Technical Contents

Engineering Guide: Cnc 5 Axes

Engineering Insight: The Critical Role of Precision in 5-Axis CNC Machining

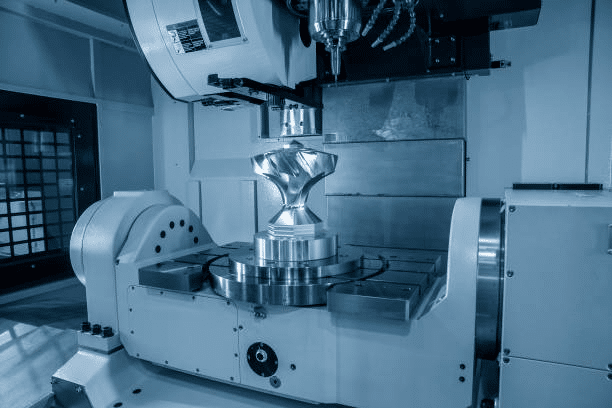

In the realm of advanced manufacturing, 5-axis CNC machining represents the pinnacle of precision engineering. Unlike conventional 3-axis systems, 5-axis machines enable tool movement across five distinct axes simultaneously—X, Y, Z, and two rotational axes (typically A and B). This capability allows for the machining of highly complex geometries with exceptional accuracy, reduced setup times, and superior surface finishes. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric—it is a foundational requirement for industries where failure is not an option.

Precision in 5-axis CNC machining directly influences part integrity, functional performance, and long-term reliability. In aerospace, defense, and high-performance automotive applications, even micrometer-level deviations can result in catastrophic system failures. Our engineering team adheres to strict tolerances—often within ±0.005 mm—to ensure every component meets or exceeds international quality standards. This level of control is achieved through advanced motion control systems, high-rigidity machine structures, and continuous in-process monitoring.

Wuxi Lead Precision Machinery has cultivated deep expertise in delivering mission-critical components for elite applications. Our machining solutions have supported projects tied to Olympic-grade equipment and military-grade systems, where performance under extreme conditions is non-negotiable. These experiences have refined our understanding of material behavior, thermal compensation, and dynamic tool path optimization—key factors in maintaining precision across extended production runs.

Our 5-axis platforms are engineered for stability and repeatability. Utilizing FANUC or Siemens CNC controls, high-torque direct-drive spindles, and real-time error correction systems, we ensure consistent output across batches. Additionally, our integrated probing systems allow for on-machine inspection, minimizing post-processing adjustments and reducing overall lead time.

Below are the technical specifications of our flagship 5-axis CNC machining center, reflecting our commitment to precision and performance.

| Specification | Detail |

|---|---|

| Axis Configuration | X, Y, Z, A (±120°), B (360° continuous) |

| Spindle Speed | 24,000 rpm (optional 30,000 rpm) |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Table Size | 600 mm × 600 mm (optional 800 mm × 800 mm) |

| Maximum Workpiece Weight | 800 kg |

| Control System | Siemens 840D Solution Line or FANUC 31i-B5 |

| Tool Magazine Capacity | 30T, 60T, or 120T (optional) |

| Rapid Traverse (X/Y/Z) | 60 / 60 / 50 m/min |

| Surface Finish Capability | Ra ≤ 0.4 µm (achievable with fine finishing passes) |

At Wuxi Lead Precision Machinery, we combine decades of technical innovation with real-world application experience to deliver 5-axis machining solutions that meet the most demanding requirements. Whether supporting national defense initiatives or enabling record-breaking athletic performance, our machines are built to perform—precisely, reliably, and consistently.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining Capabilities

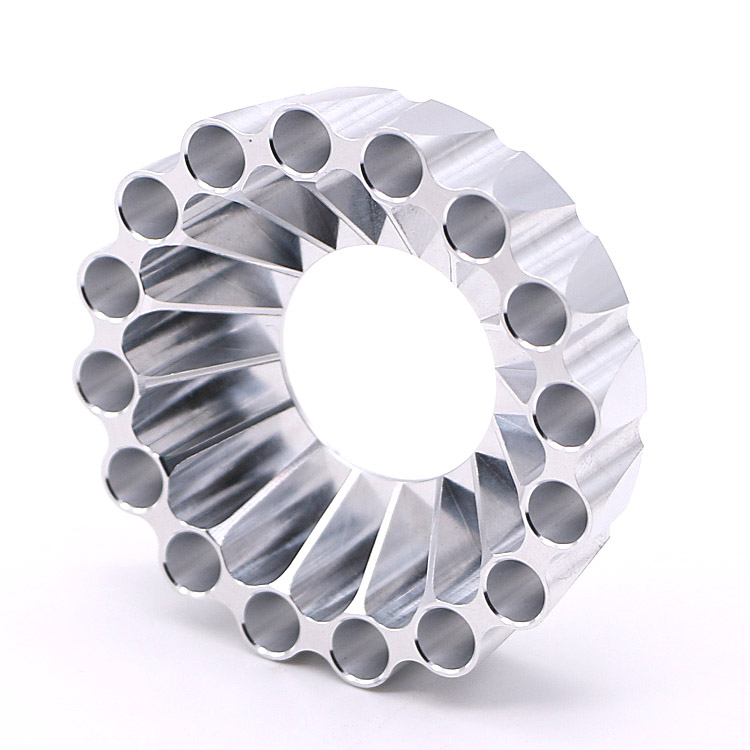

Wuxi Lead Precision Machinery delivers uncompromising precision for complex geometries through our state-of-the-art 5-axis CNC machining centers. Utilizing DMG MORI, Hermle, and Makino platforms, we achieve simultaneous multi-directional toolpath control, eliminating manual repositioning and ensuring micron-level accuracy on intricate aerospace, medical, and energy components. Our integrated approach combines high-speed machining with thermal stability management, maintaining ±0.003 mm positional repeatability across extended production runs. This capability enables the production of monolithic structural components with undercuts, deep cavities, and organic contours impossible with 3-axis systems, significantly reducing assembly requirements and enhancing part integrity.

Quality control is embedded at every stage, anchored by Zeiss CONTURA and GLOBAL S CMM systems performing full 3D dimensional verification against CAD models. Each component undergoes rigorous first-article inspection and in-process validation, with real-time SPC data analysis ensuring conformance to AS9100 and ISO 13485 standards. Our metrology lab validates critical features including GD&T callouts, surface finishes, and material properties, providing comprehensive traceability reports for every shipment. This closed-loop process guarantees that tolerances are not merely theoretical but consistently achieved in serial production.

The following table details our certified machining tolerances for critical parameters:

| Parameter | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.003 mm | CMM / Optical Comparator |

| Angular Features | ±0.005° | ±0.001° | CMM / Precision Angle Gauge |

| Positional Accuracy | ±0.008 mm | ±0.002 mm | CMM / Laser Interferometer |

| Surface Roughness | Ra 0.8 μm | Ra 0.2 μm | Profilometer |

| True Position (GD&T) | ±0.015 mm | ±0.005 mm | CMM / Vision System |

Material versatility spans titanium alloys, Inconel, aluminum 7075-T7351, PEEK, and hardened tool steels up to 65 HRC. Our engineers optimize toolpaths using hyperMILL and NX CAM software, minimizing vibration and thermal distortion while maximizing material removal rates. This technical foundation allows us to machine thin-walled structures under 0.5 mm thickness and micro-features with sub-10-micron precision—essential for fuel nozzles, implant interfaces, and satellite mechanisms.

Beyond dimensional accuracy, we prioritize process stability through predictive maintenance protocols and operator certification programs. Every machine undergoes daily laser calibration, while our ERP system tracks tool wear compensation and environmental conditions. This systematic rigor ensures that your most demanding specifications translate directly into flawless physical components, reducing scrap rates and accelerating time-to-market for mission-critical applications. Partner with Wuxi Lead to transform complex designs into reality with engineering certainty.

Material & Finish Options

Material selection is a critical factor in high-precision 5-axis CNC machining, directly influencing part performance, durability, and manufacturability. At Wuxi Lead Precision Machinery, we specialize in optimizing material choices for complex components across aerospace, medical, and industrial applications. The most commonly processed materials—aluminum, steel, and titanium—each offer distinct mechanical properties and respond uniquely to machining and finishing processes such as anodizing.

Aluminum is widely favored for its excellent strength-to-weight ratio, thermal conductivity, and machinability. Grade 6061-T6 and 7075-T6 are particularly prevalent in structural and aerospace components due to their corrosion resistance and high tensile strength. Aluminum’s low density allows for rapid material removal, making it ideal for intricate geometries achievable through 5-axis machining. However, its softness requires careful toolpath strategies to avoid burring and maintain dimensional accuracy.

Steel, particularly alloy steels like 4140 and stainless variants such as 304 and 17-4 PH, provides superior strength, wear resistance, and structural integrity under high loads. These materials are essential for tooling, hydraulic components, and medical devices requiring sterilization and long-term reliability. While more challenging to machine due to higher hardness and work hardening tendencies, modern 5-axis CNC systems equipped with high-torque spindles and advanced cooling techniques ensure precision and surface quality. Post-machining heat treatments are often applied to enhance mechanical properties.

Titanium, especially Grade 5 (Ti-6Al-4V), is the material of choice for extreme environments. Its exceptional strength-to-density ratio, corrosion resistance, and biocompatibility make it indispensable in aerospace and medical implant manufacturing. However, titanium’s low thermal conductivity and high chemical reactivity demand specialized tooling, reduced cutting speeds, and precise coolant application to prevent tool wear and maintain surface integrity. 5-axis machining excels here by minimizing setups and improving access to complex contours, reducing the risk of distortion during prolonged operations.

Surface finishing plays a vital role in part functionality and longevity. Anodizing is a key post-processing technique for aluminum components, enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat anodizing) delivers thicker, more durable coatings suitable for high-wear applications. Color options and sealing processes further customize performance and aesthetics. It is important to note that anodizing adds dimensional thickness; therefore, critical tolerances must be accounted for during the machining phase.

Below is a comparative overview of key material specifications relevant to 5-axis CNC machining:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Grades | Typical Applications | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 310–570 | 2.7 | 6061-T6, 7075-T6 | Aerospace, Enclosures | Excellent |

| Steel (Alloy) | 655–1000 | 7.8 | 4140, 4340 | Tooling, Shafts | Moderate |

| Stainless Steel | 505–1300 | 7.9 | 304, 316, 17-4 PH | Medical, Marine | Fair |

| Titanium | 900–1170 | 4.5 | Ti-6Al-4V (Gr5) | Aerospace, Implants | Poor to Moderate |

Understanding material behavior and finish requirements ensures optimal part performance and cost efficiency. At Wuxi Lead Precision Machinery, we integrate material science with advanced 5-axis CNC capabilities to deliver precision-engineered components tailored to your application demands.

Manufacturing Process & QC

Precision 5-Axis CNC Production Process: Zero Defects Execution

At Wuxi Lead Precision Machinery, our 5-axis CNC production process is engineered for uncompromising quality, integrating Design, Prototyping, and Mass Production into a seamless Zero Defects framework. This methodology eliminates costly errors and ensures first-time-right outcomes for complex aerospace, medical, and energy components. We prioritize rigorous validation at every stage, transforming client specifications into flawless physical parts through systematic engineering control.

The Design phase begins with advanced CAD/CAM integration and comprehensive virtual machining simulation. Our engineers perform detailed geometric dimensioning and tolerancing (GD&T) analysis alongside material stress modeling, identifying potential toolpath collisions, thermal distortions, or fixture weaknesses before metal is cut. Finite Element Analysis (FEA) validates structural integrity under operational loads, while Process Failure Mode and Effects Analysis (PFMEA) proactively mitigates manufacturing risks. This digital twin approach ensures manufacturability and reduces physical iteration cycles by up to 70%, establishing a defect-proof foundation.

Prototyping transitions virtual models into tangible validation. We produce first-article parts using the exact production 5-axis machines, tooling, and materials specified for the final run. Each prototype undergoes full-spectrum metrology: Coordinate Measuring Machine (CMM) scans verify micron-level dimensional accuracy against CAD nominal data, surface profilometry confirms critical finish requirements, and non-destructive testing (NDT) checks subsurface integrity. Client sign-off requires documented conformance to all specifications, with any deviations triggering immediate root-cause analysis and process correction—not part rework. This stage confirms process capability indices (Cp/Cpk > 1.67) before scaling.

Mass Production deploys Statistical Process Control (SPC) with real-time monitoring across all 5-axis machining centers. In-process probes automatically measure critical features after each operation, feeding dimensional data into our centralized quality management system. Any drift toward tolerance limits triggers immediate machine recalibration or tool compensation, preventing non-conforming output. Full traceability links each component to specific machine parameters, tool wear logs, and operator certifications. Our closed-loop system, combined with 100% post-machining CMM verification for critical features, guarantees sustained Zero Defects performance at scale. Every shipment includes a full quality dossier validating conformance.

This integrated workflow ensures that design intent, prototype validation, and production execution operate as a single quality continuum. The result is consistent delivery of mission-critical components where failure is not an option.

Wuxi Lead 5-Axis Production Specifications

| Parameter | Specification | Standard Verified |

|---|---|---|

| Positioning Accuracy | ±0.005 mm | ISO 230-2:2015 |

| Repeatability | ±0.001 mm | ISO 230-2:2015 |

| Maximum Work Envelope | Ø 1200 mm x 1000 mm H | Custom Configurable |

| Spindle Speed Range | 20 – 30,000 RPM | High-Speed Options |

| Surface Finish (Typical) | Ra 0.4 µm | Aerospace Grade |

| In-Process Metrology | On-Machine Probing | Renishaw Systems |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched CNC 5-Axis Machining Excellence

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and engineering mastery. As a global leader in high-end CNC 5-axis machining, we specialize in producing complex, mission-critical components for industries where tolerances matter most: aerospace, medical devices, energy, and advanced automation. Our commitment to innovation, quality control, and on-time delivery makes us the preferred manufacturing partner for forward-thinking engineering teams worldwide.

When you choose to collaborate with Lead Precision, you gain access to advanced 5-axis CNC technology operated by expert engineers with over 15 years of experience in precision manufacturing. Our facility in Wuxi, China, is equipped with state-of-the-art machinery, ISO 9001-certified processes, and rigorous in-line inspection systems to ensure every component meets the highest standards of accuracy and repeatability. From prototyping to high-volume production, we scale with your needs without compromising on quality.

Our 5-axis machining centers eliminate the need for multiple setups, reducing lead times and enhancing geometric accuracy. With simultaneous multi-axis movement, we achieve intricate contours, tight tolerances down to ±0.005 mm, and superior surface finishes—essential for components used in high-performance environments. Whether you’re developing turbine blades, surgical instruments, or lightweight structural parts, our capabilities are engineered to exceed expectations.

We understand that every project begins with trust. That’s why we offer full transparency throughout the manufacturing process, including real-time progress updates, detailed inspection reports, and direct engineering support. Our team works closely with your design and R&D departments to optimize manufacturability, reduce costs, and accelerate time-to-market.

Below are the core technical specifications of our 5-axis CNC machining platform:

| Specification | Detail |

|---|---|

| Machine Types | DMG MORI, MAZAK, and HAAS 5-axis CNC centers |

| Axis Configuration | Trunnion table and swivel head options |

| Travel Range (X/Y/Z) | Up to 1,200 / 600 / 500 mm |

| Rotary Axis (A & B) | ±120° / 360° |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Materials Processed | Aluminum alloys, titanium, stainless steel, Inconel, PEEK, composites |

| Max Workpiece Weight | 800 kg |

| Tolerance Capability | ±0.005 mm |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm) |

Partnering with Wuxi Lead Precision Machinery means aligning with a team that treats your project as our own. We combine cutting-edge technology with deep technical insight to solve your most demanding manufacturing challenges.

Take the next step toward precision excellence. Contact us today at [email protected] to discuss your 5-axis machining requirements. Let Lead Precision be the engine behind your innovation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.