Technical Contents

Engineering Guide: Abs Injection Molding Pellets

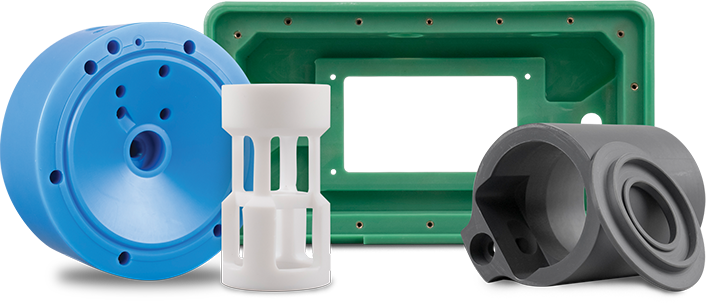

Engineering Insight: ABS Injection Molding Pellet Precision in High-Performance Manufacturing

Precision in ABS injection molding begins not with the machine, but with the raw material itself. ABS pellets are not a commodity input; they are a critical engineering variable directly influencing part integrity, dimensional stability, and production efficiency. At Wuxi Lead Precision Machinery, we understand that inconsistent pellet properties propagate through the entire manufacturing chain, introducing defects that compromise even the most advanced metal tooling and machinery. Variations in melt flow index, moisture content, or thermal stability disrupt the delicate thermal and pressure profiles required for aerospace-grade components or medical devices. Moisture content exceeding 0.4% causes hydrolysis during processing, leading to splay, reduced impact strength, and surface imperfections. Inconsistent melt flow index directly impacts fill patterns, weld line strength, and internal stresses, resulting in warpage or dimensional drift unacceptable in precision assemblies. Contaminants or inconsistent pigment dispersion further degrade surface finish and mechanical performance, necessitating costly rework or scrap.

The following table outlines essential ABS pellet specifications where precision is non-negotiable for high-end manufacturing:

| Property | Critical Range | Standard Test Method | Impact of Deviation |

|---|---|---|---|

| Melt Flow Index (220°C/10kg) | 5.0 – 25.0 g/10 min | ASTM D1238 / ISO 1133 | Poor flow control, weld line weakness, inconsistent part density |

| Moisture Content | ≤ 0.4% | ASTM D618 / ISO 62 | Hydrolysis, splay, reduced molecular weight, surface defects |

| Density | 1.04 – 1.06 g/cm³ | ASTM D792 / ISO 1183 | Inconsistent shrinkage, dimensional inaccuracies |

| Vicat Softening Point | 98 – 110°C | ASTM D1525 / ISO 306 | Reduced heat resistance, part deformation in service |

| Residual Styrene Monomer | ≤ 0.5% | ASTM D2476 | Odor issues, potential long-term stability concerns |

These precise material parameters are foundational for our metal injection molding systems to deliver optimal performance. Our custom-engineered screw and barrel assemblies, designed for exact thermal management and shear control, rely on consistent pellet feedstock to maintain micron-level tolerances during high-pressure injection. Variability in the ABS compound forces the machine to compensate, accelerating wear on critical metal components and destabilizing the process window. This is where Wuxi Lead’s deep engineering expertise becomes indispensable. We design machinery not just to meet nominal specifications, but to actively manage the inherent variability of industrial materials through robust control systems and wear-resistant metallurgy.

Our commitment to precision under extreme conditions is validated by demanding applications. We engineered specialized molding systems for components used in Olympic timing infrastructure, where sub-millimeter tolerances and absolute reliability under continuous operation were mandatory. Similarly, our military-grade machinery solutions meet stringent DoD requirements for parts operating in harsh environments, demanding exceptional repeatability and material consistency that only starts with precisely controlled ABS pellets. For manufacturers targeting the highest tiers of aerospace, defense, or medical device production, pellet specification adherence is not optional—it is the baseline for achieving the zero-defect output that Wuxi Lead Precision Machinery consistently enables through integrated material science and metal manufacturing excellence.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored for high-performance applications in aerospace, automotive, medical, and industrial sectors. While our core expertise lies in custom metal manufacturing, we provide integrated support for clients utilizing engineering thermoplastics such as ABS injection molding pellets—particularly in the production of precision metal components used in molding tools, fixtures, and automated handling systems. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, which enable complex geometries, tight tolerances, and superior surface finishes critical for high-repeatability molding environments.

Our 5-axis CNC machining platforms offer simultaneous multi-axis motion, allowing for intricate contouring and complete part fabrication in a single setup. This reduces cumulative error, improves dimensional consistency, and significantly enhances throughput for mold inserts, ejector plates, and hot runner systems commonly used in ABS injection molding applications. The ability to machine undercuts, deep cavities, and organic forms without re-fixturing ensures that tooling components meet the exacting standards required for high-volume plastic part production.

Quality assurance is integral to our manufacturing process. Every component undergoes comprehensive inspection using a Zeiss coordinate measuring machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) requirements. Our CMM inspection routines are programmed to verify critical features such as hole locations, profile accuracy, flatness, and positional tolerances. Data reports are generated for every batch, providing full traceability and supporting customer audits or quality certifications such as ISO 9001.

We maintain strict environmental and process controls within our machining facility to minimize thermal drift and vibration, ensuring measurement stability down to the micron level. In addition to CMM inspection, we employ surface roughness testers, hardness gauges, and optical comparators to validate material and finish specifications.

The following table outlines our standard machining capabilities and achievable tolerances for metal components used in precision tooling and automation systems:

| Specification | Capability |

|---|---|

| Maximum Work Envelope (XYZ) | 1200 mm × 800 mm × 700 mm |

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.01 mm |

| Geometric Tolerance (Flatness, Perpendicularity) | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | As low as 0.4 μm (polished finishes available) |

| Repeatability | ±0.003 mm |

| Materials Processed | Stainless Steel, Tool Steel, Aluminum Alloys, Titanium, Brass, PEEK (for fixtures) |

All processes are supported by in-house engineering review, CAD/CAM programming, and real-time tool monitoring to ensure consistency and on-time delivery. At Wuxi Lead Precision Machinery, we combine precision engineering with rigorous quality control to deliver metal components that directly enhance the performance and reliability of ABS injection molding systems.

Material & Finish Options

Material Selection for Precision Metal Components

Selecting the optimal material is critical for achieving performance, durability, and cost efficiency in custom metal manufacturing. At Wuxi Lead Precision Machinery, we specialize in machining high-integrity components from aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties and compatibility with finishing processes like anodizing, directly impacting part functionality in demanding industrial applications.

Aluminum alloys, particularly 6061-T6 and 7075-T6, deliver an exceptional strength-to-weight ratio and excellent machinability. They are ideal for aerospace brackets, automotive heat sinks, and structural frames where weight reduction is paramount. Aluminum readily accepts anodizing, which enhances surface hardness, corrosion resistance, and aesthetic consistency. Type II (sulfuric acid) anodizing provides standard protection, while Type III (hard coat) delivers wear resistance for hydraulic components.

Steel variants, including 4140, 17-4 PH, and 304/316 stainless, offer superior strength, fatigue resistance, and thermal stability. Carbon steels like 4140 are cost-effective for high-stress shafts and tooling, while stainless grades excel in corrosive environments such as marine hardware or medical devices. Anodizing is not applicable to steel; instead, passivation (for stainless) or zinc plating ensures corrosion resistance. For extreme wear applications, nitriding or chrome plating may be specified.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), provide unmatched strength-to-weight performance and exceptional corrosion resistance in aggressive media like seawater or chemical baths. They are indispensable for aerospace landing gear, biomedical implants, and offshore drilling components. Titanium can be anodized to create decorative or functional oxide layers, though its natural oxide film already offers robust protection.

The following table summarizes key properties to guide material selection:

| Material | Tensile Strength (ksi) | Corrosion Resistance | Common Applications |

|---|---|---|---|

| Aluminum 7075-T6 | 83 | Moderate | Aerospace fittings, military hardware |

| Steel 4140 | 110 | Low (uncoated) | Shafts, gears, tooling fixtures |

| Steel 316 Stainless | 80 | Excellent | Marine components, medical devices |

| Titanium Ti-6Al-4V | 130 | Exceptional | Aircraft engine parts, implants |

Surface finishing significantly extends component lifespan. Anodizing thickness must align with operational demands: 0.0002″ for basic protection versus 0.001″ for severe abrasion resistance. Always consider the interplay between material choice, environmental exposure, and functional requirements. For instance, saltwater-exposed marine housings demand 316 stainless or anodized aluminum, never bare carbon steel.

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to match materials and finishes to your exact application. Our engineering team conducts rigorous material verification per AMS, ASTM, and ISO standards, ensuring every component meets stringent performance criteria. Consult our specialists early in the design phase to optimize material selection, reduce lifecycle costs, and avoid costly rework. Precision begins with the right foundation.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the production process for custom metal components begins with meticulous design engineering. When manufacturing parts from ABS injection molding pellets, our design phase integrates material science with advanced CAD/CAM technologies to ensure compatibility between the thermoplastic properties of ABS and the functional requirements of the final metal-reinforced component. Our engineers conduct finite element analysis (FEA) to simulate stress distribution, thermal behavior, and structural integrity under operational loads. This ensures that every design is optimized for both manufacturability and performance. We collaborate closely with clients to refine geometries, draft angles, wall thicknesses, and gate locations to prevent defects such as warping, sink marks, or voids during injection molding. The result is a digitally validated model ready for prototyping, fully compliant with ISO 9001 quality standards.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC-machined molds or 3D-printed tooling, depending on complexity and volume requirements. Prototypes are produced using the same grade of ABS injection molding pellets intended for mass production, ensuring material consistency. Each prototype undergoes rigorous functional testing, including dimensional inspection via coordinate measuring machines (CMM), thermal cycling, and mechanical load testing. This phase allows us to identify and correct potential flaws in mold flow, cooling efficiency, or ejection mechanisms. Feedback is integrated into the digital model, and design iterations are executed swiftly. Our zero-defect philosophy demands that every prototype meets exact client specifications before transitioning to full-scale manufacturing.

Mass Production: Consistency, Control, and Quality Assurance

With design and prototyping complete, we initiate mass production using fully automated injection molding systems equipped with real-time monitoring. Our state-of-the-art facilities in Wuxi utilize hydraulic and electric presses with precise temperature, pressure, and cycle time controls. The ABS pellets are dried prior to processing to eliminate moisture, preventing surface defects and molecular degradation. Each shot is monitored through integrated sensors that detect deviations in fill time, pressure spikes, or cooling anomalies. Statistical process control (SPC) systems log data for traceability and continuous improvement. Finished parts undergo 100% visual inspection and batch sampling for metrological validation. Non-conforming units are immediately quarantined, ensuring zero-defect delivery.

Key Process Specifications

| Parameter | Specification |

|---|---|

| Material | ABS Injection Molding Pellets (Custom Grades) |

| Melt Temperature Range | 210°C – 240°C |

| Mold Temperature | 40°C – 80°C |

| Injection Pressure | 70 – 150 MPa |

| Cycle Time (Typical) | 30 – 90 seconds |

| Dimensional Tolerance | ±0.05 mm (per ISO 2768-m) |

| Surface Finish | Ra 0.8 – 3.2 µm (Custom Textures Available) |

| Quality Standard | ISO 9001:2015, IATF 16949 (Automotive) |

| Production Capacity | Up to 500,000 units/month |

Through integrated design, validated prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers defect-free metal-reinforced components with unmatched consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Precision Metal Components for High-Performance ABS Molding Systems

Wuxi Lead Precision Machinery operates at the core of advanced manufacturing infrastructure, specializing in the custom metal components essential for reliable, high-output ABS injection molding systems. While we do not produce ABS pellets ourselves, our expertise lies in engineering the critical metal elements that directly impact your molding process efficiency, part quality, and machine longevity. Confusion regarding material supply versus precision engineering capability is common; our distinct value is delivering the ultra-precise metal foundations upon which successful ABS pellet processing depends. Partnering with us means securing components built to exacting standards, ensuring your molding equipment performs optimally under demanding production cycles.

Our CNC-machined metal parts form the backbone of robust ABS molding operations. We manufacture mold bases, cavity and core inserts, ejector systems, guide pins, bushings, and specialized hot runner components from premium tool steels and alloys. Each component undergoes rigorous dimensional verification and surface treatment processes to achieve micron-level tolerances and exceptional wear resistance. This precision directly translates to reduced cycle times, minimized flash, extended mold life, and consistent part quality from your ABS pellets. We understand that downtime in ABS production is costly; our components are engineered for maximum durability and seamless integration, mitigating failure points within your molding system.

The performance of your ABS molding operation is intrinsically linked to the quality of its metal components. Below are key specifications we consistently achieve for critical molding system parts:

| Parameter | Capability | Relevance to ABS Molding Systems |

|---|---|---|

| Material | P20, H13, S136, 420SS, Custom Alloys | Optimized for thermal stability & corrosion resistance against ABS processing |

| Tolerance | ±0.002 mm (Linear) | Ensures precise cavity dimensions for dimensional accuracy of molded ABS parts |

| Surface Finish | Ra 0.05 µm (Mirror Polish) | Critical for part release, cosmetic quality, and preventing ABS residue buildup |

| Hardness | Up to 52 HRC (Post-Treatment) | Maximizes wear resistance for high-volume ABS production cycles |

| Max Workpiece Size | 1200 x 800 x 600 mm | Accommodates large mold bases and complex multi-cavity systems |

Choosing Wuxi Lead Precision Machinery as your metal component partner provides tangible advantages for your ABS injection molding throughput and quality control. We move beyond standard machining to offer collaborative engineering support, identifying potential failure modes in your current setup and proposing optimized solutions. Our ISO 9001-certified processes guarantee traceability and repeatability, while our strategic location in Wuxi ensures efficient logistics for global clients. We invest in the latest multi-axis CNC technology and coordinate measuring machines specifically to meet the stringent demands of molding equipment manufacturers and high-volume ABS processors.

Do not let substandard metal components compromise the performance of your ABS injection molding lines. Elevate your system’s reliability and output quality with parts engineered for the rigors of continuous production. Contact our engineering and sales team directly to discuss your specific ABS molding system requirements. We will provide a detailed capability assessment and quotation within 24 hours.

Initiate your precision metal component solution today. Email [email protected] for expert consultation and technical specifications.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.