Technical Contents

Engineering Guide: Copper Laser Cutting Services

Engineering Insight: Copper Laser Cutting Services

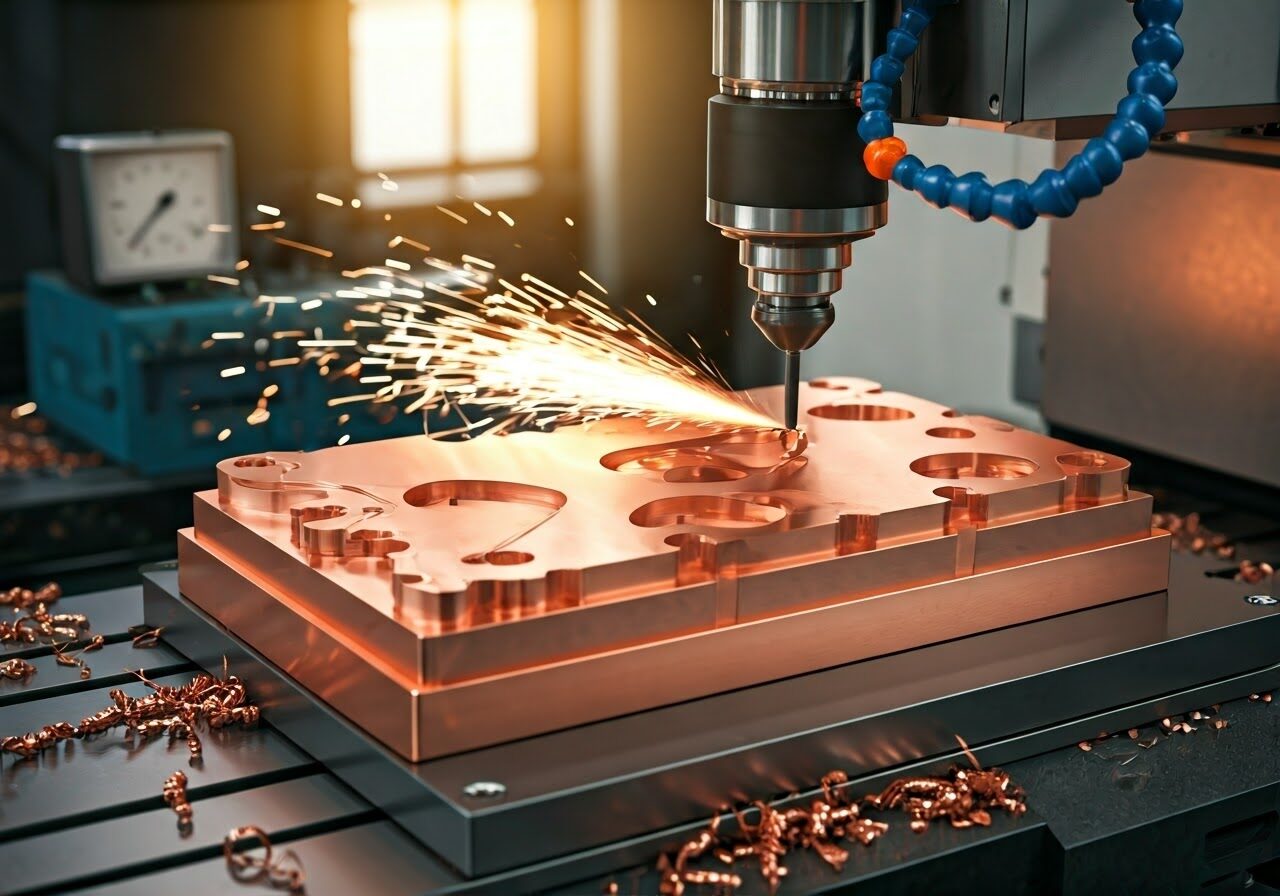

Copper laser cutting services represent a critical capability within advanced sheet metal fabrication, particularly for industries demanding high electrical conductivity, thermal performance, and long-term reliability. Copper, while highly functional, presents unique challenges in processing due to its exceptional reflectivity and thermal conductivity. These material properties demand not only specialized laser technology but also deep engineering expertise to ensure cut quality, dimensional accuracy, and process repeatability. At Wuxi Lead Precision Machinery, we have mastered these complexities through years of focused innovation and application-specific refinement.

Precision in copper laser cutting is non-negotiable. Even minor deviations in kerf width or edge squareness can compromise the performance of components used in power transmission, high-frequency electronics, or aerospace systems. Reflectivity issues can lead to inconsistent energy absorption, risking incomplete cuts or thermal damage. To counter this, our fiber laser systems are equipped with anti-reflective optics and real-time beam modulation, ensuring stable interaction between the laser and copper surface. Furthermore, our adaptive control algorithms dynamically adjust power, pulse frequency, and assist gas parameters based on material thickness and geometry, minimizing dross formation and maintaining edge integrity.

Our experience in delivering precision copper components extends to mission-critical applications. Wuxi Lead has supported projects tied to Olympic infrastructure developments and high-reliability military systems, where failure is not an option. These engagements required not only micron-level tolerances but also full traceability, rigorous quality control, and compliance with international standards. Our team’s ability to consistently meet these demands underscores our leadership in the field of advanced metal processing.

Beyond technical capability, we emphasize process optimization. From nesting efficiency to minimizing heat-affected zones, every aspect of copper laser cutting is engineered for performance and cost-effectiveness. Our engineers work closely with clients during the design-for-manufacturability phase to ensure that part geometry, material selection, and finishing requirements align with optimal production workflows.

The following table outlines key technical specifications for our copper laser cutting services:

| Parameter | Specification |

|---|---|

| Material | Pure Copper (C10100, C11000), Oxygen-Free Copper |

| Thickness Range | 0.2 mm – 6.0 mm |

| Laser Source | High-Brightness Fiber Laser (up to 6 kW) |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Minimum Feature Size | 0.3 mm (holes), 0.5 mm (slots) |

| Edge Roughness (Ra) | ≤ 3.2 µm (typical) |

| Kerf Width Tolerance | ±0.05 mm |

| Assist Gases | Nitrogen, Oxygen (selective applications) |

| Max Cutting Speed | Up to 25 m/min (thin sheets, <1 mm) |

At Wuxi Lead Precision Machinery, we combine cutting-edge technology with proven engineering excellence to deliver copper laser cutting services that meet the highest standards of precision and reliability. Our commitment to quality ensures that every component performs flawlessly in the most demanding environments.

Precision Specs & Tolerances

Advanced Copper Laser Cutting Capabilities at Wuxi Lead Precision Machinery

Copper presents unique challenges in laser processing due to its high thermal conductivity and reflectivity, demanding specialized expertise and advanced equipment to achieve precision results. At Wuxi Lead Precision Machinery, we leverage purpose-built high-power fiber laser systems engineered specifically for non-ferrous metals like copper. Our process utilizes optimized wavelength parameters, controlled assist gases, and dynamic power modulation to overcome reflectivity issues, ensuring clean, dross-free cuts with minimal thermal distortion even on pure electrolytic copper and common alloys such as C11000 and C10100. This capability is critical for industries requiring superior electrical conductivity and thermal management, including power electronics, RF components, and high-end busbar manufacturing.

Our technical foundation rests on state-of-the-art 5-axis CNC laser cutting platforms. These systems provide unparalleled flexibility for complex geometries, enabling precise bevel cutting, intricate contours, and three-dimensional part fabrication directly from solid copper stock or sheet. The integrated 5-axis motion control ensures consistent edge quality and dimensional accuracy across all angles, eliminating the need for secondary machining operations on many features. This reduces lead times and part handling while maintaining stringent geometric tolerances essential for assembly-critical components. All cutting parameters are meticulously programmed and monitored in real-time via our Siemens or Fanuc CNC controls, guaranteeing process repeatability batch after batch.

Rigorous quality assurance is non-negotiable for copper components where conductivity and fit are paramount. Every critical dimension undergoes verification using calibrated Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMMs, operating within a temperature-stabilized metrology lab, provide micron-level traceability against customer CAD models and first-article inspection reports. This comprehensive inspection protocol covers not only linear dimensions but also complex form tolerances, hole positions, and surface finish characteristics specific to laser-cut copper edges. Full inspection documentation, including GD&T analysis, is provided with every production run, ensuring complete compliance with aerospace, medical, and industrial standards.

The following table details our standard achievable tolerances for copper laser cutting, reflecting our commitment to high-precision manufacturing under controlled environmental conditions:

| Material Thickness (mm) | Dimensional Tolerance (± mm) | Positional Tolerance (± mm) |

|---|---|---|

| 0.5 – 1.0 | 0.05 | 0.03 |

| 1.0 – 2.0 | 0.08 | 0.05 |

| 2.0 – 3.0 | 0.10 | 0.07 |

| 3.0 – 6.0 | 0.15 | 0.10 |

Notes: Tolerances apply to OFHC copper (C10100/C11000) sheets. Achievable results depend on part geometry, feature density, and specified edge quality requirements. All measurements certified per ISO 2768-mK under controlled lab conditions (20°C ±1°C). Tighter tolerances available upon engineering review.

Wuxi Lead Precision Machinery delivers more than cutting services; we provide engineered solutions for the most demanding copper fabrication applications. Our combination of specialized laser technology, multi-axis precision control, and metrology-grade quality validation ensures your copper components meet the exacting performance standards required in advanced manufacturing sectors. Partner with us for reliable, high-integrity copper parts where conductivity, fit, and function cannot be compromised.

Material & Finish Options

Material Selection for High-Precision Copper Laser Cutting Services

When selecting materials for high-precision laser cutting applications, copper presents unique challenges and opportunities due to its exceptional thermal and electrical conductivity. While copper is the primary focus, understanding its interaction with common companion materials such as aluminum, steel, and titanium is essential for optimal design and manufacturing outcomes. At Wuxi Lead Precision Machinery, we specialize in processing copper and related metals with fiber laser technology engineered to overcome reflectivity and heat dissipation issues inherent in high-conductivity materials.

Copper requires high peak power and precise beam control to initiate and maintain a clean cut. Our 6 kW to 12 kW fiber lasers are optimized for this purpose, ensuring minimal dross and tight tolerances down to ±0.1 mm. However, in multi-material assemblies, secondary metals often play structural or functional roles. Aluminum, known for its lightweight and corrosion resistance, can be cut with similar laser parameters but requires inert gas assist (nitrogen) to prevent oxidation. Steel—particularly stainless grades like 304 and 316—is highly compatible with laser cutting and offers excellent edge quality with minimal post-processing. Titanium, though less common, demands strict environmental control due to its reactivity at high temperatures, requiring argon shielding during cutting to avoid embrittlement.

Each material responds differently to thermal input, which influences joint design, nesting efficiency, and finishing requirements. For instance, copper and aluminum expand significantly under heat, necessitating compensation in dimensional programming. Steel exhibits lower thermal expansion, allowing for denser part nesting on sheet stock. Titanium, while dimensionally stable, requires slower cutting speeds to manage heat accumulation.

Post-cut finishing further differentiates these materials. Anodizing is a critical surface treatment for aluminum, enhancing wear resistance and enabling electrical insulation or color coding for identification. This electrochemical process builds a controlled oxide layer, ideal for aerospace, medical, and electronics applications. Copper, by contrast, is rarely anodized but often plated (nickel, tin, or gold) for improved solderability or corrosion resistance. Steel may undergo passivation or powder coating, while titanium naturally forms a protective oxide layer, though it can be bead blasted for aesthetic consistency.

The following table outlines key material properties and laser processing parameters:

| Material | Thickness Range (mm) | Laser Power Required (kW) | Assist Gas | Typical Tolerance (± mm) | Common Applications |

|---|---|---|---|---|---|

| Copper | 0.5 – 8.0 | 6 – 12 | Nitrogen/Argon | 0.1 | Busbars, connectors, RF components |

| Aluminum | 0.5 – 10.0 | 4 – 8 | Nitrogen | 0.1 | Enclosures, heat sinks, frames |

| Steel | 0.5 – 12.0 | 3 – 6 | Oxygen/Nitrogen | 0.1 | Chassis, brackets, industrial parts |

| Titanium | 0.5 – 6.0 | 6 – 10 | Argon | 0.1 | Aerospace, medical implants |

Understanding these material characteristics ensures optimal design for manufacturability and performance. At Wuxi Lead Precision Machinery, we support clients in selecting the right material and finish combinations to meet exacting industrial standards.

Manufacturing Process & QC

Copper Laser Cutting Production Process: Design to Zero Defect Mass Production

Copper presents unique challenges in laser cutting due to its high thermal conductivity and reflectivity, demanding specialized processes to achieve the precision required for high-end applications in electronics, power transmission, and thermal management. At Wuxi Lead Precision Machinery, our integrated production workflow ensures dimensional accuracy, superior edge quality, and absolute adherence to the Zero Defects philosophy from initial concept through final shipment. This rigorous methodology is fundamental to delivering copper components that meet the stringent demands of aerospace, medical, and semiconductor industries.

The process begins with meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with the client to review CAD files, focusing specifically on copper’s material behavior. We assess feature geometry, kerf width implications, thermal distortion risks, and nesting efficiency. Critical parameters such as minimum feature size, internal corner radii, and part spacing are optimized using advanced simulation software to prevent melt adhesion or dross formation inherent in copper processing. This proactive DFM stage eliminates potential failure points before any material is cut, ensuring the design is inherently manufacturable to zero-defect standards.

Following design validation, precision prototyping is executed using our dedicated copper-optimized fiber laser systems. These machines employ specific wavelength settings and high-brightness sources to overcome reflectivity challenges, coupled with ultra-pure nitrogen assist gas to prevent oxidation and ensure clean, oxide-free edges essential for conductivity and weldability. Prototypes undergo rigorous first-article inspection against all critical dimensions and surface finish requirements. Material specifications are strictly controlled, as shown in the table below, forming the baseline for mass production.

| Parameter | Specification for Copper Laser Cutting | Standard Met |

|---|---|---|

| Material Thickness | 0.1 mm – 3.0 mm | ASTM B152 / C1100 |

| Tolerance (±) | 0.05 mm (up to 1.5mm); 0.10 mm (>1.5mm) | ISO 2768-mK |

| Surface Roughness | Ra ≤ 3.2 µm | ISO 4287 |

| Edge Perpendicularity | ≤ 0.15 mm | Internal Standard |

| Kerf Width | 0.12 mm – 0.25 mm (material dependent) | Process Specific |

Zero Defect Mass Production leverages the validated prototype parameters within a fully controlled environment. Production runs utilize in-process monitoring systems tracking laser power, gas pressure, and cutting head position in real-time, automatically adjusting to maintain consistency. Every sheet undergoes pre-cut verification for flatness and material certification. Post-cut, 100% critical dimension inspection is performed using calibrated CMMs and optical comparators, with statistical process control (SPC) data continuously analyzed. Non-conforming parts are immediately quarantined and root cause analysis initiated, preventing defect escape. Final parts are handled with ESD-safe protocols and packaged to prevent surface damage, ensuring the copper components arrive ready for immediate high-value assembly, defect-free. This closed-loop system guarantees repeatability and fulfills our commitment to zero-defect delivery on every order.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Copper Laser Cutting Services

When precision, reliability, and consistency define your production standards, partnering with a leader in advanced sheet metal fabrication becomes essential. At Wuxi Lead Precision Machinery, we specialize in high-accuracy copper laser cutting services tailored to meet the rigorous demands of industries such as electronics, telecommunications, medical devices, and high-end industrial equipment. Our state-of-the-art fiber laser technology is specifically optimized for processing copper—a highly reflective and thermally conductive material that requires expert handling and precision engineering.

Copper presents unique challenges in laser cutting due to its high reflectivity and thermal conductivity, which can lead to inconsistent cuts, edge burring, or material warping if not managed correctly. At Lead Precision, we overcome these challenges with advanced laser systems equipped with specialized beam delivery optics, adaptive power control, and inert gas assist techniques. Our processes ensure clean, burr-free edges, tight tolerances, and superior surface quality—critical for applications where electrical performance and mechanical fit are non-negotiable.

Our facility in Wuxi, China, operates under strict ISO 9001-certified quality management systems, ensuring every copper component we produce meets exact customer specifications. From prototype development to high-volume production runs, our team of CNC engineers and manufacturing specialists collaborate closely with clients to optimize designs, reduce material waste, and accelerate time-to-market. Whether you require intricate cutouts for heat dissipation plates, busbars, RF shielding components, or custom connectors, we deliver precision-cut copper parts with repeatability and consistency.

We support a wide range of copper grades, including C11000, C10100, and oxygen-free electronic copper, in thicknesses ranging from 0.2 mm to 3.0 mm. Our laser systems provide exceptional edge quality with minimal heat-affected zones, preserving the material’s electrical and thermal properties. With automated material handling and in-process inspection, we maintain high throughput without compromising on precision.

Below are the key technical specifications of our copper laser cutting capabilities:

| Parameter | Specification |

|---|---|

| Material | Pure Copper (C11000, C10100, OFE) |

| Thickness Range | 0.2 mm – 3.0 mm |

| Laser Type | High-Power Fiber Laser (Single-Mode Optics) |

| Maximum Power | 6 kW |

| Positioning Accuracy | ±0.02 mm |

| Repeatability | ±0.01 mm |

| Minimum Feature Size | 0.3 mm (holes), 0.5 mm (slots) |

| Edge Roughness (Ra) | ≤ 3.2 µm (typical) |

| Gas Assist | Nitrogen or Argon (high-purity) |

| Lead Time (Standard) | 5–7 working days (prototype), 10–12 (batch) |

Partnering with Wuxi Lead Precision Machinery means gaining access to advanced manufacturing expertise, responsive engineering support, and scalable production capacity—all backed by a commitment to quality and customer success. For your next high-precision copper fabrication project, contact us today at [email protected] to discuss your requirements and receive a detailed technical consultation. Let Lead Precision be your trusted partner in precision sheet metal innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.