Technical Contents

Engineering Guide: 3D Printing Service Usa

Engineering Insight Precision Imperatives in US Metal Additive Manufacturing

Achieving dimensional accuracy in metal additive manufacturing transcends basic part production; it defines functional reliability in critical applications. For US aerospace, medical, and defense sectors, tolerances below ±0.05mm are non-negotiable. Variability at the micron level directly impacts fatigue life, assembly integrity, and regulatory compliance. Substandard precision triggers cascading costs: failed inspections, redesign cycles, and field failures. True engineering-grade metal 3D printing demands rigorous process control from powder characterization through post-processing, not merely machine operation. This precision foundation separates prototyping services from true production partners capable of mission-critical components.

Wuxi Lead Precision Machinery operates at this exacting tier. Our US client engagements consistently address the precision gap observed in domestic metal AM providers. We implement closed-loop laser monitoring, in-situ thermal imaging, and proprietary stress-relief protocols calibrated to ASTM F3301-18 standards. This systematic approach ensures geometric fidelity across builds, eliminating the “black box” uncertainty that plagues inconsistent suppliers. Our facility’s ISO 13485 and AS9100 certifications reflect this commitment to traceable, auditable precision—not theoretical capabilities.

The necessity of such rigor is proven in high-stakes environments. We engineered titanium lattice structures for Olympic bobsled runners requiring uniform wall thickness within 15μm to optimize ice friction dynamics. Similarly, our military-grade drone components undergo 100% CT scanning to verify internal channel integrity at 20μm resolution, meeting MIL-STD-810G vibration thresholds. These projects demanded more than printing; they required predictive compensation for thermal distortion and material phase changes during build—expertise forged through 12,000+ production metal AM parts.

Key precision metrics defining our US service delivery include:

| Parameter | Performance Standard | Verification Method | Critical Application Impact |

|---|---|---|---|

| Layer Resolution | 20-50 μm | Optical Profilometry | Surface finish for hydraulic seals |

| Dimensional Tolerance | ±0.025mm to ±0.05mm | CMM + GD&T Analysis | Aerospace turbine blade fit |

| Feature Repeatability | < 10μm (3σ) | Statistical Process Control | Medical implant thread accuracy |

| Internal Geometry Deviation | < 30μm | Micro-CT Scanning | Fuel nozzle flow dynamics |

US manufacturers increasingly recognize that offshore precision engineering, when executed to Western regulatory standards, solves urgent capacity and quality challenges. Lead Precision’s US technical team collaborates directly with design engineers to optimize support structures and orientation—transforming tolerance stacks from theoretical specs into guaranteed outcomes. We don’t just meet drawings; we validate performance through destructive and non-destructive testing specific to your operational environment. For projects where precision dictates success, contact our US engineering desk to discuss build parameter validation and first-article inspection protocols.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions for global industries requiring precision, reliability, and consistency. As a trusted partner in high-end component production, we integrate state-of-the-art 5 Axis CNC machining technology to meet the most demanding design and engineering specifications. Our machining centers are engineered to handle complex geometries, tight tolerances, and high-volume production runs with unmatched accuracy. By leveraging simultaneous multi-axis motion, we achieve superior surface finishes and intricate detailing that traditional 3-axis systems cannot replicate. This capability is essential for industries such as aerospace, medical devices, energy, and advanced automation, where part performance is non-negotiable.

Our 5 Axis CNC systems operate with continuous tool-path control, minimizing setup changes and reducing the risk of human error. This translates into faster turnaround times, improved part consistency, and reduced secondary operations. Materials commonly processed include titanium, stainless steel, aluminum alloys, Inconel, and other high-performance metals. Each machine is maintained to OEM standards and operated by certified machinists with extensive experience in precision engineering. Our manufacturing environment is ISO 9001 certified, ensuring every phase of production adheres to rigorous quality management protocols.

Quality control is embedded into every stage of the manufacturing process. All critical dimensions are verified using Coordinate Measuring Machine (CMM) inspection, providing full metrological traceability and compliance with ASME Y14.5 and ISO 1101 standards. Our CMM systems are calibrated annually and supported by certified inspection technicians who generate detailed First Article Inspection (FAI) and Production Part Approval Process (PPAP) reports upon request. This level of inspection ensures that every component meets or exceeds customer-specified tolerances and design intent.

The following table outlines the standard tolerance capabilities achievable through our 5 Axis CNC machining and inspection processes:

| Feature | Standard Tolerance | Precision Tolerance (Optional) |

|---|---|---|

| Linear Dimensions (mm) | ±0.025 mm | ±0.010 mm |

| Hole Diameter (mm) | ±0.025 mm | ±0.005 mm |

| Positional Tolerance | ±0.05 mm | ±0.01 mm |

| Flatness (per 100 mm) | 0.02 mm | 0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

All tolerances are validated through CMM inspection and supported by comprehensive quality documentation. Wuxi Lead Precision Machinery is committed to delivering components that perform flawlessly in mission-critical applications. Our technical capabilities, combined with disciplined quality assurance, position us as a preferred manufacturing partner for clients seeking precision metal parts with global compliance and repeatability.

Material & Finish Options

Material Selection for High-Performance Metal Additive Manufacturing

Selecting the optimal material for metal additive manufacturing (AM) is critical for achieving functional performance, cost efficiency, and project viability in demanding industrial applications. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your end-use requirements, considering mechanical strength, thermal behavior, corrosion resistance, weight constraints, and post-processing needs. This guide focuses on three foundational metal alloys and essential finishing for precision components.

Aluminum alloys, particularly AlSi10Mg, dominate lightweight structural applications requiring good thermal conductivity and moderate strength. Ideal for aerospace brackets, heat exchangers, and automotive prototypes, AlSi10Mg offers excellent castability in AM processes and a favorable strength-to-weight ratio. However, its lower melting point and strength compared to steels necessitate careful thermal management in high-stress or elevated-temperature environments. Post-build anodizing significantly enhances surface hardness and corrosion resistance, making it suitable for exposed components.

Stainless steel variants, especially 316L and 17-4 PH, deliver superior strength, high-temperature resistance, and exceptional corrosion performance. 316L is the benchmark for marine, chemical, and medical applications due to its biocompatibility and resistance to pitting. 17-4 PH provides high yield strength through precipitation hardening, critical for aerospace actuators, valves, and tooling. While denser than aluminum, steel offers robust durability and weldability. Stress relief or HIP (Hot Isostatic Pressing) is often required post-print to eliminate internal stresses and ensure dimensional stability.

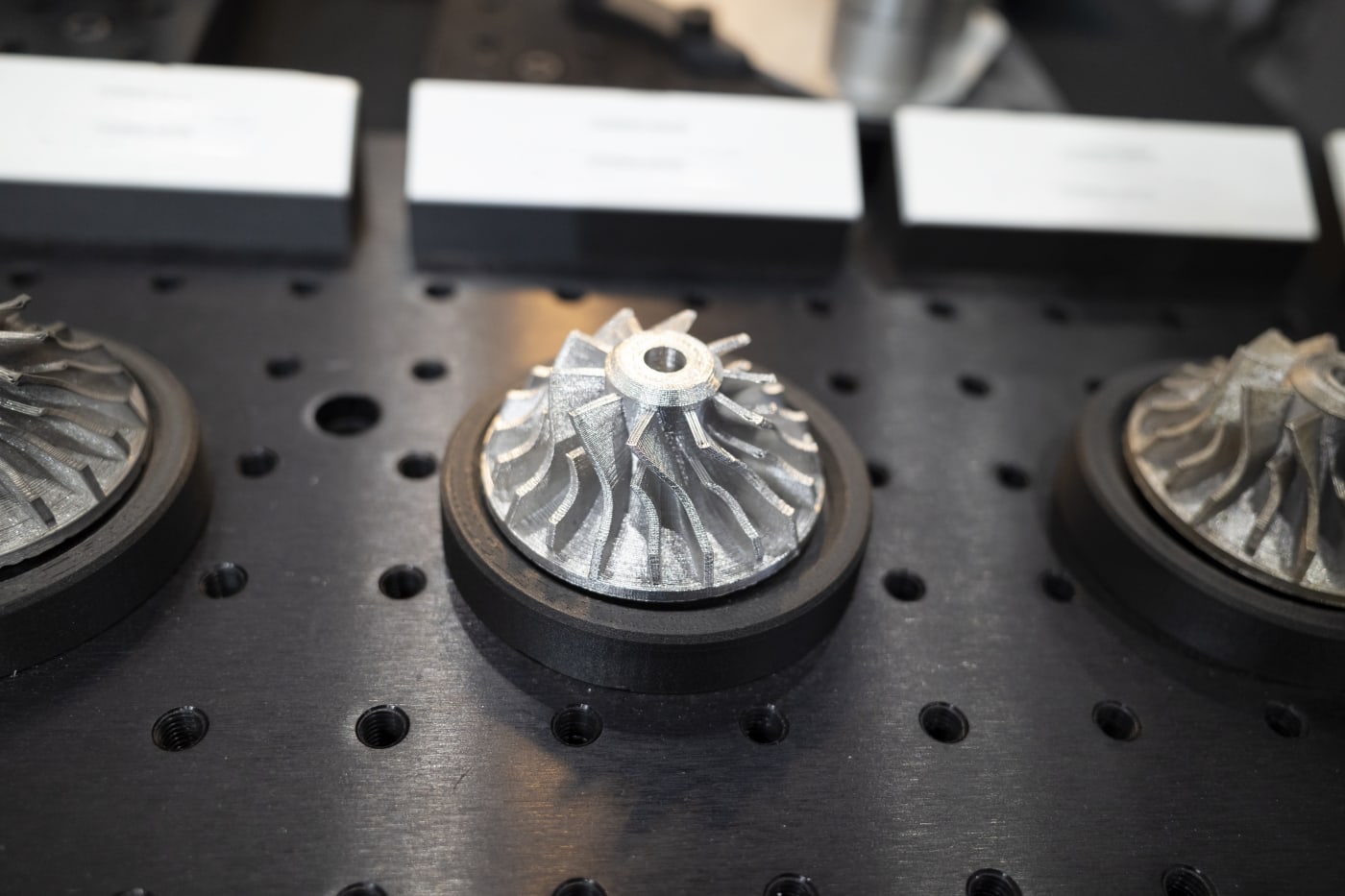

Titanium alloys, primarily Ti6Al4V (Grade 5), are indispensable for aerospace, biomedical implants, and high-performance motorsports. Its exceptional strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosion justify the higher material and processing costs. Ti6Al4V components, such as turbine blades or orthopedic fixtures, benefit from AM’s ability to create complex, lightweight geometries unachievable through traditional machining. Surface finishing like bead blasting or chemical etching is standard to remove residual powder and prepare for critical applications.

Anodizing is a vital electrochemical finish exclusively for aluminum parts, creating a durable, non-conductive oxide layer. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dyeing capability for identification. Type III (hardcoat) anodizing delivers significantly thicker, harder surfaces for severe wear environments, enhancing component lifespan. Proper pre-treatment and process control are essential to avoid dimensional changes or surface defects on intricate AM geometries.

Key mechanical properties for common AM metal alloys are summarized below. Values represent typical as-built conditions; heat treatment significantly alters performance.

| Material | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Density (g/cm³) | Key Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 190-230 | 280-350 | 8-12 | 2.67 | Lightweight structures, heat sinks |

| 316L Stainless | 300-450 | 550-700 | 30-50 | 8.00 | Marine, medical, chemical systems |

| 17-4 PH Steel | 950-1100 | 1000-1250 | 10-15 | 7.75 | Aerospace, tooling, high-strength parts |

| Ti6Al4V | 880-950 | 950-1050 | 10-15 | 4.43 | Aerospace, biomedical, motorsports |

Material selection must begin with a clear definition of functional requirements and environmental exposure. Partnering with an experienced AM manufacturer like Wuxi Lead ensures optimal material pairing, process parameter validation, and post-processing integration to transform your design into a reliable, high-performance component. Define your critical factors first—we handle the precision execution.

Manufacturing Process & QC

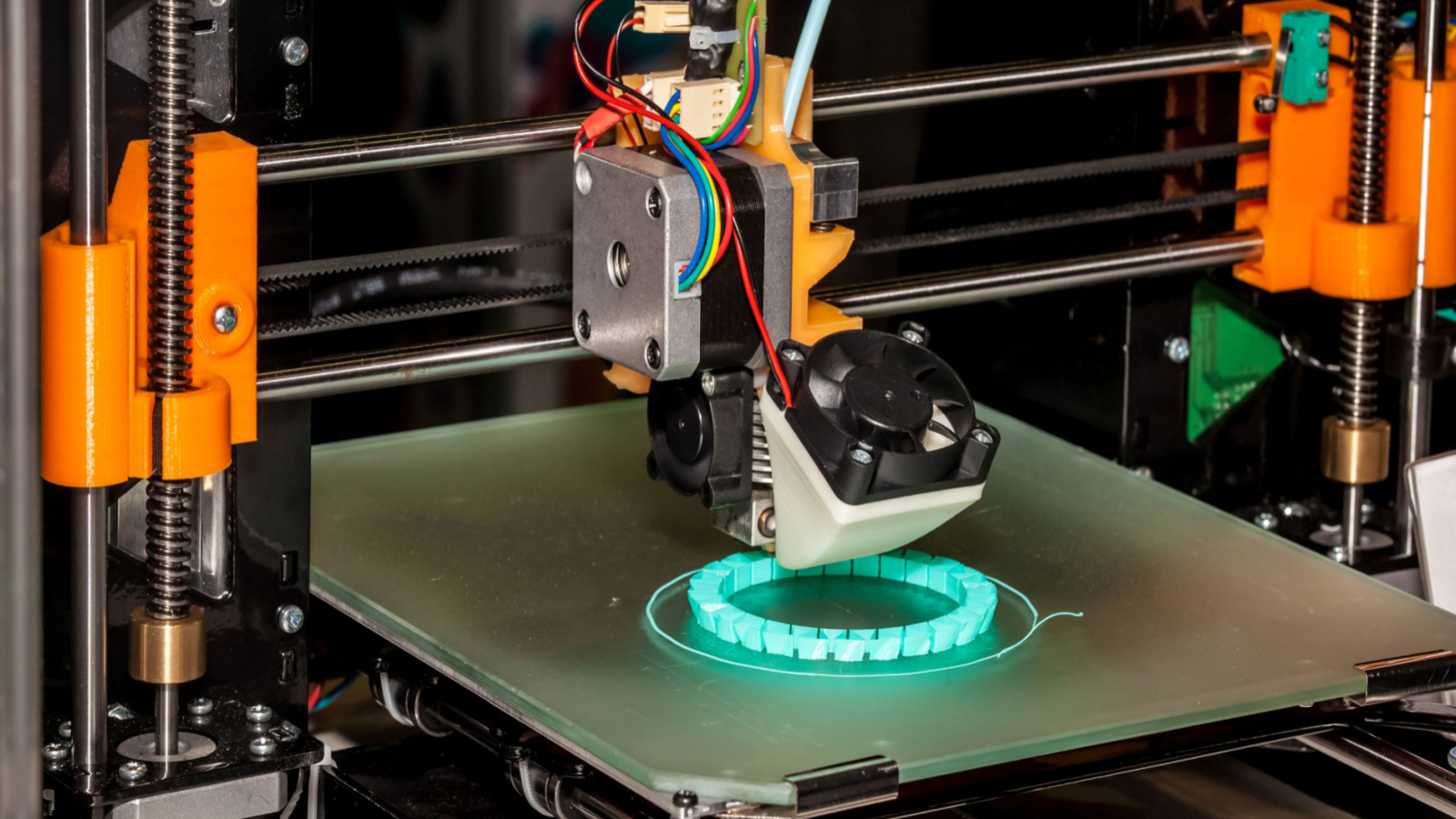

The production process at Wuxi Lead Precision Machinery is engineered for precision, consistency, and zero-defect delivery in custom metal manufacturing. Serving high-end industrial clients across aerospace, medical, energy, and automation sectors, our workflow integrates advanced 3D printing technology with rigorous quality assurance to ensure every component meets exact design intent and performance requirements. The journey from concept to mass production follows a disciplined three-phase approach: Design, Prototyping, and Mass Production.

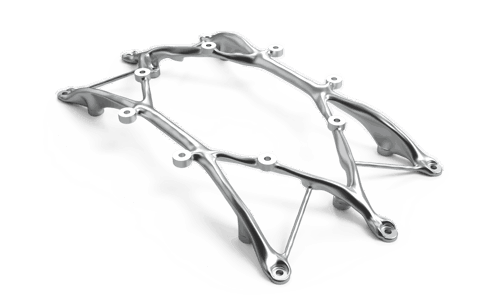

Design is the foundation of every successful manufacturing project. Our engineering team collaborates closely with clients to translate conceptual ideas into manufacturable designs optimized for metal additive processes. Utilizing advanced CAD and simulation software, we perform structural, thermal, and flow analysis to validate performance under real-world conditions. Design for Additive Manufacturing (DfAM) principles are applied to reduce weight, consolidate assemblies, and enhance functional performance—all while ensuring printability and post-processing feasibility. Material selection is determined during this phase, with options including titanium alloys, Inconel, stainless steel, aluminum, and tool steels, based on mechanical, thermal, and environmental demands.

Prototyping transforms digital designs into physical validation units. Using state-of-the-art metal 3D printing systems such as SLM (Selective Laser Melting) and DMLS (Direct Metal Laser Sintering), we produce functional prototypes with near-net-shape accuracy and full material properties. This phase enables rapid iteration, fit-testing, and performance evaluation under operational loads. Each prototype undergoes full metrology inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional compliance. Any necessary design refinements are implemented before release to production, minimizing risk and ensuring first-time-right outcomes.

Mass Production is executed with the same precision as prototyping but scaled for volume. Our production floor integrates automated powder handling, in-situ monitoring, and real-time process control to maintain repeatability across batches. Every build is tracked through a digital twin system, ensuring full traceability of parameters, materials, and inspection data. Post-processing—including stress relieving, HIP (Hot Isostatic Pressing), precision machining, and surface finishing—is performed in-house to maintain tight control over final quality. Final inspection includes non-destructive testing (NDT), mechanical testing, and microstructure analysis to certify zero-defect status.

The following table outlines key production specifications:

| Parameter | Capability |

|---|---|

| Build Envelope (max) | 500 x 500 x 500 mm |

| Layer Thickness | 20 – 50 µm |

| Dimensional Accuracy | ±0.05 mm |

| Surface Roughness (as-printed) | Ra 8 – 12 µm |

| Post-Processing Options | CNC Machining, HIP, Polishing, Coating |

| Materials Supported | Ti6Al4V, Inconel 718, 316L, AlSi10Mg, Maraging Steel |

| Quality Standards | ISO 9001, AS9100, NADCAP (NDE) |

Our end-to-end process ensures that every component delivered meets the highest standards of performance, reliability, and quality—enabling our clients in the USA and beyond to deploy mission-critical metal parts with full confidence.

Why Choose Wuxi Lead Precision

Elevate Your Metal Manufacturing Capabilities with Lead Precision

In the demanding landscape of US-based 3D printing services, achieving true end-to-end production excellence requires seamless integration of advanced additive processes with precision metal fabrication. Wuxi Lead Precision Machinery bridges this critical gap, delivering uncompromising quality for complex metal components that exceed aerospace, medical, and industrial standards. Our Wuxi-based facility operates under stringent ISO 9001:2015 and AS9100D certifications, ensuring every part meets the exacting tolerances and material integrity your high-value applications demand. We specialize in transforming 3D-printed metal substrates into mission-critical finished components through CNC machining, precision grinding, and surface finishing—eliminating supply chain fragmentation while guaranteeing dimensional accuracy down to ±0.005mm.

Our technical capabilities are engineered to solve the most challenging post-processing hurdles faced by US 3D printing providers. The table below details our core manufacturing specifications for metal components:

| Capability | Specification Range | Supported Materials |

|---|---|---|

| Dimensional Tolerance | ±0.005mm to ±0.025mm | Titanium (Gr5, Gr23), Inconel 718, 17-4PH, 316L SS |

| Max Work Envelope | 1200 x 800 x 600 mm | Aluminum 7075-T6, Tool Steels (H13, S7) |

| Surface Finish | Ra 0.2µm to Ra 1.6µm | Cobalt Chrome, Maraging Steel (18Ni300) |

| Secondary Processes | CNC Milling, Wire EDM, Precision Grinding | HIP, Heat Treatment, Passivation, Anodizing |

| Quality Assurance | CMM, 3D Scanning, Metallurgical Testing | Full Material Traceability & PPAP Documentation |

This technical foundation enables US 3D printing service providers to confidently bid on projects requiring hybrid manufacturing solutions—where additive freedom meets subtractive precision. We actively collaborate during the design phase to optimize part geometry for manufacturability, reducing lead times by up to 40% while mitigating distortion risks inherent in metal additive processes. Our engineering team provides DFM feedback within 24 hours of receiving CAD files, ensuring your designs transition smoothly from digital model to certified physical component.

Partnering with Lead Precision means securing a single-source solution for complex metal parts that demand zero-defect performance. We understand the urgency of your production schedules and maintain dedicated capacity for US clients, with standard lead times of 15–20 days for machined components from approved prints. All communications are managed through our US-based technical sales team, ensuring seamless time-zone coordination and cultural alignment. Your intellectual property remains protected under strict NDA protocols, with ITAR-compliant handling available for defense-related projects.

Advance your manufacturing value proposition by integrating Lead Precision’s certified metal expertise into your service offerings. Submit your RFQ with CAD files and technical requirements to [email protected] for a detailed capability assessment and competitive quotation within 48 business hours. Our engineering team stands ready to discuss material selection, tolerance optimization, and scalable production strategies tailored to your specific application challenges. Trust the partner chosen by leading US aerospace integrators and medical device innovators for precision you can measure—and deliver.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.