Technical Contents

Engineering Guide: Machine Shop Seattle

Engineering Insight: The Role of Precision in Modern Machine Shop Operations – A Seattle Perspective

In the evolving landscape of advanced manufacturing, precision stands as the cornerstone of reliability, performance, and innovation. For industrial clients in high-demand sectors such as aerospace, defense, and medical technology, the tolerance for error is not merely reduced—it is eliminated. This standard is especially critical in regions like Seattle, where machine shop operations support some of the most technologically advanced industries in the world. At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is a requirement.

Seattle’s industrial ecosystem thrives on integration between design innovation and manufacturing excellence. Whether supporting next-generation aerospace platforms or custom automation systems, machine shops in the region demand partners capable of delivering components with micron-level accuracy, repeatable consistency, and full traceability. These expectations align directly with our engineering philosophy at Wuxi Lead. With over 15 years of experience in custom metal manufacturing, we have developed a reputation for producing mission-critical components that meet or exceed the stringent requirements of Olympic-standard equipment and military-grade systems.

Our work with Olympic training apparatus required sub-5-micron tolerances to ensure flawless mechanical response under dynamic loads. Similarly, our contributions to defense-related subsystems demanded compliance with MIL-STD-810 and rigorous material certification protocols. These projects were not defined by their scale, but by their uncompromising engineering standards—standards that we apply to every client engagement, regardless of industry.

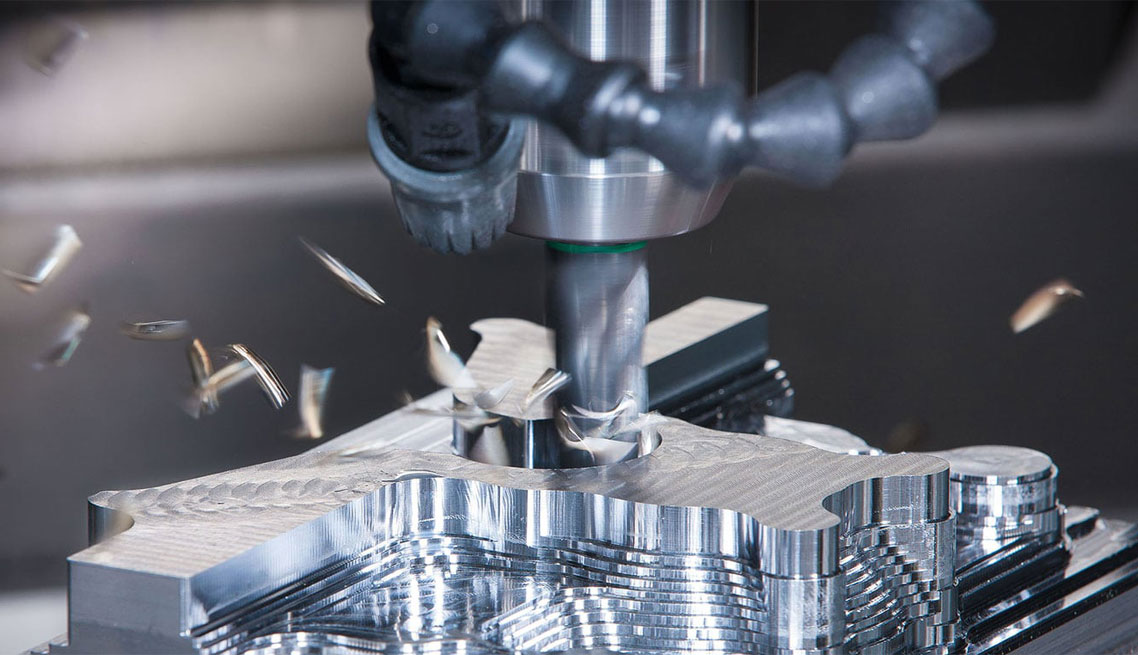

Precision engineering begins with advanced CNC multi-axis machining centers, but it is sustained through process control, metrology, and material science expertise. At Wuxi Lead, we utilize real-time in-process gauging, laser alignment systems, and coordinate measuring machines (CMM) to validate dimensional accuracy at every production stage. Our quality management system is ISO 9001:2015 certified, ensuring full documentation and compliance for every component we manufacture.

For machine shops in Seattle seeking a reliable offshore partner, the challenge is not just cost efficiency—it is consistency, communication, and technical alignment. We bridge this gap through dedicated engineering support, digital twin modeling, and rapid prototyping capabilities that enable seamless integration into client workflows.

The future of precision manufacturing lies in the synergy between regional innovation hubs and globally capable suppliers. Wuxi Lead Precision Machinery is positioned to deliver that synergy, combining Chinese manufacturing scalability with European-level quality standards.

| Specification | Detail |

|---|---|

| Maximum Tolerance | ±0.002 mm (±0.00008 in) |

| Standard Materials | Aluminum 6061/7075, Stainless Steel 303/316, Titanium Grade 5, Inconel 718 |

| Machining Capabilities | 5-axis CNC milling, CNC turning, Swiss machining, EDM |

| Surface Finish | Ra 0.4 µm (16 µin) standard, down to Ra 0.1 µm (4 µin) |

| Quality Standards | ISO 9001:2015, MIL-STD-810, AS9100 (compliant processes) |

| Lead Time (Prototype) | 7–14 days, depending on complexity |

Precision is not achieved by accident. It is engineered, validated, and guaranteed. For Seattle’s high-performance machine shop sector, Wuxi Lead offers a proven partner in precision—backed by real-world results in the most demanding applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Applications

At Wuxi Lead Precision Machinery, our technical foundation is built upon advanced multi-axis CNC manufacturing and rigorous quality assurance systems, engineered to meet the exacting standards of aerospace, medical, and industrial clients. We specialize in transforming complex designs into high-integrity metal components through integrated processes that prioritize accuracy, repeatability, and material efficiency. Our facility operates as a seamless extension of your engineering team, delivering solutions where conventional machining reaches its limits.

Our core strength lies in 5-axis simultaneous CNC milling and turning centers, enabling single-setup production of intricate geometries with minimal human intervention. This capability eliminates cumulative error from multiple fixtures, ensuring critical features maintain precise spatial relationships across all axes. Machines feature thermal compensation systems and sub-micron repeatability, handling materials from aerospace-grade titanium and Inconel to medical stainless steel and aluminum alloys. Complex contours, deep cavities, and organic shapes are executed with optimized tool paths that maximize surface finish and dimensional stability while reducing cycle times by up to 40% compared to 3-axis alternatives.

Quality is non-negotiable. Every component undergoes systematic inspection via calibrated Coordinate Measuring Machines (CMM) with probing accuracy to ±0.0001″ (2.5µm). Our CMM protocols include full 3D scanning against CAD models, comprehensive GD&T validation, and automated reporting with traceable calibration certificates. This closed-loop process ensures conformance to AS9100 and ISO 13485 standards, providing documented evidence of compliance for critical applications. Statistical process control (SPC) data is integrated into production workflows, enabling real-time adjustments to maintain tolerance bands without interrupting throughput.

The following table details our standard and precision tolerance capabilities across key parameters. These ranges reflect achievable performance under controlled environmental conditions with appropriate material selection and design considerations.

| Feature Type | Standard Tolerance | Precision Range | Material Applicability |

|---|---|---|---|

| Linear Dimensions | ±0.001″ (0.025mm) | ±0.0001″ (0.0025mm) | All metals (Al, Ti, SS, etc.) |

| Geometric (GD&T) | ±0.002″ (0.05mm) | ±0.0002″ (0.005mm) | Critical aerospace/medical |

| Surface Finish (Ra) | 32 µin | 8 µin | Machined surfaces |

| Hole Positioning | ±0.0008″ (0.02mm) | ±0.00015″ (0.004mm) | Precision assemblies |

| Thread Conformance | Class 2A/2B | Class 3A/3B | Fasteners, hydraulic systems |

This technical rigor extends beyond equipment specs. Our engineering team collaborates during DFx (Design for Manufacturability) reviews to identify opportunities for consolidating part counts, optimizing material usage, and enhancing producibility—directly impacting your cost structure and lead times. For Seattle-based manufacturers facing capacity constraints or complex project demands, our integrated 5-axis and inspection ecosystem delivers certified precision without compromising on scalability. Partner with Wuxi Lead to convert engineering intent into flawlessly executed components, backed by data-driven quality assurance at every stage.

Material & Finish Options

Material selection is a critical step in precision manufacturing, directly influencing performance, durability, and cost-efficiency of end components. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for global clients, including high-demand markets such as machine shop Seattle. Our expertise spans aluminum, steel, and titanium—three of the most widely used metals in aerospace, automotive, medical, and industrial applications. Understanding the mechanical properties and finishing options of these materials ensures optimal part design and longevity.

Aluminum is favored for its lightweight nature, excellent thermal and electrical conductivity, and strong corrosion resistance. It is particularly suitable for applications requiring high strength-to-weight ratios, such as in aerospace and transportation. The most common grades we machine are 6061-T6 and 7075-T6, offering balanced machinability and structural integrity. Aluminum is also highly receptive to anodizing, a finishing process that enhances surface hardness and wear resistance while allowing for color coding and improved aesthetics.

Steel, particularly stainless steel grades like 304 and 316, provides superior strength, durability, and resistance to high temperatures and corrosion. It is ideal for applications in harsh environments, including marine, chemical processing, and medical equipment. While heavier than aluminum, steel offers excellent weldability and dimensional stability. For parts requiring high wear resistance or load-bearing capacity, we often recommend alloy steels such as 4140 or tool steels, which can be heat-treated to achieve specific hardness profiles.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the premium choice for extreme performance environments. It offers an exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility, making it indispensable in aerospace, defense, and medical implant industries. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s long-term reliability justifies its use in mission-critical applications.

Anodizing is a key surface treatment for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving corrosion and wear resistance. Type II (sulfuric acid) anodizing is commonly used for general protection and dyeing, while Type III (hardcoat anodizing) provides a thicker, harder surface suitable for high-wear environments. Anodized finishes are non-conductive and can be tailored to meet specific aesthetic or functional requirements.

Below is a comparison of key mechanical properties for commonly used materials:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Common Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 276 | 2.70 | Aerospace, structural components |

| Stainless Steel 316 | 570 | 275 | 8.00 | Marine, medical, chemical |

| Alloy Steel 4140 | 850 | 655 | 7.85 | Automotive, tooling, machinery |

| Titanium Ti-6Al-4V | 900 | 830 | 4.43 | Aerospace, defense, medical |

Selecting the right material and finish requires a comprehensive understanding of operational demands. Wuxi Lead Precision Machinery supports clients in making informed decisions, ensuring every component meets exacting standards for performance and reliability.

Manufacturing Process & QC

Precision Manufacturing Workflow: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our integrated production process for custom metal components delivers uncompromising quality for demanding sectors like aerospace and medical device manufacturing. We eliminate the traditional disconnect between design intent and manufacturability through a rigorously controlled sequence: Design for Manufacturability (DFM) analysis, precision prototyping, and scalable mass production—all engineered for Zero Defects compliance. This closed-loop methodology ensures your Seattle-based operations receive parts that perform flawlessly on schedule, every time.

The process initiates with collaborative DFM engineering. Our team reviews your CAD models against material properties, machine capabilities, and geometric complexity. We identify potential stress points, optimize wall thicknesses, and refine tolerances to prevent costly revisions during production. Utilizing Siemens NX and Mastercam, we simulate toolpaths and material flow, ensuring the design is not only feasible but optimized for high yield and minimal waste. This phase reduces time-to-market by resolving 95% of potential issues before metal is cut.

Prototyping transitions validated designs into physical reality under full production conditions. We manufacture initial units using the same CNC multi-axis mills, Swiss lathes, and grinding equipment deployed for volume runs. Each prototype undergoes comprehensive metrology: CMM inspection, surface roughness testing, and material verification against ASTM/AMS standards. Critical dimensions are tracked in real-time SPC charts. This validation step confirms functionality, assembly fit, and process stability—providing Seattle engineers with confidence before committing to full-scale production.

Mass production leverages the insights from prototyping within a Zero Defects framework. Every stage incorporates automated in-process gauging and statistical process control. Our facility employs real-time machine monitoring to detect tool wear deviations before they impact quality. Each component batch includes full traceability—material certs, heat numbers, and inspection data are digitally linked to the work order. Final inspection utilizes Zeiss CMMs and optical comparators, with all critical features measured to tolerances exceeding ISO 2768-mK. Non-conforming parts are physically quarantined; root cause analysis triggers immediate process correction, ensuring defects never reach your facility.

Key production capabilities supporting this workflow include:

| Parameter | Capability Range | Industry Standard Compliance |

|---|---|---|

| Tolerances | ±0.0001″ (2.5µm) | AS9100, ISO 13084 |

| Surface Finish | Ra 0.4µm (16µin) achievable | ASTM E1461 |

| Materials | Titanium, Inconel, 17-4PH, 6061 | AMS, ASTM, EN standards |

| Max Work Envelope | 2000 x 1000 x 800 mm | N/A |

| Process Control | Real-time SPC, Cpk ≥ 1.67 | IATF 16949 |

This seamless integration of engineering rigor, prototype validation, and closed-loop production control guarantees components that meet Seattle’s exacting performance requirements. Wuxi Lead transforms your specifications into defect-free reality—accelerating your assembly lines while eliminating costly rework and supply chain disruptions. Partner with us for manufacturing precision that moves your projects forward.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When your projects demand precision, reliability, and scalability, partnering with Wuxi Lead Precision Machinery ensures access to world-class custom metal manufacturing capabilities. Based in Wuxi, China, we serve global clients—including engineering firms, industrial OEMs, and advanced manufacturers in key markets such as Seattle—who require high-integrity components built to exacting standards. Our facility integrates advanced CNC machining, multi-axis milling, precision turning, and comprehensive quality control systems to deliver components that meet or exceed international specifications.

Seattle’s manufacturing ecosystem thrives on innovation and performance-driven solutions. At Lead Precision, we align with this ethos by offering tailored production strategies that support low-volume prototyping, mid-range batches, and high-volume production runs. Our engineers work closely with your technical team to review designs, suggest manufacturability improvements, and ensure seamless transition from concept to finished part—on time and within budget.

We specialize in complex components for aerospace, medical devices, automation systems, energy equipment, and industrial machinery. Materials we routinely process include aluminum alloys, stainless and carbon steels, titanium, brass, and engineered plastics—each handled with strict adherence to material certifications, dimensional tolerances, and surface finish requirements.

Our ISO 9001-certified production environment is equipped with state-of-the-art machinery and supported by a quality management system that includes CMM inspection, first-article reporting, and full traceability documentation. Whether you require tight tolerances of ±0.005 mm or complex geometries via 5-axis CNC machining, our team ensures every component meets your functional and regulatory demands.

Below are key technical specifications that define our manufacturing capacity

| Capability | Specification |

|---|---|

| CNC Machining | 3-axis to 5-axis milling, turning, mill-turn |

| Maximum Work Envelope | 1200 x 800 x 650 mm (X-Y-Z) |

| Tolerance | Standard: ±0.01 mm, Precision: ±0.005 mm |

| Surface Finish | As low as Ra 0.4 µm (16 µin), customizable |

| Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics |

| Production Volume | Prototypes to 50,000+ units annually |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days |

| Quality Standards | ISO 9001, Full Inspection Reports, PPAP, FAI |

Partnering with Lead Precision means more than sourcing parts—it means gaining a strategic manufacturing ally committed to technical excellence and long-term collaboration. We understand the competitive pressures facing machine shops and engineering firms in Seattle, and we are structured to support your growth with scalable, cost-effective, and technically superior manufacturing solutions.

Start your next project with confidence. Contact us today at [email protected] to discuss your requirements, request a quote, or receive design for manufacturability feedback. Let Lead Precision be the foundation of your precision component supply chain.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.