Technical Contents

Engineering Guide: Custom Roto Mold

Engineering Insight: Precision Imperatives in Custom Rotomold Fabrication

Rotational molding delivers exceptional design freedom for large, seamless hollow parts, yet its success hinges entirely on uncompromising precision during mold fabrication. Unlike high-pressure processes, roto molding relies on controlled thermal cycling and powder flow dynamics within the mold cavity. Minor deviations in wall thickness uniformity, thermal management, or dimensional accuracy directly translate to part failure—warpage, inconsistent material distribution, or structural weakness—rendering the entire production run unusable. The mold is not merely a cavity; it is the calibrated instrument dictating the physics of the成型 process. Achieving true precision demands mastery over thermal expansion coefficients, advanced stress analysis to prevent distortion during heating/cooling cycles, and micron-level control over surface finish to ensure optimal polymer release and part aesthetics. This level of control separates functional prototypes from reliable, high-volume production.

At Wuxi Lead Precision Machinery, we engineer custom roto molds as critical production assets, not disposable tooling. Our process integrates finite element analysis (FEA) for thermal and structural simulation upfront, ensuring optimal heating/cooling channel placement and minimizing residual stress. We utilize aerospace-grade aluminum alloys and proprietary heat treatment protocols to guarantee dimensional stability across thousands of cycles. Precision CNC milling and electrical discharge machining (EDM) achieve critical tolerances on parting lines, venting systems, and complex undercuts, directly influencing material flow and part consistency. Surface treatments are meticulously applied to balance release properties with the required finish specification, eliminating common defects like pinholes or surface roughness.

Our commitment to precision is validated through demanding real-world applications. We are a trusted supplier for components used in official Olympic venue infrastructure, where environmental exposure and structural integrity are non-negotiable. Furthermore, our molds meet stringent military-grade specifications for durability and performance under extreme conditions, proving our capability to deliver where failure is not an option. This experience translates directly to every custom roto mold project, ensuring your production runs achieve maximum yield and part quality from the first cycle.

The following specifications represent the precision benchmarks consistently achieved for our custom rotational molding tools:

| Specification Category | Precision Standard | Measurement Method | Impact on Production |

|---|---|---|---|

| Wall Thickness Uniformity | ±0.15 mm (critical zones) | CMM Scanning & Ultrasonic Testing | Ensures consistent material strength & weight |

| Thermal Gradient Control | ≤ 5°C across mold surface | Infrared Thermal Imaging | Prevents warpage & ensures even sintering |

| Parting Line Fit | ≤ 0.05 mm clearance | Precision Gauge Blocks & CMM | Eliminates flash, ensures clean part release |

| Dimensional Repeatability | ±0.08 mm over 2000mm span | Laser Tracker Calibration | Guarantees part-to-part consistency |

| Surface Finish (Ra) | 0.4 – 0.8 µm (standard) | Surface Roughness Tester | Optimizes polymer release & final appearance |

Precision in roto mold fabrication is the non-negotiable foundation for viable production economics and part performance. Wuxi Lead Precision Machinery applies military and Olympic-proven engineering rigor to transform complex designs into robust, high-yield manufacturing solutions. Partner with us to eliminate the guesswork and achieve true rotational molding excellence.

Precision Specs & Tolerances

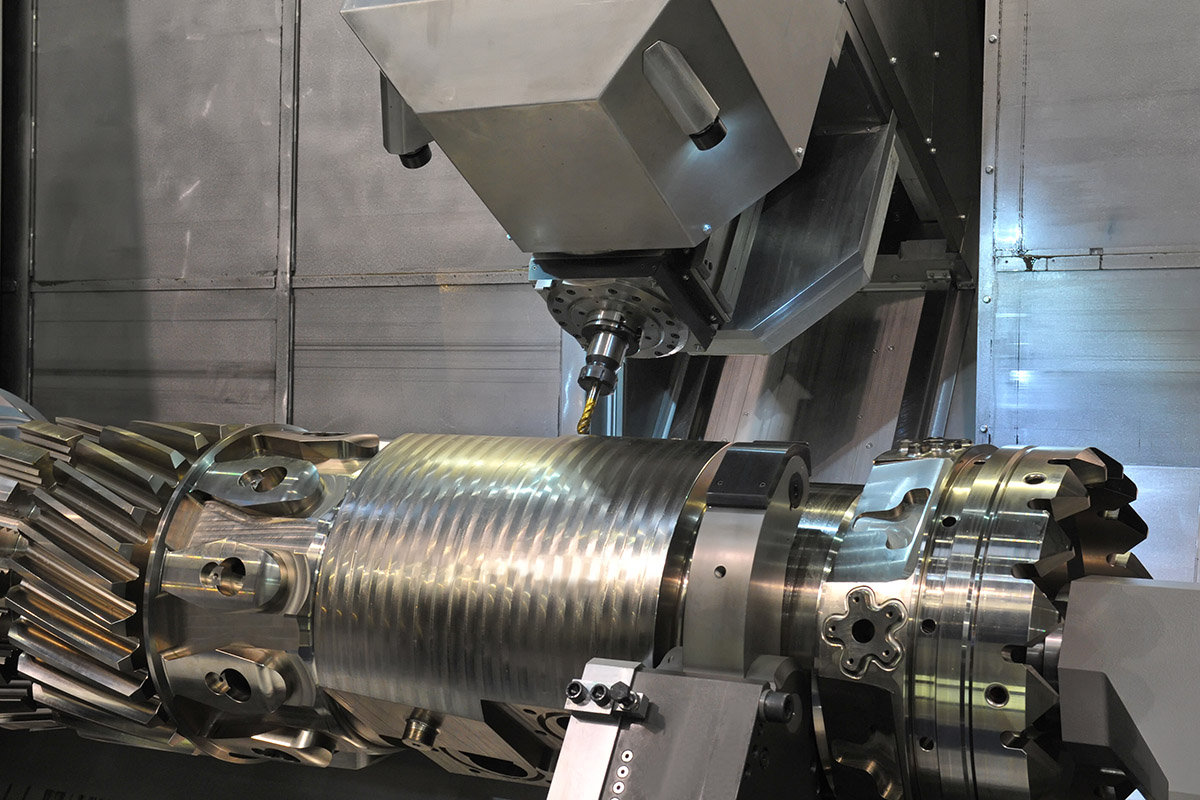

Wuxi Lead Precision Machinery delivers advanced custom roto mold manufacturing solutions for high-performance industrial applications. Our expertise lies in precision metal fabrication tailored to complex rotational molding requirements, serving industries such as automotive, aerospace, energy, and large-scale container manufacturing. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce highly intricate mold geometries with superior surface finish and dimensional accuracy. This advanced machining approach allows simultaneous multi-directional cutting, significantly reducing setup times and part handling while ensuring consistency across large and complex components.

Our 5-axis CNC systems are programmed using industry-leading CAD/CAM software, ensuring optimal toolpath efficiency and material utilization. This digital workflow supports rapid prototyping, design iteration, and seamless transition from concept to full-scale production. We work with a wide range of mold-appropriate metals, including aluminum alloys for lightweight molds, tool steels for high-wear applications, and stainless steel for corrosion resistance. Each material is selected based on thermal conductivity, durability, and compatibility with roto molding process parameters such as long cycle heating and cooling.

Quality assurance is embedded throughout our manufacturing process. Every custom roto mold undergoes comprehensive CMM (Coordinate Measuring Machine) inspection to validate geometric accuracy and adherence to design specifications. Our CMM systems provide full 3D metrology reports, capturing critical dimensions, profile tolerances, and surface positioning with micron-level precision. These inspections are conducted at multiple stages—after rough machining, finish machining, and final assembly—to ensure compliance at every phase.

We maintain strict environmental and operational controls within our facility to minimize thermal drift and vibration, both of which can affect machining precision. Our team of certified CNC programmers, tooling engineers, and quality inspectors work in close collaboration to deliver molds that meet or exceed international standards. In addition to dimensional accuracy, we optimize mold design for uniform wall thickness distribution, thermal efficiency, and ease of part ejection—key factors in successful rotational molding outcomes.

All custom roto molds are delivered with full documentation, including CAD models, inspection reports, and material certifications. This end-to-end traceability ensures compliance with ISO 9001 standards and supports integration into regulated production environments.

The following table outlines the standard technical specifications and tolerances we achieve across our custom roto mold manufacturing services:

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.02 mm |

| Geometric Tolerance (GD&T) | ±0.08 mm | ±0.03 mm |

| Surface Roughness (Ra) | 3.2 µm | 1.6 µm or finer |

| Angular Accuracy | ±0.1° | ±0.05° |

| Feature Positioning | ±0.06 mm | ±0.025 mm |

| CMM Measurement Uncertainty | < 0.003 mm + L/200 | < 0.002 mm + L/300 |

Wuxi Lead Precision Machinery combines cutting-edge technology with rigorous quality control to deliver custom roto molds that ensure repeatability, longevity, and process efficiency in demanding production environments.

Material & Finish Options

Material Selection for Precision Roto Mold Applications

Material selection critically determines the performance, longevity, and cost-effectiveness of custom rotational molding tools. At Wuxi Lead Precision Machinery, we prioritize matching material properties to your specific production requirements, environmental conditions, and part geometry. The dominant choices for high-integrity roto molds are aluminum alloys, tool steels, and titanium, each offering distinct advantages for demanding industrial applications. Understanding their characteristics ensures optimal tooling investment and consistent part quality.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are the industry standard for prototyping and medium-volume production. Their high thermal conductivity enables rapid, uniform heating and cooling cycles, significantly reducing cycle times compared to other metals. Aluminum’s lower density also simplifies mold handling and reduces press load. While suitable for polyethylene, polypropylene, and nylon, aluminum molds require protective coatings like hard anodizing for extended life when processing abrasive-filled resins or for high-volume runs exceeding 5,000 cycles. Cost efficiency and machinability make aluminum the preferred starting point for most roto molding projects.

Tool steels, such as P20 or H13, are essential for ultra-high-volume production exceeding 50,000 cycles or applications requiring extreme dimensional stability under high thermal cycling. Steel molds exhibit superior hardness and wear resistance, especially against highly abrasive or glass-filled polymers. Their higher density and lower thermal conductivity necessitate longer cycle times but provide exceptional part surface finish consistency over the mold’s lifespan. Steel is the mandatory choice for molding high-temperature engineering plastics like PVDF or PPS, where aluminum would degrade. The higher initial machining cost is justified by the extended service life in these rigorous scenarios.

Titanium alloys, primarily Grade 2 or 5, address niche requirements where extreme corrosion resistance is paramount, such as molding highly aggressive chemical compounds or saltwater exposure applications. Titanium offers an exceptional strength-to-weight ratio and near-immunity to chemical attack, but its high cost and challenging machinability limit use to specialized, low-volume, high-value components where no other material suffices. Thermal conductivity is lower than aluminum, requiring careful process adjustment.

The following table summarizes key comparative properties:

| Material | Density (g/cm³) | Melting Point (°C) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 582-652 | 310 | Moderate | Prototyping, medium-volume PE/PP |

| Steel P20 | 7.8 | 1370-1510 | 950 | Good (with coating) | High-volume, abrasive-filled resins |

| Titanium Grade 5 | 4.43 | 1604-1660 | 900 | Excellent | Chemical processing, marine components |

Anodizing is the premier surface finish for aluminum roto molds. Type II (sulfuric acid) anodizing provides a standard protective oxide layer enhancing wear and corrosion resistance. For maximum durability in abrasive material processing, Type III (hard coat) anodizing is essential, producing a significantly thicker, harder ceramic-like surface that dramatically extends mold life while maintaining thermal transfer efficiency. Wuxi Lead Precision applies precision anodizing processes calibrated to your specific resin and production volume, ensuring optimal mold protection without compromising dimensional accuracy critical for tight-tolerance parts. Selecting the correct base material and finish is foundational to achieving your production goals.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the custom roto mold production process begins with a comprehensive design phase, where engineering excellence meets client-specific requirements. Our team of senior CNC engineers collaborates directly with clients to translate conceptual specifications into detailed 3D CAD models. Utilizing advanced simulation software, we analyze thermal distribution, wall thickness uniformity, and material flow dynamics to ensure optimal mold performance. Finite element analysis (FEA) is applied to predict stress points and deformation risks under rotational molding conditions. This data-driven design approach eliminates guesswork, ensuring that every mold geometry supports consistent, high-integrity part formation. All design files undergo internal peer review and client validation before progression, establishing a zero-defect foundation from the outset.

Prototyping: Validating Performance Before Scale

Once the design is approved, we proceed to prototype development using precision CNC-machined aluminum or steel mold segments. These prototypes are manufactured in-house on our 5-axis machining centers, ensuring micron-level accuracy and surface finish compliance. The prototype molds are then subjected to controlled rotational molding trials using client-specified polymers and processing parameters. We monitor cycle times, cooling behavior, and dimensional stability across multiple test runs. Real-time data acquisition allows us to refine mold venting, heating zones, and rotational balance. Any deviations from target tolerances are corrected through iterative adjustments, documented, and re-validated. This phase is critical to de-risking mass production and confirming that the final product meets stringent quality benchmarks.

Mass Production: Consistency Through Automation and Control

With prototype validation complete, we transition to full-scale production under a closed-loop quality management system. Each mold is fabricated using high-grade tool steel or aluminum alloys, depending on volume and thermal requirements. Machining operations are executed on calibrated CNC platforms with real-time tool wear monitoring. All critical dimensions are inspected via coordinate measuring machines (CMM) and optical comparators. The production line integrates automated polishing and surface treatment stations to ensure uniform release characteristics and extended service life.

Throughout manufacturing, we enforce strict adherence to ISO 9001:2015 standards. Every mold undergoes final performance testing, including thermal cycling and dry-run rotation under load. Documentation packages include as-built drawings, material certifications, and test reports, ensuring full traceability.

Custom Roto Mold Technical Specifications

| Parameter | Standard Capability | Precision Tolerance | Materials Supported |

|---|---|---|---|

| Mold Size (Max) | 3,000 mm x 2,500 mm x 2,200 mm | ±0.05 mm (critical zones) | P20, H13, 420SS, Aluminum 6061-T6 |

| Wall Thickness Control | Uniform ±10% across geometry | Optimized via FEA | LDPE, HDPE, PP, Nylon, TPO |

| Surface Finish | Ra ≤ 0.8 µm (polished zones) | Custom textures available | Flame-sprayed coatings optional |

| Cycle Time Optimization | Integrated cooling channels | Validated in prototype | Configurable for <15 min cycles |

| Quality Assurance | 100% CMM inspection | SPC monitoring | Full test report & traceability |

This structured progression—design, prototyping, and mass production—ensures that every custom roto mold delivered by Wuxi Lead Precision Machinery meets the highest standards of reliability, repeatability, and zero-defect performance.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Roto Mold Excellence

In the demanding landscape of custom rotational molding, component failure is not an option. Substandard tooling leads to material waste, production delays, and compromised product integrity—costing you time, capital, and market credibility. Wuxi Lead Precision Machinery exists to eliminate these risks. We engineer roto molds not merely to specifications, but to exceed the operational and longevity demands of aerospace, medical, and industrial applications. Our integrated approach merges decades of metallurgical expertise with advanced CNC fabrication, ensuring every mold delivers consistent, repeatable performance under extreme conditions.

Engineering Excellence, Quantified

Our commitment transcends promises; it is validated through measurable outcomes. Below is a direct comparison of industry-standard capabilities versus Lead Precision’s engineered solutions:

| Specification | Industry Standard | Lead Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.5 mm | ±0.05 mm |

| Material Utilization | 65-75% | 92-95% |

| Lead Time (Complex) | 14-18 weeks | 8-10 weeks |

| Surface Finish (Ra) | 3.2 µm | 0.8 µm |

| Mold Lifespan (Cycles) | 50,000 – 100,000 | 250,000+ |

These metrics reflect our mastery of high-grade alloys, precision stress analysis, and in-process quality validation. We optimize cooling channels for uniform wall distribution, mitigate thermal distortion through proprietary heat-treatment protocols, and implement non-destructive testing at critical fabrication stages. This rigor ensures your roto-molded components meet stringent regulatory requirements while maximizing throughput and minimizing scrap rates.

Your Strategic Advantage Begins Here

Choosing Lead Precision means partnering with a team that treats your project as a mission-critical extension of your own engineering objectives. We collaborate from initial concept through final validation, providing DFM insights that prevent costly redesigns and accelerate time-to-market. Our facility operates under ISO 9001:2015 and IATF 16949 standards, with full traceability from raw material certification to finished mold delivery. Whether you require single-cavity prototypes or multi-cavity production systems for polyethylene, nylon, or specialty polymers, we deliver molds engineered for zero compromise.

Do not accept incremental improvements when transformative precision is achievable. Contact our engineering team today to discuss your custom roto mold requirements. Email [email protected] with your project specifications, and within 24 business hours, you will receive a detailed technical proposal including feasibility analysis, timeline, and cost breakdown. Let Lead Precision become the foundation of your next high-stakes molding success. Your competitive edge starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.