Technical Contents

Engineering Guide: Large Scale 3D Printing Service

Engineering Insight: Precision as the Non-Negotiable Foundation of Large-Scale Metal 3D Printing

In the realm of large-scale metal additive manufacturing, raw build volume alone is a misleading metric for industrial viability. True value emerges only when massive component production meets uncompromising dimensional accuracy and repeatability. For mission-critical applications in aerospace, energy, and defense, tolerances beyond ±0.1mm risk catastrophic assembly failure, structural weakness, or accelerated fatigue – consequences measured in project delays, safety hazards, and millions in scrap. Precision at scale is not an aspiration; it is the absolute prerequisite for functional integration and performance validation. Achieving this demands far more than a large chamber; it requires integrated engineering rigor spanning thermal management, in-situ monitoring, sophisticated post-processing, and metrology traceable to national standards.

Wuxi Lead Precision Machinery operates at this demanding intersection of scale and accuracy. Our engineering heritage, forged through delivering components for Olympic infrastructure projects requiring micron-level consistency under extreme environmental loads and classified defense systems where failure is not an option, defines our approach. We understand that large-scale 3D printing introduces unique challenges: thermal gradients causing warpage over meter-scale builds, residual stress accumulation affecting final geometry, and the critical need for precision machining integration after printing. Our solution integrates proprietary build parameter optimization with real-time melt pool monitoring and closed-loop thermal control systems. Crucially, every large-format build undergoes rigorous coordinate measuring machine (CMM) validation against the original CAD model before final CNC finishing, ensuring the printed net shape aligns perfectly with downstream precision machining requirements. This hybrid AM-CNC workflow, managed under one roof, eliminates tolerance stack-up errors inherent in fragmented supply chains.

The table below outlines the core precision capabilities underpinning our large-scale metal 3D printing service for industrial applications:

| Parameter | Capability | Industrial Significance |

|---|---|---|

| Max Build Envelope | 2000 x 1200 x 800 mm (LxWxH) | Enables single-piece production of structural frames, housings, and large tooling |

| As-Built Accuracy | ±0.1 mm / 100 mm (typical) | Ensures dimensional stability for critical mating surfaces without excessive post-machining |

| Repeatability (Batch) | ±0.05 mm (verified via CMM) | Guarantees consistent part geometry across production runs for assembly line integration |

| Supported Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg, Maraging Steel | High-performance alloys meeting aerospace and defense material specifications |

| Integrated Post-Process | 5-Axis CNC Milling, Stress Relieving, HIP | Delivers final net-shape precision and mechanical properties meeting AS9100 standards |

Precision in large-scale additive manufacturing transcends technical specification sheets. It represents the confidence that a printed turbine housing will mate flawlessly with its counterpart after final machining, or that a structural bracket for offshore energy equipment will withstand decades of cyclic loading without dimensional drift. At Wuxi Lead Precision Machinery, our Olympic and military-grade project experience instills the discipline to treat every large-scale print not as an experiment, but as a certified component where accuracy is engineered in from the first micron of the first layer. When your project demands zero-compromise accuracy at unprecedented scale, the engineering process matters as much as the machine.

Precision Specs & Tolerances

Technical Capabilities in High-Volume Metal 3D Printing and Precision Finishing

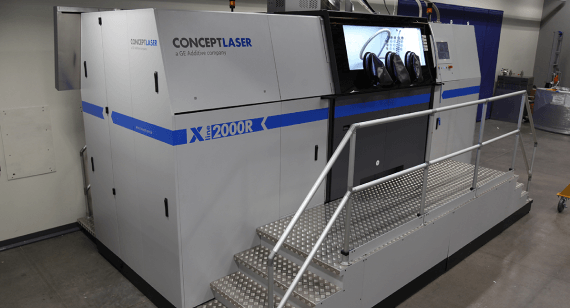

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to support large-scale 3D printing services with uncompromising precision, repeatability, and material integrity. As a leader in custom metal manufacturing, we integrate additive technologies with advanced subtractive processes to deliver end-use components that meet the most stringent industrial requirements. Our production ecosystem is anchored by state-of-the-art 5-axis CNC machining centers and comprehensive metrology systems, ensuring that every part conforms to exact design specifications.

Our large-scale metal 3D printing capabilities utilize industrial-grade laser powder bed fusion (LPBF) systems, compatible with a wide range of high-performance alloys including stainless steel (316L, 17-4 PH), titanium (Ti6Al4V), aluminum (AlSi10Mg), and nickel-based superalloys (Inconel 718, 625). These systems enable the production of complex, lightweight geometries that are difficult or impossible to achieve through traditional manufacturing, while maintaining mechanical properties suitable for aerospace, medical, energy, and high-performance automotive applications.

Post-printing, components undergo precision finishing via our HAAS and DMG MORI 5-axis CNC machining platforms. These systems provide simultaneous multi-directional cutting, allowing for tight-tolerance features, refined surface finishes, and accurate datums on highly complex forms. The integration of 5-axis technology eliminates the need for multiple setups, reducing cumulative error and improving geometric consistency across high-volume production runs.

To ensure dimensional accuracy and long-term reliability, every critical component passes through our coordinate measuring machine (CMM) inspection process. Using Zeiss CONTURA and Hexagon GLOBAL Performance CMMs equipped with tactile and optical probes, we perform full first-article inspections (FAI) and batch sampling per AS9102 and ISO 17025 standards. Our quality control protocols include GD&T validation, surface roughness analysis, and material certification traceability, providing full documentation for audit and compliance purposes.

The following table outlines our standard technical specifications and achievable tolerances across the manufacturing workflow:

| Parameter | Capability |

|---|---|

| 3D Printing Build Volume (max) | 500 x 500 x 400 mm |

| Layer Thickness Range | 20 – 50 µm |

| Typical As-Printed Surface Roughness (Ra) | 12 – 18 µm |

| 5-Axis CNC Positioning Accuracy | ±0.005 mm |

| CNC Achievable Surface Finish (Ra) | 0.8 – 3.2 µm |

| Dimensional Tolerance (CNC Finishing) | ±0.01 mm (standard), ±0.005 mm (tight) |

| Geometric Tolerance (GD&T) | ±0.02 mm (form/profile), ±0.01 mm (position) |

| CMM Measurement Uncertainty | ±0.0025 mm (at 95% confidence) |

| Materials Supported | Stainless Steel 316L, 17-4 PH; Ti6Al4V; AlSi10Mg; Inconel 718, 625; Tool Steel (Maraging, H13) |

Through the seamless integration of large-scale additive manufacturing, precision 5-axis CNC machining, and rigorous CMM-based quality assurance, Wuxi Lead Precision Machinery delivers high-integrity metal components at scale—engineered for performance, certified for compliance, and built for industry.

Material & Finish Options

Strategic Material Selection for Large-Scale Metal 3D Printing

Material choice fundamentally dictates the performance, cost efficiency, and manufacturability of large-scale 3D printed metal components. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your specific functional requirements and production scale. Aluminum alloys offer an exceptional strength-to-weight ratio and thermal conductivity, making them ideal for aerospace brackets, heat exchangers, and automotive structural components where weight reduction is critical. Our large-format systems excel with AlSi10Mg, providing near-net-shape complexity unattainable through casting while maintaining excellent cast-like surface finish potential. Steel variants, particularly 316L stainless steel, deliver superior strength, hardness, and corrosion resistance for demanding industrial applications like marine hardware, chemical processing equipment, and high-wear tooling. This material withstands rigorous post-processing and welding, essential for integrating printed sections into larger assemblies. For the most extreme environments, titanium Grade 5 (Ti-6Al-4V) is unmatched. Its high strength-to-weight ratio, biocompatibility, and resistance to fatigue and corrosion make it indispensable for aerospace structural parts, medical implants, and deep-sea components. While titanium requires stringent atmospheric control during printing, Wuxi Lead’s certified large-scale platforms ensure consistent microstructure and mechanical properties across massive builds.

Surface finishing is equally critical for functionality and longevity. Anodizing is the primary post-process for aluminum parts, significantly enhancing surface hardness, wear resistance, and corrosion protection. Our standard Type II sulfuric acid anodizing achieves a 15-25 micron coating thickness, providing excellent adhesion for primers and paints while allowing precise color dyeing for identification. Crucially, anodizing is not applicable to steel or titanium in the same functional manner; steel typically requires passivation or specialized coatings like HVOF, while titanium anodizing serves primarily decorative or minor wear-resistance purposes. Selecting the correct anodizing spec early avoids costly redesigns or performance failures in service.

Material performance characteristics must guide your selection. The following table details key properties for common large-scale printing alloys:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Max Continuous Temp (°C) | Primary Large-Scale Applications |

|---|---|---|---|---|

| AlSi10Mg | 2.67 | 290-360 | 250 | Aerospace ducting, lightweight brackets, heat sinks |

| 316L Stainless Steel | 8.00 | 550-650 | 870 | Marine components, chemical valves, pump housings |

| Ti-6Al-4V | 4.43 | 900-1000 | 600 | Aircraft landing gear, medical prosthetics, racing components |

Understanding these material fundamentals prevents over-engineering and optimizes lead times. Wuxi Lead Precision Machinery leverages extensive metallurgical expertise to advise on the optimal material and finishing combination for your large-scale project, ensuring parts meet stringent aerospace, medical, or industrial standards from the first build. Engage our engineering team early to translate your performance requirements into a robust, cost-effective manufacturing solution.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the foundation of every successful large-scale 3D printing project begins with a meticulously engineered design phase. Our engineering team collaborates directly with clients to translate conceptual requirements into manufacturable, high-integrity metal components. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize geometries for structural performance, thermal stability, and material efficiency. Design for Additive Manufacturing (DfAM) principles are rigorously applied to eliminate unnecessary mass, reduce assembly complexity, and enhance functional integration. Each design undergoes internal peer review and client validation to ensure alignment with performance, tolerance, and scalability requirements before proceeding to prototyping.

Prototyping: Validating Performance and Process

Prototyping is not a mere formality—it is a critical validation step in our zero-defect manufacturing philosophy. Using our industrial-grade metal additive systems, we produce functional prototypes in the intended production alloy, enabling accurate assessment of mechanical properties, fit, and performance under real-world conditions. These prototypes undergo comprehensive metrology inspection via coordinate measuring machines (CMM) and 3D laser scanning to verify dimensional accuracy within ±0.05 mm. In addition, non-destructive testing (NDT), including computed tomography (CT) scanning and ultrasonic inspection, is employed to detect internal porosity or anomalies. Feedback from this phase is integrated into final design refinements, ensuring that the transition to mass production is seamless and risk-free.

Mass Production: Scalable Precision with Zero Defects

With design and prototype approval, we initiate large-scale 3D printing production using our fleet of high-power, multi-laser metal additive manufacturing systems. These machines are maintained under ISO 9001-certified conditions and operated by certified technicians trained in process consistency and quality assurance. Each build is monitored in real-time with in-situ melt pool monitoring and layer-wise imaging to detect deviations instantaneously. Our production workflow is fully traceable, with every component assigned a digital passport recording laser parameters, atmosphere conditions, and post-processing history. Post-build, parts undergo stress-relief heat treatment, support removal via robotic de-featuring, and precision machining where required. Final inspection includes surface roughness measurement, hardness testing, and batch mechanical testing to ensure compliance with ASTM or ISO standards.

Production Specifications

| Parameter | Specification |

|---|---|

| Build Volume (Max) | 1,000 x 800 x 500 mm |

| Layer Thickness | 20–60 µm |

| Dimensional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 12–25 µm |

| Common Materials | 316L, 17-4PH, Inconel 718, Ti6Al4V, AlSi10Mg |

| Post-Processing Options | HIP, CNC Machining, Polishing, Coating |

| Quality Standards | ISO 9001, ASTM F75, ISO 23278 (MT/PT) |

This end-to-end process ensures that every component produced meets the highest standards of quality, consistency, and performance—delivering true zero-defect manufacturing at scale.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Metal Additive Manufacturing

Selecting a metal additive manufacturing partner is a strategic decision impacting product integrity, time-to-market, and total cost of ownership. Wuxi Lead Precision Machinery delivers more than large-scale 3D printing services; we provide engineered production solutions validated through rigorous aerospace, medical, and energy sector deployments. Our integrated facility in Wuxi combines industrial-scale metal AM systems with precision post-processing capabilities under one roof, eliminating supply chain fragmentation and quality handoffs that compromise complex projects. We operate under AS9100D and ISO 13485 certified processes, ensuring every component meets stringent regulatory requirements while maintaining full material traceability from powder to finished part.

Our technical differentiators address the core challenges of scaling metal AM production. Unlike generalist service bureaus, we specialize in high-value applications requiring certified materials, geometric complexity, and repeatable microstructural properties. Our engineering team collaborates from design feasibility through serial production, applying topology optimization and support structure intelligence to maximize yield and minimize waste. This proactive approach reduces lead times by up to 40% compared to conventional subcontracting models while ensuring first-article approval rates exceed 95%.

The following specifications demonstrate our production-grade capabilities for demanding industrial applications

| Parameter | Capability | Industrial Relevance |

|---|---|---|

| Build Volume | Ø500 x 1000 mm (L-PBF) | Full-scale aerospace brackets, hydraulic manifolds |

| Materials | Ti-6Al-4V, Inconel 718, 316L, AlSi10Mg | Certified aerospace/medical alloys with full PMI reports |

| Layer Thickness | 20–60 μm | Critical for thin-walled fluidic components |

| Dimensional Accuracy | ±0.05 mm + 0.02 mm/mm | Meets ASME Y14.5 GD&T for mating surfaces |

| Surface Finish (as-built) | Ra 8–12 μm | Reduces post-machining requirements |

| In-Process Monitoring | Melt pool analytics, O₂ < 50 ppm | Ensures defect-free builds for NDT-critical parts |

Partnering with Lead Precision means accessing production capacity designed for volume. Our 12-metal AM fleet operates 24/7 with automated powder management and integrated CNC machining centers, enabling end-to-end production of components up to 150 kg. We mitigate your supply chain risk through dual-source material qualification and dedicated production cells for high-volume programs. When your project demands uncompromised quality at scale, our engineering team provides actionable data—not just quotes—to de-risk adoption.

Initiate your project evaluation today. Contact our Application Engineering team at [email protected] with your CAD files and requirements. We will respond within 4 business hours with a detailed manufacturability analysis, timeline projection, and cost breakdown. Specify your target industry and annual volume needs to receive a customized capability dossier. For urgent RFQs, include “Priority Evaluation” in the subject line to expedite technical review. Secure your production capacity slot with a qualified partner committed to your program’s success from prototype to full-rate manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.