Technical Contents

Engineering Guide: F Molding

Engineering Insight: The Critical Role of Precision in f Molding

In the realm of custom metal manufacturing, f molding stands as a specialized process that demands uncompromising precision, advanced tooling, and deep engineering expertise. At Wuxi Lead Precision Machinery, we define f molding not merely as a production technique but as a convergence of metallurgical science, dimensional accuracy, and process control. This level of sophistication is essential when serving high-stakes industries such as aerospace, defense, and high-performance infrastructure, where component failure is not an option.

f molding involves the precise shaping of metal alloys under controlled thermal and mechanical conditions to achieve complex geometries with consistent microstructural integrity. The success of this process hinges on micron-level tolerances, uniform material density, and repeatable cycle control. Even minor deviations in temperature, pressure, or cooling rates can result in internal porosity, warping, or reduced fatigue resistance—defects that are unacceptable in mission-critical applications.

Our experience at Wuxi Lead Precision Machinery spans over two decades of delivering f molding solutions for projects requiring the highest standards of quality and reliability. Notably, our components have been integrated into systems used in Olympic-grade sporting infrastructure, where performance consistency under dynamic loads is paramount. Additionally, we have supported military-grade equipment manufacturing, where environmental resilience and long-term durability are non-negotiable. These achievements underscore our capability to meet and exceed the rigorous demands of precision-driven sectors.

What sets our f molding process apart is our vertically integrated production ecosystem. From in-house alloy analysis and mold design to real-time process monitoring and post-production metrology, every stage is engineered for repeatability and traceability. We employ closed-loop feedback systems that continuously adjust parameters during molding cycles, ensuring that each component conforms to exact specifications. Furthermore, our cleanroom-class molding environments minimize contamination risks, preserving material purity and surface integrity.

The following table outlines key technical specifications that define our f molding capabilities:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.01 mm |

| Surface Finish (Ra) | 0.4 – 1.6 µm |

| Alloy Compatibility | Titanium, Inconel, Stainless Steel, Aluminum Alloys |

| Max Part Weight | 25 kg |

| Tooling Lifespan | >50,000 cycles (hardened steel molds) |

| Process Control System | Real-time CNC & IoT-enabled monitoring |

| Post-Processing Options | CNC Machining, Heat Treatment, Passivation |

At Wuxi Lead Precision Machinery, we recognize that precision in f molding is not an incremental advantage—it is the foundation of performance, safety, and trust. Our proven track record in elite engineering applications reflects our commitment to delivering components that perform flawlessly, every time. For OEMs and system integrators operating at the edge of technological possibility, precision is not optional. It is engineered.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Molding Applications

Wuxi Lead Precision Machinery delivers uncompromising precision for critical metal components within high-performance molding systems. Our engineering-centric approach integrates advanced multi-axis machining with rigorous metrology to ensure every part meets the exacting demands of injection, blow, and compression molding applications where thermal stability, wear resistance, and micron-level accuracy are non-negotiable. We specialize in manufacturing complex cores, cavities, inserts, and structural mold components from hardened tool steels, stainless alloys, and specialty metals, transforming design intent into dimensionally perfect reality.

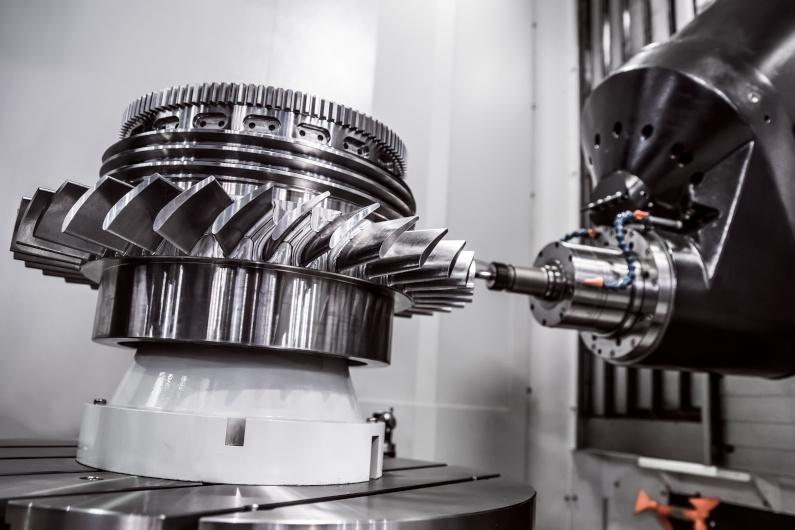

Our foundation lies in a modern fleet of 5-axis CNC machining centers, enabling the production of geometrically intricate features in a single setup. This capability eliminates cumulative errors inherent in multi-setup processes, critical for maintaining tight positional tolerances across complex mold geometries. Simultaneous 5-axis motion allows for optimal tool engagement and access to deep pockets and undercuts, ensuring superior surface integrity and reducing secondary operations. All machining processes utilize high-rigidity machines with thermal compensation systems, operating under strict environmental controls to minimize thermal drift during extended production runs. Material optimization strategies are applied to maximize component lifespan under high-cycle molding conditions.

Quality assurance is embedded at every stage, not merely a final checkpoint. Comprehensive CMM inspection is performed using calibrated Zeiss and Hexagon systems, providing full 3D geometric verification against CAD models. Our inspection protocols adhere to ISO 10360 standards, with all measurements traceable to NIST standards through accredited calibration chains. Critical features undergo 100% inspection, while statistical process control monitors key parameters across production batches. Surface finish analysis via profilometry ensures compliance with specified roughness values essential for part release and surface aesthetics in the final molded product. Material certifications and heat treatment verification are standard documentation components.

The following table details our standard achievable tolerances for critical molding components, reflecting our commitment to repeatability in serial production environments. These values represent typical capabilities for hardened tool steels (HRC 48-52) and stainless alloys; specific project requirements may allow for tighter control.

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM |

| Geometric Position | ±0.015 mm | ±0.008 mm | CMM |

| Flatness | 0.010 mm / 100 mm | 0.005 mm / 100 mm | CMM / Optical Flat |

| Cylindricity | 0.012 mm | 0.006 mm | CMM |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

This precision engineering capability directly translates to reduced mold tryout cycles, extended tool life, and consistent part quality for our clients. By controlling tolerances at the source through integrated CNC and metrology excellence, Wuxi Lead ensures your molding systems perform reliably at peak efficiency, minimizing downtime and maximizing output value in the most demanding production environments. Our technical team collaborates closely with your design engineers to validate manufacturability and optimize component performance from prototype through full-scale production.

Material & Finish Options

Material Selection for High-Precision F Molding Applications

In high-end manufacturing processes such as F molding, material selection plays a pivotal role in determining the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced CNC technologies to deliver precision-engineered parts tailored to demanding industrial applications. The choice between aluminum, steel, and titanium must be guided by mechanical requirements, environmental exposure, weight constraints, and surface finish needs.

Aluminum is widely favored in F molding due to its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly suitable for aerospace, automotive, and consumer electronics applications where lightweight construction is critical. The 6061 and 7075 aluminum alloys are most commonly used, offering good machinability and weldability. When enhanced surface hardness and protection are required, anodizing is the preferred finish. Anodizing creates a durable, wear-resistant oxide layer that can also be dyed for aesthetic or identification purposes.

Steel remains the material of choice for applications demanding high tensile strength, structural integrity, and resistance to wear. Alloys such as 4140 and 304 stainless steel are frequently selected based on load-bearing needs and environmental conditions. While heavier than aluminum, steel provides superior durability under high-stress conditions. For corrosive environments, stainless variants offer inherent resistance, though additional coatings may be applied depending on service life expectations.

Titanium, though more costly, delivers unmatched performance in extreme conditions. Its high strength-to-density ratio, excellent corrosion resistance, and ability to withstand elevated temperatures make it ideal for aerospace, medical, and defense applications. Titanium’s low thermal expansion and biocompatibility further expand its utility in precision-critical systems. However, its machining难度 requires specialized tooling and expertise—areas where Wuxi Lead excels.

Surface finishing, particularly anodizing, significantly enhances the functional and aesthetic qualities of metal components. While primarily applied to aluminum, anodizing improves corrosion resistance, electrical insulation, and adhesion for paint primers. Type II (sulfuric acid) and Type III (hardcoat) anodizing are the most common, with the latter providing thicker, more durable coatings for industrial use.

Below is a comparative overview of key material properties relevant to F molding processes.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Alloys | Typical Applications | Suitable for Anodizing |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310–570 | 6061, 7075 | Aerospace, Electronics | Yes |

| Steel | 7.8 | 500–2000 | 4140, 304 SS | Industrial Machinery, Tools | No |

| Titanium | 4.5 | 900–1200 | Grade 5 (Ti-6Al-4V) | Medical, Defense, Aviation | Limited (specialized) |

Selecting the optimal material and finish for F molding requires a comprehensive understanding of both application demands and manufacturing capabilities. At Wuxi Lead Precision Machinery, we collaborate closely with clients to ensure material choices align with performance goals, production efficiency, and long-term reliability.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept

Our process begins with rigorous digital design validation. Using integrated CAD/CAM systems and advanced simulation software, we model every component under real-world thermal and stress conditions. This phase includes comprehensive Design for Manufacturability (DFM) analysis to eliminate geometric risks before physical production. Clients collaborate with our engineering team to optimize wall thickness, gating systems, and material flow, ensuring the design inherently supports zero-defect outcomes. Finite element analysis (FEA) predicts potential porosity or distortion, allowing preemptive correction. All specifications are cross-referenced against ISO 9001 and IATF 16949 standards, establishing a defect-proof foundation.

Prototyping: Validated Performance Before Scale

Rapid prototyping employs hardened steel tooling identical to mass production dies, not soft alloys. Each prototype undergoes full dimensional inspection via CMM and 3D scanning against CAD nominal data, with tolerances held to ±0.025 mm. Functional testing includes pressure decay checks, metallurgical analysis, and assembly validation under client-specified loads. We document every iteration in a closed-loop report, highlighting deviations and corrective actions. This phase confirms process capability indices (Cp/Cpk >1.67) and secures client sign-off on First Article Inspection (FAI) reports, ensuring the transition to volume production carries zero unresolved risks.

Mass Production: Sustained Zero-Defect Execution

Volume manufacturing leverages statistically controlled processes with real-time SPC monitoring. Our automated die casting cells feature in-cavity pressure sensors and thermal imaging to detect micro-variation in fill patterns or cooling rates. Every 15 minutes, automated vision systems inspect critical features, while X-ray fluorescence verifies material composition. All data feeds into a centralized quality dashboard, triggering immediate containment if parameters drift beyond ±1σ limits. We implement poka-yoke fixtures and automated gaging at each station, achieving Six Sigma quality (≤3.4 defects per million). Final shipment requires 100% first-pass yield validation with full traceability to melt lot and machine parameters.

Critical Process Specifications

| Parameter | Capability | Measurement Standard |

|———–|————|———————-|

| Dimensional Tolerance | ±0.025 mm | ISO 2768-mK |

| Surface Roughness | Ra 0.8 μm | ASME B46.1 |

| Material Purity | AlSi10Mg: ≤0.12% Fe | ASTM E1251 |

| Porosity Level | Class 1 (MIL-STD-2175) | ASTM E505 Level 1 |

| Production Volume Range | 1,000–500,000+ units | Client-defined |

Zero Defects: The Non-Negotiable Outcome

This phased methodology transforms theoretical quality into measurable reality. By embedding defect prevention at design, validating with production-intent tooling, and enforcing real-time statistical control, we achieve consistent zero-defect delivery. Every component ships with a digital quality passport detailing process stability data, material certs, and inspection records—providing auditable proof that precision isn’t aspirational, but engineered. For mission-critical applications, this isn’t just manufacturing; it’s risk elimination.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and innovation are non-negotiable in high-end manufacturing. As a trusted leader in custom metal fabrication, we specialize in delivering engineered solutions tailored to the exacting demands of global industries—from automotive and aerospace to medical devices and advanced automation. When you partner with us, you’re not just sourcing components—you’re gaining a strategic manufacturing ally committed to excellence at every stage.

Our integrated production ecosystem combines state-of-the-art CNC machining, multi-axis milling, precision turning, and advanced fabrication techniques with rigorous quality assurance protocols. Every process is optimized for repeatability, tight tolerance control, and material efficiency, ensuring your components meet the highest performance standards. Whether you require low-volume prototypes or high-volume production runs, our flexible manufacturing model adapts seamlessly to your project’s scale and complexity.

What sets us apart is our engineering-first approach. Our team of experienced CNC engineers and manufacturing specialists collaborates directly with your design and R&D teams to optimize part geometry, material selection, and manufacturability. We perform comprehensive Design for Manufacturing (DFM) analysis to identify potential challenges early, reduce lead times, and lower overall production costs—without compromising on quality.

All components are produced in our ISO 9001-certified facility in Wuxi, China, where cutting-edge equipment meets disciplined process control. From raw material inspection to final packaging, every step is documented and traceable, ensuring full compliance with international standards. Our commitment to continuous improvement drives innovation in tooling strategies, automation integration, and lean manufacturing practices—delivering measurable value to your supply chain.

We serve clients across North America, Europe, and Asia, earning long-term partnerships through technical transparency, on-time delivery, and uncompromising precision. When your application demands zero-defect performance, our team is ready to exceed expectations.

To begin your next project with confidence, contact us today at [email protected]. Our engineering team is available for technical consultations, quoting, and DFM reviews—ensuring your design transitions smoothly from concept to certified production. Let Wuxi Lead Precision Machinery be your trusted partner in high-performance metal manufacturing.

Key Manufacturing Capabilities

| Capability | Specification Range | Tolerance | Materials Supported |

|---|---|---|---|

| CNC Machining | 3-axis to 5-axis | ±0.005 mm | Aluminum, Stainless Steel, Titanium, Brass, Alloy Steel |

| Precision Turning | Max Diameter: 300 mm, Max Length: 600 mm | ±0.003 mm | Steel, Aluminum, Copper Alloys, Plastics |

| Milling | Work Envelope: 1200 x 800 x 600 mm | ±0.01 mm | Carbon Steel, Tool Steel, Exotic Alloys |

| Surface Finish | Ra 0.2 to Ra 3.2 µm | Controlled per ISO 1302 | All machined components |

| Quality Standards | ISO 9001:2015 Certified, Full Inspection Reporting | CMM, Optical Comparator, Caliper | First Article & Batch Inspection Available |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.