Technical Contents

Engineering Guide: Fabrication Design App

Engineering Insight Precision in Sheet Metal Fabrication Design Applications

Achieving dimensional accuracy in sheet metal fabrication is non-negotiable for high-integrity components. Tolerances measured in thousandths of an inch directly impact assembly fit, structural performance, and end-product longevity. Modern fabrication design applications serve as the critical digital bridge between conceptual engineering and physical realization, embedding precision requirements at the earliest design phase. These tools prevent costly downstream errors by simulating bend allowances, predicting springback, and validating manufacturability against machine capabilities before a single sheet is cut. Neglecting this integrated precision focus during design inevitably leads to iterative prototyping, production delays, and compromised component functionality – consequences unacceptable in aerospace, defense, or critical infrastructure sectors.

Wuxi Lead Precision Machinery operates at this uncompromising standard daily. Our engineering team leverages decades of hands-on CNC fabrication expertise, honed through delivering mission-critical components for Olympic venue structural systems and certified military-grade assemblies. These projects demand absolute adherence to geometric dimensioning and tolerancing (GD&T) standards where a 0.05mm deviation can trigger complete rejection. Our practical experience informs how we configure and utilize fabrication design applications, ensuring the software models reflect real-world machine behavior, material properties, and quality control protocols. This operational insight transforms the application from a mere drafting tool into a predictive manufacturing control system.

The core precision parameters embedded within a robust fabrication design application must align with industrial machining realities. The following table outlines critical specifications our engineering team prioritizes when evaluating or implementing such systems for high-tolerance sheet metal work:

| Parameter | Critical Range for High-Precision Work | Impact of Inaccuracy |

|---|---|---|

| Linear Tolerance | ±0.05mm to ±0.1mm | Assembly misalignment, fit failures |

| Angular Tolerance | ±0.5° to ±1.0° | Structural instability, sealing issues |

| Hole Position Tolerance | ±0.03mm to ±0.08mm | Bolt pattern mismatches, stress points |

| Bend Allowance Accuracy | Material-specific within 0.1% | Dimensional stack-up errors, scrap parts |

| Springback Prediction | < 2° deviation | Repeated rework, tooling adjustments |

At Lead Precision, we integrate these precision parameters directly into our fabrication design workflow. Our applications are calibrated using empirical data from thousands of production runs on our state-of-the-art Amada and Trumpf systems. This ensures virtual models accurately predict physical outcomes, minimizing trial-and-error. When your design application reflects the true capabilities and constraints of precision sheet metal fabrication – informed by real-world military and Olympic-scale project execution – it becomes the foundation for first-time-right manufacturing. We engineer not just components, but confidence in every dimension. Partner with a manufacturer whose digital precision mirrors its physical execution.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance in high-demand industrial applications. Our technical capabilities are anchored in state-of-the-art equipment, rigorous quality assurance protocols, and a deep understanding of complex manufacturing requirements across aerospace, medical, automation, and energy sectors. At the core of our production capacity is a fully integrated 5-axis CNC machining platform, enabling us to execute intricate geometries and tight-tolerance components with exceptional accuracy and efficiency.

The integration of 5-axis CNC technology allows for simultaneous multi-directional cutting, reducing setup times and minimizing cumulative error. This capability supports the fabrication of complex sheet metal enclosures, structural components, and precision housings that require compound angles, deep cavities, or non-orthogonal features. Unlike conventional 3-axis systems, our 5-axis machines maintain tool engagement from multiple vectors, ensuring superior surface finish and dimensional consistency across high-mix, low-volume, and prototype production runs. Advanced CAD/CAM software drives these systems, ensuring seamless translation from design intent to physical part with minimal deviation.

Quality is not a final checkpoint but a continuous process at Wuxi Lead. Every component undergoes a structured quality control workflow, beginning with incoming material verification and extending through in-process inspections to final validation. Central to our quality assurance is the use of a Coordinate Measuring Machine (CMM) for full 3D dimensional inspection. The CMM provides metrology-grade data, verifying critical features such as hole positions, flatness, angularity, and profile tolerances against GD&T callouts. This level of inspection ensures compliance with ISO 2768 and customer-specific standards, with full traceability and inspection reports available upon request.

Our sheet metal fabrication processes are optimized to meet stringent tolerance requirements across a range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys. Below is a summary of our standard achievable tolerances under controlled conditions.

| Feature | Standard Tolerance | Notes |

|---|---|---|

| Linear Dimensions | ±0.05 mm | Up to 300 mm; ±0.1 mm >300 mm |

| Hole Diameter | +0.1 / -0.0 mm | Reamed or precision drilled |

| Hole Position | ±0.08 mm | Relative to datum |

| Angular Tolerance | ±0.1° | For formed and machined features |

| Flatness | 0.1 mm per 100 mm | Verified via CMM or surface plate |

| Surface Finish (machined) | Ra 0.8 – 3.2 µm | Adjustable based on application |

| Feature-to-Feature (5-axis) | ±0.05 mm | Critical for complex assemblies |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC fabrication with metrology-backed quality control to deliver components that meet the highest standards of engineering integrity. Our technical capabilities are designed to support innovation in product development and ensure reliability in end-use performance.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting optimal materials is foundational to achieving performance, cost efficiency, and manufacturability in sheet metal projects. At Wuxi Lead Precision Machinery, we prioritize materials that align with your application’s mechanical, environmental, and aesthetic demands while ensuring seamless integration with our CNC fabrication processes. Below, we detail critical considerations for aluminum, steel, and titanium—three cornerstone materials in high-end manufacturing—alongside anodizing finish specifications.

Aluminum alloys like 5052-H32 and 6061-T6 dominate aerospace, electronics, and medical enclosures due to their strength-to-weight ratio, corrosion resistance, and weldability. These grades machine cleanly with minimal tool wear, supporting tight tolerances down to ±0.05 mm. For structural components requiring higher strength, steel variants such as SPCC (cold-rolled) and SUS304 stainless offer superior durability and magnetic properties. SPCC excels in deep-drawn parts, while SUS304 provides essential corrosion resistance for food processing or marine environments. Titanium Grade 2 is reserved for extreme scenarios—think aerospace actuators or biomedical implants—where its unparalleled strength, biocompatibility, and resistance to 500°C+ temperatures justify higher costs. Note that titanium’s low thermal conductivity demands specialized tooling and slower feed rates to prevent work hardening.

Anodizing is the premier finish for aluminum, enhancing surface hardness, wear resistance, and adhesion for paints or adhesives. Type II (sulfuric acid) anodizing achieves 5–25 μm thickness for general industrial use, while Type III (hard coat) reaches 25–50 μm for military or hydraulic components requiring extreme abrasion resistance. Critical design considerations include masking non-anodized areas to maintain electrical contact points and allowing 10–15% dimensional growth on critical features. We strictly control electrolyte temperature and current density to ensure uniform coating thickness within ±2 μm, preventing dimensional drift in precision assemblies.

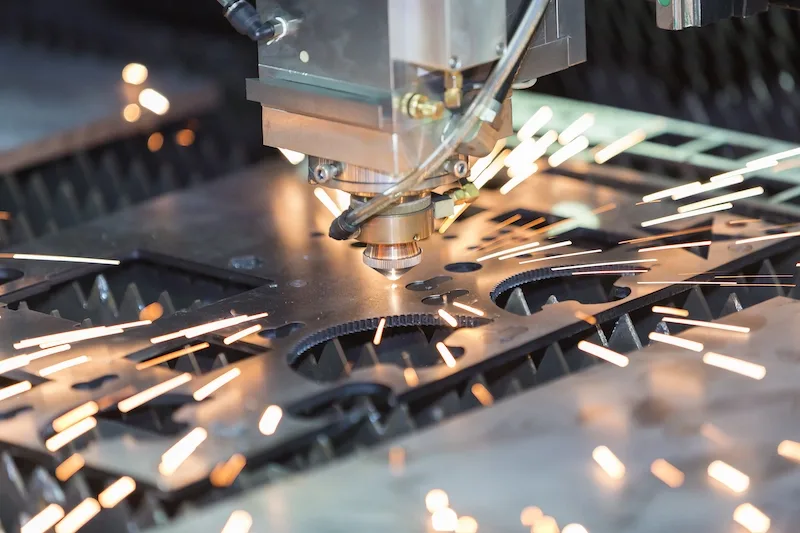

Our CNC press brakes and laser cutters accommodate sheet thicknesses from 0.5 mm to 6 mm across all three materials, with titanium requiring pre-annealing for bends under 1.5 mm. Below are key fabrication parameters for common grades:

| Material | Common Grades | Thickness Range (mm) | Max Tensile Strength (MPa) | Key Fabrication Notes |

|---|---|---|---|---|

| Aluminum | 5052-H32 | 0.5–6.0 | 228 | Low springback; ideal for complex bends |

| 6061-T6 | 0.8–4.0 | 310 | Requires sharp tools; prone to burring | |

| Steel | SPCC | 0.5–5.0 | 340 | Excellent formability; minimal burr |

| SUS304 | 0.8–4.0 | 520 | Slow cutting speeds; anti-spatter measures | |

| Titanium | Gr 2 | 0.5–3.0 | 450 | Low thermal conductivity; argon shielding |

Material choice directly impacts lead time and cost. Aluminum offers the fastest throughput, while titanium may extend production by 30–40% due to secondary operations. Always specify finish requirements early—our engineers will advise on anodizing thickness tolerances to avoid rework. For mission-critical applications, we recommend prototyping with your target material to validate formability and finish adherence. Contact our technical team to optimize your design for manufacturability.

Manufacturing Process & QC

Sheet Metal Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, precision in sheet metal fabrication begins long before the first cut. Our process is engineered to deliver flawless results through a tightly integrated workflow that spans design, prototyping, and full-scale production. This systematic approach ensures every component meets exact technical and quality standards—ultimately achieving zero-defect manufacturing.

The foundation of our process lies in advanced digital design. Using industry-leading CAD/CAM software, our engineering team collaborates with clients to refine 3D models for manufacturability. Design for Manufacturing and Assembly (DFM/A) principles are applied rigorously to optimize material usage, minimize complexity, and enhance structural integrity. This phase includes detailed simulation of bending sequences, laser cutting paths, and tolerance analysis, ensuring that every design is not only functional but production-ready. All data is stored and version-controlled within our fabrication design app, enabling real-time collaboration and traceability.

Once the design is finalized, we proceed to prototyping. A small batch of parts is produced using the same equipment and materials intended for mass production. This allows us to validate dimensional accuracy, surface finish, and assembly fit under real-world conditions. Any discrepancies are identified and corrected at this stage through iterative refinement. Our prototyping cycle is rapid—typically completed within 5 to 7 working days—enabling swift client feedback and reducing time-to-market. All prototype data, including inspection reports and process parameters, is logged in the app, creating a digital twin for future production runs.

With the prototype approved, we transition seamlessly into mass production. Our automated production lines integrate fiber laser cutting, CNC punching, precision bending, and robotic welding systems, all calibrated to maintain micron-level accuracy. Each stage is monitored through real-time quality control checkpoints, including in-process metrology and final first-article inspection. Statistical Process Control (SPC) is employed to detect trends and prevent deviations before they occur. The entire workflow is traceable through our fabrication design app, which records machine settings, operator inputs, and inspection data for every batch.

Our zero-defect philosophy is enforced through a combination of advanced technology, rigorous process discipline, and continuous improvement. Every employee is trained in Lean Six Sigma methodologies, and non-conformance reports trigger immediate root cause analysis and corrective action.

The following table outlines key specifications and capabilities across our production process:

| Parameter | Design Phase | Prototyping Phase | Mass Production Phase |

|---|---|---|---|

| Lead Time | 3–5 working days | 5–7 working days | 10–20 working days (scalable) |

| Tolerance Control | ±0.05 mm (simulated) | ±0.05 mm (measured) | ±0.05 mm (SPC-monitored) |

| Materials Supported | Steel, Stainless, Aluminum, Galvanized | Same as production | Full industrial range |

| Equipment Used | CAD/CAM, Simulation Tools | Laser Cutters, CNC Bending | Automated Lines, Robotics |

| Quality Documentation | DFM Report, 3D Model | FAI Report, CMM Data | Batch Traceability, SPC Charts |

This end-to-end integration ensures that what is designed is exactly what is produced—consistently, reliably, and without defect.

Why Choose Wuxi Lead Precision

Elevate Your Fabrication Outcomes Through Strategic Partnership

Global OEMs and precision engineering firms consistently select Wuxi Lead Precision Machinery as their sheet metal fabrication partner due to our unwavering commitment to technical excellence and seamless integration within modern digital workflows. Our facility operates at the intersection of advanced manufacturing capability and intelligent design validation, ensuring your fabrication design app outputs translate directly into flawless physical components. We eliminate the traditional disconnect between virtual models and real-world production through rigorous Design for Manufacturability (DFM) analysis embedded within our quoting process. This proactive approach identifies potential manufacturability constraints early, reducing iteration cycles and accelerating time-to-market without compromising on geometric complexity or material integrity.

Our technical infrastructure supports the most demanding specifications inherent in aerospace, medical, and industrial automation applications. The table below details core capabilities relevant to high-integrity sheet metal production.

| Parameter | Specification Range | Precision Standard | Supported Materials |

|---|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | ±0.05 mm | SS304/316, AL5052/6061, SPCC, SGCC |

| Tolerance Control | ±0.02 mm (critical features) | ISO 2768-mK | Bead-blasted, anodized, passivated finishes |

| Max Form Size | 1500 mm x 3000 mm | Per GD&T ASME Y14.5 | Laser-cut, CNC-punched, hydraulic press |

| Secondary Ops | Welding (TIG/MIG), CNC bending, hardware insertion | ISO 13920 Class B | In-house deburring, cleaning, inspection |

Partnering with Lead Precision means leveraging a production ecosystem engineered for compatibility with leading fabrication design applications. Our API-enabled quoting system ingests native CAD files directly from your workflow, applying real-time manufacturability checks against our machine capabilities and material databases. This integration prevents design rework by flagging issues like minimum bend radii violations, hole-to-edge conflicts, or tool clearance limitations before order placement. Your engineering team retains full control while gaining actionable insights to optimize designs for cost and yield.

We understand that precision sheet metal fabrication is not a commodity transaction but a critical extension of your engineering process. Our technical account managers—each with 10+ years in metalforming—collaborate directly with your design and procurement teams to refine specifications, suggest value-engineering alternatives, and establish traceable quality protocols. Every component undergoes first-article inspection with CMM reports and material certifications, ensuring compliance with ISO 9001:2015 and customer-specific requirements.

Initiate your project review by contacting [email protected]. Include your fabrication design app file and target volume for a comprehensive DFM analysis within 24 business hours. Our engineering team will provide actionable feedback, a transparent cost breakdown, and lead time validation aligned with your production schedule. For urgent RFQs, reference code APP-INT2024 to expedite processing. Trust Wuxi Lead Precision Machinery to transform digital designs into certified, high-performance metal components—where engineering intent meets manufacturing reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.