Technical Contents

Engineering Guide: Moulding Methods

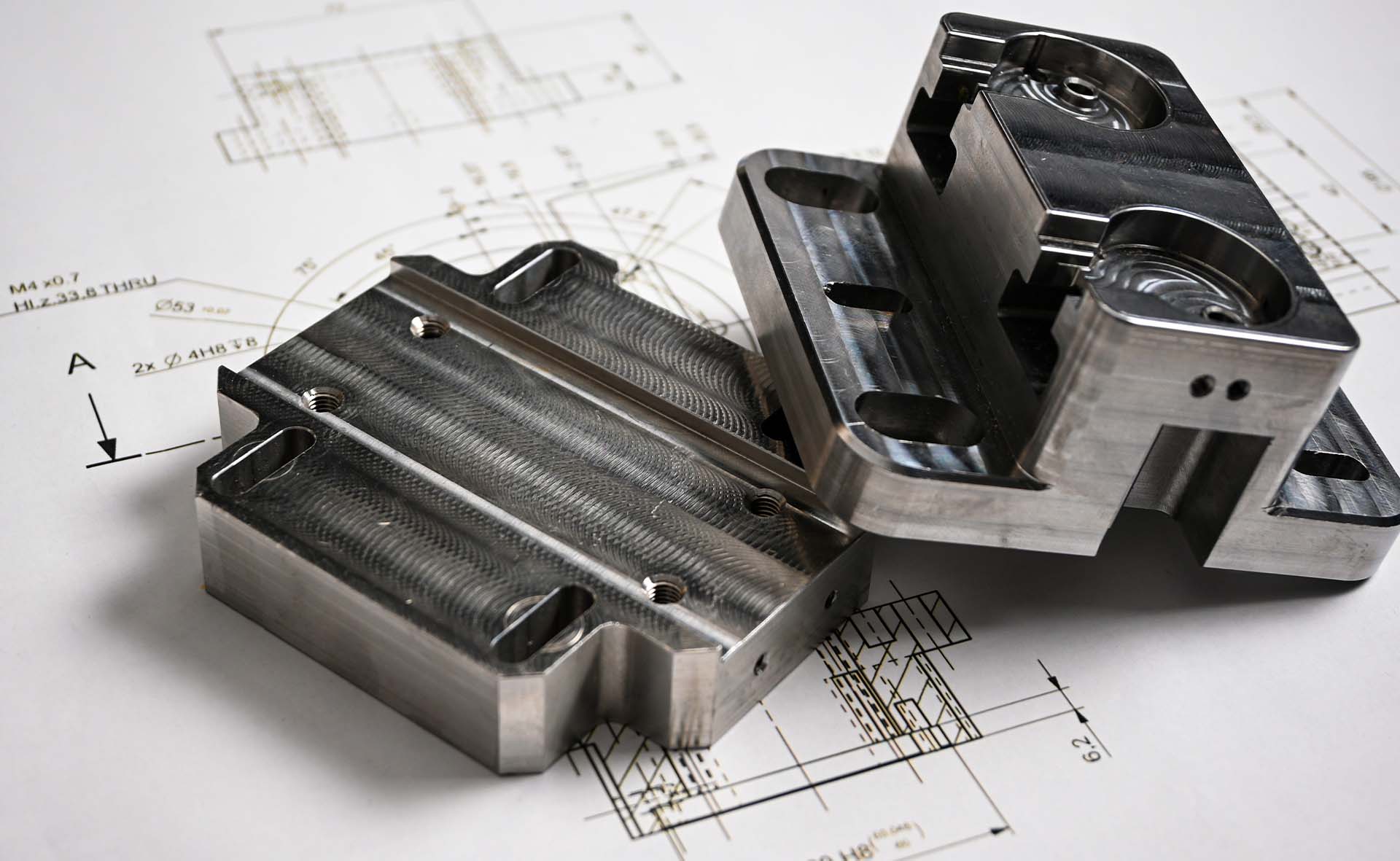

Engineering Insight Precision in Metal Moulding Methods

Achieving micron-level consistency in metal moulding is non-negotiable for mission-critical applications. In aerospace hydraulics or medical implant components, tolerances exceeding ±0.025mm induce catastrophic thermal distortion, fatigue failure, or fluid leakage. Surface finish deviations beyond Ra 0.8µm accelerate wear in high-cycle systems, directly compromising operational lifespan. Precision moulding transcends dimensional accuracy—it ensures material grain structure integrity, residual stress distribution, and geometric repeatability across production runs. At Wuxi Lead Precision Machinery, we treat every micrometer as a functional requirement, not a statistical target.

Our process control protocols originate from zero-failure mandates in defense and elite infrastructure projects. Components fabricated for Olympic venue structural systems demanded sub-5µm flatness across 2-meter spans, while military-grade actuator housings required hermetic seals under 10,000 PSI cyclic loading. These projects validated our closed-loop metrology approach: integrating in-process laser scanning with thermal compensation algorithms to neutralize ambient and tooling-induced drift. Without such rigor, even premium alloys like Inconel 718 exhibit unpredictable phase transformation during solidification, undermining fatigue resistance.

The table below compares core metal moulding methods against precision-critical benchmarks. Note how tolerance capability directly correlates with post-processing complexity and lifecycle cost:

| Method | Material Range | Tolerance Capability | Surface Finish (Ra) | Lead Precision Application Examples |

|---|---|---|---|---|

| Investment Casting | Superalloys, Ti, SS | ±0.05mm to ±0.15mm | 1.6µm to 3.2µm | Turbine blades (aerospace), surgical tools |

| High-Pressure Die Casting | Al, Mg, Zn alloys | ±0.025mm to ±0.1mm | 0.8µm to 1.6µm | EV battery housings, drone structural frames |

| Precision Forging | Ti, Ni, Steel alloys | ±0.01mm to ±0.05mm | 0.4µm to 0.8µm | Military hydraulic manifolds, satellite couplings |

Wuxi Lead’s expertise lies in selecting and optimizing the method that minimizes total cost of ownership. For instance, precision forging achieves near-net-shape tolerances for titanium aerospace fittings, eliminating 70% of CNC machining time versus investment casting—critical when producing Olympic-grade suspension components under accelerated timelines. Our MIL-STD-810G validated workflows deploy real-time X-ray porosity mapping during solidification, ensuring zero internal defects in safety-critical castings.

This precision heritage translates to client advantage: reduced scrap rates, extended service intervals, and certification readiness for AS9100 or ISO 13485 frameworks. When tolerances define reliability, moulding method selection becomes an engineering imperative—not a cost exercise. Partner with a manufacturer whose process discipline has been stress-tested where failure is unacceptable.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions through precision engineering and state-of-the-art production technologies. Our technical capabilities are anchored in high-performance 5-axis CNC machining, enabling the production of complex, high-integrity components for demanding industries such as aerospace, medical, energy, and automation. With full in-house control from design support to final inspection, we ensure every component meets the most rigorous standards for form, fit, and function.

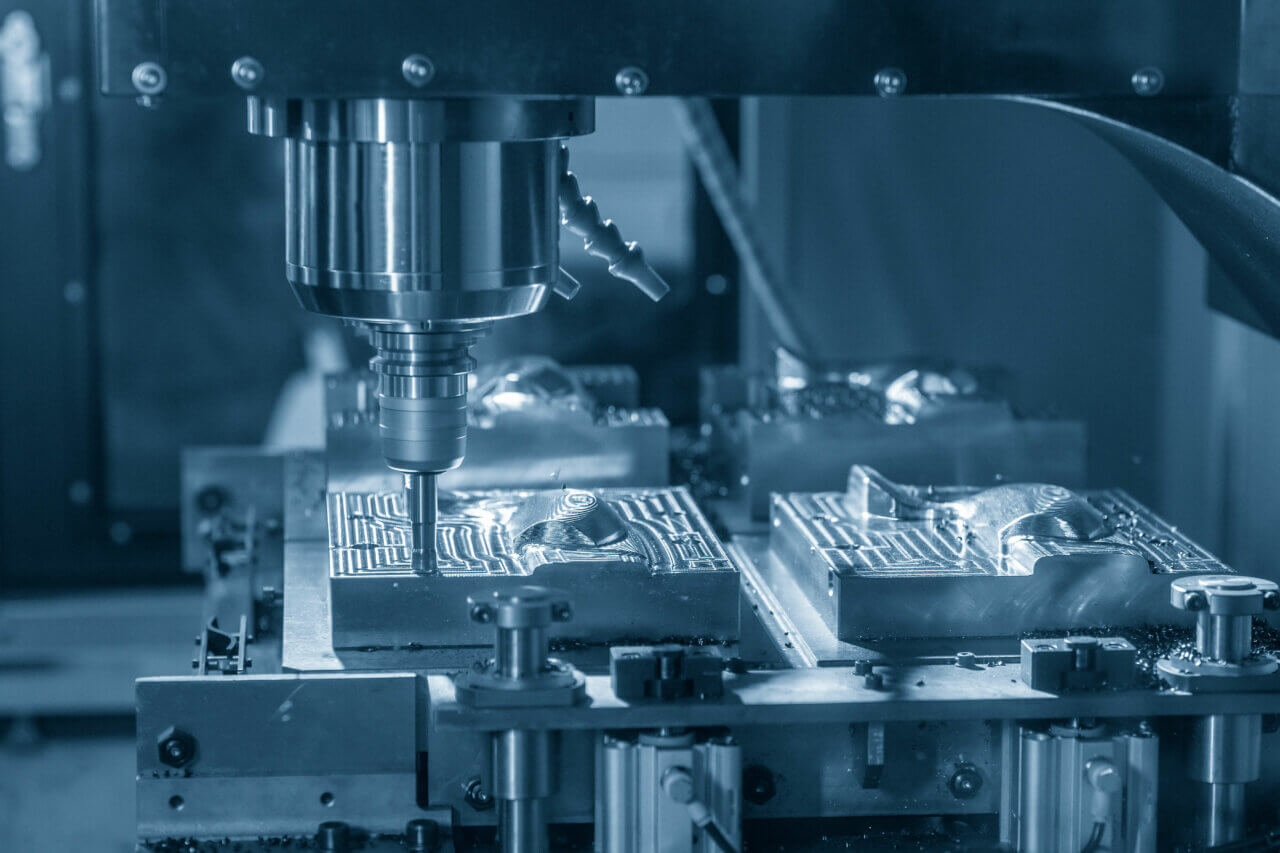

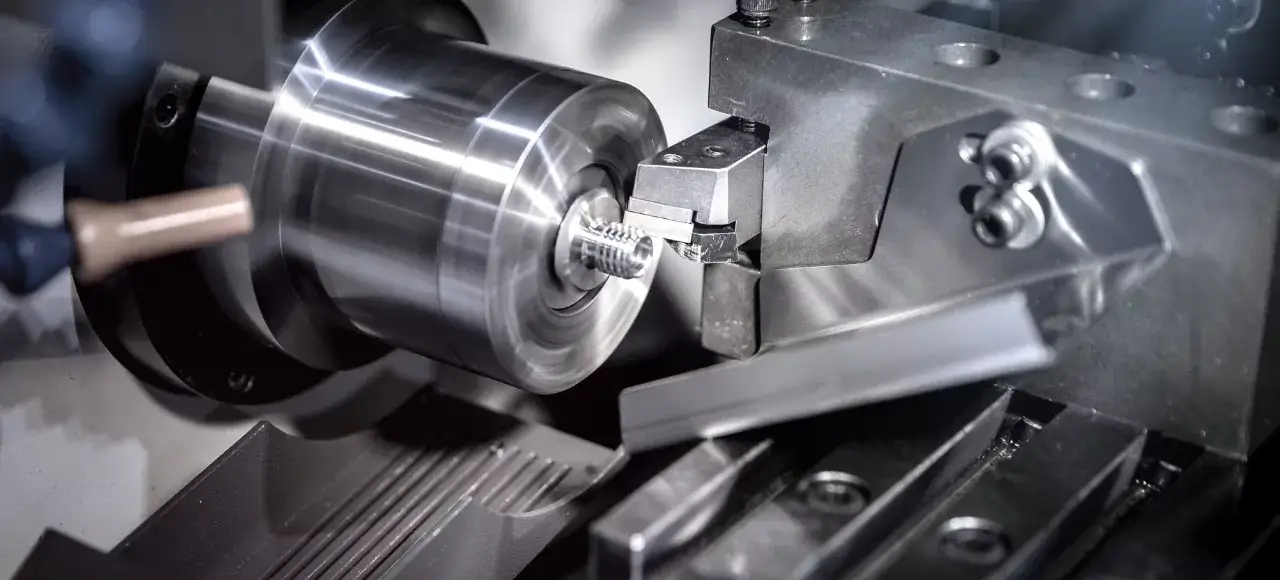

Our 5-axis CNC machining centers provide unparalleled flexibility and accuracy in metal part fabrication. By enabling simultaneous movement across five axes, these systems allow for intricate geometries and compound angles to be machined in a single setup, reducing lead times and minimizing potential for error. This capability is critical when producing high-precision molds, tooling, and functional prototypes where consistency and repeatability are paramount. We work with a wide range of engineering-grade metals, including aluminum alloys, stainless steels, titanium, and hardened tool steels, ensuring material properties align with application requirements.

Quality is integrated into every phase of production. All components undergo comprehensive dimensional verification using a Coordinate Measuring Machine (CMM), ensuring compliance with tight tolerances and geometric specifications. Our CMM inspection process is fully programmable and traceable, supporting both first-article inspection reports (FAIR) and batch-level quality documentation. This metrology-backed approach provides customers with full confidence in part accuracy and process stability.

To support design and manufacturing alignment, our engineering team collaborates closely with clients during the prototyping and production phases. We offer Design for Manufacturability (DFM) analysis to optimize part geometry, reduce machining time, and improve long-term reliability. Whether producing single prototype units or scaling to medium-volume production runs, our systems are designed for seamless transition from concept to final part.

The table below outlines the standard precision tolerances achievable across key machining parameters. These values reflect typical performance under controlled conditions and can be further tightened based on specific application needs.

| Parameter | Standard Tolerance | Typical Achievable |

|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.003 mm |

| Positional Tolerance | ±0.010 mm | ±0.005 mm |

| Angular Accuracy | ±0.005° | ±0.002° |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Geometric Tolerance (Flatness, Roundness) | 0.010 mm | 0.005 mm |

All tolerances are verified using calibrated CMM equipment with full inspection reporting available upon request. At Wuxi Lead Precision Machinery, we combine advanced 5-axis CNC technology with metrology-grade quality assurance to deliver custom metal components that meet the highest standards of precision and performance.

Material & Finish Options

Material Selection for Precision Moulding: Aluminum, Steel, Titanium & Anodizing

Selecting the optimal material is foundational to successful precision moulding, directly impacting part performance, tool life, production cost, and final finish quality. At Wuxi Lead Precision Machinery, our engineering team prioritizes material properties aligned with your specific application demands, environmental conditions, and functional requirements. Understanding the distinct characteristics of Aluminum, Steel, and Titanium is critical for high-integrity components.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are renowned for their excellent strength-to-weight ratio, superior thermal and electrical conductivity, and inherent corrosion resistance. These properties make aluminum ideal for aerospace brackets, automotive heat sinks, and electronic enclosures where weight reduction and thermal management are paramount. Its high machinability allows for complex geometries and tight tolerances at efficient production rates, significantly reducing cycle times compared to harder metals. Aluminum readily accepts various finishes, with anodizing being the industry standard for enhanced surface durability and aesthetics.

Steel, especially tool steels like H13 or P20 and stainless grades such as 304 and 17-4 PH, delivers exceptional hardness, wear resistance, and structural strength at elevated temperatures. This makes steel indispensable for high-volume production moulds, structural components requiring extreme load-bearing capacity, and parts operating in harsh, high-wear environments like hydraulic systems or industrial machinery frames. While machining steel requires more robust tooling and slower parameters than aluminum, its longevity in demanding applications often justifies the initial investment. Post-machining treatments like nitriding or passivation are common for corrosion resistance.

Titanium alloys, primarily Grade 5 (Ti-6Al-4V), offer an unparalleled combination of high strength, extremely low density, and outstanding corrosion resistance, particularly in saline or chemical environments. Its biocompatibility makes it essential for medical implants and aerospace critical components. However, titanium presents significant machining challenges due to its low thermal conductivity, high chemical reactivity leading to tool adhesion, and tendency for work hardening. Specialized toolpaths, rigid setups, and controlled feeds/speeds are mandatory, requiring the expertise Wuxi Lead applies to maximize tool life and surface integrity.

Anodizing is the premier surface finishing process for aluminum components. This electrochemical conversion creates a hard, porous oxide layer integral to the base metal. Type II (Sulfuric Acid) anodizing provides good corrosion resistance and dye acceptance for color coding. Type III (Hardcoat) anodizing delivers exceptional surface hardness, wear resistance, and electrical insulation, crucial for high-abrasion applications like hydraulic pistons or firearm components. Proper pre-treatment and process control ensure consistent thickness, adhesion, and performance.

The following table summarizes key comparative properties for informed selection:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Best For Applications Requiring |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061-T6) | Good (Native/Anodized) | Excellent | Lightweight structures, heat dissipation, cost efficiency |

| Steel | 7.8 | 1000+ (4140) | Varies (Stainless High) | Moderate to Poor | High strength, wear resistance, structural integrity |

| Titanium | 4.5 | 900 (Ti-6Al-4V) | Excellent | Poor | Maximum strength/weight, extreme corrosion resistance |

Wuxi Lead Precision Machinery leverages deep material science expertise to guide your selection, ensuring the chosen alloy and finish meet your performance targets while optimizing manufacturability and total cost of ownership. Our engineers collaborate closely to translate material properties into successful, high-yield production.

Manufacturing Process & QC

Design: The Foundation of Precision Moulding

At Wuxi Lead Precision Machinery, every successful metal moulding project begins with a meticulously engineered design phase. This stage integrates advanced CAD/CAM software with deep metallurgical expertise to translate client specifications into manufacturable, high-tolerance components. Our engineering team conducts comprehensive design for manufacturability (DFM) analysis, identifying potential stress points, material flow issues, and cooling inefficiencies before any physical work begins. Finite element analysis (FEA) is employed to simulate thermal and mechanical behavior under operational conditions, ensuring structural integrity and longevity. This proactive approach minimizes risk and aligns the design with both performance requirements and production efficiency, setting the benchmark for zero-defect manufacturing.

Prototyping: Validating Performance and Precision

Once the design is finalized, we proceed to prototype development using high-precision CNC machining and low-volume moulding runs. These prototypes are not merely visual models—they are fully functional parts subjected to rigorous in-house testing protocols. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM), material hardness testing, and fit/function validation in simulated assembly environments. We collaborate closely with clients during this phase, incorporating feedback and making micro-adjustments to the mould geometry, gating systems, or ejection mechanisms as needed. This iterative validation ensures that all variables are optimized prior to full-scale production, effectively eliminating unforeseen defects and reducing time-to-market.

Mass Production: Scalable Excellence with Zero Defects

With prototype approval, we transition seamlessly into mass production using state-of-the-art die casting, stamping, and precision forging technologies. Our automated production lines are integrated with real-time monitoring systems that track critical parameters such as temperature, pressure, cycle time, and tool wear. Statistical process control (SPC) is applied continuously, enabling immediate detection and correction of deviations. Every component is inspected using both automated vision systems and manual quality checkpoints, ensuring compliance with ISO 9001 and IATF 16949 standards. Our closed-loop feedback system allows for dynamic process adjustments, maintaining consistency across batches of tens of thousands of parts.

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm – ±0.02 mm |

| Material Compatibility | Aluminum Alloys (A380, ADC12), Zinc Alloys (Zamak 3,5), Magnesium, Steel Alloys |

| Tooling Lifespan | Up to 200,000 cycles (depending on material and complexity) |

| Production Capacity | 50,000 – 500,000 units/month |

| Surface Finish | Ra 0.4 µm – 3.2 µm (custom coatings available) |

| Quality Standards | ISO 9001, IATF 16949, RoHS compliant |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers custom metal moulded components with uncompromising quality, repeatability, and performance—ensuring zero defects and total client confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision: Engineered Excellence in Metal Moulding

In high-stakes metal manufacturing, the margin for error in moulding processes is non-existent. Suboptimal tooling, inconsistent material flow, or inadequate process control directly translate to scrap, delays, and compromised component integrity. Wuxi Lead Precision Machinery exists to eliminate these risks. We are not merely a supplier; we are your strategic engineering partner, dedicated to transforming complex metal moulding challenges into validated, high-yield production realities. Our integrated approach combines deep metallurgical expertise with advanced CNC manufacturing capabilities, ensuring every mould, die, and precision component we deliver meets the exacting demands of aerospace, medical, and high-performance industrial applications. We understand that true precision begins long before the press activates – it starts with collaborative engineering focused on your specific material, geometry, and performance requirements.

Our commitment to precision is quantifiable. We leverage state-of-the-art CNC machining centers and rigorous metrology protocols to achieve tolerances and surface finishes that consistently exceed industry benchmarks. The following table details core capabilities underpinning our moulding solutions:

| Parameter | Lead Precision Capability | Typical Industry Standard |

|---|---|---|

| Linear Tolerance | ±0.005 mm | ±0.025 mm |

| Surface Roughness (Ra) | 0.2 µm | 0.8 µm |

| Material Hardness Range | Up to 60 HRC (pre-hardened tool steels) | Up to 52 HRC |

| Maximum Work Envelope | 1200 x 800 x 600 mm | 800 x 500 x 400 mm |

| Process Validation | Full GD&T reporting, CMM certification | Basic dimensional checks |

This level of control is not accidental. It stems from our vertically integrated facility in Wuxi, China, where every stage – from initial CAD/CAM programming and electrode fabrication to high-speed machining and final inspection – occurs under one roof with unwavering quality oversight. Our engineering team collaborates directly with yours during the design-for-manufacturability phase, identifying potential moulding pitfalls early and optimizing toolpaths for material efficiency and cycle time reduction. We specialize in challenging alloys including titanium, Inconel, and hardened tool steels, applying validated process parameters to ensure structural integrity and dimensional stability in the final formed part.

Choosing Wuxi Lead Precision Machinery means selecting a partner invested in your long-term success. We provide comprehensive technical documentation, proactive process monitoring, and responsive engineering support throughout the product lifecycle. Our goal is to become an extension of your manufacturing team, reducing your total cost of ownership through minimized waste, accelerated time-to-market, and guaranteed repeatability. Do not let inadequate moulding capabilities constrain your innovation or compromise your product quality. The engineering rigor and manufacturing excellence required for next-generation metal components demand a partner with proven precision.

Initiate your precision partnership today. Contact our engineering sales team directly at [email protected] to discuss your specific metal moulding project requirements. Provide your component drawings, material specifications, and volume needs. We will respond within 24 business hours with a detailed technical and commercial proposal, outlining how our capabilities align with your objectives. Elevate your manufacturing outcomes with Wuxi Lead Precision Machinery – where exacting standards meet engineered solutions.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.