below outlines the core precision capabilities underpinning our engineering execution for complex sheet metal fabrication:

| Process | Typical Tolerance Capability | Validation Method | Industry Benchmark Standard |

|---|---|---|---|

| Laser Cutting | ±0.05 mm | CMM, Optical Comparator | ISO 2768-mK |

| CNC Punching | ±0.08 mm | First Article Inspection (FAI) | ISO 2768-mK |

| Press Brake Forming | ±0.1° angular / ±0.1 mm | Laser Tracker, Height Gauge | ISO 2768-fine |

| Dimensional Validation | 2.5μm + L/300 μm (CMM) | Zeiss CONTURA G2 Metrology Lab | ASME B89.4.1020 |

When fabricating components for the Beijing Winter Olympics timing infrastructure, tolerances consistently held within ±0.02 mm were non-negotiable to ensure sensor alignment accuracy impacting athlete results. Similarly, military communication chassis we produce undergo environmental stress screening where dimensional stability under thermal cycling is as critical as the initial cut. These projects exemplify how precision is not a singular specification but a holistic engineering discipline. For sheet metal systems inc and your demanding clientele, partnering with a manufacturer whose precision pedigree is proven in the world’s most exacting applications mitigates risk and ensures your systems perform flawlessly from prototype to full production. Precision is the language of reliability; we speak it fluently.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in sheet metal fabrication, engineered to meet the exacting demands of high-performance industries such as aerospace, medical, automotive, and industrial equipment. Our facility integrates state-of-the-art 5-axis CNC machining systems, enabling complex geometries and high-precision components from a single setup. This level of automation reduces human error, improves repeatability, and significantly shortens production cycles—critical advantages for clients requiring rapid prototyping and scalable production runs.

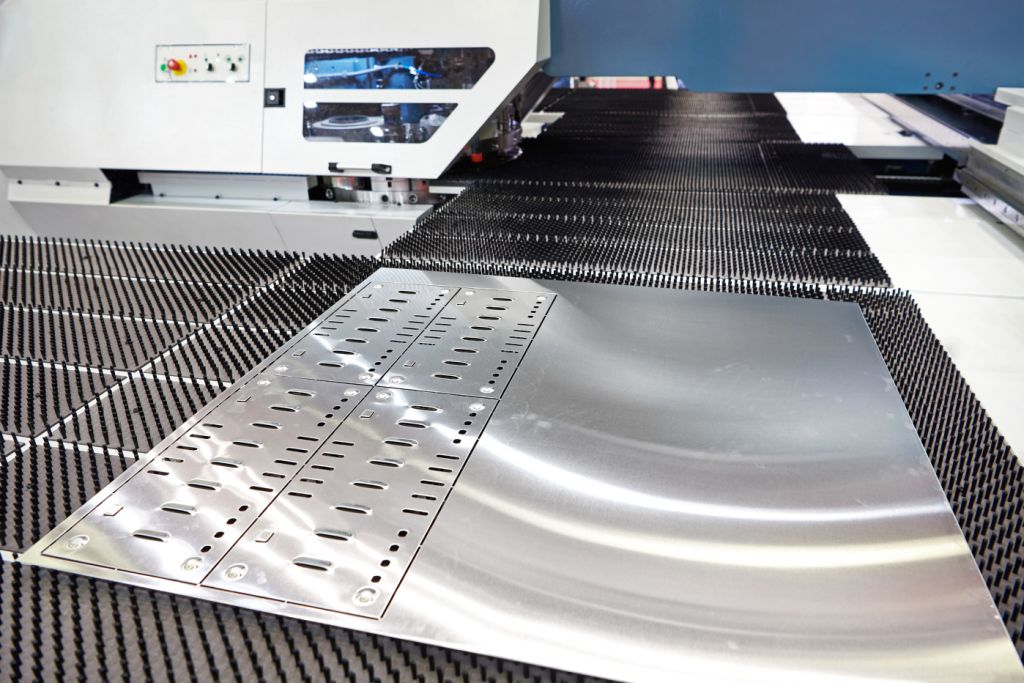

Our 5-axis CNC technology supports simultaneous multi-directional cutting, allowing for intricate contours, undercuts, and detailed features that are unattainable with conventional 3-axis systems. This capability is particularly valuable in fabricating sheet metal enclosures, brackets, housings, and structural components where dimensional complexity and tight tolerances are non-negotiable. Materials are machined with minimal fixturing, preserving material integrity and reducing the risk of deformation—especially important when working with thin-gauge metals or sensitive alloys.

Quality assurance is embedded into every stage of production. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring full metrological validation against CAD models and engineering drawings. The CMM system provides micron-level accuracy in verifying form, fit, and function, with detailed inspection reports available for full traceability. This data-driven approach to quality control meets ISO 9001 standards and supports compliance with industry-specific regulations, including AS9100 for aerospace applications.

In addition to advanced machinery and inspection protocols, our engineering team employs in-depth process optimization techniques, including tool path simulation and thermal compensation algorithms, to maintain consistency across batch production. This technical rigor ensures that every component conforms to the highest standards of precision and reliability.

The following table outlines the standard tolerances achievable across common fabrication operations at Wuxi Lead Precision Machinery:

| Operation | Typical Tolerance | Material Thickness Range | Notes |

|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | 0.5 – 25 mm | Aluminum, stainless steel, titanium, brass |

| Laser Cutting | ±0.025 mm | 0.8 – 12 mm | High-speed cutting with minimal kerf |

| Punching | ±0.05 mm | 0.5 – 6 mm | Turret and CNC punch compatibility |

| Bending | ±0.1° angular | 0.5 – 10 mm | CNC press brake with back gauge |

| Hole Positioning | ±0.02 mm | All thicknesses | Verified via CMM inspection |

| Surface Flatness | 0.05 mm per 100 mm | Up to 1500 x 3000 mm | Critical for sealing and mating surfaces |

These capabilities are supported by a continuous improvement framework, ensuring that Wuxi Lead remains at the forefront of precision sheet metal fabrication. Clients benefit from a seamless integration of design support, prototyping, and volume manufacturing—all executed with uncompromising precision and technical accountability.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material choice fundamentally impacts performance, cost, and longevity in sheet metal fabrication. At Wuxi Lead Precision Machinery, our CNC fabrication experience shows optimal selection requires aligning material properties with specific application demands, environmental exposure, and budget constraints. Understanding the core characteristics of Aluminum, Steel, and Titanium is essential for high-value manufacturing outcomes.

Aluminum alloys, particularly 5052 and 6061-T6, dominate applications requiring an exceptional strength-to-weight ratio and inherent corrosion resistance. Their non-magnetic nature and excellent thermal/electrical conductivity make them ideal for aerospace components, electronic enclosures, and transportation structures. While softer than steel, aluminum’s machinability and weldability are superior. Critical for exposed parts, anodizing transforms the surface into a durable, wear-resistant oxide layer, significantly enhancing corrosion protection and allowing for color coding. Unanodized aluminum remains vulnerable in harsh chemical or marine environments.

Carbon steel, especially grades like 1008 and 1010, offers high strength, structural integrity, and cost-effectiveness for load-bearing frames, chassis, and industrial machinery housings. Its magnetic properties are advantageous for certain applications. However, carbon steel requires protective finishes like powder coating or galvanization to prevent rust, adding process steps and cost. Stainless steel variants (304, 316) provide inherent corrosion resistance through chromium content, making them suitable for medical devices, food processing equipment, and marine hardware, though at a higher material cost than carbon steel.

Titanium, primarily Grade 2 and 5, delivers unparalleled strength-to-weight ratio, extreme corrosion resistance across nearly all environments, and biocompatibility. These properties justify its use in critical aerospace, defense, and medical implant applications. However, titanium’s high material cost, challenging machinability, and specialized welding requirements significantly increase fabrication expenses. Its adoption is typically reserved for mission-critical components where performance justifies the premium.

Anodizing is not merely cosmetic for aluminum; it is a critical functional finish. The electrochemical process creates a hard, porous oxide layer integral to the base metal. Type II (sulfuric acid) anodizing provides good corrosion and wear resistance with dyeing capability. Type III (hardcoat) anodizing produces a much thicker, denser layer for severe wear applications. Proper sealing after dyeing is mandatory to lock in color and maximize corrosion resistance. Selecting the correct anodizing type and thickness directly impacts the part’s service life.

Material properties must guide the decision. The following table summarizes key comparative specifications for common sheet metal fabrication grades.

| Material | Typical Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Relative Cost |

|---|---|---|---|---|

| Aluminum 6061-T6 | 240-275 | 2.7 | Very Good (Anodized) | Medium |

| Carbon Steel 1010 | 180-200 | 7.85 | Poor (Requires Coating) | Low |

| Stainless 304 | 205-215 | 8.0 | Excellent | Medium-High |

| Titanium Grade 5 | 880-900 | 4.43 | Exceptional | Very High |

Selecting the right material and finish is a strategic engineering decision. Wuxi Lead Precision Machinery partners with clients to analyze operational requirements, ensuring the chosen sheet metal solution delivers optimal performance, durability, and value within the fabrication process. Contact our engineering team for application-specific material recommendations.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for sheet metal fabrication is engineered for precision, consistency, and zero-defect delivery. We serve high-end industrial clients globally, where reliability and repeatability are non-negotiable. Our integrated workflow spans three critical phases: Design, Prototyping, and Mass Production—each governed by strict quality protocols and advanced manufacturing standards.

The process begins with Design, where our engineering team collaborates closely with client specifications. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we develop detailed 3D models and flat patterns optimized for manufacturability. Design for Assembly (DFA) and Design for Manufacturing (DFM) principles are applied rigorously to eliminate potential flaws before physical production. Material selection, bend allowances, grain direction, and tolerance stacking are analyzed to ensure dimensional accuracy across the production run.

Following design finalization, we move to Prototyping. This phase serves as a physical validation of the design intent. Using high-precision laser cutting, CNC punching, and automated bending cells, we produce a limited batch of components for functional and dimensional testing. Our prototype parts are subjected to rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning. Any deviations are traced back to the root cause, and design or process adjustments are made in real time. This iterative verification ensures that the transition to mass production is risk-free.

Mass Production leverages our fully automated production lines, featuring integrated robotic material handling, real-time monitoring, and in-process quality checks. Each stage—cutting, forming, welding, surface finishing, and assembly—is controlled by CNC systems with closed-loop feedback. Statistical Process Control (SPC) is implemented at every critical control point to monitor process capability and maintain a Cpk ≥ 1.67. Our facility operates under ISO 9001:2015 and IATF 16949 standards, ensuring full traceability from raw material to finished product.

To maintain zero-defect output, we employ a multi-tiered quality assurance strategy. This includes first-article inspection, in-line dimensional checks, final functional testing, and 100% visual inspection where applicable. Non-conforming parts are quarantined immediately, and corrective actions are documented and implemented across the production system.

Below are key technical specifications of our sheet metal fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.3 mm – 6.0 mm (steel, stainless, aluminum) |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.1°, ±0.1 mm |

| Laser Cutting Power | Up to 12 kW fiber laser |

| CNC Press Brake Capacity | Up to 300 tons, 4 m length |

| Minimum Bend Radius | 0.5× material thickness |

| Surface Roughness (Ra) | ≤ 1.6 μm (after finishing) |

| Production Capacity | Up to 50,000 parts per month |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS |

Our end-to-end process ensures that every component shipped meets the highest standards of precision and reliability, making Wuxi Lead Precision Machinery a trusted partner for mission-critical sheet metal solutions.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Fabrication Through Strategic Partnership

In the competitive landscape of precision sheet metal manufacturing, selecting a partner capable of translating complex engineering requirements into flawless physical components is paramount. Wuxi Lead Precision Machinery stands as your dedicated solution provider, engineered to eliminate the bottlenecks that compromise project timelines and product integrity. We recognize that inconsistent tolerances, extended lead times, and communication gaps between design intent and production output directly impact your market responsiveness and brand reputation. Our integrated approach bridges this gap through advanced technology, rigorous process control, and a commitment to collaborative engineering support.

Partnering with Lead Precision means accessing a vertically integrated facility where every stage—from laser cutting and CNC punching to precision bending and robotic welding—is optimized under one roof. Our ISO 9001:2015 and IATF 16949 certified systems ensure repeatability down to ±0.05mm tolerances, while our engineering team proactively engages during the DFMA phase to optimize manufacturability and reduce total project costs. Unlike transactional suppliers, we function as an extension of your technical staff, providing real-time production data, first-article inspection reports, and rapid design-for-manufacture feedback. This proactive collaboration minimizes rework, accelerates time-to-market, and guarantees components that perform as engineered in final assembly.

Critical capabilities enabling your success are quantified below:

| Capability | Specification Range | Key Equipment |

|---|---|---|

| Laser Cutting | 0.5mm–3mm Stainless Steel | Bystronic BySprint 3015i |

| CNC Punching | 0.8mm–2.5mm Carbon Steel | Amada Pega 367 |

| Press Brake Forming | 0.5mm–6mm, ±0.1° Angular Tolerance | Trumpf TruBend Series 7000 |

| Tolerance Control | ±0.05mm (Critical Features) | Zeiss Coordinate Measuring Machine |

| Material Certification | Full Mill Test Reports Provided | EN 10130, ASTM A653, JIS G3141 |

This technical foundation is reinforced by our operational agility. We maintain dedicated production cells for high-mix/low-volume runs common in aerospace and medical device sectors, alongside scalable capacity for automotive-tier production volumes. Our digital workflow integrates seamlessly with your PLM systems, providing end-to-end traceability from raw material lot tracking to final shipment documentation. Every shipment undergoes stringent first-article and in-process inspections, with non-destructive testing available for mission-critical components.

The next phase of your manufacturing strategy demands a partner invested in your engineering success, not merely fulfilling a purchase order. Contact our technical sales team today to initiate a capability review for your current or upcoming project. Forward your CAD files and specifications to [email protected] for a detailed manufacturability analysis and competitive quotation within 72 business hours. Our engineers are prepared to discuss material optimization, secondary operation integration, and logistics coordination tailored to your supply chain requirements. Do not allow fabrication limitations to constrain your product innovation—secure precision, reliability, and responsive partnership with Wuxi Lead Precision Machinery. Your engineering excellence deserves manufacturing execution without compromise.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.