Technical Contents

Engineering Guide: Medical Device Injection Mold

Engineering Insight: Precision Imperatives in Medical Device Injection Molding

Achieving absolute dimensional accuracy and surface integrity in medical device injection molds is non-negotiable. These components directly impact patient safety, device functionality, and regulatory compliance. A tolerance deviation of mere microns can compromise the seal integrity of a drug delivery system, alter fluid dynamics in surgical instruments, or create micro-crevices harboring biological contaminants. Surface finish variations below the visual threshold can affect cell adhesion in implants or cause particulate generation incompatible with sterile environments. The cost of failure extends beyond rejected parts; it risks patient harm, costly recalls, and significant delays in FDA or CE Mark approval cycles. Precision engineering is not merely a manufacturing goal—it is the foundational requirement for viable medical device production.

Sub-micron repeatability in mold cavity fabrication ensures consistent part geometry across millions of cycles. This demands advanced CNC machining capabilities, rigorous thermal stability control during manufacturing, and metrology systems capable of verifying features at the nanometer level. Material selection and heat treatment processes must be optimized to prevent microscopic deformation under high injection pressures and sterilization temperatures. Every aspect—from gate design to cooling channel placement—requires computational fluid dynamics simulation and empirical validation to eliminate warp, sink, or internal stresses that could manifest in final devices. The mold is the silent regulator of product quality; its precision dictates the ceiling of what the production process can achieve.

Wuxi Lead Precision Machinery applies aerospace and defense-grade engineering rigor to medical mold manufacturing. Our facility’s proven capability in producing components for Olympic timing systems—where microsecond accuracy is mandatory—and critical military hardware—requiring operation under extreme environmental stress—directly translates to medical molding excellence. This heritage instills a culture where ISO 13485 compliance is the baseline, not the peak. We deploy the same multi-axis grinding, electro-discharge machining, and coordinate measuring machine protocols used for mission-critical defense applications to ensure medical molds meet the unyielding demands of Class III devices. Our engineers understand that a mold cavity for an insulin pen must perform with the same unwavering reliability as a component in a satellite guidance system.

The following specifications represent our standard deliverables for medical injection molds, exceeding typical industry benchmarks:

| Parameter | Specification | Relevance to Medical Molding |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm (±0.00004 in) | Ensures fit/function of microfluidic channels and sealing surfaces |

| Surface Roughness (Cavity) | Ra 0.025 µm (Ra 1 µin) | Prevents bacterial adhesion; critical for implant biocompatibility |

| Material Hardness | 52-58 HRC (H13 tool steel) | Maintains geometry under 30,000+ tonnage cycles; resists corrosion from bio-materials |

| Thermal Stability | Δ ≤ 0.003 mm at 180°C | Eliminates part distortion during high-temp sterilization processes |

| Validation Documentation | Full traceability per ISO 13485 | Accelerates regulatory submissions; provides audit-ready data trails |

When lives depend on dimensional perfection, mold precision becomes a clinical imperative. Wuxi Lead Precision Machinery delivers molds engineered to transform regulatory challenges into production advantages—reducing validation time, maximizing yield, and ensuring every device meets the uncompromising standards of modern healthcare. Partner with engineers who treat micron tolerances as seriously as mission-critical defense specifications.

Precision Specs & Tolerances

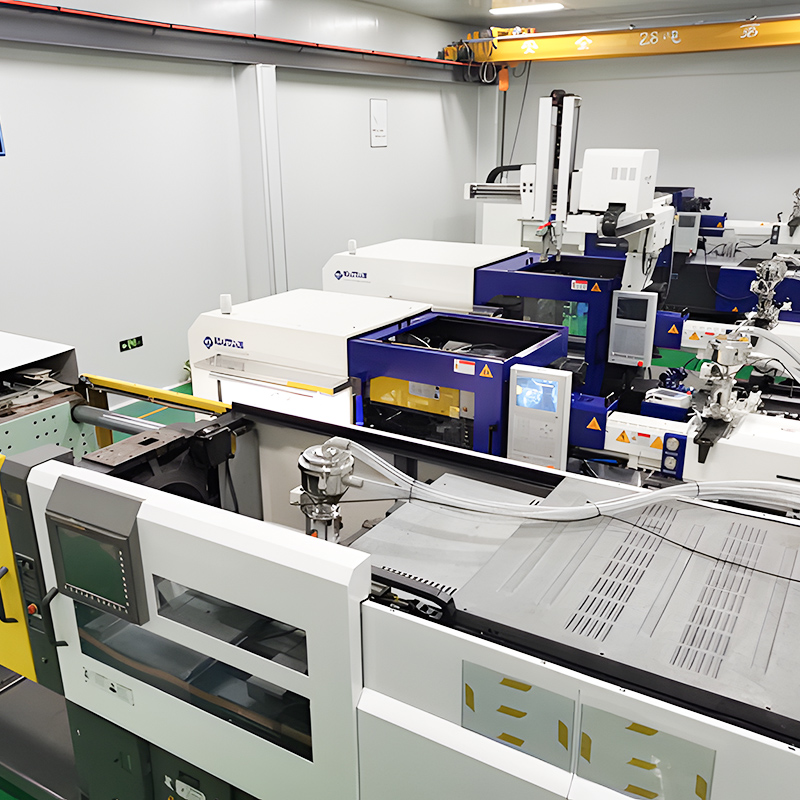

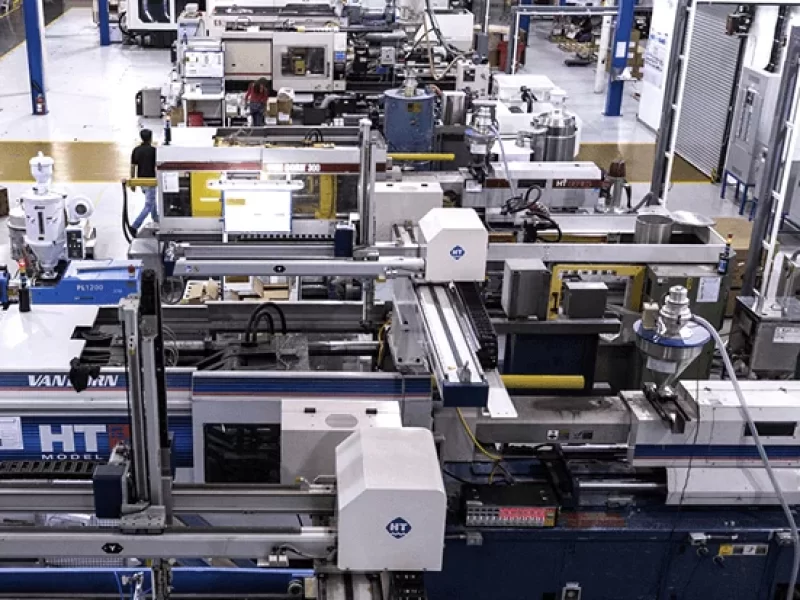

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to meet the stringent demands of the medical device industry. Our expertise in precision injection mold production is built upon a foundation of cutting-edge equipment, rigorous quality assurance protocols, and deep technical know-how. Every stage of our manufacturing process is optimized for repeatability, accuracy, and compliance with international medical standards.

At the core of our technical capacity is our fleet of 5-axis CNC machining centers. These advanced systems enable us to produce highly complex mold geometries with exceptional surface finish and dimensional accuracy. Unlike conventional 3-axis machines, 5-axis CNC technology allows simultaneous movement across five planes, reducing setup time and minimizing human intervention. This results in tighter tolerances, improved part consistency, and the ability to machine intricate undercuts and contours essential for medical-grade molds. Our programming team utilizes state-of-the-art CAD/CAM software to generate optimized toolpaths, ensuring efficient material removal and extended tool life while maintaining micron-level precision.

Quality control is integral to our manufacturing philosophy, particularly in the medical sector where failure is not an option. All molds undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), which provides non-contact and tactile measurement of critical features with sub-micron accuracy. Our CMM systems are calibrated to ISO 17025 standards and operated by certified metrology technicians. Full inspection reports are generated for every project, documenting conformity to customer specifications and regulatory requirements. In addition to CMM analysis, we perform in-process inspections, first-article inspections (FAI), and final validation testing to ensure defect-free output.

We specialize in molds for single-use surgical instruments, drug delivery systems, diagnostic components, and implantable device housings—applications where material biocompatibility, sterilization resistance, and absolute reliability are paramount. Our engineers work closely with clients during the design-for-manufacturability (DFM) phase to identify potential risks, optimize gate locations, cooling channels, and ejection systems, and ensure seamless transition from prototype to full-scale production.

The following table outlines our standard technical specifications and achievable tolerances for medical device injection molds:

| Feature | Specification |

|---|---|

| Machining Technology | 5-Axis CNC Milling |

| Maximum Work Envelope | 1200 × 800 × 600 mm |

| Minimum Feature Size | 0.1 mm |

| Typical Surface Finish | Ra 0.2 – 0.8 µm |

| Dimensional Tolerance | ±0.005 mm (critical features) |

| Positional Tolerance | ±0.003 mm |

| Runout Tolerance | ≤ 0.005 mm |

| Material Compatibility | P20, H13, S136, 420SS, 17-4PH, Titanium Alloys |

| Quality Standard | ISO 13485, ISO 9001:2015 |

Wuxi Lead Precision Machinery combines technological excellence with disciplined process control to deliver injection molds that meet the highest benchmarks in the medical manufacturing sector.

Material & Finish Options

Material Selection for Medical Device Injection Molds: Precision and Compliance

Selecting the optimal material for medical device injection molds is critical for ensuring part quality, regulatory compliance, and production longevity. At Wuxi Lead Precision Machinery, we prioritize materials meeting stringent ISO 13485 and USP Class VI requirements, where biocompatibility and resistance to repeated sterilization cycles are non-negotiable. Aluminum, steel, and titanium each serve distinct roles, but their suitability hinges on specific application demands and production volume.

Aluminum alloys, particularly 7075-T6, offer rapid prototyping and low-volume production advantages due to excellent machinability and thermal conductivity. This facilitates faster cycle times during initial validation. However, aluminum lacks the hardness and wear resistance required for high-volume medical manufacturing. Its susceptibility to wear under abrasive resins and lower resistance to chemical degradation during autoclaving or EtO sterilization limits its use to pre-production stages or very short runs. Surface treatments like hard anodizing (Type III) can enhance surface hardness to 50-60 HRC and improve corrosion resistance, but cannot overcome the base material’s inherent limitations for sustained production.

Tool steels dominate high-volume medical mold manufacturing. Pre-hardened steels like P20 offer cost-effective solutions for moderate cycle counts. For demanding applications requiring superior polishability, corrosion resistance, and extended life under aggressive sterilization regimes, we specify H13 for hot-runner systems and highly polished stainless variants such as S136 (AISI 420 modified) or 420F. These grades achieve hardness levels of 50-58 HRC post-heat treatment, providing exceptional resistance to pitting, chloride-induced corrosion, and wear from filled polymers. Their non-porous surfaces, achievable through diamond polishing to Ra < 0.025 µm, are essential for preventing bacterial adhesion and ensuring cleanability – a fundamental requirement in implantable and surgical device production.

Titanium alloys (e.g., Ti-6Al-4V) are rarely used for the mold cavity itself due to high cost and challenging machinability. Their primary application lies in specialized inserts for molding highly corrosive biocompatible polymers where even stainless steel may degrade. Standard anodizing is ineffective on steel; instead, electropolishing or specialized passivation per ASTM A967 is mandatory to maximize corrosion resistance and surface integrity for medical molds.

Key Material Properties for Medical Molds

| Material | Typical Hardness (HRC) | Corrosion Resistance | Thermal Conductivity (W/m·K) | Primary Medical Application |

|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 (Base) | Low | 130 | Prototyping, very low-volume trials |

| P20 Steel | 28-32 (Pre-hard) | Moderate | 28-36 | Moderate cycle count production |

| H13 Steel | 48-52 | Good | 24-30 | Hot-runner systems, core/cavity |

| S136 Stainless | 50-58 | Excellent | 20-25 | High-polish cavities, corrosive resins |

| Titanium Ti-6Al-4V | 32-36 (Base) | Exceptional | 6-7 | Specialized inserts only |

Material choice directly impacts mold performance, maintenance frequency, and total cost of ownership. For production exceeding 10,000 cycles involving critical components, hardened stainless steels like S136 are the industry standard, balancing longevity, polishability, and sterilization resilience. Always validate material selection against the specific polymer, sterilization method, and part geometry early in the design phase. Wuxi Lead Precision Machinery provides comprehensive material certification and surface finish validation to ensure your mold meets the highest medical manufacturing standards from day one. Consult our engineering team during the RFQ stage to optimize your material strategy.

Manufacturing Process & QC

The production process for medical device injection molds at Wuxi Lead Precision Machinery follows a rigorously controlled sequence designed to ensure zero defects and full compliance with the highest international standards. Each stage—design, prototyping, and mass production—is engineered for precision, repeatability, and regulatory traceability, meeting the exacting demands of the medical device industry.

Design begins with a comprehensive analysis of the client’s technical specifications, including part geometry, material compatibility, and functional requirements. Our engineering team employs advanced CAD/CAM software to develop 3D models and perform mold flow simulations, identifying potential defects such as warpage, sink marks, or air traps before any metal is cut. This virtual validation ensures optimal gate location, cooling channel layout, and ejection system design. All designs adhere to ISO 13485 and FDA guidelines, with full documentation for design history files (DHF). Tolerances are maintained within ±0.002 mm, critical for components used in surgical instruments, drug delivery systems, and implantable devices.

Prototyping follows the approved design phase, utilizing high-precision CNC machining, wire EDM, and surface grinding to fabricate mold components from medical-grade steels such as 420 stainless steel, 17-4 PH, or titanium alloys. Rapid turnaround of prototype molds allows for initial test shots using the actual production resin. These prototypes undergo full dimensional inspection via coordinate measuring machines (CMM) and are evaluated for functionality, surface finish, and assembly performance. Any deviations are corrected through iterative refinement, ensuring the mold performs flawlessly under real-world conditions. This stage is critical for risk mitigation and often includes first-article inspection reports (FAIR) and process failure mode and effects analysis (PFMEA).

Mass production commences only after formal client approval of the prototype. Molds are mounted on state-of-the-art electric or hybrid injection molding machines with closed-loop process control, ensuring consistent shot-to-shot repeatability. Each production run is monitored in real-time using sensors that track pressure, temperature, and cycle time. Automated vision inspection systems detect surface anomalies, while statistical process control (SPC) charts maintain process capability indices (Cp/Cpk > 1.67). Every component is traceable through batch numbers and material certifications. Cleanroom molding options (ISO Class 7 or better) are available for sterile applications.

Our end-to-end process is built on a zero-defect philosophy, integrating design excellence, empirical validation, and continuous monitoring to deliver injection molds that perform reliably in life-critical medical environments.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Standard Materials | 420 SS, 17-4 PH, Titanium, 2316 Stainless |

| Surface Finish | Ra ≤ 0.05 µm (mirror polish available) |

| Mold Life | 1,000,000+ cycles (depending on material and design) |

| Compliance Standards | ISO 13485, FDA 21 CFR Part 820, ISO 10993 (biocompatibility support) |

| Production Environment | Standard and Cleanroom (ISO Class 7/8) options |

| Inspection Tools | CMM, Optical Comparator, Vision System, SPC Monitoring |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Medical Mold Excellence

Selecting a manufacturing partner for critical medical injection molds demands more than technical capability; it requires proven expertise in regulatory rigor, micron-level precision, and unwavering commitment to patient safety. At Wuxi Lead Precision Machinery, we engineer molds that consistently deliver zero-defect components for Class I, II, and III medical devices. Our integrated approach spans material science, ultra-precision machining, and full validation support, ensuring your mold performs flawlessly from first article to high-volume production. We operate under strict ISO 13485-certified protocols within controlled cleanroom environments, eliminating contamination risks inherent in standard manufacturing.

Our technical mastery addresses the unique challenges of medical polymers like PEEK, PEI, and implant-grade resins. We optimize thermal management systems to prevent warpage during sterilization cycles and implement multi-axis micro-milling for cavities requiring ±0.001mm tolerances. Every mold undergoes rigorous in-house validation, including cavity pressure analysis, flow simulation verification, and 100% CMM inspection against ASME Y14.5 standards. This eliminates costly iterations and accelerates your time-to-market. Below are core specifications defining our medical mold capabilities.

| Specification Category | Performance Standard | Medical Industry Relevance |

|---|---|---|

| Cavity Precision | ±0.001 mm (40 μm) | Ensures dimensional stability under sterilization |

| Steel Grades | H13 ESR, 420SS, Maraging Steel | Corrosion resistance for biocompatible resins |

| Surface Finish | SPI A1 (Ra 0.025 μm) to custom textures | Critical for drug delivery device sealing |

| Validation Documentation | Full IQ/OQ/PQ, Material Traceability | Meets FDA 21 CFR Part 820 requirements |

| Cleanroom Production | ISO Class 7 (10,000) standard | Prevents particulate contamination |

Beyond technical execution, we function as your strategic extension. Our engineering team collaborates during DFM stages to resolve gate vestige risks, ejection challenges, and material flow issues before steel cutting begins. We provide comprehensive mold maintenance programs with predictive wear analytics, reducing unplanned downtime by up to 35% in long-run productions. For complex multi-cavity systems, our proprietary balancing technology ensures uniform filling across 32+ cavities—critical for diagnostic consumables requiring identical performance.

The cost of mold failure in medical manufacturing extends far beyond rework; it jeopardizes patient outcomes and regulatory standing. Partner with an organization where precision is non-negotiable and compliance is engineered into every process. Wuxi Lead Precision Machinery has delivered 1,200+ medical molds to global OEMs with zero field recalls attributed to mold performance. Contact us today to discuss your next project’s technical requirements. Our engineering team will provide a detailed capability analysis within 24 hours.

Contact [email protected] to initiate a confidential technical consultation. Specify “Medical Mold Project” in your subject line for priority engineering review. Let us demonstrate how precision manufacturing becomes your competitive advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.