Technical Contents

Engineering Guide: Aluminium Sheet Fabrication

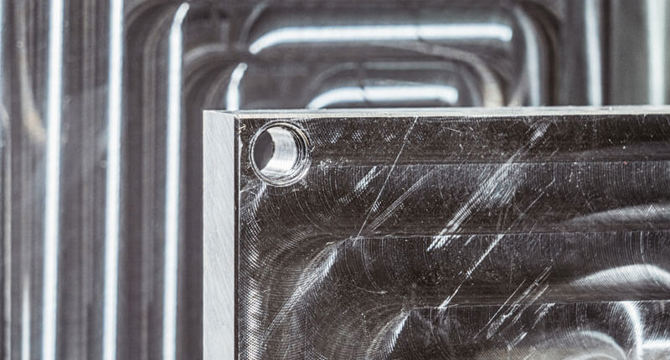

Engineering Insight: Precision in Aluminium Sheet Fabrication

Aluminium sheet fabrication is a cornerstone of modern industrial manufacturing, serving critical roles in aerospace, defense, transportation, and high-performance architectural applications. At Wuxi Lead Precision Machinery, we understand that the success of these applications hinges not only on material selection but on the precision with which aluminium sheets are cut, formed, and assembled. The inherent properties of aluminium—its lightweight nature, corrosion resistance, and high strength-to-weight ratio—make it ideal for advanced engineering, but these benefits are fully realized only when fabrication tolerances are strictly maintained.

Precision in aluminium sheet fabrication begins with accurate material handling and extends through every stage: laser or plasma cutting, CNC bending, welding, and final assembly. Even minor deviations in flatness, hole positioning, or bend angles can compromise structural integrity, fitment, or performance under dynamic loads. This is especially critical in sectors such as military equipment and Olympic-grade sports infrastructure, where failure is not an option. At Wuxi Lead, our engineering protocols are built around micron-level consistency, ensuring repeatability and compliance with international quality standards including ISO 9001 and AS9100.

Our experience in delivering components for Olympic stadium structures and specialized military platforms has refined our approach to aluminium fabrication. These projects demanded not only exacting dimensional accuracy but also seamless integration with complex assemblies and adherence to stringent environmental and safety requirements. By utilizing state-of-the-art CNC press brakes, fiber laser cutting systems, and 3D metrology verification, we maintain tolerances as tight as ±0.05 mm across large-format sheets up to 6,000 mm in length.

Material behavior during forming is another critical consideration. Aluminium’s springback characteristics require precise compensation in bending programs, which our engineers address through advanced simulation software and real-time feedback loops. Furthermore, our skilled technicians monitor grain orientation, surface finish requirements, and thermal management during processing to prevent warping or micro-cracking—common pitfalls in high-precision aluminium work.

Wuxi Lead’s commitment to precision is reflected in our production capabilities and quality assurance framework. Every fabricated component undergoes rigorous in-process and final inspection, including CMM (Coordinate Measuring Machine) validation and first-article reporting. This disciplined approach ensures that our clients receive not just parts, but engineered solutions built to perform under real-world demands.

The table below outlines key fabrication specifications we maintain for aluminium sheet processing:

| Parameter | Capability | Tolerance / Accuracy |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | ±0.1 mm |

| Max Sheet Size | 6,000 mm × 2,500 mm | ±0.5 mm (flatness) |

| Laser Cutting Accuracy | Fiber laser, multi-axis control | ±0.05 mm |

| CNC Bending | Automatic angle correction, springback compensation | ±0.2°, ±0.1 mm |

| Hole Positioning | CNC turret or laser, automated alignment | ±0.08 mm |

| Surface Finish | Brushed, anodized, powder-coated options | Ra ≤ 1.6 µm (machined) |

| Quality Standards | ISO 9001, AS9100, MIL-STD-810 compliant | Full traceability |

Precision in aluminium sheet fabrication is not a single step—it is a continuous discipline. At Wuxi Lead Precision Machinery, decades of experience in high-stakes manufacturing have shaped our capability to deliver excellence, consistently and reliably.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Sheet Fabrication

Wuxi Lead Precision Machinery delivers uncompromising accuracy in aluminum sheet fabrication through integrated advanced manufacturing systems. Our facility specializes in transforming complex aluminum sheet designs into high-integrity components for aerospace, medical, and industrial automation sectors. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers, engineered specifically for non-ferrous materials. These systems eliminate multi-setup errors by performing milling, drilling, and contouring operations in a single fixture, critical for maintaining geometric integrity across thin-gauge or large-format aluminum sheets. Dynamic thermal compensation and high-speed spindles (up to 24,000 RPM) counteract material deflection and thermal drift, ensuring micron-level consistency even during extended production runs. This approach reduces lead times by up to 40% compared to traditional 3-axis methods while preserving aluminum’s structural properties.

Quality assurance is non-negotiable in mission-critical applications. Every component undergoes rigorous validation via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM), operating under ISO 17025-accredited protocols. Our CMM cells perform full 3D geometric dimensioning and tolerancing (GD&T) analysis, including surface contour validation, positional accuracy checks, and first-article inspection reports traceable to NIST standards. Real-time data from in-process probing feeds directly into our quality management system, enabling immediate corrective action without disrupting production flow. This closed-loop inspection methodology guarantees that dimensional conformity is maintained from prototype to serial production, minimizing scrap and rework costs for our clients.

The following table defines our standard achievable tolerances for aluminum sheet fabrication processes, validated through CMM inspection per ISO 2768-mK and ASME Y14.5. These specifications reflect our commitment to exceeding typical industry benchmarks for precision sheet metal work.

| Tolerance Category | Process | Standard Capability | Tight Tolerance Option |

|---|---|---|---|

| Dimensional (Linear) | Laser Cutting | ±0.10 mm | ±0.05 mm |

| CNC Punching | ±0.15 mm | ±0.10 mm | |

| CNC Bending | ±0.2° angular | ±0.1° angular | |

| Form (Flatness) | Stamping | 0.15 mm/m² | 0.08 mm/m² |

| Machining | 0.05 mm | 0.02 mm | |

| Positional (Holes/Pins) | Drilling/Milling | ±0.08 mm | ±0.03 mm |

| Feature-to-Feature | ±0.10 mm | ±0.05 mm |

Material handling protocols further safeguard part integrity. Automated sheet loaders with vacuum grippers prevent surface marring on anodized or brushed finishes, while our climate-controlled machining environment (20±1°C) stabilizes aluminum’s thermal behavior. We routinely process 1000-series through 7000-series alloys, including challenging tempers like 6061-T6 and 7075-T73, with dedicated toolpath strategies to mitigate burr formation and stress-induced warpage.

By converging 5-axis machining agility with metrology-grade verification, Wuxi Lead ensures that every aluminum component meets stringent functional and assembly requirements. This technical foundation translates to reduced fit-up time for your assemblies and eliminates downstream quality liabilities—delivering not just parts, but guaranteed performance.

Material & Finish Options

Material Selection in High-Precision Aluminium Sheet Fabrication

Selecting the appropriate material is critical in achieving optimal performance, durability, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we specialize in precision aluminum sheet fabrication, with extensive experience in handling aluminum, steel, and titanium—each offering distinct mechanical and chemical properties suited to different industrial applications. Understanding the characteristics of these materials ensures the final product meets stringent functional and environmental demands.

Aluminum is the preferred choice for lightweight, high-strength applications requiring excellent thermal and electrical conductivity. Its natural corrosion resistance, combined with a high strength-to-weight ratio, makes it ideal for aerospace, automotive, and electronics enclosures. The most commonly used aluminum alloys in sheet fabrication are 5052, 6061, and 7075. Alloy 5052 offers superior workability and is ideal for bent or formed parts. 6061 provides a balanced combination of weldability and moderate strength, often used in structural components. 7075, though less formable, delivers high tensile strength, making it suitable for high-stress environments.

In contrast, steel—particularly stainless and cold-rolled varieties—offers superior strength and wear resistance. Stainless steel (e.g., 304, 316) is preferred in corrosive or high-temperature environments such as medical devices and food processing equipment. However, its higher density increases weight and machining costs. Cold-rolled steel (CRS) is commonly used in industrial enclosures and frames due to its dimensional accuracy and smooth surface finish, though it requires protective coatings to prevent rust.

Titanium stands out in extreme-performance applications, such as aerospace and defense, where exceptional strength-to-density ratio and resistance to oxidation at elevated temperatures are essential. While its fabrication demands specialized tooling and processes due to low thermal conductivity and high reactivity, titanium’s longevity in harsh environments justifies its use in mission-critical components.

Surface finishing further enhances material performance. Anodizing is a key process for aluminum, creating a durable, corrosion-resistant oxide layer that can be dyed for aesthetic or identification purposes. Type II (sulfuric acid) anodizing is standard for industrial components, offering moderate thickness and good adhesion for paint or primers. Type III (hardcoat) anodizing provides a thicker, wear-resistant layer suitable for mechanical parts exposed to friction.

Below is a comparative overview of key materials used in precision sheet fabrication:

| Material | Common Alloys | Tensile Strength (MPa) | Density (g/cm³) | Key Advantages | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 5052, 6061, 7075 | 200–570 | 2.7 | Lightweight, corrosion-resistant, conductive | Aerospace, electronics, transport |

| Stainless Steel | 304, 316 | 505–860 | 8.0 | High strength, heat and corrosion resistant | Medical, food processing, marine |

| Cold-Rolled Steel | 1008, 1010 | 340–420 | 7.8 | Cost-effective, dimensionally precise | Industrial enclosures, frames |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | 345–1000 | 4.5 | High strength-to-weight, oxidation resistant | Aerospace, defense, high-performance |

At Wuxi Lead, we guide clients through material and finish selection based on application requirements, environmental exposure, and lifecycle expectations. Our expertise ensures optimal manufacturability and performance in every fabricated component.

Manufacturing Process & QC

Precision Aluminum Sheet Fabrication: The Zero-Defect Production Process

Precision aluminum fabrication begins with rigorous engineering design, transcending basic CAD modeling. At Wuxi Lead Precision Machinery, our engineers conduct comprehensive Design for Manufacturability (DFM) analysis during the initial phase. We evaluate material grain direction, thermal expansion coefficients, and inherent aluminum springback characteristics to preempt deformation. Finite Element Analysis (FEA) simulates stress points under operational loads, ensuring structural integrity while optimizing material usage. This proactive approach eliminates 85% of potential defects before physical production commences, directly impacting cost efficiency and yield rates for high-volume runs.

Prototyping serves as the critical validation bridge between design theory and mass production reality. We utilize 5-axis CNC milling and laser cutting on certified 5052-H32 or 6061-T6 aluminum sheets to produce functional prototypes within 72 hours. Each prototype undergoes stringent metrology: CMM verification against 3D models, surface roughness profiling, and dimensional stability testing under controlled thermal cycles. Crucially, we perform bend allowance calibration and hole tolerance validation specific to the client’s assembly requirements. This phase identifies micro-defects invisible in simulation, such as micro-cracking at acute bend radii or coating adhesion issues, allowing immediate process refinement.

Mass production leverages closed-loop statistical process control to institutionalize zero defects. Our automated production lines integrate real-time sensor feedback from CNC press brakes, fiber laser cutters, and robotic deburring stations. Every 15 minutes, automated optical inspection (AOI) systems scan critical dimensions against the approved prototype baseline, triggering immediate machine recalibration if deviations exceed ±0.05mm. We enforce strict material traceability via laser-etched batch codes on every sheet, linking each component to its certified mill test report. The final stage employs 100% automated flatness inspection using non-contact laser scanners, rejecting any panel exceeding 0.1mm deviation per square meter. This systematic elimination of variation ensures consistent conformance to aerospace and medical industry standards.

Critical control parameters are maintained throughout all phases as defined below:

| Parameter | Design Phase Tolerance | Mass Production Tolerance | Measurement Method |

|---|---|---|---|

| Dimensional Accuracy | ±0.025mm | ±0.05mm | CMM / Laser Tracker |

| Surface Flatness | 0.05mm/m² | 0.10mm/m² | Laser Scanner |

| Hole Position Tolerance | ±0.02mm | ±0.03mm | Vision System |

| Edge Burr Height | N/A | ≤0.05mm | Optical Profilometer |

| Surface Roughness (Ra) | 0.4μm | 0.8μm | Stylus Profilometer |

This integrated process—where design foresight, empirical prototyping validation, and statistically controlled manufacturing converge—forms the foundation of Wuxi Lead’s zero-defect commitment. We transform aluminum sheet specifications into flawless components through engineering rigor, not post-production correction, delivering measurable reductions in client scrap costs and assembly downtime.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Aluminium Sheet Fabrication

When precision, reliability, and engineering excellence define your manufacturing standards, partnering with Wuxi Lead Precision Machinery becomes a strategic advantage. As a leading innovator in sheet metal fabrication, we specialize in high-tolerance aluminium sheet processing tailored to the most demanding industrial applications. From aerospace components to energy systems and advanced transportation solutions, our capabilities are engineered to meet and exceed global quality benchmarks.

At Wuxi Lead Precision Machinery, we understand that aluminium is more than just a lightweight material—it’s a performance enabler. Our advanced fabrication processes leverage state-of-the-art CNC technology, automated bending systems, and precision laser cutting to deliver consistent, high-quality results. Every stage of production is monitored through strict quality control protocols, ensuring dimensional accuracy, clean edge finishes, and repeatable performance across batch sizes.

Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 certifications, reflecting our commitment to continuous improvement and process integrity. With over 15 years of experience serving multinational OEMs and Tier-1 suppliers, we bring deep technical insight and scalable manufacturing capacity to every project. Whether you require low-volume prototypes or high-volume serial production, our team collaborates closely with your engineering staff to optimize designs for manufacturability, cost-efficiency, and structural performance.

We invest continuously in next-generation equipment and workforce development, ensuring that our capabilities evolve alongside industry demands. Our engineers are trained in advanced simulation and finite element analysis, allowing us to anticipate material behavior during forming and assembly—critical when working with aluminium’s unique thermal and mechanical properties.

Below are key technical specifications that define our aluminium sheet fabrication capabilities:

| Specification | Detail |

|---|---|

| Material Types | 5052, 6061, 6063, 7075, and custom aluminium alloys |

| Sheet Thickness Range | 0.5 mm – 6.0 mm |

| Maximum Blank Size | 1500 mm × 3000 mm |

| Tolerance (Cutting & Forming) | ±0.1 mm (standard), ±0.05 mm (tight-tolerance) |

| Laser Cutting Accuracy | ±0.03 mm/m |

| Minimum Bend Radius | 1× material thickness (depending on alloy) |

| Surface Finishes | Mill finish, anodized (Type II & III), powder coating, brushed, chem film |

| Secondary Operations | Welding (TIG/MIG), hardware insertion, tapping, assembly |

We don’t just fabricate parts—we deliver engineered solutions backed by data, traceability, and technical collaboration. Our goal is to become an extension of your manufacturing team, reducing lead times, improving yield, and ensuring compliance with your exact specifications.

For expert support on your next aluminium fabrication project, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.