Technical Contents

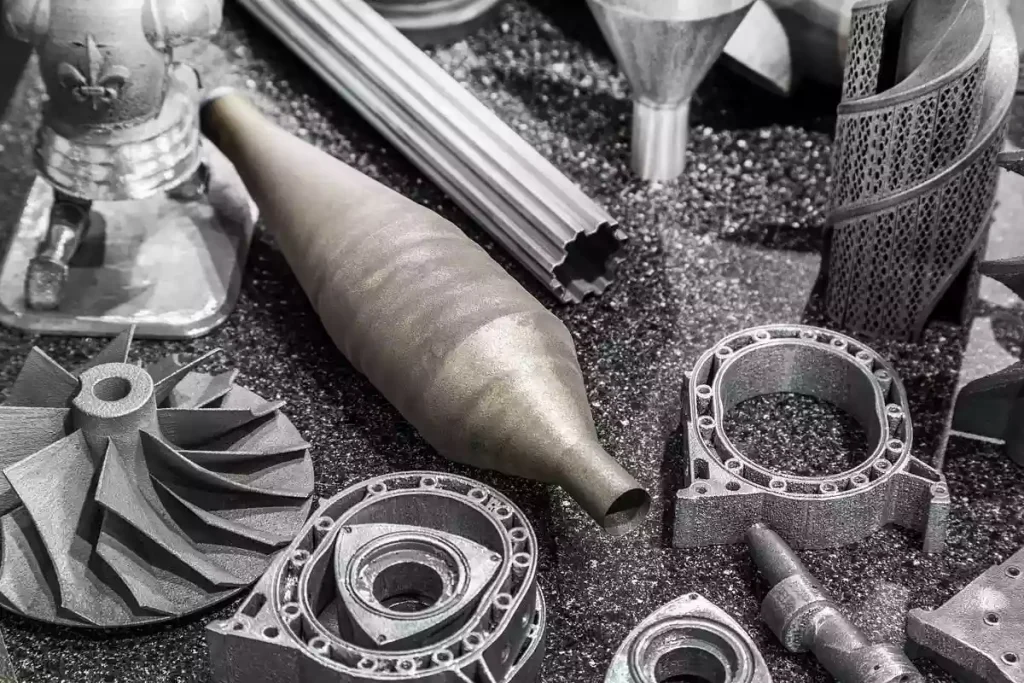

Engineering Guide: Cheap Metal 3D Printing Service

Engineering Insight: The True Value of Precision in Affordable Metal 3D Printing

In the evolving landscape of custom metal manufacturing, the term “cheap metal 3D printing service” often raises concerns about quality, consistency, and long-term reliability. At Wuxi Lead Precision Machinery, we redefine affordability—not by compromising on precision, but by optimizing engineering efficiency and production scalability. True value in metal additive manufacturing lies not in the lowest initial cost, but in the repeatability, accuracy, and performance of the final component.

Precision in metal 3D printing is non-negotiable, especially when serving industries such as aerospace, defense, and high-performance sports equipment. Our involvement in Olympic-grade equipment production and military-grade component development underscores our commitment to exacting standards. These applications demand micron-level tolerances, full material integrity, and stringent post-processing protocols—benchmarks we uphold even in cost-optimized production runs.

Affordability should not equate to cutting corners. Instead, it reflects advanced process control, intelligent design for additive manufacturing (DfAM), and vertical integration that reduces overhead without sacrificing output quality. At Lead Precision, we leverage years of metallurgical expertise and in-house quality assurance to deliver parts that meet ISO 9001 and AS9100 standards, ensuring every component performs under real-world stress conditions.

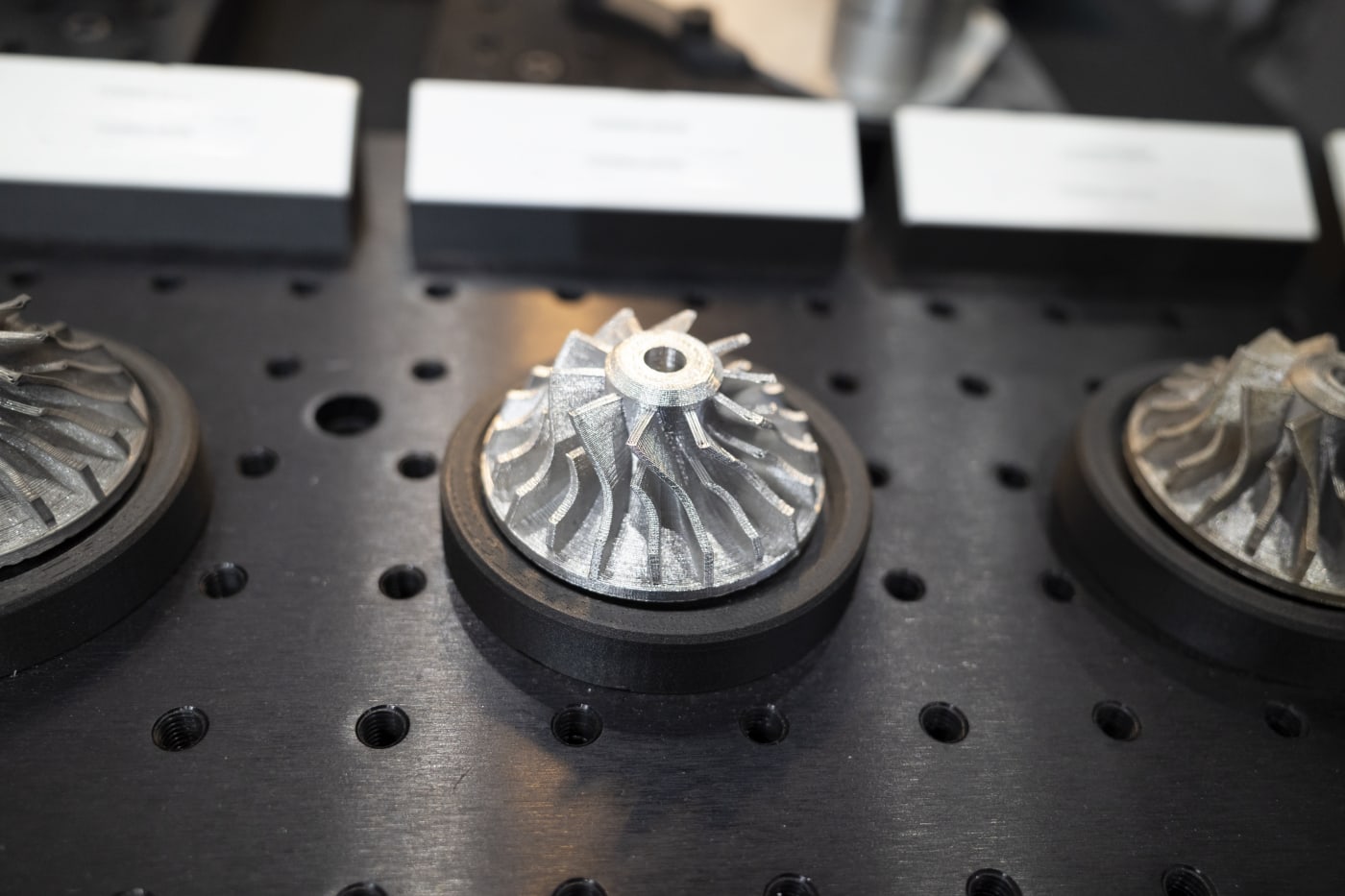

Our metal 3D printing services utilize state-of-the-art laser powder bed fusion (LPBF) systems, capable of producing complex geometries with exceptional surface finish and internal integrity. By fine-tuning parameters such as layer thickness, laser power, and scan strategy, we achieve optimal density (>99.95%) and mechanical properties that match or exceed traditional wrought materials.

Below are key technical specifications that define our metal 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 60 µm |

| Positional Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 10 – 15 µm |

| Post-Processed Finish | Ra < 3.2 µm (polished/shot-peened) |

| Material Options | Stainless Steel 316L, Inconel 718, Ti-6Al-4V, AlSi10Mg, Tool Steel (Maraging) |

| Density | >99.95% (verified via X-ray and CT scanning) |

| Heat Treatment Options | Stress relief, Hot Isostatic Pressing (HIP), Solution & Aging |

Our experience with mission-critical components has taught us that precision begins long before the laser engages—design validation, support structure optimization, and thermal simulation are all integral to success. We apply the same rigor whether producing a single prototype or scaling to batch production, ensuring consistent outcomes across all volume tiers.

At Wuxi Lead Precision Machinery, we prove that a cost-effective metal 3D printing service can still be a premium engineering solution. Precision isn’t an add-on—it’s the foundation.

Precision Specs & Tolerances

Precision Metal Additive Manufacturing: Where Cost Efficiency Meets Aerospace-Grade Quality

At Wuxi Lead Precision Machinery, our “cheap metal 3D printing service” redefines affordability without compromising on industrial rigor. We achieve this through seamless integration of metal additive manufacturing with precision subtractive processes, eliminating hidden costs from secondary operations and quality failures. Our technical foundation lies in advanced 5-axis CNC machining centers—specifically DMG MORI CTX beta 1250 and Hermle C32U—paired with direct metal laser sintering (DMLS) systems. This hybrid approach ensures complex geometries are not only printed economically but also finished to exacting tolerances in a single workflow, reducing lead times by up to 40% versus conventional outsourcing chains.

Critical to our cost-effective model is in-house post-processing capability. Every printed component undergoes precision milling, drilling, and surface finishing on our 5-axis platforms, removing support structures and achieving critical feature accuracy that standalone printing cannot deliver. This eliminates the need for third-party CNC services, a common cost and quality bottleneck in budget-focused metal AM. Our facility maintains strict environmental controls for powder handling and print stability, ensuring material integrity for demanding alloys like Ti-6Al-4V, Inconel 718, and 17-4 PH stainless steel.

Quality assurance is non-negotiable. Each part receives 100% first-article inspection via Zeiss CONTURA CMM systems, validating dimensions against AS9100-certified protocols. Statistical process control (SPC) data is documented for full traceability, providing clients with objective proof of conformance—not just price competitiveness. This proactive QC prevents costly scrap and rework, directly contributing to your bottom line. Below are achievable tolerances for common applications:

| Material | Process | Standard Tolerance | Surface Finish (Ra) |

|---|---|---|---|

| Ti-6Al-4V | DMLS + 5-Axis Finish | ±0.025 mm | 1.6–3.2 μm |

| Inconel 718 | DMLS + 5-Axis Finish | ±0.030 mm | 1.6–3.2 μm |

| 17-4 PH SS | DMLS + 5-Axis Finish | ±0.020 mm | 1.0–2.5 μm |

| Aluminum AlSi10Mg | DMLS Only | ±0.050 mm | 6.3–12.5 μm |

Your cost savings originate from engineered efficiency, not compromised standards. We optimize build orientation and support structures using NX software to minimize material waste, while our 5-axis CNC capabilities achieve tight tolerances on internal channels, thin walls, and undercuts—features that often require expensive EDM or manual finishing elsewhere. For instance, hydraulic manifolds with 0.8mm internal passages are machined to ±0.015 mm tolerance after printing, avoiding assembly of multiple components.

This integrated methodology delivers true total cost reduction: lower per-part pricing, zero hidden rework expenses, and accelerated time-to-assembly. When you partner with Wuxi Lead, “cheap” signifies intelligent manufacturing economics—where every micron of precision directly translates to your operational savings. Contact our engineering team to validate your specific tolerance requirements against our capability matrix.

Material & Finish Options

Material Selection for High-Precision Metal 3D Printing

Selecting the appropriate material is critical when leveraging a high-end metal 3D printing service for industrial applications. At Wuxi Lead Precision Machinery, we offer advanced additive manufacturing solutions using premium-grade aluminum, steel, and titanium alloys. Each material brings distinct mechanical properties, thermal performance, and corrosion resistance, making them suitable for specific engineering requirements across aerospace, automotive, medical, and energy sectors.

Aluminum alloys, particularly AlSi10Mg, are widely used for lightweight structural components requiring high strength-to-density ratios. This alloy exhibits excellent thermal conductivity and good fatigue resistance, ideal for heat exchangers, engine parts, and drone components. Its low density reduces overall system weight without compromising performance, making it a preferred choice in mobility and aerospace applications where fuel efficiency and payload capacity are paramount.

Stainless steel variants such as 316L and 17-4 PH provide superior corrosion resistance and mechanical strength. These materials are commonly selected for harsh-environment applications including marine hardware, chemical processing equipment, and medical implants. 316L offers exceptional ductility and weldability, while 17-4 PH can be precipitation hardened to achieve tensile strengths exceeding 1000 MPa, bridging the gap between standard steels and high-strength alloys.

Titanium, specifically Ti6Al4V (Grade 5), stands at the forefront of performance-critical industries. With an outstanding strength-to-weight ratio and biocompatibility, it dominates aerospace structural components, prosthetics, and high-performance automotive parts. Its resistance to extreme temperatures and corrosive environments ensures long-term reliability under stress, justifying its use in mission-critical systems despite higher raw material costs.

Post-processing surface treatments further enhance part functionality. Anodizing is a key finishing option available for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, surface hardness, and corrosion protection. Decorative or functional coloring can also be achieved through dye integration during anodization, supporting both branding and identification needs in complex assemblies.

Below is a comparative overview of key material properties used in our metal 3D printing service:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 480 | 370 | 2.67 | 8–12 | Aerospace, automotive, heat sinks |

| 316L Stainless Steel | 590–700 | 300–400 | 8.0 | 35–50 | Medical devices, marine systems |

| 17-4 PH Steel | 1000–1300 | 850–1000 | 7.8 | 10–15 | Tooling, aerospace actuators |

| Ti6Al4V | 900–950 | 800–850 | 4.43 | 8–12 | Aviation, medical implants |

Material choice directly influences part performance, longevity, and manufacturability. Our engineering team at Wuxi Lead Precision Machinery supports clients in selecting the optimal alloy and finish based on operational demands, environmental exposure, and geometric complexity. By combining precision metal 3D printing with expert material science, we deliver components that meet the highest industrial standards.

Manufacturing Process & QC

Precision Metal Additive Manufacturing Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our economical metal 3D printing service delivers uncompromising quality through a rigorously controlled, closed-loop production process. We transform complex designs into certified aerospace, medical, and industrial components with zero defects, ensuring every part meets stringent international standards. This begins with deep Design for Additive Manufacturing (DfAM) collaboration. Our engineering team reviews your CAD model for optimal build orientation, support structure minimization, and thermal stress management. We identify potential anisotropy risks and suggest geometry refinements to maximize part integrity and reduce post-processing costs, ensuring manufacturability without sacrificing performance.

Prototyping is not merely a validation step but a critical process qualification phase. Using identical industrial-grade EOS M 400-4 or SLM Solutions S400 systems as mass production, we build functional prototypes with your specified material. Each prototype undergoes comprehensive metrology: CT scanning verifies internal porosity and dimensional accuracy against the nominal CAD, while mechanical testing confirms fatigue strength and material properties meet ASTM F3301/F3318 or ISO 20753 standards. This data validates the build strategy and feeds directly into the production control plan, eliminating guesswork.

Mass production leverages our ISO 9001 and AS9100 certified workflow. Raw materials undergo strict batch traceability and chemical composition verification before entering climate-controlled powder handling systems. Builds run under real-time melt pool monitoring with AI-driven anomaly detection, automatically pausing for intervention if deviations occur. Post-processing follows a defined sequence: precision wire EDM for base separation, automated support removal, HIP densification for critical applications, and multi-axis CNC machining for critical features. Every component then enters our Zero Defects gate: first-article inspection (FAI) per AS9102, 100% CMM verification of critical dimensions, and final visual inspection under 10x magnification. Non-conforming parts are quarantined for root cause analysis, ensuring only flawless components ship with full material and process documentation.

This integrated approach guarantees repeatability and cost efficiency without quality trade-offs. Below are key process specifications enabling this precision:

| Parameter | Capability | Industry Standard Reference |

|---|---|---|

| Material Options | Ti6Al4V ELI, Inconel 718, 17-4PH SS, AlSi10Mg, CoCrMo | ASTM F3001, F3055, F3188 |

| Build Volume | Up to Ø250 x 325 mm (EOS M 400-4) | |

| Layer Thickness | 20-60 µm | |

| Dimensional Accuracy | ±0.02 mm per 100 mm (post-machining) | AS9102 Rev D |

| Surface Roughness (as-built) | Ra 8-12 µm (optimized orientation) | ISO 25178 |

| Porosity Level | <0.1% (with HIP) | ASTM E1077 |

| Certification | ISO 9001, AS9100, MTRs, FAI Reports |

Our process eliminates the false economy of low-cost printing by embedding quality at every stage. Partner with Wuxi Lead for metal additive production where affordability meets absolute reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Value in Metal 3D Printing

At Wuxi Lead Precision Machinery, we redefine what it means to deliver a truly cost-effective metal 3D printing service without compromising on precision, quality, or engineering integrity. As a trusted name in custom metal manufacturing, we specialize in supporting global industries—from aerospace and medical devices to automotive and energy—by transforming complex designs into high-performance metal components. Our advanced additive manufacturing capabilities, combined with rigorous quality control and lean production practices, allow us to offer competitive pricing while maintaining the highest standards of dimensional accuracy and material performance.

When you choose to partner with Lead Precision, you’re not just sourcing parts—you’re gaining a strategic manufacturing ally. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, ensuring optimal build orientation, minimal material waste, and reduced post-processing time. This proactive approach not only accelerates time-to-market but also significantly lowers overall production costs. With in-house metal 3D printing using state-of-the-art laser powder bed fusion (LPBF) technology, we support a wide range of industrial-grade alloys, including titanium, stainless steel, aluminum, and Inconel, tailored to your application requirements.

Our facility in Wuxi, China, operates under ISO 9001-certified processes, with full traceability, real-time monitoring, and comprehensive inspection protocols using coordinate measuring machines (CMM) and metallurgical analysis. Every component is built to meet or exceed international standards, ensuring reliability in mission-critical applications. Whether you require low-volume prototypes or scalable batch production, our agile manufacturing model adapts to your volume needs with consistent turnaround and repeatable quality.

We understand that in high-end manufacturing, “cheap” should never mean “compromised.” That’s why our pricing model is built on efficiency, not shortcuts. By optimizing machine utilization, reducing lead times, and leveraging our deep expertise in metal additive processes, we deliver a cost-competitive solution that maintains the precision and structural integrity your projects demand.

Explore how we can support your next metal 3D printing project with unmatched value and technical excellence.

| Specification | Detail |

|---|---|

| Printing Technology | Laser Powder Bed Fusion (LPBF) |

| Build Envelope | Up to 250 x 250 x 325 mm |

| Layer Thickness | 20–50 µm |

| Supported Materials | 316L Stainless Steel, 17-4PH, Inconel 718, Ti6Al4V, AlSi10Mg |

| Surface Roughness (as-built) | Ra 10–15 µm |

| Dimensional Accuracy | ±0.05 mm/mm (typical) |

| Post-Processing Options | Stress relieving, HIP, CNC machining, polishing, coating |

| Quality Standards | ISO 9001, Full Material Certification, First Article Inspection (FAI) Reports |

Contact us today at [email protected] to discuss your project requirements and receive a detailed quote. Let Wuxi Lead Precision Machinery be your trusted partner in precision metal additive manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.