Technical Contents

Engineering Guide: Cnc Milling Machine China

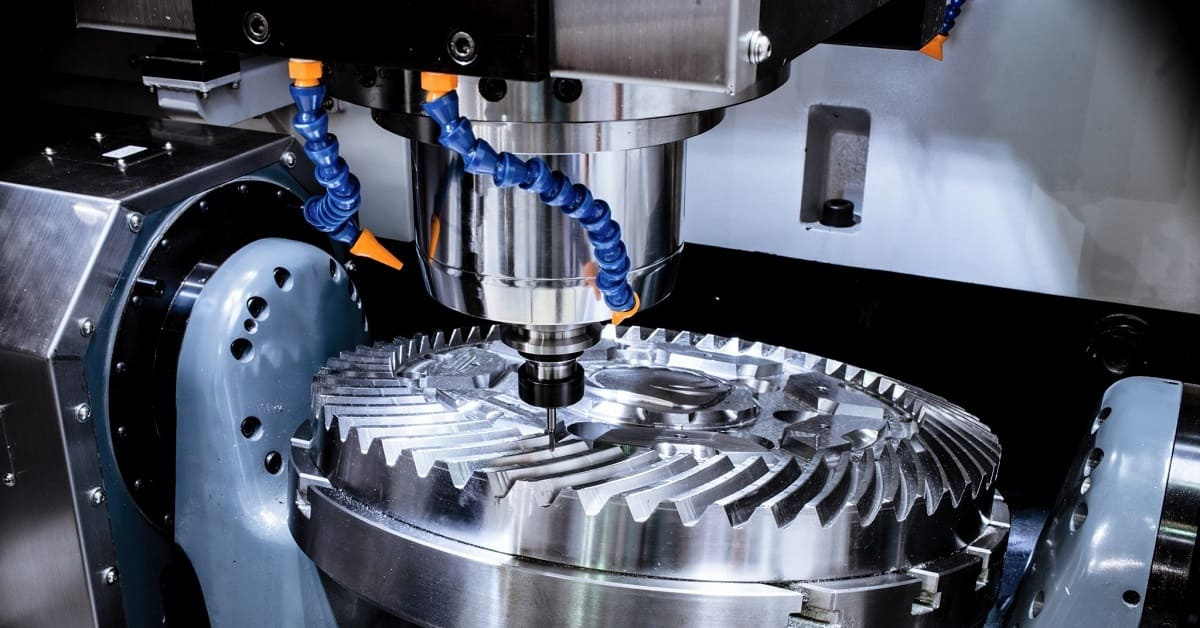

Engineering Insight: The Role of Precision in CNC Milling Machines from China

In the global landscape of precision manufacturing, CNC milling machines from China have evolved from cost-effective alternatives to high-performance systems trusted by aerospace, defense, and medical industries. At the core of this transformation lies an unwavering commitment to precision — not merely as a technical specification, but as a foundational engineering principle. For manufacturers sourcing advanced machining solutions, understanding the true meaning of precision in CNC milling is essential to ensuring product reliability, repeatability, and long-term return on investment.

Precision in CNC milling encompasses more than tight tolerances. It involves thermal stability, dynamic rigidity, spindle accuracy, linear motion system performance, and advanced control integration. A machine may claim sub-micron repeatability, but without a thermally stable cast iron base, precision-ground linear guides, and a high-frequency spindle with minimal runout, such claims can quickly degrade under real-world production conditions. This is where Chinese manufacturers with deep engineering expertise, such as Wuxi Lead Precision Machinery, distinguish themselves from commodity producers.

With over two decades of experience in high-end CNC development, Wuxi Lead has supplied mission-critical machining systems for applications demanding the highest levels of accuracy and durability. Our engineering teams have contributed to projects for Olympic-standard sporting equipment manufacturing and precision components used in military defense systems. These applications require not only micron-level accuracy but also long-term consistency under continuous operation and stringent environmental conditions. Our machines are designed and validated using laser interferometry, 3D probing systems, and in-process thermal compensation algorithms to ensure performance integrity across shifts and seasons.

At Wuxi Lead, we recognize that precision begins at the design stage. Finite element analysis (FEA) is used to optimize frame stiffness, while modular configurations allow customization without compromising structural integrity. Each machine undergoes a 72-hour continuous run-in test under load, simulating real production stress to validate thermal behavior and dynamic accuracy before shipment.

Below are key specifications from our flagship 5-axis CNC milling platform, reflecting the engineering standards applied across our precision series:

| Specification | Performance Value |

|---|---|

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed (Standard) | 12,000 rpm |

| Spindle Runout (at nose) | ≤1.0 µm |

| Table Size (X-Y) | 800 mm × 600 mm |

| Linear Axis Travel (X/Y/Z) | 800 / 600 / 500 mm |

| Rapid Traverse Rate | 48 m/min |

| Control System | Fanuc 31i-B5 |

| Thermal Compensation | Real-time, dual-sensor system |

These metrics represent more than data points — they reflect a philosophy of engineering excellence cultivated through demanding applications and continuous innovation. When selecting a CNC milling machine from China, buyers must look beyond initial cost and evaluate the total cost of precision: the ability to maintain accuracy over time, reduce scrap rates, and support advanced manufacturing workflows.

Wuxi Lead Precision Machinery stands at the forefront of this evolution, delivering CNC solutions where precision is not promised — it is proven.

Precision Specs & Tolerances

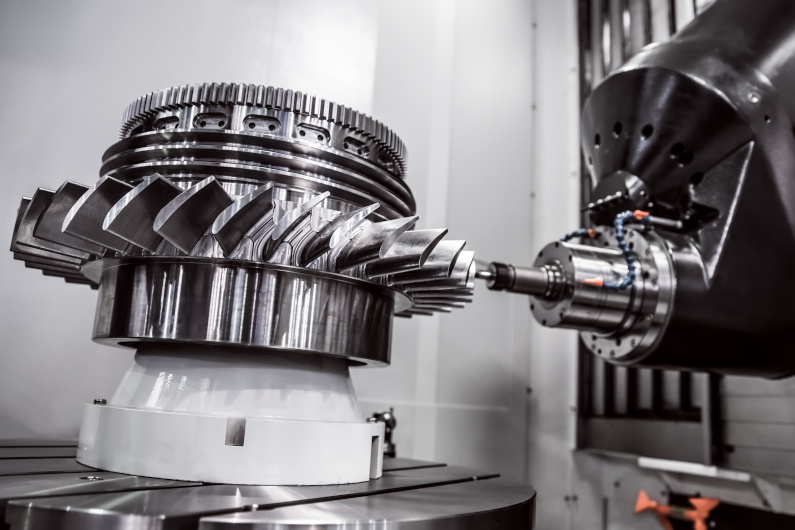

Technical Capabilities: Precision Execution for Demanding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision through advanced multi-axis CNC milling and rigorous quality control systems. Our core manufacturing capability centers on state-of-the-art 5-axis CNC machining centers, specifically selected for their stability, accuracy, and ability to handle complex geometries in a single setup. We utilize premium equipment from leading global manufacturers including DMG MORI and Makino, featuring high-torque spindles, thermal compensation systems, and sub-micron repeatability. These machines are equipped with high-precision linear scales and advanced FANUC or Siemens controls, ensuring consistent dimensional accuracy and superior surface finishes across diverse materials such as aerospace alloys, medical-grade titanium, hardened steels, and engineered composites. The integration of 5-axis simultaneous machining significantly reduces lead times, minimizes potential for human error inherent in multiple setups, and enables the production of intricate components impossible with conventional 3-axis technology, directly supporting our clients’ most challenging design requirements.

Quality assurance is not a final step but an integrated process throughout production. Every component undergoes stringent inspection using calibrated Coordinate Measuring Machines (CMMs), primarily Zeiss models renowned for metrological excellence. Our AS9100-compliant quality management system mandates full first-article inspection reports (FAIR) and in-process checks against critical dimensions defined in engineering drawings and international standards. Skilled metrology technicians utilize advanced CAD comparison software to perform comprehensive geometric dimensioning and tolerancing (GD&T) analysis, verifying form, position, profile, and runout with micron-level certainty. This systematic approach, combined with environmental controls within our metrology lab, guarantees that every part shipped meets or exceeds the specified tolerances and functional requirements, providing our aerospace, medical, and energy sector clients with absolute confidence in component integrity and performance.

The following table details the standard and achievable geometric tolerances consistently maintained across our production processes under controlled conditions. These values represent our typical production capability for features machined on our 5-axis platforms and verified by our CMM systems, reflecting the high standard expected in precision contract manufacturing.

| Feature Type | Standard Production Tolerance | Achievable Tolerance (Optimized Conditions) |

|---|---|---|

| Linear Dimensions | ±0.010 mm (±0.0004″) | ±0.002 mm (±0.00008″) |

| Hole Diameter | ±0.008 mm (±0.0003″) | ±0.003 mm (±0.00012″) |

| Positional Tolerance | ±0.015 mm (±0.0006″) | ±0.005 mm (±0.0002″) |

| Flatness | 0.010 mm (0.0004″) | 0.003 mm (0.00012″) |

| Circular Runout | 0.012 mm (0.0005″) | 0.005 mm (0.0002″) |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.2 µm (8 µin) |

This documented capability, underpinned by our investment in cutting-edge 5-axis technology and metrology infrastructure, ensures Wuxi Lead consistently transforms complex engineering concepts into high-integrity, functionally perfect components. We provide the technical foundation necessary for success in applications where precision is non-negotiable.

Material & Finish Options

Material selection is a critical phase in precision CNC milling, directly influencing part performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-accuracy CNC milling services tailored for demanding industries such as aerospace, medical, and advanced automation. Our expertise enables clients to make informed decisions when selecting between aluminum, steel, and titanium—three of the most widely used engineering metals in high-performance applications.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and machinability. Grade 6061-T6 is a common choice for prototypes and structural components due to its weldability and moderate strength. For more demanding environments, 7075-T6 offers superior strength, often used in aerospace frameworks. Aluminum’s low density makes it ideal for applications where weight reduction is paramount without sacrificing rigidity.

Steel, particularly alloy and stainless variants, delivers exceptional strength, wear resistance, and thermal stability. 4140 alloy steel is frequently selected for high-stress mechanical parts such as shafts and tooling, thanks to its hardenability and toughness. Stainless steel 304 and 316 are preferred in medical and food processing equipment due to their outstanding corrosion resistance and compliance with hygiene standards. While heavier than aluminum, steel provides unmatched durability under load and elevated temperatures.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments. Its exceptional strength-to-density ratio, biocompatibility, and resistance to high-temperature oxidation make it indispensable in aerospace, defense, and implantable medical devices. Though more challenging to machine due to its low thermal conductivity and tendency to gall, titanium’s long-term performance justifies its use in mission-critical components.

Surface finishing further enhances material performance. Anodizing is a widely used electrochemical process for aluminum, improving surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing allows for color dyeing and is suitable for most industrial applications. Type III, or hard anodizing, produces a thicker, denser oxide layer, ideal for components exposed to high abrasion or extreme environments. Anodized finishes also provide excellent electrical insulation and aesthetic consistency.

Below is a comparative overview of key material properties and recommended applications:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Key Applications | Machinability |

|---|---|---|---|---|---|

| Aluminum | 310 (7075-T6) | 2.7 | 6061-T6, 7075-T6 | Aerospace, Enclosures | Excellent |

| Steel (Alloy) | 850–1000 (4140) | 7.85 | 4140, 4340 | Shafts, Tooling | Good |

| Stainless Steel | 505–700 (304/316) | 8.0 | 304, 316 | Medical, Food Processing | Moderate |

| Titanium | 900–1000 (Ti-6Al-4V) | 4.43 | Gr 2, Gr 5 | Aerospace, Implants | Challenging |

At Wuxi Lead Precision Machinery, we support clients from material selection through final finishing, ensuring optimal performance and compliance with international quality standards. Our CNC milling capabilities are designed to handle these advanced materials with micron-level precision, delivering components that meet the highest engineering demands.

Manufacturing Process & QC

Precision Production Process: From Concept to Zero Defects

At Wuxi Lead Precision Machinery, our CNC milling production process is engineered for uncompromising quality and repeatability, ensuring every component meets exacting global standards. We integrate advanced technology with rigorous quality management across three critical phases: Design, Prototyping, and Mass Production. This structured approach is fundamental to achieving our Zero Defects commitment for clients demanding precision from Chinese manufacturing.

The Design phase begins with comprehensive CAD/CAM integration and meticulous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with client specifications, utilizing Siemens NX and Mastercam software to optimize toolpaths, minimize cycle times, and preempt potential machining challenges. Material selection is validated against performance requirements, and all geometric tolerances are rigorously assessed against ISO 2768-mK standards. This upfront engineering rigor eliminates conceptual flaws, ensuring the digital model is fully manufacturable before any metal is cut, forming the bedrock of defect prevention.

Prototyping transitions the validated design into physical reality under controlled conditions. We deploy our high-precision 5-axis milling centers to produce initial samples using the exact production tooling, fixtures, and materials specified for the final run. Each prototype undergoes exhaustive metrology: Coordinate Measuring Machine (CMM) inspections verify all critical dimensions against the CAD model, surface roughness testers confirm finish requirements, and functional testing validates performance. This stage is not merely a form check; it is a complete process validation. Only when every prototype parameter falls within the tightest tolerance bands and receives full client sign-off do we authorize progression to mass production. This step is non-negotiable for mitigating risk.

Mass Production leverages the perfected process under our Zero Defects Quality Management System. Every machine center operates with real-time process monitoring, utilizing integrated sensors for vibration analysis, thermal compensation, and in-cycle probing. Statistical Process Control (SPC) charts track critical dimensions continuously, triggering immediate intervention if trends approach specification limits. Our production floor enforces 100% first-article inspection and defined sampling plans per ANSI/ASQ Z1.4, with final inspection encompassing full CMM reports, visual checks under calibrated lighting, and traceability to raw material certifications. Defects are measured in PPM, not percentages, achieved through relentless process control and empowered operator quality ownership.

Key production capabilities enabling this Zero Defects outcome include:

| Parameter | Specification | Verification Method |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | Laser Interferometer |

| Repeatability | ±0.001 mm | Ballbar Test ISO 230-4 |

| Surface Finish (Typ.) | Ra 0.8 μm | Surface Roughness Tester |

| Geometric Tolerance | ISO 2768-mK / IT6 | CMM Inspection Report |

| Process Capability (CpK) | ≥ 1.67 | SPC Data Analysis |

This closed-loop process, from intelligent design through validated prototyping to meticulously monitored mass production, is how Wuxi Lead delivers precision CNC milled components that consistently exceed international expectations, proving Chinese manufacturing excellence is defined by process, not just price.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched CNC Milling Excellence

When sourcing high-performance CNC milling machines from China, precision, reliability, and long-term partnership matter. At Wuxi Lead Precision Machinery, we go beyond manufacturing—we engineer success for global industrial leaders. With over 15 years of expertise in precision CNC machining, our engineering-driven approach ensures every machine delivers micron-level accuracy, robust durability, and seamless integration into advanced production environments.

Our CNC milling machines are engineered for industries where performance cannot be compromised—automotive, aerospace, medical device manufacturing, and high-end industrial equipment. Each machine is built with premium-grade components, including high-torque spindles, rigid cast-iron beds, and advanced Siemens or Fanuc controls, ensuring repeatable accuracy under continuous operation. We design not just for today’s demands, but for the evolving needs of smart factories and Industry 4.0 integration.

What sets Wuxi Lead apart is our commitment to co-engineering solutions. We don’t offer off-the-shelf compromises. Instead, we collaborate with your engineering and operations teams to tailor machine configurations, work envelopes, tooling systems, and automation interfaces to your exact production requirements. Whether you need a 3-axis vertical milling center for complex mold work or a 5-axis simultaneous machining solution for aerospace components, our team ensures optimal performance and ROI.

Our facility in Wuxi, Jiangsu Province, is equipped with state-of-the-art assembly lines and rigorous quality control protocols. Every machine undergoes a 72-hour continuous run test, thermal stability verification, and laser calibration to guarantee compliance with ISO 10791 and GB/T 18400 standards. We back our machines with comprehensive global support, including on-site installation, operator training, and 24/7 technical assistance.

Partnering with Wuxi Lead Precision Machinery means gaining a true engineering ally—one that stands behind every spindle rotation, every axis movement, and every part produced.

Technical Specifications of Lead Precision CNC Milling Series

| Model | Axis Configuration | Table Size (mm) | X/Y/Z Travel (mm) | Spindle Speed (rpm) | Positioning Accuracy (mm) | Control System |

|---|---|---|---|---|---|---|

| LP-V800 | 3-Axis | 800 × 500 | 800 × 500 × 500 | 8,000 | ±0.005 | Fanuc 0i-MF |

| LP-V1000 | 3+2 Axis | 1000 × 600 | 1000 × 600 × 600 | 8,000 | ±0.005 | Siemens 828D |

| LP-H1200 | Horizontal 4-Axis | 1200 × 1000 | 1200 × 1000 × 800 | 6,000 | ±0.008 | Siemens 840D |

| LP-5X2000 | 5-Axis Simultaneous | 1300 × 1000 | 1100 × 900 × 800 | 12,000 | ±0.003 | Heidenhain TNC640 |

Contact us today to discuss your next high-precision machining project. Let Wuxi Lead Precision Machinery become your trusted partner in advanced manufacturing. Email us at [email protected] and receive a detailed technical proposal tailored to your production goals.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.