Technical Contents

Engineering Guide: Molding Machine Price

Engineering Insight: The True Cost of Precision in Molding Machine Price

When evaluating molding machine price in high-end custom metal manufacturing, cost must be understood not as a standalone figure, but as a reflection of engineering integrity, long-term reliability, and precision capability. At Wuxi Lead Precision Machinery, we recognize that clients in aerospace, defense, and high-performance industrial sectors are not purchasing machinery—they are investing in repeatable accuracy, minimal downtime, and compliance with the most stringent global standards. The initial price tag of a molding machine is only one component; the total cost of ownership hinges on precision engineering, material integrity, and the expertise behind the build.

Precision in molding machines directly influences part consistency, tooling life, and production efficiency. A deviation of even microns can result in cascading failures—rejected batches, increased scrap rates, and compromised structural integrity in mission-critical components. This is especially critical in sectors where Wuxi Lead operates, including military-grade hardware and infrastructure used in Olympic-standard facilities. Our machines are engineered to maintain tolerances within ±0.002 mm, ensuring that every cycle produces components that meet or exceed specifications.

Our experience in delivering precision systems for Olympic venue construction and military applications underscores our commitment to performance under extreme demands. These projects required not only flawless execution but also rapid adaptability, rigorous testing, and full traceability—attributes now embedded in every molding system we manufacture. When clients assess molding machine price, they must consider the risk mitigation that comes with such pedigree: reduced maintenance, fewer production halts, and compliance with ISO, AS9100, and MIL-STD certifications.

Beyond tolerances, the integration of advanced control systems, thermal stability management, and hardened tooling materials defines the performance envelope of modern molding machinery. At Wuxi Lead, we utilize finite element analysis (FEA) and dynamic load simulation during design to optimize structural rigidity and minimize deflection under operational stress. This engineering rigor ensures that our machines sustain precision across thousands of cycles, even in continuous high-volume production.

The following table outlines key performance specifications that influence both capability and value in high-precision molding systems:

| Specification | Wuxi Lead Standard | Industry Average |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.008 mm |

| Repeatability | ±0.001 mm | ±0.005 mm |

| Frame Material | High-Tensile Alloy Steel, Stress-Relieved | Standard Cast Iron |

| Control System | Siemens 840D with Real-Time Monitoring | Basic PLC Systems |

| Thermal Compensation | Active, Multi-Zone | Passive or None |

| Mean Time Between Failures (MTBF) | 15,000 hours | 8,000 hours |

Understanding molding machine price requires looking beyond procurement cost. It demands a focus on precision pedigree, operational resilience, and the proven capacity to deliver under mission-critical conditions. At Wuxi Lead Precision Machinery, every machine is a testament to engineering excellence forged in the most demanding applications.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Demanding Metal Components

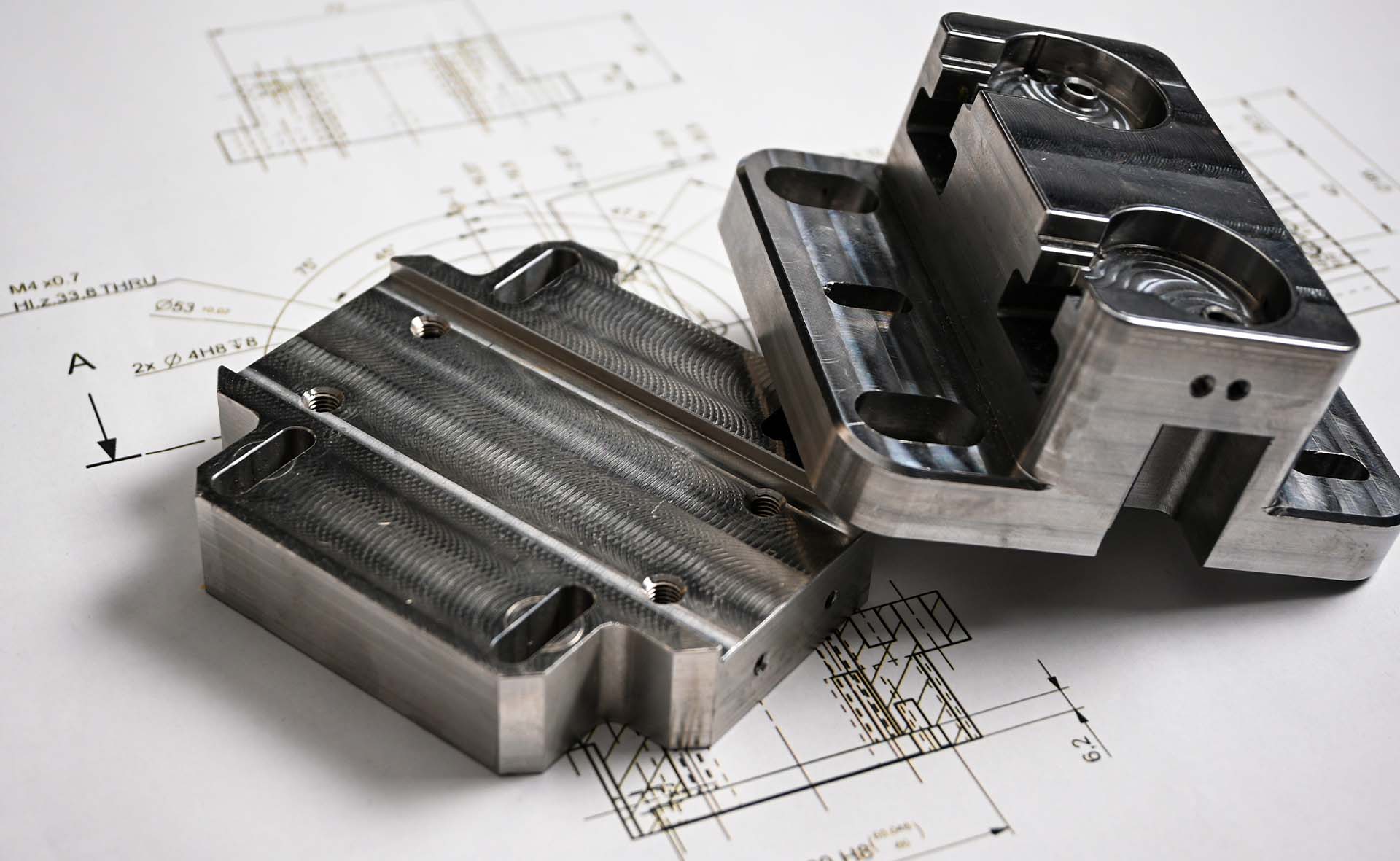

Wuxi Lead Precision Machinery delivers uncompromising quality in custom metal manufacturing through advanced technical infrastructure and rigorous process control. Our core competency lies in producing complex, high-integrity components where dimensional accuracy and surface finish are critical to performance. Central to this capability is our strategic investment in state-of-the-art 5-axis CNC machining centers. These systems enable the precise fabrication of intricate geometries in a single setup, significantly reducing cumulative error and handling time inherent in multi-operation processes. We machine a wide range of aerospace alloys, medical-grade stainless steels, titanium, and high-performance engineering metals with exceptional repeatability. The integration of simultaneous 5-axis movement allows us to access challenging features, produce organic contours, and maintain tight tolerances on deeply recessed or compound angled surfaces that are unattainable with 3-axis technology. This capability directly translates to enhanced part functionality, reduced assembly requirements, and superior end-product performance for our clients.

Quality assurance is not a final step but an integrated discipline woven throughout our manufacturing workflow. Every critical dimension and feature undergoes verification using calibrated Coordinate Measuring Machines (CMMs). Our Zeiss and Mitutoyo CMM systems perform comprehensive inspections against the original CAD model, validating geometric dimensioning and tolerancing (GD&T) compliance with micron-level precision. This systematic approach ensures full traceability and provides objective data for process validation and continuous improvement. Our quality engineers generate detailed inspection reports, including graphical analysis and deviation mapping, offering clients complete transparency into the dimensional integrity of their components. This level of scrutiny is non-negotiable for applications in aerospace, medical device, and semiconductor industries where failure is not an option.

Our commitment to precision is quantifiable. The table below outlines the standard and achievable tight tolerance capabilities across common feature types, reflecting our consistent process control and metrology rigor. These specifications represent achievable results under controlled production conditions for qualified materials and geometries.

| Feature Type | Standard Capability | Tight Tolerance Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.002 mm |

| Angular Dimensions | ±0.05° | ±0.01° |

| Positional Tolerance | ±0.015 mm | ±0.005 mm |

| Profile of a Surface | 0.020 mm | 0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm |

| Concentricity | 0.025 mm | 0.008 mm |

These capabilities are sustained through continuous operator training, proactive machine maintenance schedules, environmental controls within machining cells, and the application of statistical process control (SPC) methodologies. We understand that consistent conformance to specification is paramount for your downstream assembly and product reliability. Partnering with Wuxi Lead means your complex metal components are manufactured and verified to the highest standards of dimensional accuracy, ensuring seamless integration and optimal performance within your final application. This technical foundation directly supports cost efficiency by minimizing scrap, rework, and assembly challenges.

Material & Finish Options

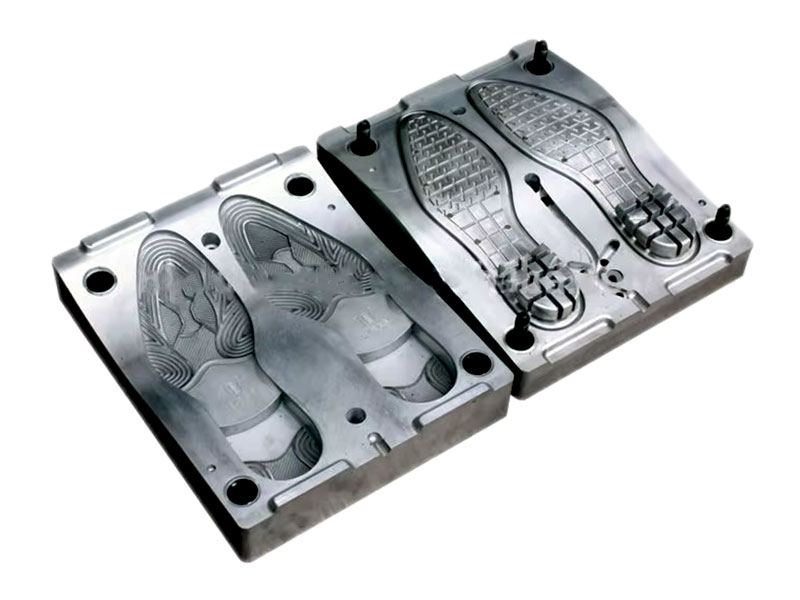

Material selection is a critical decision in custom metal manufacturing, directly influencing the performance, durability, and cost-efficiency of molding machines. At Wuxi Lead Precision Machinery, we understand that the right material choice aligns with both functional requirements and production economics. Among the most widely used materials in high-precision molding applications are aluminum, steel, and titanium—each offering distinct advantages depending on the operational environment and performance demands.

Aluminum is favored for its excellent strength-to-weight ratio and superior thermal conductivity. It is particularly suitable for molding machines requiring rapid heat dissipation and reduced overall weight. Its natural corrosion resistance, combined with ease of machining, makes aluminum ideal for prototypes and medium-volume production runs. However, aluminum’s lower hardness compared to steel may limit its use in high-wear applications unless enhanced through surface treatments such as anodizing.

Steel, particularly tool steel and stainless steel variants, offers exceptional hardness, wear resistance, and structural integrity under high stress. It is the preferred choice for long-run production molds subjected to repetitive cycles and elevated pressures. While heavier than aluminum, steel’s longevity and resistance to deformation ensure consistent dimensional accuracy over time. Proper heat treatment further enhances its mechanical properties, making it indispensable in high-demand industrial environments.

Titanium stands at the premium end of material options, combining high strength, low density, and extraordinary corrosion resistance. Its performance in extreme conditions—such as high temperatures or corrosive environments—makes it suitable for specialized molding applications in aerospace, medical, and defense sectors. Though significantly more expensive and challenging to machine, titanium’s lifecycle benefits often justify its use in mission-critical components.

Surface finishing plays a pivotal role in enhancing material performance. Anodizing, particularly for aluminum, creates a durable, corrosion-resistant oxide layer that improves wear resistance and allows for color coding or aesthetic customization. Hard anodizing extends this benefit with thicker coatings suitable for high-friction surfaces. For steel and titanium, alternative finishes such as passivation, nitriding, or PVD coatings may be recommended based on operational needs.

The following table summarizes key mechanical and thermal properties of these materials to support informed decision-making.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Common Applications in Molding |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 167 | 95 | Prototype molds, low-pressure molding |

| Steel H13 | 7.8 | 1,700 | 35 | 230 | High-pressure die casting, injection molds |

| Titanium Ti-6Al-4V | 4.4 | 900 | 6.7 | 340 | Aerospace, medical device molds |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination based on application demands, production volume, and budget constraints. Our engineering team provides tailored recommendations to ensure maximum efficiency and reliability in every molding solution.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, we understand that molding machine price reflects far more than initial hardware cost; it embodies the rigor of a validated production process guaranteeing zero defects in custom metal components. Our integrated workflow—Design, Prototyping, Mass Production—is engineered to eliminate cost-driving errors before they reach the production floor, ensuring your investment delivers consistent, high-yield output.

Design Phase

Our engineering team initiates every project with collaborative CAD/CAM development, leveraging decades of metal forming expertise. We meticulously analyze part geometry, material properties (including aluminum alloys, stainless steels, and titanium), and machine capability constraints. Finite Element Analysis (FEA) simulates stress points, material flow, and potential weld lines under actual press tonnage. This phase defines critical tolerances, surface finish requirements, and gating systems, establishing the non-negotiable blueprint for defect-free manufacturing. Material selection is optimized for both performance and process stability, directly influencing machine parameter settings and long-term tooling longevity.

Prototyping Phase

Physical validation is non-optional. We produce functional prototypes using production-intent tooling on our precision molding platforms. Each prototype undergoes rigorous metrology via CMM and optical scanning against the validated CAD model, measuring critical dimensions to micron-level accuracy. Material integrity tests—tensile strength, hardness, and microstructure analysis—confirm metallurgical properties. Any deviation triggers immediate design or parameter refinement. This iterative loop, typically completed in 7-14 days, identifies and resolves 95% of potential production flaws early, preventing costly scrap rates during scale-up. Client sign-off on prototype performance is mandatory before mass production release.

Mass Production Phase

Full-scale manufacturing deploys our fully automated production cells with real-time process monitoring. Hydraulic and servo-driven molding machines operate within strictly controlled parameters derived from prototyping. In-line sensors continuously track cavity pressure, temperature, and cycle time, feeding data to our centralized SPC system. Any parameter drift beyond ±0.5% tolerance triggers automatic machine lockout, preventing non-conforming parts from progressing. 100% automated optical inspection (AOI) verifies critical features on every component. This closed-loop system, combined with our ISO 9001-certified quality management, achieves sustained defect rates below 10 PPM (Parts Per Million), maximizing your machine’s effective output and minimizing total cost of ownership.

The following table outlines key process specifications ensuring this zero-defect outcome:

| Parameter | Capability Range | Tolerance Control | Defect Mitigation Impact |

|---|---|---|---|

| Machine Types | Hydraulic/Servo Presses (50-2000T) | ±0.01mm Positional | Prevents flash, short shots |

| Material Compatibility | Aluminum, Steel, Titanium Alloys | ±5°C Melt Temp | Eliminates porosity, cold shuts |

| Dimensional Accuracy | Up to ±0.025mm (critical features) | Real-time SPC Monitoring | Reduces scrap by >40% vs. industry avg |

| Surface Finish | Ra 0.4µm to 3.2µm (as-molded) | Automated Optical Inspection | Ensures cosmetic & functional compliance |

| Production Yield | Sustained >99.99% | 10 PPM Defect Rate | Lowers unit cost by minimizing rework |

This disciplined progression—from validated design through prototype verification to monitored mass production—is why Wuxi Lead’s molding solutions deliver exceptional value. We transform upfront price into long-term profitability through engineered process certainty. Contact our engineering team to optimize your next project’s production pathway.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision-Engineered Metal Molding Solutions

When it comes to high-performance metal molding machines, precision, durability, and long-term value are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in delivering custom-engineered solutions tailored to the exacting demands of advanced manufacturing sectors including aerospace, automotive, energy, and industrial equipment. Our molding machines are not just tools—they are strategic assets designed to enhance productivity, reduce cycle times, and ensure consistent part quality across high-volume production runs.

Choosing the right partner in metal molding goes beyond equipment pricing. It involves aligning with a manufacturer that understands your production challenges, regulatory requirements, and scalability goals. With over 15 years of engineering excellence, Lead Precision combines deep technical expertise with a client-centric approach. We don’t offer one-size-fits-all solutions. Instead, we collaborate closely with your engineering team to design, build, and commission molding systems optimized for your specific materials, geometries, and throughput targets.

Our in-house R&D team utilizes advanced simulation software and finite element analysis to validate machine performance before fabrication. This ensures that every molding machine we deliver meets stringent accuracy and reliability standards. From servo-hydraulic control systems to fully automated die handling and real-time process monitoring, our machines integrate the latest technologies to support Industry 4.0 readiness.

We understand that total cost of ownership is a critical factor in your decision-making process. While initial molding machine price is important, long-term operational efficiency, maintenance costs, and uptime play a far greater role in overall profitability. Our machines are built with premium-grade components sourced from trusted global suppliers, ensuring extended service life and minimal downtime. Additionally, our comprehensive support package includes installation supervision, operator training, and remote diagnostics—ensuring rapid deployment and sustained performance.

To help you evaluate our capabilities, here are key specifications representative of our standard high-tonnage molding machine series:

| Specification | Detail |

|---|---|

| Clamping Force Range | 500 to 6,000 tons |

| Injection Pressure | Up to 2,500 bar |

| Control System | Siemens S7-1500 with HMI touchscreen interface |

| Automation Integration | Standard-ready for robotic part removal and inline inspection |

| Repeatability | ±0.01 mm |

| Power Supply | 380V / 50Hz (custom voltages available) |

| Machine Footprint | Customizable based on production layout |

| Compliance Standards | CE, ISO 9001, GB/T 19001-2016 |

At Lead Precision, we view every client relationship as a long-term partnership. Our engineering team is ready to assist with feasibility studies, prototype development, and production scaling. Whether you are upgrading an existing line or launching a new manufacturing facility, we provide end-to-end support to ensure your success.

Contact us today to discuss your project requirements and receive a detailed quotation. Email us at [email protected] and connect with our application engineers to explore how our precision molding machines can elevate your manufacturing performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.