Technical Contents

Engineering Guide: Ultem Injection Molding

Engineering Insight: ULTEM Injection Molding and the Critical Role of Precision

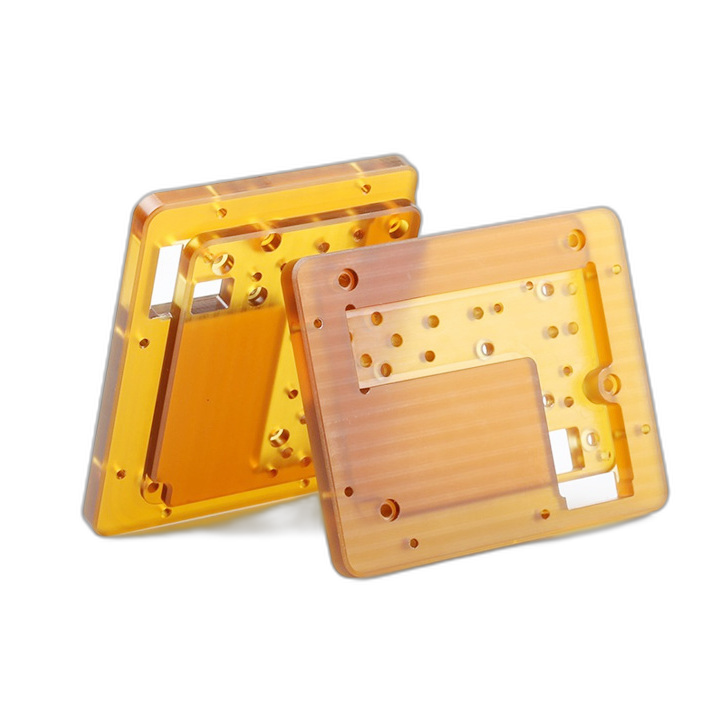

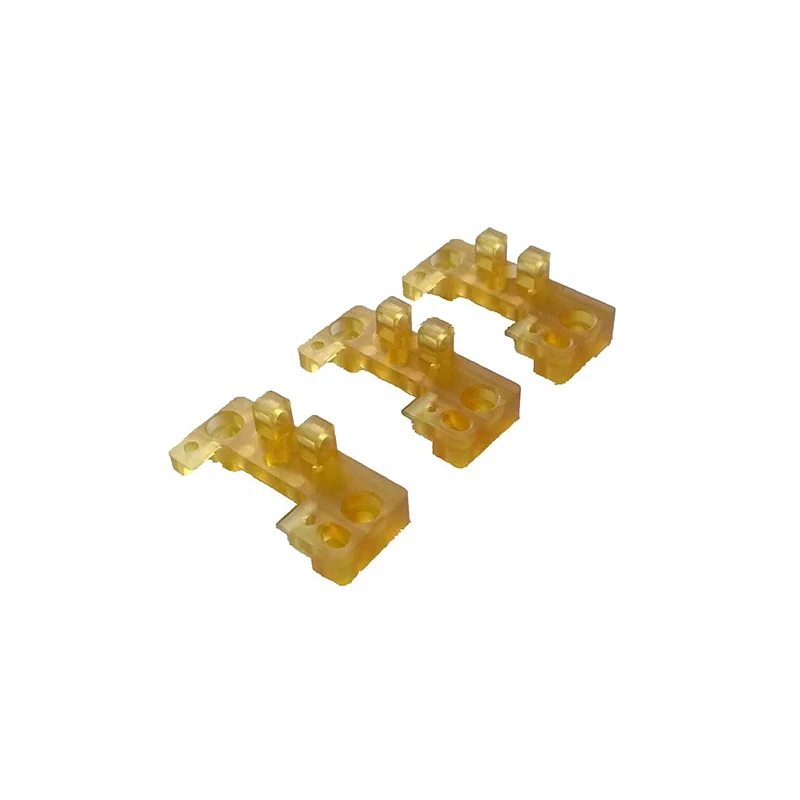

ULTEM injection molding represents one of the most demanding processes in high-performance thermoplastic manufacturing. As a polyetherimide (PEI) resin, ULTEM offers exceptional thermal stability, mechanical strength, and inherent flame resistance, making it a material of choice in aerospace, medical, defense, and semiconductor industries. However, these advantages are only fully realized when the injection molding process is executed with extreme precision. At Wuxi Lead Precision Machinery, we understand that success in ULTEM molding is not simply about material selection—it is about mastering the interplay of temperature, pressure, tooling accuracy, and cycle control.

The challenges of ULTEM injection molding stem from its high processing temperatures—typically between 340°C and 400°C—and its sensitivity to thermal gradients. Any inconsistency in mold temperature or cooling rates can lead to internal stresses, warpage, or compromised mechanical properties. This requires tooling systems capable of maintaining tight thermal uniformity and structural integrity under prolonged thermal cycling. Our experience in custom metal manufacturing, particularly in tooling for high-reliability applications, has positioned us to deliver molds that meet these exacting demands.

Precision in ULTEM molding extends beyond temperature control. Dimensional accuracy is paramount, especially when components are designed for tight-fitting assemblies in mission-critical systems. At Lead Precision, we utilize CNC-machined steel molds with tolerances held within ±0.005 mm, ensuring repeatability across production runs. Our in-house quality assurance systems, including CMM (Coordinate Measuring Machine) inspection and thermal imaging analysis, validate both mold performance and final part conformity.

Our engineering team brings proven expertise from projects serving Olympic-standard equipment manufacturers and military-grade defense systems. These applications demand zero-defect performance under extreme conditions—requirements that mirror the expectations of ULTEM-based components. This background informs our approach to mold design, material selection, and process validation, ensuring that every ULTEM part we produce meets the highest benchmarks for reliability and consistency.

The following table outlines key specifications and capabilities relevant to ULTEM injection molding at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Compatibility | ULTEM (PEI) grades 1000, 2300, 9000, HU1000 |

| Mold Temperature Range | 170°C – 190°C (controlled) |

| Melt Temperature | 340°C – 400°C |

| Tooling Material | H13, S136, or 420 Stainless Pre-Hardened Steel |

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish Options | SPI A1, A2, B1, B2, or Custom Microtexture |

| Production Capacity | Prototype to High-Volume Runs |

| Quality Standards | ISO 9001:2015, PPAP, FAI, Full Traceability |

In high-end manufacturing, ULTEM is not just a material—it is a performance commitment. At Wuxi Lead Precision Machinery, we engineer that commitment into every mold and every part.

Precision Specs & Tolerances

Technical Capabilities for Ultem Injection Molding Tooling

Wuxi Lead Precision Machinery delivers mission-critical metal tooling solutions engineered specifically for high-performance Ultem (PEI) injection molding applications. Our expertise bridges precision metal manufacturing and the demanding thermal and mechanical requirements of Ultem processing. We recognize that Ultem’s low thermal conductivity, high processing temperatures (340–420°C), and inherent shrinkage characteristics demand exceptional mold stability and dimensional control—challenges met through our integrated technical infrastructure.

Our core capability centers on 5-axis CNC machining using DMG MORI and Hermle platforms, equipped with high-frequency spindles and integrated tool measurement systems. This technology enables single-setup machining of complex cavity/core geometries, critical for minimizing parting line mismatches and ejector pin wear in Ultem molds. Simultaneous 5-axis interpolation ensures precise undercuts and conformal cooling channels, directly addressing Ultem’s tendency toward warpage and sink marks by optimizing thermal management within the tool. All machining operations adhere to strict thermal stability protocols, including controlled shop environments (20±0.5°C) and in-process thermal compensation routines to counteract material drift during extended cycles.

Quality assurance is anchored by Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with VAST XT gold sensors and Calypso software. Every mold undergoes full geometric dimensioning and tolerancing (GD&T) validation against CAD models, with particular focus on critical Ultem-specific features: gate geometries, vent depths, and cooling circuit alignment. Our CMM workflow includes thermal soak testing—molds are measured at both ambient and simulated operating temperatures (up to 180°C) to validate performance under real-world conditions. This proactive approach mitigates field failures caused by coefficient of thermal expansion (CTE) mismatches between mold steel and Ultem resin.

The following table details our achievable tolerances for Ultem injection molds, reflecting both standard industry benchmarks and our optimized processes for high-temperature polymers:

| Feature Type | Standard Tolerance | Ultem-Optimized Tolerance | Measurement Method |

|---|---|---|---|

| Cavity/Core Match | ±0.025 mm | ±0.010 mm | CMM at 20°C & 120°C |

| Parting Line Flatness | 0.02 mm/m | 0.008 mm/m | Laser interferometer |

| Cooling Channel Pos. | ±0.05 mm | ±0.02 mm | CMM with articulated probe |

| Gate Diameter | ±0.01 mm | ±0.005 mm | Optical comparator |

| Ejector Pin Clearance | +0.01/-0.00 mm | +0.005/-0.00 mm | Air gaging |

These specifications are validated through our ISO 17025-accredited metrology lab, with full traceability to NIST standards. We further support Ultem projects with material science consultation—leveraging decades of experience with H13, S136, and maraging steels—to optimize mold longevity against Ultem’s abrasive fillers and corrosive degradation byproducts. By integrating advanced metal fabrication with polymer-specific process intelligence, Wuxi Lead ensures molds achieve >500,000 cycles while maintaining Ultem’s stringent aerospace and medical part requirements. Partner with us to transform Ultem’s processing challenges into production advantages.

Material & Finish Options

Material Selection for Ultimaker Injection Molding: Precision Engineering with Aluminum, Steel, and Titanium

In high-performance Ultimaker injection molding applications, material selection is critical to ensuring long-term durability, dimensional accuracy, and thermal efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for advanced molding systems, leveraging aluminum, steel, and titanium based on operational demands. Each material offers distinct mechanical and thermal properties that directly influence mold life, cycle time, and part quality.

Aluminum alloys, particularly 7075 and 6061-T6, are widely used for prototyping and low-to-medium volume production. Their high thermal conductivity allows for faster cooling cycles, reducing overall production time. Aluminum is also easier to machine, enabling complex mold geometries with tight tolerances. However, its lower hardness compared to steel makes it less suitable for high-wear applications or corrosive environments unless enhanced with surface treatments such as hard anodizing.

Steel, especially tool steels like H13, P20, and S136, remains the standard for high-volume injection molding. These grades provide exceptional hardness, wear resistance, and thermal stability under repeated cycling. H13, for example, excels in hot-work environments due to its resistance to thermal fatigue, making it ideal for molds subjected to high injection pressures and temperatures. While steel molds have longer lead times and higher machining costs, their extended service life and dimensional stability justify the investment for large-scale production.

Titanium alloys, such as Ti-6Al-4V, are selected for specialized applications requiring extreme strength-to-density ratios and corrosion resistance. Though rarely used for full mold bodies due to cost and machinability challenges, titanium is often integrated into critical mold components like ejector pins or core inserts where weight reduction and longevity are paramount. Its biocompatibility and inertness also make it suitable for medical-grade molding operations.

Surface finishing plays a pivotal role in mold performance and part ejection. Anodizing, particularly Type III (hard anodizing), is a preferred finish for aluminum molds. This electrochemical process creates a dense, wear-resistant oxide layer that enhances surface hardness up to 60 HRC, improves corrosion resistance, and reduces friction. For steel molds, alternatives such as nitriding or chrome plating are more common, though polished or textured surfaces may be applied depending on the desired part finish.

The table below summarizes key mechanical and thermal properties of the primary materials used in Ultimaker injection mold fabrication.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 40–45 (anodized) | 570 | 130 | Prototype & medium-volume molds |

| Steel H13 | 48–52 | 1,700 | 35 | High-pressure, high-temperature molds |

| Steel P20 | 28–32 | 900 | 30 | Large cavity molds, pre-hardened |

| Titanium Ti-6Al-4V | 36–41 | 950 | 7 | High-strength, lightweight inserts |

Selecting the optimal material and finish requires a comprehensive understanding of production volume, part complexity, and environmental conditions. At Wuxi Lead Precision Machinery, we support clients in making informed decisions backed by precision engineering and decades of custom manufacturing expertise.

Manufacturing Process & QC

Ultem Injection Molding: Precision Execution from Design to Zero-Defect Production

Ultem (PEI) injection molding demands exceptional process control due to the material’s high-performance characteristics and stringent end-use requirements in aerospace, medical, and semiconductor applications. At Wuxi Lead Precision Machinery, our integrated workflow ensures dimensional accuracy, material integrity, and absolute compliance from initial concept through high-volume manufacturing. This disciplined approach eliminates costly iterations and guarantees first-article approval.

The process begins with rigorous Design for Manufacturing (DFM) analysis. Our engineering team collaborates closely with clients to optimize part geometry, gate placement, and cooling channel design specifically for Ultem’s high melt viscosity and thermal stability. Finite Element Analysis (FEA) simulates filling, packing, and cooling phases to preempt warpage or residual stress. Material selection is critical; we validate Ultem grades (e.g., PEI 1000, 2300) against thermal, chemical, and regulatory requirements early, ensuring compatibility with sterilization or extreme environments. This phase establishes the foundation for defect prevention by addressing manufacturability before tooling commences.

Prototyping leverages our high-precision, temperature-stable molds and advanced monitoring systems. Short-run production on production-intent machinery validates the DFM outcomes under real processing conditions. We measure critical dimensions, mechanical properties, and surface finish against aerospace or medical standards (e.g., ASTM D638, ISO 10993). Real-time cavity pressure and temperature data identify micro-variation risks. Only when prototypes consistently meet all specifications—verified through our in-house metrology lab—do we transition to mass production. This stage is non-negotiable for mitigating scale-up risks.

Mass production executes under our Zero Defects protocol. Every molding cycle is governed by tightly controlled parameters monitored via integrated sensors and Statistical Process Control (SPC). Automated vision systems inspect 100% of critical features, while in-line rheology checks ensure material consistency. Our cleanroom-compliant facilities (ISO Class 7/8 optional) eliminate particulate contamination. Continuous feedback loops adjust for ambient fluctuations, and full traceability—from raw material lot to finished part—supports rapid root-cause analysis. This closed-loop system sustains CpK >1.67, ensuring every Ultem component meets the exacting demands of mission-critical applications.

Critical Process Parameters for Ultem PEI 1000 are strictly maintained as follows:

| Parameter | Target Range | Tolerance Control |

|---|---|---|

| Melt Temperature | 340°C – 380°C | ± 3°C |

| Mold Temperature | 170°C – 190°C | ± 2°C |

| Drying Conditions | 150°C for 3-4 hours | Dew Point < -40°C |

| Injection Pressure | 80 – 120 MPa | ± 5 MPa |

Wuxi Lead’s end-to-end ownership of the Ultem molding process—from material science expertise to closed-loop production—translates complex engineering requirements into flawless, repeatable output. We deliver not just parts, but certified performance assurance for your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Ultimate Performance in Ultem Injection Molding

At Wuxi Lead Precision Machinery, we specialize in high-precision custom metal manufacturing engineered to meet the rigorous demands of advanced polymer processing—specifically Ultem (PEI) injection molding. Ultem is a high-performance thermoplastic known for its exceptional thermal stability, mechanical strength, and resistance to chemicals and flame. Successfully molding Ultem requires more than standard equipment—it demands precision-engineered tooling, temperature-controlled systems, and deep material science expertise. That’s where we deliver unmatched value.

Our engineering team at Lead Precision combines decades of experience in mold design, CNC machining, and thermal management systems to develop custom solutions tailored to your Ultem production requirements. Whether you’re manufacturing aerospace components, medical devices, or electrical insulators, our molds ensure dimensional accuracy, repeatable cycle times, and long service life under high-temperature processing conditions.

We understand that Ultem’s processing window is narrow and challenging. Molding temperatures typically exceed 340°C, and improper mold design or material selection can lead to warpage, poor surface finish, or premature tool failure. To address this, we utilize high-grade tool steels such as H13 and S136, apply advanced surface treatments like PVD coating, and integrate optimized heating and cooling channels to maintain thermal uniformity. Every mold we produce undergoes rigorous quality inspection using CMM and thermal imaging to ensure it performs flawlessly under real-world conditions.

Our commitment extends beyond tooling. We offer full project lifecycle support—from initial design consultation and finite element analysis (FEA) simulations to prototyping, validation, and ongoing maintenance. This holistic approach minimizes downtime, reduces scrap rates, and accelerates time-to-market for your critical components.

Below are key technical specifications that define our Ultem injection molding capabilities:

| Specification | Detail |

|---|---|

| Maximum Mold Size | 1200 mm × 800 mm × 800 mm |

| Tolerance Range | ±0.005 mm |

| Tool Steel Options | H13, S136, 1.2344, 1.2738 |

| Surface Treatments | PVD, Nitriding, Electroless Nickel Plating |

| Processing Temperature Support | Up to 400°C |

| Cooling System Design | Conformal Cooling, Dual-Zone Control |

| Lead Time (Standard Mold) | 25–35 days |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical-grade) |

Partnering with Wuxi Lead Precision Machinery means aligning with a manufacturer that treats your production challenges as our own. We don’t just build molds—we engineer performance, reliability, and efficiency into every component we deliver.

For expert support in Ultem injection molding tooling and custom metal manufacturing, contact us today at [email protected]. Let our team help you achieve superior part quality, reduced cycle times, and long-term cost savings.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.