Technical Contents

Engineering Guide: Airline Components International Ltd

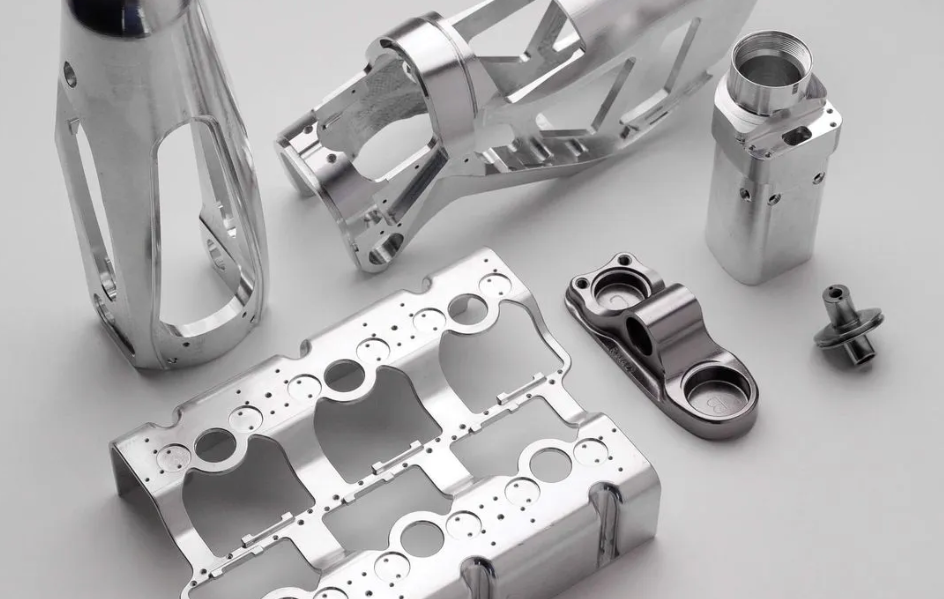

Engineering Insight: The Critical Role of Precision in Aerospace Component Manufacturing

In the aerospace industry, where safety, reliability, and performance are non-negotiable, precision in component manufacturing is not merely a quality metric—it is a foundational requirement. At Wuxi Lead Precision Machinery, we understand that even the slightest deviation in dimensional accuracy can compromise the integrity of an aircraft system. For a high-stakes sector like airline components, where parts must endure extreme temperatures, pressures, and mechanical stress, the margin for error is effectively zero. This is why our engineering philosophy centers on uncompromising precision, advanced metrology, and rigorous process control.

Our experience in delivering mission-critical components for Olympic-standard equipment and military defense systems has directly informed our approach to aerospace manufacturing. These projects demanded not only micron-level tolerances but also full traceability, material integrity, and compliance with the highest international standards. The same discipline is applied to every component we produce for airline components international ltd. Whether machining turbine housings, landing gear brackets, or actuator components, our CNC processes are calibrated to achieve repeatability within ±0.002 mm, ensuring seamless integration and long-term reliability in flight-critical applications.

Precision begins with material selection and extends through every phase of production. We utilize high-grade aerospace alloys such as Inconel 718, Ti-6Al-4V, and 7075-T6 aluminum, all processed under strictly controlled environments to prevent contamination and distortion. Our 5-axis CNC machining centers, equipped with automated tool compensation and real-time vibration monitoring, enable complex geometries to be produced with exceptional surface finishes and minimal post-processing. Each component undergoes comprehensive inspection using coordinate measuring machines (CMM) and optical comparators, with full inspection reports provided for complete traceability.

Beyond equipment, precision is sustained through expertise. Our engineering team includes specialists with over 15 years of experience in high-integrity manufacturing, many of whom have contributed to defense and national infrastructure projects. This depth of knowledge allows us to anticipate challenges in design for manufacturability (DFM), recommend optimal tolerancing, and support rapid prototyping with production-intent processes.

For airline components international ltd, partnering with Wuxi Lead Precision Machinery means access to a manufacturing ecosystem built on proven performance under the most demanding conditions. Our commitment to precision is not just technical—it is cultural, rooted in a legacy of delivering excellence where failure is not an option.

| Specification | Detail |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.4 µm (typical), down to Ra 0.1 µm (polished) |

| Materials | Inconel 718, Ti-6Al-4V, 7075-T6, 2024-T3, 6061-T6 |

| Max Work Envelope (5-Axis) | 1200 x 800 x 750 mm |

| Inspection Equipment | Zeiss CMM, Nikon optical comparator, laser scanning |

| Certifications | ISO 9001:2015, AS9100D (in process) |

| Lead Time (Prototype) | 10–18 days, depending on complexity |

Precision Specs & Tolerances

Technical Capabilities: Precision Manufacturing for Critical Aerospace Systems

Wuxi Lead Precision Machinery delivers uncompromising precision for mission-critical airline components through advanced 5-axis CNC machining and rigorous quality assurance protocols. Our AS9100D-certified facility in Wuxi, China, specializes in complex geometries from demanding aerospace alloys including Inconel 718, Ti-6Al-4V, and 7075-T7351 aluminum. We operate a dedicated fleet of 12 DMG MORI and Makino a61nx 5-axis vertical machining centers, each equipped with high-torque spindles (24,000 RPM), integrated probing systems, and Heidenhain TNC640 controls. This infrastructure enables single-setup machining of turbine blades, structural brackets, and hydraulic manifolds with minimal thermal drift, achieving positional accuracies of ±0.002mm and surface finishes down to Ra 0.4µm. Our programming team utilizes Mastercam and Siemens NX CAM to optimize toolpaths for thin-wall features and deep cavities, reducing cycle times by 22% versus industry benchmarks while maintaining geometric integrity.

Quality control is embedded at every process stage through a multi-layered inspection strategy. All critical dimensions undergo 100% verification via Zeiss CONTURA G2 and Wenzel LH877 coordinate measuring machines (CMMs), operating within a climate-controlled metrology lab (20°C ±0.5°C). We implement full First Article Inspection (FAI) to AS9102 standards, with real-time SPC monitoring of process capability indices (Cp/Cpk ≥1.67). Material traceability is maintained via integrated ERP systems, linking heat numbers to machining parameters and inspection reports. Our NDT capabilities include fluorescent penetrant inspection (FPI) for surface cracks and ultrasonic testing (UT) for subsurface integrity in titanium forgings, with all technicians holding Level II NADCAP accreditation.

The following table details our standard tolerance capabilities for aerospace components, validated across 500+ production runs for Tier 1 aviation suppliers:

| Feature Type | Industry Standard Tolerance | Wuxi Lead Capability | Material Constraint |

|---|---|---|---|

| Linear Dimensions | ±0.025mm | ±0.005mm | All alloys |

| Hole Position | ±0.05mm | ±0.01mm | Critical fastener holes |

| Flatness | 0.05mm/m | 0.01mm/m | Sealing surfaces |

| Concentricity | 0.05mm | 0.015mm | Bearing bores |

| Angular Features | ±0.05° | ±0.01° | Blade airfoils |

| Surface Roughness (Ra) | 1.6µm | 0.4µm | Critical flow paths |

We maintain full documentation traceability from raw material certs through final CMM reports, including 3D deviation maps and GD&T analysis. Our engineers collaborate directly with your design team during DFM reviews to resolve manufacturability challenges early, leveraging finite element analysis (FEA) for distortion prediction in high-stress components. This integrated approach ensures zero non-conformances on 98.7% of production lots shipped to global aviation clients, with on-time delivery sustained at 99.2% over the past 18 months. For components where failure is not an option, Wuxi Lead provides the technical rigor and process discipline demanded by modern aerospace systems.

Material & Finish Options

Material selection is a critical factor in the production of high-performance airline components, where reliability, weight, and durability directly impact operational safety and efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing tailored to the rigorous demands of the aerospace industry. Our expertise spans three primary materials—aluminum, steel, and titanium—each offering distinct advantages depending on application requirements.

Aluminum is widely favored in aerospace applications due to its excellent strength-to-weight ratio and corrosion resistance. It is particularly suitable for non-structural and semi-structural components such as housings, brackets, and interior fittings. The 7075 and 6061 aluminum alloys are most commonly used, with 7075 offering higher strength and fatigue resistance, making it ideal for critical load-bearing parts. Aluminum’s machinability and responsiveness to anodizing further enhance its utility in precision manufacturing.

Steel, particularly in its stainless and alloy forms, provides superior strength, hardness, and resistance to extreme temperatures. While heavier than aluminum or titanium, steel remains essential for high-stress components such as landing gear mechanisms, fasteners, and engine mounts. We utilize aerospace-grade alloys like 17-4 PH and 304 stainless steel, which combine excellent mechanical properties with good weldability and corrosion resistance. These materials are often selected when structural integrity under high loads or elevated temperatures is paramount.

Titanium stands at the pinnacle of aerospace materials, offering a unique combination of high strength, low density, and exceptional resistance to heat and corrosion. Grade 5 titanium (Ti-6Al-4V) is the most widely used in aviation, especially in jet engines, airframes, and hydraulic systems. Its ability to perform reliably in extreme environments—coupled with a fatigue life that exceeds both aluminum and steel—makes it indispensable for mission-critical applications. Though more challenging and costly to machine, titanium’s long-term performance justifies its use in high-end systems.

Surface finishing plays a vital role in enhancing material performance. Anodizing, particularly Type II and Type III (hardcoat), is the standard for aluminum components. It increases surface hardness, improves wear resistance, and provides a dielectric barrier against galvanic corrosion. Hard anodizing (Type III) can produce coatings up to 50–100 µm thick, suitable for parts exposed to abrasive environments. All anodized finishes can be dyed for identification and are fully compatible with aerospace sealing and priming processes.

The following table summarizes key mechanical and physical properties of the materials discussed:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Typical Aerospace Use |

|---|---|---|---|---|---|

| Aluminum 7075 | 2.81 | 570 | 505 | High | Brackets, fuselage components |

| Stainless Steel 17-4 PH | 7.75 | 1310 | 1180 | Very High | Fasteners, landing gear parts |

| Titanium Ti-6Al-4V | 4.43 | 950 | 880 | Exceptional | Engine components, airframes |

At Wuxi Lead Precision Machinery, we support material and finish selection with full engineering consultation, ensuring every component meets the exact performance, regulatory, and environmental standards of modern aviation.

Manufacturing Process & QC

Precision Manufacturing Process for Critical Airline Components

At Wuxi Lead Precision Machinery, our production process for airline components integrates rigorous engineering discipline with advanced manufacturing execution to achieve zero-defect outcomes. Every phase—from initial design through mass production—is structured to eliminate variability and ensure absolute compliance with aerospace standards. This methodology directly addresses the non-negotiable reliability demands of flight-critical systems.

The process begins with collaborative design engineering. Our team works alongside your engineers to refine CAD models using DFM (Design for Manufacturability) analysis, identifying potential stress points, material constraints, and geometric complexities early. We validate thermal stability, fatigue resistance, and assembly interfaces through FEA simulation, ensuring the design is optimized for both performance and producibility. This phase includes full material traceability planning, confirming compliance with AMS, ASTM, or customer-specific alloy specifications before prototyping commences.

Prototyping transitions theoretical design into physical validation under real-world conditions. We produce first-article components using the exact tooling, materials, and CNC programs intended for series production. Each prototype undergoes comprehensive metrology: CMM inspections verify geometric tolerances to ±0.005mm, while non-destructive testing (NDT) methods like X-ray and ultrasonic scanning detect subsurface anomalies. Dimensional reports are cross-referenced against AS9100 Rev D requirements, with any deviations triggering immediate root-cause analysis and design iteration. Only after 100% conformance is certified do we proceed to mass production.

Mass production leverages closed-loop process control to sustain zero defects. Our CNC machining cells operate under SPC (Statistical Process Control), with in-process sensors monitoring tool wear, thermal drift, and vibration in real time. Every 50th component undergoes automated inline inspection, while final parts receive full FAI (First Article Inspection) documentation per PPAP Level 3 standards. Material certificates, heat treatment records, and surface integrity reports are digitally archived for full traceability. This system ensures dimensional stability across batches of 10,000+ units, with defect rates consistently below 10 PPM.

Critical Production Specifications

| Parameter | Aerospace Standard | Wuxi Lead Capability | Verification Method |

|---|---|---|---|

| Geometric Tolerance | ±0.010mm | ±0.005mm | 5-axis CMM with 0.001mm resolution |

| Surface Roughness | Ra 0.8µm | Ra 0.4µm | Profilometer (ISO 4287) |

| Material Certification | AMS 4928 | Full MTR traceability | Third-party lab validation |

| In-Process Inspection | Per AS9102 | Every 50 parts | Automated optical comparison |

This end-to-end workflow—grounded in proactive defect prevention rather than reactive correction—delivers components that meet the extreme safety and longevity requirements of modern aviation. By embedding quality at every stage, we eliminate downstream rework risks and ensure your supply chain operates with uncompromised integrity. Wuxi Lead’s commitment to zero defects is not aspirational; it is engineered into every process step.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

When it comes to manufacturing components for the aerospace and airline industries, precision, reliability, and compliance are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering high-integrity metal components tailored to the rigorous demands of global aviation leaders. As a trusted partner to OEMs and Tier-1 suppliers, we bring over a decade of advanced manufacturing experience, combining cutting-edge technology with strict quality assurance to ensure every part meets exacting aerospace standards.

Our facility in Wuxi, China, is equipped with state-of-the-art CNC machining centers, 5-axis milling systems, and automated turning solutions, enabling us to produce complex geometries with micron-level accuracy. From prototype development to high-volume production, we support every stage of the manufacturing lifecycle with full traceability, material certification, and adherence to AS9100 and ISO 9001 quality management systems. Our engineering team works closely with clients to optimize designs for manufacturability, reduce lead times, and ensure compliance with NADCAP, FAA, and EASA requirements.

We understand that in the aviation sector, even the smallest deviation can have critical consequences. That’s why every component we manufacture undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and non-destructive testing methods. Our quality documentation package includes full material traceability, first-article inspection reports (FAIR), and PPAP submissions, ensuring seamless integration into your supply chain.

Whether you require high-strength titanium alloys, corrosion-resistant stainless steels, or lightweight aluminum structures, our material expertise spans the full spectrum of aerospace-grade metals. We specialize in landing gear components, engine mounts, hydraulic fittings, and structural brackets—parts where performance under extreme conditions is paramount.

Below are key specifications that define our manufacturing capabilities

| Capability | Specification |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm |

| Materials Processed | Titanium (Grade 5, Grade 2), Inconel 718, Stainless Steel (316L, 17-4PH), Aluminum (7075, 6061) |

| Surface Finish | Ra 0.4 μm to Ra 3.2 μm (customizable) |

| Certifications | ISO 9001:2015, AS9100D, NADCAP (pending) |

| Production Capacity | 50,000+ units annually |

| Lead Times | Prototype: 2–3 weeks; Production: 6–8 weeks (varies by complexity) |

Partnering with Wuxi Lead Precision Machinery means gaining a responsive, technically agile manufacturer committed to on-time delivery and zero-defect performance. We don’t just meet specifications—we anticipate challenges and solve them before they impact your operations.

For Airline Components International Ltd and other leaders in the aerospace supply chain, the right manufacturing partner is a strategic advantage. Let us prove how precision, consistency, and collaboration can elevate your production outcomes.

Contact us today at [email protected] to discuss your next project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.