Technical Contents

Engineering Guide: Prototype Plastic Injection Molding

Engineering Insight: The Critical Role of Precision in Prototype Plastic Injection Molding

In the realm of advanced manufacturing, prototype plastic injection molding stands as a cornerstone process for validating design integrity, functionality, and manufacturability before full-scale production. At Wuxi Lead Precision Machinery, we recognize that the success of any injection-molded component begins with precision—both in tooling and process control. This level of accuracy is not merely a technical requirement; it is a strategic necessity that directly impacts performance, cost-efficiency, and time-to-market.

Prototype plastic injection molding is more than a preliminary step—it is a high-stakes engineering simulation. Even minor deviations in cavity dimensions, gate placement, or cooling channel design can result in warpage, sink marks, or inconsistent material flow. These defects, if undetected during prototyping, propagate into mass production, leading to costly rework, supply chain delays, and compromised product quality. Precision ensures that prototypes behave as true representatives of final parts, enabling reliable testing under real-world conditions.

At Wuxi Lead, our approach integrates metrology-grade machining with advanced simulation software to achieve tolerances as tight as ±0.002 mm. Our engineers utilize mold flow analysis to predict material behavior, optimize gate locations, and minimize residual stress. This data-driven methodology ensures that every prototype not only meets dimensional specifications but also reflects the mechanical and aesthetic qualities of the end product.

Our expertise in precision extends beyond commercial applications. Wuxi Lead has delivered mission-critical components for Olympic-standard equipment and military-grade systems, where failure is not an option. These projects demanded not only flawless execution but also rigorous documentation, traceability, and compliance with international standards. The same discipline is applied to every prototype injection molding project we undertake, ensuring clients receive parts that are as reliable as they are accurate.

Material selection, mold steel quality, and process repeatability are equally vital. We work with a broad spectrum of engineering-grade thermoplastics—including PEEK, ABS, PC, and PPS—machining molds from hardened steels such as H13, S136, or 420 stainless to ensure longevity and surface fidelity. Each mold is built to withstand iterative testing while maintaining dimensional stability across multiple cycles.

The table below outlines key specifications that define our prototype injection molding capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Mold Material | H13, S136, 420 Stainless, P20 (hardened) |

| Surface Finish | SPI Finish A1 to D3, textured, polished, etched |

| Part Weight Range | 0.1 g – 1,500 g |

| Cycle Time Optimization | Real-time monitoring and adaptive control |

| Tooling Lead Time | 2–6 weeks (depending on complexity) |

| Supported Plastics | ABS, PC, PP, PE, POM, PEEK, PA6/66, PPS, etc. |

| Quality Certification | ISO 9001, Full First Article Inspection (FAI) |

Precision in prototype plastic injection molding is not an isolated goal—it is the foundation of innovation. At Wuxi Lead Precision Machinery, we combine decades of metallurgical expertise, state-of-the-art CNC machining, and a proven track record in high-demand sectors to deliver prototypes that accelerate development and de-risk production. When performance matters, precision leads.

Precision Specs & Tolerances

Technical Capabilities: Precision Mold Manufacturing for Prototype Injection Molding

Wuxi Lead Precision Machinery delivers critical metal components enabling high-fidelity prototype plastic injection molding. Our core expertise lies in manufacturing the precision molds, tooling, and inserts required for successful plastic part prototyping and low-volume production. We bridge the gap between plastic part design intent and physical reality through advanced metal fabrication, ensuring molds meet the stringent demands of rapid iteration and functional validation.

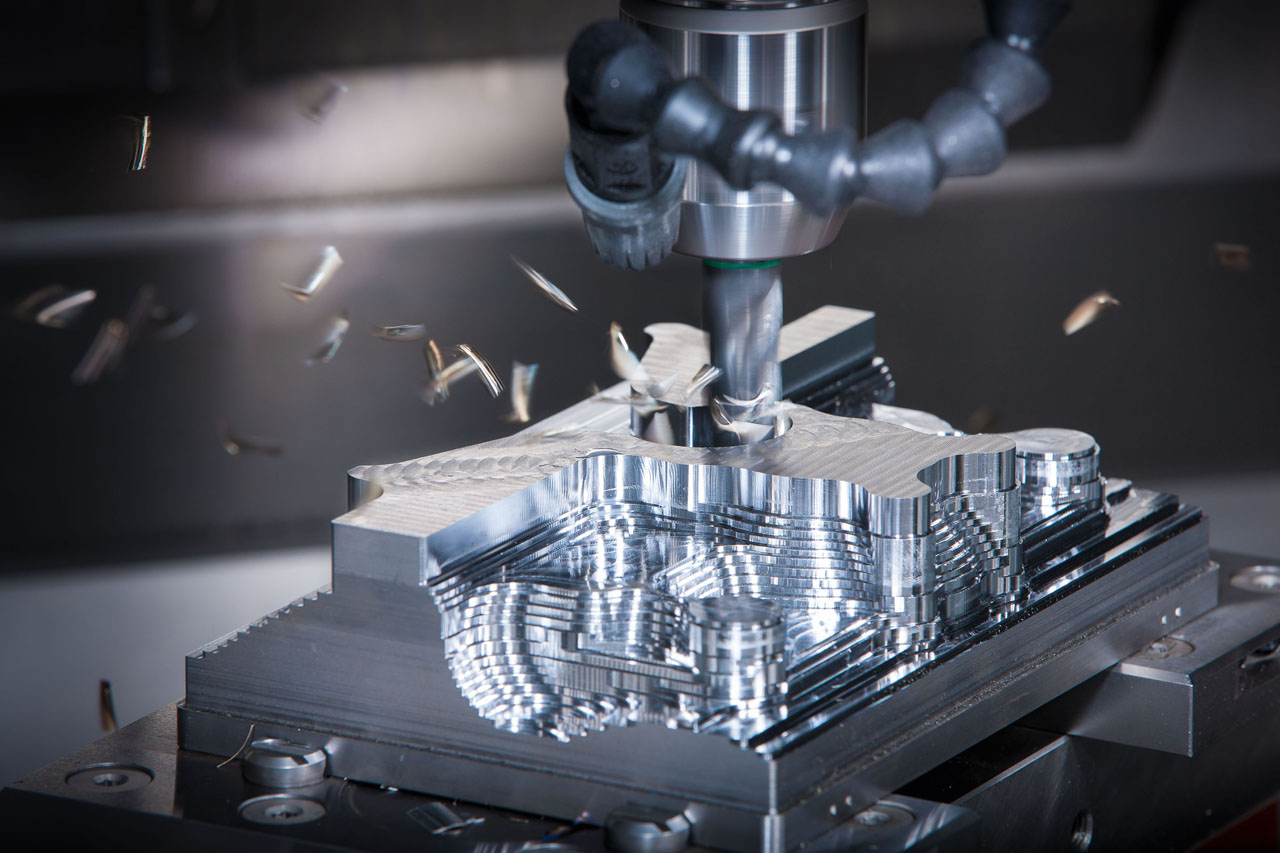

Central to our capability is a dedicated fleet of 5-axis CNC machining centers. This technology allows us to produce complex mold geometries—such as deep cavities, undercuts, and intricate core pins—in a single setup. Simultaneous multi-axis movement eliminates manual repositioning errors, significantly improving accuracy while reducing lead times for prototype molds. We specialize in machining hardened tool steels (including P20, H13, S136) and aluminum alloys, optimizing cutting strategies for material integrity and surface finish critical to plastic flow and part ejection. Our programming leverages advanced CAM software to generate efficient toolpaths that maintain geometric precision across all mold features.

Quality assurance is non-negotiable in mold manufacturing. Every critical dimension undergoes rigorous validation using state-of-the-art Coordinate Measuring Machines (CMM). Our CMM inspection process provides full traceability, generating detailed reports that correlate actual part geometry against CAD nominal values. This metrology-driven approach ensures cavity and core alignment, vent depth, cooling channel placement, and parting line integrity meet exact specifications before mold trials commence. We validate both static dimensions and dynamic fitment, guaranteeing molds function as intended during the plastic injection process to minimize prototype iterations.

The following table details our standard and precision tolerance capabilities for critical mold features. Achievable tolerances depend on part geometry, material, and feature size; our engineering team collaborates closely with clients to define realistic targets for each prototype project.

| Feature Type | Standard Tolerance | Precision Tolerance | Measurement Method |

|---|---|---|---|

| Cavity/Core Dimensions | ±0.025 mm | ±0.005 mm | CMM |

| Parting Line Match | ±0.010 mm | ±0.003 mm | CMM/Height Gauge |

| Core Pin Diameters | ±0.010 mm | ±0.002 mm | CMM/Optical Comparator |

| Slider Alignment | ±0.020 mm | ±0.005 mm | CMM |

| Surface Finish (Ra) | 0.8 µm | 0.2 µm | Profilometer |

Our integrated process—from material selection and 5-axis machining to CMM-certified inspection—ensures molds consistently achieve the dimensional stability and surface quality required for defect-free plastic prototypes. This precision directly translates to reduced scrap rates, faster cycle validation, and accelerated time-to-market for your plastic components. Partner with Wuxi Lead to transform your prototype injection molding concepts into physically validated realities with engineering-grade accuracy.

Material & Finish Options

Material Selection for Prototype Plastic Injection Molding in Custom Metal Manufacturing

In the domain of prototype plastic injection molding, the selection of mold material is a critical determinant of both part quality and production efficiency. At Wuxi Lead Precision Machinery, we emphasize precision-driven material choices that align with project timelines, volume requirements, and part complexity. While the final product may be plastic, the mold—typically crafted from metal—dictates dimensional accuracy, surface finish, and durability. Aluminum, steel, and titanium represent the primary material options, each offering distinct advantages depending on application demands.

Aluminum is widely favored for prototyping due to its excellent machinability and rapid turnaround. It allows for faster mold fabrication, making it ideal for low-volume production or design validation. Its thermal conductivity supports efficient cooling, reducing cycle times during testing phases. However, aluminum’s lower hardness limits its use in extended production runs, especially with abrasive resins.

Steel, particularly tool steels like P20 or H13, delivers superior hardness and wear resistance. This makes it the preferred choice for high-volume prototyping or bridge tooling that mimics full-scale production conditions. While machining steel molds requires more time and precision, the extended service life and ability to maintain tight tolerances justify the investment for medium to high-volume applications.

Titanium, though less common in mold construction, offers exceptional strength-to-density ratio and corrosion resistance. Its application is typically reserved for specialized environments where weight reduction or resistance to aggressive processing conditions is paramount. However, higher material and machining costs limit its use to niche industrial or aerospace-related prototypes.

Surface finishing, particularly anodizing, plays a vital role in enhancing mold performance. Anodizing increases surface hardness and improves wear and corrosion resistance—especially beneficial for aluminum molds. Type II (sulfuric acid) anodizing is commonly applied to achieve a protective oxide layer, while Type III (hardcoat anodizing) offers greater thickness and durability for demanding applications. Anodized surfaces also facilitate mold release, reducing maintenance frequency and improving part consistency.

Below is a comparative overview of key material properties relevant to prototype injection molding:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Anodizing Compatibility |

|---|---|---|---|---|

| Aluminum (7075-T6) | 40–45 | 130 | Low-volume prototyping, rapid tooling | Excellent (Type II & III) |

| Steel (P20) | 28–32 | 28–36 | Medium to high-volume prototyping, bridge tooling | Limited (not typically anodized) |

| Steel (H13) | 45–50 | 25–30 | High-stress, high-temperature molding | Limited |

| Titanium (Grade 5) | 35–40 | 6–7 | Specialized, corrosion-resistant molds | Possible (thin oxide layer) |

At Wuxi Lead Precision Machinery, we integrate material science with precision engineering to deliver molds that meet exacting prototype requirements. Our expertise ensures optimal material and finish selection, balancing performance, cost, and lead time for every client’s unique manufacturing challenge.

Manufacturing Process & QC

Precision Plastic Injection Molding: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery we engineer the critical metal tooling foundation for high-integrity plastic injection molding. Our process rigorously bridges design intent to flawless mass production ensuring dimensional conformance and material performance meet exacting industrial standards. This disciplined approach eliminates costly iterations and field failures.

The journey begins with collaborative Design for Manufacturability DFM analysis. Our engineers scrutinize 3D CAD models identifying potential sink marks warpage or ejection challenges early. We simulate melt flow cooling rates and fiber orientation using Moldflow software validating structural integrity before metal is cut. This phase establishes precise gate locations optimal wall transitions and robust cooling channel layouts directly influencing final part quality and cycle time efficiency. Client design intent is preserved while embedding manufacturability.

Prototyping transitions validated designs into physical reality using production-intent steel molds machined to tight tolerances. This stage is not merely about form fit function but rigorous process window validation. We systematically document critical parameters ensuring repeatability before scaling. Key validation metrics include:

| Parameter | Standard Tolerance | Validation Method |

|---|---|---|

| Dimensional Accuracy | ±0.025 mm | CMM Measurement |

| Cavity Pressure | ±5 bar | In-Mold Sensors |

| Cooling Time | ±0.5 sec | Thermal Imaging |

| Shot Weight Consistency | ±0.1% | Gravimetric Analysis |

| Surface Finish | Ra 0.8 µm | Profilometry |

Mass production leverages this validated foundation deploying closed-loop Zero Defects systems. Real-time monitoring tracks cavity pressure temperature and clamp force against the established golden parameters. Statistical Process Control SPC charts detect micro-variations before they manifest as defects. Automated vision systems inspect 100% of critical features verifying dimensions and surface integrity. Our hardened P20 or H13 steel molds maintain thermal stability within ±0.5°C throughout extended runs ensuring consistent part geometry. Tooling maintenance protocols based on actual cycle counts prevent degradation related to wear or thermal fatigue.

Zero Defects is achieved through systemic prevention not post-production sorting. Every process variable from material drying to injection speed is controlled within scientifically determined limits. Traceability links each component to specific machine settings and raw material batches enabling rapid root cause analysis should anomalies occur. This integrated methodology transforms prototyping insights into predictable high-yield manufacturing eliminating scrap rework and supply chain disruption for our clients demanding uncompromised quality in aerospace medical and automotive applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Prototype Plastic Injection Molding

At Wuxi Lead Precision Machinery, we understand that precision, speed, and reliability are non-negotiable in today’s competitive manufacturing landscape. As a leading provider of custom metal manufacturing solutions based in China, we specialize in delivering high-accuracy prototype plastic injection molding services tailored to the exacting demands of global industries. Whether you are developing a medical device, automotive component, or consumer electronics housing, our engineering-driven approach ensures your prototype transitions seamlessly from concept to physical reality with minimal lead time and maximum repeatability.

Our state-of-the-art facilities integrate advanced CNC machining, mold design, and injection molding technologies, enabling us to produce high-fidelity prototypes that reflect the performance and aesthetics of final production parts. We utilize premium-grade steels and advanced simulation software to optimize mold flow, cooling, and part ejection—ensuring that every prototype meets stringent dimensional tolerances and surface finish requirements. Our team of experienced engineers works closely with clients throughout the development cycle, offering design for manufacturability (DFM) feedback, material selection guidance, and rapid iteration support to accelerate time-to-market.

What sets Wuxi Lead Precision Machinery apart is our commitment to transparency, quality, and partnership. We treat every project as a collaborative effort, providing real-time updates, detailed inspection reports, and full documentation to ensure complete traceability. Our ISO 9001-certified processes and in-house tooling capabilities allow us to maintain strict control over every phase of production, from initial mold fabrication to final part delivery.

Below are the key technical specifications we support for prototype plastic injection molding:

| Specification | Capability |

|---|---|

| Clamping Force Range | 50 to 1,200 tons |

| Shot Weight | Up to 1,500 grams |

| Tolerance | ±0.02 mm typical |

| Surface Finish | SPI A1, A2, B1, B2, VDI 3400, textured, polished |

| Materials | ABS, PC, PP, PA (Nylon), POM, PMMA, PBT, PEI, and medical-grade resins |

| Mold Steel | P20, 718H, 2738, S136, H13, 420 stainless |

| Lead Time (Prototype Mold) | 15 to 25 days, depending on complexity |

| Prototype Quantity | 10 to 10,000 pieces per run |

| Secondary Operations | Ultrasonic welding, insert molding, painting, laser marking, assembly |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally focused on innovation, precision, and long-term success. We are equipped to support low-volume prototyping and bridge production, ensuring your design is validated under real-world conditions before committing to full-scale tooling.

For expert guidance and a seamless prototyping experience, contact us today at [email protected]. Let us help you turn your vision into a high-performance reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.