Technical Contents

Engineering Guide: Cnc Werkzeuge

Engineering Insight: The Critical Role of Precision in CNC Werkzeuge

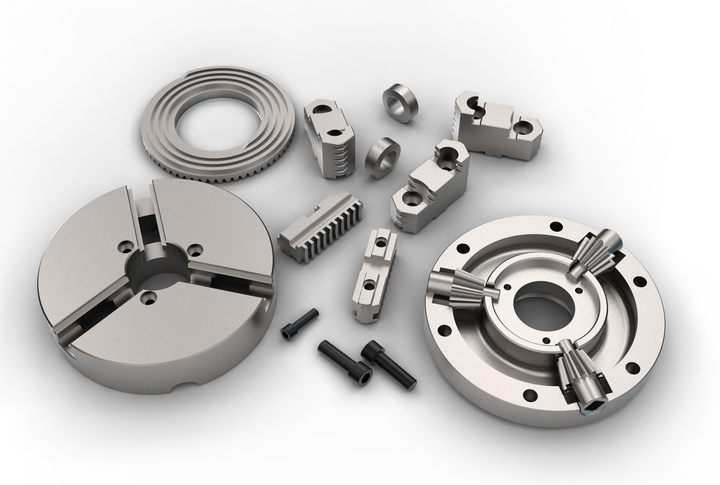

In the world of high-performance manufacturing, the term CNC werkzeuge—German for CNC cutting tools—represents far more than interchangeable components. These tools are the frontline agents of material transformation, responsible for translating digital design intent into physical reality with micron-level accuracy. At Wuxi Lead Precision Machinery, we understand that precision is not merely a target; it is the foundation upon which reliability, repeatability, and performance are built.

Every CNC werkzeug must meet exacting standards in geometry, material composition, thermal stability, and dynamic balance. Deviations of even a few micrometers can result in part rejection, tool wear acceleration, or catastrophic machine failure—especially in sectors such as aerospace, defense, and high-end motorsport. Our engineering team has spent over 15 years refining tooling systems capable of operating under extreme conditions, a capability proven through our contributions to Olympic-grade sporting equipment and mission-critical military components.

The precision of CNC werkzeuge directly influences surface finish, dimensional consistency, and overall process efficiency. For instance, in five-axis machining environments, where tool engagement angles and feed rates vary continuously, the cutting edge must maintain structural integrity and geometric fidelity. This demands advanced coatings, optimized flute geometries, and rigorous quality control during manufacturing. At Lead Precision, we employ ISO 13399-compliant tool data management and laser-assisted inspection systems to ensure every tool meets or exceeds international tolerance standards.

Our experience with high-stakes applications has taught us that precision is not a singular attribute but a system-level achievement. It begins with material selection—often carbide, ceramic, or polycrystalline diamond—and extends through heat treatment, grinding accuracy, and dynamic balancing. Each step is monitored using metrology-grade instrumentation, including coordinate measuring machines (CMM) and 3D optical profilers.

Below are representative specifications for a high-precision end mill used in our aerospace projects, illustrating the tolerances and performance metrics we routinely achieve.

| Specification | Value | Standard |

|---|---|---|

| Diameter Tolerance | ±0.002 mm | ISO 13399 |

| Runout at 3xD | < 0.003 mm | DIN 6535 |

| Surface Roughness (Ra) | 0.05 µm | ISO 4287 |

| Coating Thickness | 2.5 ± 0.2 µm (TiAlN) | ASTM B489 |

| Hardness | 2000 ± 50 HV | ISO 6507 |

| Maximum Operating Speed | 28,000 RPM | Balanced to G2.5 @ 25,000 RPM |

These figures reflect not just technical capability but a philosophy: that excellence in CNC werkzeuge is achieved through disciplined engineering, relentless testing, and domain-specific application knowledge. Whether supporting national defense programs or elite engineering teams, Wuxi Lead Precision Machinery delivers tooling solutions where failure is not an option. Precision isn’t just measured—it’s guaranteed.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision CNC Machining

Wuxi Lead Precision Machinery delivers uncompromising precision for complex, high-value components demanded by aerospace, medical, and advanced industrial sectors. Our core strength lies in integrating cutting-edge multi-axis machining with rigorous, data-driven quality assurance. This ensures geometric complexity is achieved without sacrificing dimensional integrity or surface fidelity, meeting the most stringent global engineering standards.

Our foundation is a modern fleet of 5-axis simultaneous CNC machining centers from leading manufacturers. These systems enable the precise, continuous coordination of all five axes (X, Y, Z, and two rotary axes) within a single setup. This capability is critical for producing intricate organic shapes, deep cavities, undercuts, and highly contoured surfaces inherent in turbine blades, surgical implants, and optical mounts. Eliminating multiple setups significantly reduces cumulative error potential, improves positional accuracy between features, and enhances overall part consistency. Advanced high-speed spindles and rigid machine structures ensure exceptional surface finishes and tight tolerances are maintained even on challenging materials like titanium alloys, Inconel, and hardened tool steels. Program optimization using sophisticated CAM software maximizes material removal rates while protecting tool life and part integrity.

Quality verification is not a final step but an integrated process. Every critical component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMMs). Our Zeiss and Mitutoyo CMMs, operating under ISO 10360-2 standards, provide full 3D geometric dimensioning and tolerancing (GD&T) validation. Probing systems capture thousands of data points, generating detailed reports that map actual part geometry against the nominal CAD model. This metrology data provides absolute traceability, confirming conformance to print specifications and enabling proactive process adjustments. Reports include comprehensive analysis of form, position, profile, and surface characteristics, delivering the documented evidence our clients require for regulatory compliance and assembly success.

The following table details the standard precision capabilities achievable across our production environment under controlled conditions. Specific project requirements may enable even tighter control.

| Specification Category | Standard Capability | Measurement Standard |

|---|---|---|

| Linear Dimensional Tolerance | ±0.002 mm (±0.00008″) | ISO 2768-mK / ASME Y14.5 |

| Angular Tolerance | ±0.001° | ISO 1101 |

| Positional Tolerance (True Position) | Ø0.003 mm (Ø0.00012″) | ISO 1101 |

| Surface Roughness (Ra) | 0.4 µm (16 µin) typical | ISO 4287 / ASME B46.1 |

| Form Tolerance (Flatness, Roundness) | 0.0015 mm (0.00006″) | ISO 1101 |

This level of precision, combined with our expertise in complex 5-axis programming and execution, ensures components function flawlessly in the most demanding applications. Wuxi Lead Precision Machinery provides the technical depth and quality rigor necessary for success in today’s high-stakes manufacturing landscape, transforming intricate designs into reality with measurable accuracy.

Material & Finish Options

Material Selection in Precision CNC Machining: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical decision in precision CNC machining, directly influencing the performance, durability, and cost-efficiency of the final component. At Wuxi Lead Precision Machinery, we specialize in high-tolerance machining of aluminum, steel, and titanium—three of the most widely used engineering metals across aerospace, automotive, medical, and industrial automation sectors. Each material offers distinct mechanical properties, machinability characteristics, and compatibility with surface treatments such as anodizing.

Aluminum is favored for its excellent strength-to-weight ratio, thermal conductivity, and corrosion resistance. It is particularly well-suited for applications where weight reduction is paramount without sacrificing structural integrity. The 6061 and 7075 aluminum alloys are commonly machined due to their weldability and high tensile strength. Aluminum also responds exceptionally well to anodizing, a process that enhances surface hardness and wear resistance while allowing for color coding and improved aesthetics. Type II (sulfuric acid) and Type III (hardcoat) anodizing are routinely applied to aluminum parts produced in our facility.

Steel, particularly in grades such as 4140, 1018, and stainless steels like 304 and 316, offers superior strength, hardness, and resistance to deformation under load. It is the material of choice for high-stress mechanical components, tooling, and structural applications requiring long-term reliability. While steel does not anodize, it can be treated with alternatives such as passivation, plating, or powder coating to improve corrosion resistance and surface finish. Our CNC centers are equipped to handle the higher cutting forces and tool wear associated with steel, ensuring tight tolerances and consistent surface quality.

Titanium, especially Grade 5 (Ti-6Al-4V), is renowned for its exceptional strength-to-density ratio and outstanding resistance to corrosion, particularly in saline or high-temperature environments. It is extensively used in aerospace and medical implant applications. However, titanium poses challenges in machining due to its low thermal conductivity and tendency to gall. At Wuxi Lead, we employ specialized tooling, controlled feed rates, and optimized coolant strategies to maintain precision and avoid material degradation during processing. Surface treatments for titanium typically include anodizing for color coding and minor wear enhancement, as well as chemical passivation for improved biocompatibility in medical uses.

The following table summarizes key properties and machining characteristics of these materials:

| Material | Common Grades | Tensile Strength (MPa) | Density (g/cm³) | Machinability Rating | Anodizing Compatible |

|---|---|---|---|---|---|

| Aluminum | 6061, 7075 | 310 – 570 | 2.7 | Excellent | Yes (Type II & III) |

| Steel | 4140, 304, 316 | 500 – 900 | 7.8 – 8.0 | Moderate | No |

| Titanium | Ti-6Al-4V (Grade 5) | 900 – 1,170 | 4.4 | Poor to Moderate | Yes (Decorative/Type II) |

Understanding these material fundamentals enables engineers and procurement teams to make informed decisions aligned with functional requirements and production efficiency. At Wuxi Lead Precision Machinery, we support clients throughout the selection process, ensuring optimal material and finish combinations for mission-critical applications.

Manufacturing Process & QC

Precision CNC Production Process: From Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, our CNC production process is engineered for uncompromising quality and repeatability, ensuring every component meets exacting global standards. We execute a rigorously controlled sequence spanning Design, Prototyping, and Mass Production, all underpinned by our Zero Defects philosophy. This integrated approach eliminates waste, minimizes risk, and guarantees consistent output for mission-critical applications in aerospace, medical, and advanced industrial sectors.

The Design Phase begins with deep client collaboration. Our engineering team utilizes advanced CAD/CAM software to translate specifications into manufacturable designs, conducting thorough DFMA (Design for Manufacturability and Assembly) and GD&T (Geometric Dimensioning and Tolerancing) analysis. Finite Element Analysis (FEA) validates structural integrity under operational loads. Crucially, we identify potential failure modes early through systematic Design Failure Mode and Effects Analysis (DFMEA), ensuring the design inherently supports defect prevention before any metal is cut. Material selection is optimized for performance, machinability, and longevity.

Prototyping transforms the validated design into physical reality for critical verification. We employ high-precision 5-axis CNC machining centers to produce functional prototypes from the specified production-grade material. Each prototype undergoes comprehensive metrology using calibrated CMMs (Coordinate Measuring Machines), optical comparators, and surface roughness testers. Dimensional accuracy, fit, function, and material properties are rigorously assessed against the original CAD model and client requirements. Client feedback on the prototype is incorporated iteratively, resolving any discrepancies and finalizing the process parameters. This stage is non-negotiable for risk mitigation and process validation.

Mass Production leverages the perfected parameters from prototyping within a fully controlled environment. Our state-of-the-art CNC cells operate under strict Statistical Process Control (SPC), with real-time monitoring of critical variables like tool wear, thermal drift, and vibration. Automated in-process gauging provides immediate feedback, triggering corrective actions before deviations occur. Every component undergoes 100% critical feature inspection using non-contact vision systems and automated CMM routines. Final inspection includes full first-article reporting (FAI) per AS9102 standards and batch-level material certification. Continuous data analysis drives proactive process refinement, ensuring sustained capability.

This seamless integration of engineering rigor, iterative validation, and real-time process control delivers tangible Zero Defects outcomes. The table below summarizes the measurable quality standards achieved across our production continuum.

| Specification Parameter | Target Value | Measurement Method | Control Standard |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | CMM / Optical Comparator | ISO 2768-mK |

| Surface Roughness (Ra) | ≤ 0.4 μm | Profilometer | ISO 1302 |

| Geometric Tolerance (GD&T) | Per Print ±0.01 mm | CMM with GD&T Analysis | ASME Y14.5 |

| Material Yield Rate | ≥ 99.5% | Traceable Batch Records | Internal SOP |

| Process Capability (Cpk) | ≥ 1.67 | SPC Chart Analysis | AIAG Guidelines |

Wuxi Lead’s commitment transcends meeting specifications; we engineer reliability into every stage. By embedding Zero Defects principles from initial design through high-volume output, we deliver CNC-machined components that perform flawlessly in the most demanding applications, safeguarding your operational success and reputation.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in CNC Werkzeuge Manufacturing

At Wuxi Lead Precision Machinery, we understand that the success of your production line depends on precision, reliability, and consistency. As a leading provider of high-end CNC machining solutions based in China, we specialize in delivering premium CNC werkzeuge engineered to meet the exacting demands of modern manufacturing. Whether you operate in aerospace, automotive, medical device production, or industrial automation, our advanced tooling systems are designed to elevate your machining performance and ensure maximum return on investment.

Our CNC werkzeuge are manufactured using state-of-the-art equipment and rigorously tested to meet international quality standards. From complex milling cutters to high-precision turning tools and custom-designed fixtures, every product we deliver is built with micron-level accuracy and durability under continuous operation. We combine advanced materials such as tungsten carbide, high-speed steel, and ceramic composites with intelligent geometries to optimize cutting efficiency, reduce tool wear, and extend service life.

What sets Wuxi Lead Precision Machinery apart is our commitment to partnership. We don’t just supply tools—we provide engineered solutions. Our team of CNC specialists works directly with your engineers to analyze your machining challenges, recommend optimal tool configurations, and support integration into your existing workflows. Whether you require standard ISO-compliant tooling or fully customized designs for niche applications, we deliver responsive, scalable support tailored to your operational needs.

Our manufacturing facility in Wuxi is equipped with 5-axis CNC grinding centers, laser marking systems, and full metrology labs to ensure every tool meets exact specifications. We maintain ISO 9001 certification and conduct in-process inspections at every stage of production. With lean manufacturing principles and a focus on continuous improvement, we guarantee on-time delivery without compromising quality.

Below are key specifications that define the performance of our CNC werkzeuge:

| Parameter | Specification |

|---|---|

| Material Options | Tungsten Carbide, HSS, Ceramic, CBN |

| Tolerance Range | ±0.002 mm |

| Surface Finish (Ra) | 0.2 – 0.8 µm |

| Coating Technologies | TiN, TiAlN, AlCrN, DLC, Multi-layer PVD/CVD |

| Tool Diameter Range | 0.5 mm – 25 mm |

| Spindle Interface Support | HSK, BT, CAT, ISO 40/50 |

| Customization Capability | Full geometric and dimensional adaptation |

| Lead Time (Standard) | 7–14 days (rush options available) |

Partnering with Wuxi Lead Precision Machinery means gaining access to a trusted global supplier with a proven track record across Europe, North America, and Asia. We support long-term contracts, volume pricing, and technical training to ensure seamless collaboration.

For inquiries, project consultations, or to request a sample kit, contact us today at [email protected]. Let us help you achieve superior machining results with CNC werkzeuge built to perform.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.